#thermal insulated roofing sheets

Text

instagram

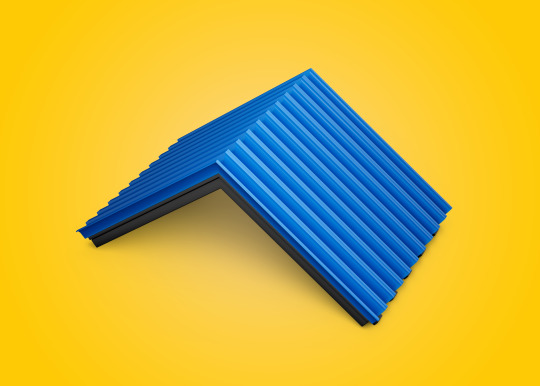

Discover the best in thermal insulated roofing sheets with METAhybrid® roofing sheets – lightweight, eco-friendly, and noise-reducing. Stay cool, save big, and enhance your space.

Visit us at www.metahybrid.in or contact us at 8550995556 | [email protected].

.

.

.

.

#thermalinsulatedroofingsheet #roof #sheet #insulatedroof #soundproofing #soundproof #heatinsulation #architecture #interiordesign #insulatedroofing #insulatedpanels #insulatedpanel #thermalinsulation #metahybrid #roofinsulation #geometric #steels

#heat insulated roof sheets#heat insulation for metal roof#insulated cladding sheets#insulated metal sheet#insulated profile sheet#insulated steel sheets#metal sheet with insulation#thermal insulated roofing sheets#thermal insulation metal sheet#thermal roof sheets#insulated thermal roofing#Colour coated thermal insulated roofing sheets#heat insulated sheet for roof#Aluminum Thermal insulated roofing sheets#Instagram

0 notes

Text

Top Advantages of Aluminum Foil Insulation for Roofs in Pre-Engineered Buildings

When a pre-engineered building has to be kept at the right temperature and durable, the best materials have to be chosen. Among all the diverse choices, aluminum foil insulation is one of the most flexible and potent selections. Maru Cool is one of the best choices for your pre-engineered building insulation. They offer higher-quality aluminum foil at affordable prices.

Now let's explore some of the advantages of aluminum foil insulation for roofs in pre-engineered buildings:

Superior Thermal Performance: Aluminum foil insulation bounces back radiant heat, stopping it from moving through the roof. This keeps your house cozy all year long, so you won't have to rely on expensive heating or cooling systems as much.

Energy Efficiency: The aluminum foil performs as an insulator during high temperatures and efficiently traps heat where a room needs to be warmer in the winter. It significantly cuts down the energy expenditure and hence has a positive environmental impact. In addition, it means that building owners will pay less for their electrical utility costs.

Durability and Longevity: Foil which is usually used to wrap aluminum is very durable and can tolerate harshness without any harm to it. It has an amazing capacity to tolerate weather like high temperatures or icy coldness, and it can also withstand moisture and sunshine. This implies that it can remain in good condition even after a long period with little maintenance.

Fire Resistance: The matter of everyone's safety in any building deeply matters, and a great point about aluminum foil insulation is that it is not flammable. Therefore it no longer helps fire to spread which guarantees safer buildings and people in it.

Lightweight and Easy Installation: The aluminum foil insulation is lighter and more convenient to work with than the conventional old-fashioned insulation stuff. This will allow a quicker and cheaper installment which is certainly a saving as far as labor and construction time are concerned, especially in pre-engineered buildings where efficiency is crucial.

Noise Reduction: Besides keeping things warm or cool, aluminum foil also makes the building quieter by stopping noise from traveling through. This means the inside of the building is more peaceful and cozy. This is helpful in places like factories or offices where loud noises can be a problem.

Environmentally Friendly: Using aluminum foil as insulation is also beneficial as it can be recycled like most of the existing materials used. Which describes it as the nature of helping the sustainability of the frontages. Moreover, it endures for a long time and reduces energy usage, and thereby reduces the carbon footprint as well.

Cost-Effectiveness: It goes without saying that although rolling out aluminum insulation may be somehow costlier in terms of the initial outlay than other alternative insulations, this type of insulation is in fact of more value in the long term. It is mainly for this reason that it costs less to run longer term, so people pay fewer bills over time. Frequently, you will have to spend a lot of money at the time of purchase, but it will only help you to cut costs on the energy consumed in the long term.

Conclusion

The aluminum foil insulation for the roof brings plenty of obvious advantages for pre-engineered building insulation. It serves as an insulator of heat to protect the building from temperature changes, consumes energy with minimal waste, stays durable for long periods, and is very eco-friendly. MaruCool, self-exclusive to top-grade insulation, is assured to provide architects, builders, and owners with pre-engineered aluminum foil to efficiently use for insulation.

#thermal reflective roof insulation#heat resistant foam insulation#double bubble insulation sheet#aluminum foil insulation for roof

0 notes

Text

Best Heat insulation and Roof insulation Services

Heat Insulation

The barrier to the flow of heat between two objects is called thermal insulation. Specially designed processes, special shapes, and selection of suitable materials are very important for the insulation of heat.

When two objects of different temperatures come in direct contact, there must be a transfer of heat between them. But by inserting an insulating material between these two objects, the flow of heat will be less than before.

How much less depends on the thickness of the insulating material, its low thermal conductivity, etc. Similarly, some other methods are adopted to reduce the flow of heat by radiation.

The lower the thermal conductivity of a material, the better it is as an insulator. Other properties of insulating materials in the field of thermal engineering are density and specificity.

What are heat-resistant materials?

It is very important to choose specially designed processes, special sizes, and suitable materials for heat insulation. Tantalum carbide (TaC) and hafnium carbide (HfC) are refractory ceramics, meaning they are exceptionally resistant to heat.

Which is the least heat-resistant metal?

The correct answer is glass. Heat conduction is the reduction in the transfer of heat between objects in thermal contact. In modern times, glass is the most common insulation.

What is the difference between a heat conductor and a heat insulator?

Of heat from a substance goes from one end to the other, it is called a heat conductor. Aluminum, iron, silver, copper, etc. are heat conductors. When there is no transfer of heat from a substance, it is called an insulator. Such as plastic, wood, etc.

Main insulation Material

Fiberglass

Mineral wool

Cellulose

Polyurethane foam

Polyurethane eps

Roof insulation

You can always tell who hasn't insulated their attic because of the pigeons and other birds sitting on the roof and enjoying all the heat coming from the house below. Summer is on the rise and clever birds are quick to take advantage of it.

Other benefits of roof insulation include

Lower heating bills

Improve the energy efficiency of your home

Increase the value of your home

Attic insulation for an average 3-bedroom semi-detached house with gas central heating can start with DIY insulation for around €50 and can take less than a year, reducing energy costs. Know about top insulation and Roof insulation.

What is Roof insulation?

Roof insulation is a barrier of material in your roof space. It can be placed between joists (horizontal joists along the floor of your attic) or rafters (slant joists that support the roof).

Why is roof insulation necessary?

In non-insulated homes, a quarter of the heat lost is dissipated through the roof. Insulating an attic or roof is a great way to increase the comfort of your home. And there's even more good news: It will last more than 40 years and should pay for itself many times over in energy savings since the cost of Roof insulation is relatively low.

Restoration of houses made of non-traditional materials.

If you live in a historic home or a home built from local traditional stone or other materials, use appropriate roof insulation materials and methods. Otherwise, your home may not stay as warm or dry as it should. It may be best to consult or hire local workers trained in the techniques involved.

#Roof Insulation#Heat Insulation#Insulation Material#thermal insulation sheet#insulation manufacturers in india#thermal insulation sheet manufacturers in india#insulation sheet for roof#Insulation Installation Services#aluminium foil insulation#thermal sheeting insulation#Insulation Sheet#thermal insulation materials in buildings#Building Insulation Material#thermal insulation material#Colour Coated Roofing Sheets#Insulated Roofing Sheets

0 notes

Text

Revolutionizing the Construction Landscape: Non-Asbestos Corrugated Sheet Making Machinery

In recent years, the construction industry has witnessed a significant shift towards more sustainable and safer building materials. One such innovation that stands at the forefront of this revolution is non-asbestos corrugated sheet making machinery. This groundbreaking technology not only champions environmental sustainability but also ensures the safety of workers by eliminating the health hazards associated with asbestos.

Understanding the Perils of Asbestos

For decades, asbestos was a popular component in building materials due to its durability and fire-resistant properties. However, it was later discovered that asbestos fibers, when inhaled, can lead to severe respiratory issues, including lung cancer and mesothelioma. This revelation necessitated an urgent move towards safer alternatives, leading to the development of non-asbestos corrugated sheets.

Enter Non-Asbestos Corrugated Sheet Making Machinery

The introduction of non-asbestos corrugated sheet making machinery marked a pivotal moment in construction material technology. These machines are engineered to produce high-quality corrugated sheets made from safe, non-asbestos materials such as cellulose fiber, cement, and silica. The result is a product that not only matches the durability and fire resistance of its asbestos-containing predecessors but also surpasses them in environmental and health safety.

How It Works

Non-asbestos corrugated sheet making machinery operates through a sophisticated process that combines raw materials (cellulose, cement, and silica) under high pressure and temperature. The mixture is then extruded into sheets, corrugated to the desired profile, and cured to achieve the required strength and durability. This highly automated process ensures consistent quality while minimizing human exposure to harmful substances.

Advantages of Non-Asbestos Corrugated Sheets

Safety: The primary benefit of these sheets is their non-toxic nature, making them safe for both the environment and human health.

Durability: Despite being lightweight, these sheets exhibit remarkable strength and longevity, resistant to both fire and water.

Energy Efficiency: The thermal properties of non-asbestos materials make these sheets excellent insulators, contributing to energy savings in buildings.

Cost-Effectiveness: While offering superior qualities, non-asbestos corrugated sheets are competitively priced, making them an economical choice for roofing and cladding.

The Future Is Here

The adoption of non-asbestos corrugated sheet making machinery is not just a technological advancement; it's a commitment to global health and environmental preservation. As more industries recognize the importance of sustainable and safe construction materials, the demand for these machines is expected to rise, signaling a new era in the construction sector.

A Call to Action

The transition to non-asbestos technologies requires concerted efforts from manufacturers, policymakers, and the construction community. By investing in non-asbestos corrugated sheet making machinery, the industry can take a significant step towards eradicating the risks associated with asbestos, paving the way for a healthier and safer future. In conclusion, non-asbestos corrugated sheet making machinery represents a transformative development in the construction materials industry. It not only offers a viable alternative to hazardous asbestos but also aligns with the global move towards sustainability. As we continue to build our future, it is technologies like these that will ensure our constructions are safe, durable, and in harmony with the environment.

2 notes

·

View notes

Text

Application of bitumen in building

Bitumen has numerous applications in the construction industry, primarily serving as an adhesive and waterproofing material. Its versatile properties make it indispensable in various building-related functions. Here are some key applications of bitumen in construction:

1. Roofing and Waterproofing:

Bitumen 60/70 is extensively used in roofing systems to provide waterproof membranes for flat roofs. Traditional bitumen roofing membranes consist of layers of bitumen sprayed with aggregate, with a carrier fabric made of polyester or glass in between. Polymer-modified bitumen sheets have become the standard for flat roof waterproofing. Bituminous roofing membranes can also be recycled easily, enhancing their sustainability.

2. Wall Sealing:

Bitumen 60/70 plays a crucial role in sealing walls, providing protection against water and moisture intrusion. It is applied to substrates such as bathrooms and toilets, which are constantly exposed to moisture, to prevent water penetration and safeguard the underlying structures.

3. Floor and Wall Insulation:

Bitumen 80/100 insulation is widely employed for building waterproofing, both horizontally and vertically. It effectively prevents water penetration into floorboards and walls, offering reliable protection. Bitumen's chemical and physical properties make it easy to work with and highly durable.

4. Sound Insulation:

Bitumen's sound-absorbing properties find applications beyond construction. It helps reduce noise transmission, such as the sound of footsteps under floor coverings. Special tar mats in cars and elevators utilize Bitumen 80/100 for sound insulation.

5. Electrical Cable Insulation:

Bitumen's low electrical conductivity makes it suitable for use as an insulating material for electrical cables. It helps protect the cables and prevent electrical hazards.

6. Other Uses:

Bitumen 80/100 & bitumen 60/70 finds application in various other areas, such as the paper industry and the manufacturing of paints and varnishes. Its thermal insulation properties are beneficial in different contexts.

From an ecological standpoint, bitumen is highly regarded for its long lifespan. It remains a popular construction material, with significant demand both domestically and in international markets. The producer of bitumen in Iran exports a large percentage of its production to other countries such as Singapore, Dubai, Panama.

In residential construction, plastic-modified bitumen (KMB) coatings are commonly used for insulation. They compete with bitumen-free FPD (Flexible Polymer Disc) seals, which are easier to apply and offer faster repair options.

Overall, the applications of bitumen in the construction industry are extensive, ranging from roofing and waterproofing to sound insulation and electrical cable insulation. Its versatility and durability make it a valuable material in various building-related functions.

Important Considerations Before Using Bitumen:

1. Surface Preparation:

Before applying bitumen, it is crucial to ensure that the surface is clean, dry, and free from any contaminants. Even the presence of dust, dirt, or grease can hinder the adhesion of the bitumen coating and compromise the effectiveness of the seal. Additionally, the surface should be free from frost. If there are old incompatible coatings, they must be removed. In the case of older buildings, previous applications of bituminous paints may not provide a suitable surface for polymer-modified bitumen (PMB) coatings.

2. Repairing Cracks and Unevenness:

Prior to applying bitumen, any cracks or unevenness on the surface should be repaired using appropriate materials like repair mortar or leveling compounds. This ensures a smooth and uniform surface, promoting better adhesion and a more effective seal.

3. Additional Preparatory Measures:

In some cases, additional preparatory measures may be necessary. One option is to use a layer of synthetic resin on the coarse-pored bed or to apply a sealing slurry. A sealing slurry is a waterproof mixture of cement and plastic that allows water vapor to pass through. The advantage of using a sealing slurry is that it can adhere well to old bituminous coatings, providing an ideal substrate for applying a thick new bituminous coating.

By following these steps and ensuring proper surface preparation, you can optimize the adhesion and effectiveness of bitumen coatings in various applications.

What are the suitable means for repairing cracks and unevenness on the surface before applying bitumen?

There are several suitable means for repairing cracks and unevenness on the surface before applying bitumen. The choice of repair method depends on the severity of the damage and the specific requirements of the project. Here are some common methods for repairing cracks and unevenness:

1. Crack Fillers and Sealants:

For smaller cracks, crack fillers or sealants can be used. These materials, such as asphalt-based crack fillers or specialized concrete crack sealants, are designed to fill and seal cracks, preventing water infiltration and further damage. They are typically applied using a caulk gun or trowel.

2. Repair Mortar:

Repair mortars are suitable for filling larger cracks, holes, or areas of unevenness. These mortars are made from a blend of cement, sand, and additives to enhance adhesion and strength. They can be mixed with water to create a workable paste and then applied to the damaged areas using a trowel or other appropriate tools. Repair mortars are commonly used for repairing concrete surfaces.

3. Leveling Compounds:

Leveling compounds, also known as self-leveling underlayments or floor levelers, are used to create a smooth and level surface. These compounds are typically made from a blend of cement, fine aggregates, and additives. They have a fluid consistency that allows them to flow and self-level over uneven areas. Leveling compounds are commonly used to repair uneven concrete or subfloor surfaces before applying flooring materials.

4. Patching Mixtures:

Patching mixtures, such as asphalt patching compounds or repair mixes, are specifically designed for repairing asphalt surfaces. They typically contain a combination of asphalt binder, aggregates, and additives. These mixtures can be applied to fill potholes, repair damaged areas, or smooth out unevenness in asphalt surfaces.

5. Resurfacing:

In cases where the damage or unevenness is more extensive, resurfacing the entire surface may be necessary. This involves applying a new layer of bitumen or asphalt mixture over the existing surface to create a smooth and uniform finish. Resurfacing can help address multiple issues, including cracks, potholes, and unevenness.

It's important to follow the manufacturer's instructions and best practices when using any repair materials. Additionally, proper surface preparation, including cleaning and removing loose debris, is essential before applying any repair method.

ATDM CO is a manufacturer and exporter of Bitumen 60/70, offering three different quality grades available in drums, bags, and bulk quantities. Our products are classified into premium, second, and third types, each with varying production costs and facilities. We provide a wide range of options to accommodate different customer needs and volume requirements.

#bitumen#bitumen 60/70#bitumen 80/100#bitumen 60/70 specs#bitumen penetration grade 60/70#bitumen 60/70 specification#bitumen 60 70#atdm co llc.

2 notes

·

View notes

Text

GROW ALL YEAR WITH AN UNDERGROUND GREENHOUSE

If eating Fresh Vegetables and Fruits Year Round is important to You and Your Family, you might consider building an Underground Greenhouse. It will keep the temperatures warmer in the Winter and help prevent overheating in the Summer; making it possible to grow your garden vegetables year round.

For the vast majority of the country, 4 feet below the surface will stay between 50° to 60°F even if the weather above the ground gets to 10°F or colder. This is what they call the thermal constant, and what the Underground Greenhouse is based on.

The original design for an Underground Greenhouse was invented in Bolivia, and was called a Walipini, an Aymara Indian word which means “a warm place.” A Walipini is a rectangular shaped Greenhouse that is dug down 6-8 feet deep in the ground. The longest area of the rectangle will face towards the south (in the Northern Hemisphere) to take advantage of the most sunlight.

The design of the Underground Greenhouse isn’t that complicated, as it can be as simple as a hole with plastic sheets laid on top. The roof seals in the heat and insulates the area to keep a warm, moist environment for your fruits and vegetables.

The location of your Walipini will depend on how big you want it to be. You’ll need enough space to grow your plants and have a small area to walk into your greenhouse. The bottom of the Greenhouse will need to be at least 5 feet above the water table in your area. The recommended size for an Underground Greenhouse is 8 x 12 feet.

When planning where your Greenhouse will be located, remember that your roof will need to receive light during the winter, also. This means that you will have to make sure that trees or buildings don't block it during the winter time when the sun is in the South. In most cases, your Underground Greenhouse should be set up East to West, with the roof facing South to take advantage of the Winter Sun.

Once it's decided where your Underground Greenhouse will be located, you can start digging. Plot out the area above ground to keep track of where you should be digging. While you’re excavating, dig at least 2 feet deeper than your desired depth. Keep your soil close by to help prop up the roof.

The walls of your Underground Greenhouse should have a minimum 6-inch slope from the roof to the floor. This will greatly reduce the amount of crumbling and caving that will occur with the soil. You can also layer the walls with a clay to prevent erosion, or use bricks to stabilize the walls of the building.

While you’re digging the hole, dig an extra 2 feet below the desired depth. You’ll fill this area with stone or gravel and then 8 inches of soil. Ideally, you’d lay larger stones and gravel on the bottom layer and the gravel would become progressively smaller until you reach the soil.

The bottom of the greenhouse should be slightly sloped from the center to the edges. Along the perimeter, you should leave a space of 2-3 feet just filled with gravel. This is designed to help the water drain more easily. Many people have also created open gravel wells in the corners of the greenhouses that allows them to collect the water. This will allow you to draw a bucket into the hole and pull out water if you find you have too much.

Once the floor is filled in with the drainage system, and the soil required for growing, the doors can be installed. Place the door frame at the base of the ramp and fill in the areas around the door as much as possible with dirt and clay. Filling in these gaps will prevent heat loss in your greenhouse.

Many times, people will use 2-inch door frames that have holes drilled into the top middle and bottom of each side. They will then use wooden stakes, dowels or rebar to secure the door frame into the soil wall.

The angle of the roof will make a big difference on the sun’s ability to heat your greenhouse. Ideally, the roof should be facing directly at the winter solstice at a 90 angle. This angle will maximize the heat during the winter solstice and minimize the heat during the summer solstice.

Now, you can use that extra soil that you have left over to create a berm. The berm is basically an extension of the north wall of the greenhouse. This allows you to control the angle of the roof by adding or taking away dirt. Build up the berm to continue the slope that you used on the wall. If you’re using bricks – continue using them on the berm.

The most economical, durable material for your roof is 4-inch PVC pipe. Using PVC elbow pieces, joiners, etc, you can create a flat roof frame that will cover your Underground Greenhouse.

After you’ve created a PVC frame, lay it in place on the top of your hole. Then lay plastic sheeting across the top of the frame and make sure that it extends past the edge of the frame by at least 1 foot. This flap will prevent run off water from the roof from running back into the greenhouse itself.

Once the plastic material is put on top of the roof frame, move inside and tack another layer of plastic wrap along the inside of the roof frame. This internal plastic sheeting will create a 4-inch barrier between the inside and outside of the roof, and will act as an insulator that will keep the heat in more effectively.

You’ll want to make sure that you leave a few inches of plastic hanging down on the lower (south) end of your roof. This will force moisture that collects on the roof to drip off above the drainage system or on top of your plants instead of at the base of the roof. If you allow the moisture to run to the base of the roof frame, it may affect the soil at that location and break down your wall, etc.

Ventilation is always crucial. You have 3 options, such as: Installing two doors, one at each end; installing a vent roughly the size of the door at the top of the back wall; or installing a chimney at the center of the back wall. Good Luck on your Greenhouse.

4 notes

·

View notes

Text

The Ultimate Guide to Finding the Best Construction Materials - Nationwide supplies

WELCOME TO NATIONWIDE BUILDING MATERIALS

Our customer base ranges from the DIY enthusiasts to general builders and major contractors. We are open for business from Mon-Fri: 8.00am to 5.30pm and Saturday: 8.00am to 12.30pm

From small jobs to extensions and new builds, We are with you every step of the way no matter how big the job. We provide a nationwide service for a wide selection of building materials

Nationwide supplies have all the building materials you need for domestic and commercial projects.

We can help with your construction material needs, including timber, aggregate & cement, drylining and insulation and with products from trusted brands, such as Blue Circle, Celcon, Celotex and Kingspan, be sure you are using reliable materials.

PIR INSULATION

PIR stands for polyisocyanurate. The best PIR (Polyisocyanurate) thermal insulation board solutions currently on the market come from the likes of Celotex, Recticel, EcoTherm, IKO, Xtratherm and Kingspan. We at Nationwide supplies have PIR (Polyisocyanurate) available from all the leading manufacturers. Visit our website at www.nationwidebm.co.uk

PIR is cooked under pressure and left to cool. It’s then cut to size

The lambda value can be as low 0.022 W/m K

Amongst the more thermally efficient insulation

PIR (Polyisocyanurate) has such a high thermal performance, it requires only half the thickness of other mineral-based insulation products. PIR (Polyisocyanurate) is one of the most efficient insulation material used in major construction projects and DIY projects. PIR (Polyisocyanurate) insulation provides acoustic and thermal properties, rigidity, durability and excellent compressive strength.

ROCKWOOL INSULATION

Rockwool is based on innovative stone wool technology. The range covers roof Insulation, floor Insulation, ceiling Insulation, internal wall insulation, external wall insulation, HVAC insulation, passive fire protection, acoustic insulation

Rockwool Insulation is a good fire resilient solutions can slow the spread of flames, contain fires locally and stop them from spreading further. Robust stone wool insulation is a key component in fire-resilient buildings, as its fibres are non-combustible and can resist high temperatures. Rockwool insulation is water repellent. In the event the insulation becomes damp or wet, the insulation, when thoroughly dried, will maintain the original performance characteristics.

Available from Nationwide supplies. Our aim is to provide building materials at competitive prices. We aim to provide excellent customer service and are always on had should you need any technical advice. We deliver nationwide and have a range of vehicles to suit your requirements.

PLASTERBOARD

Plasterboards come in various different colours, thickness and sizes. The different colours identify requirements.

To identify a few colours – White – Standard, Pink – Fire, Blue – Sound, Green – Moisture

Sheet Size – 1800×900, 2400×1200, 2700×1200, 3000×1200

Thickness – 9.5mm, 12.5mm, 15mm

Choosing the right plasterboard for the job helps meet building regulations for fire protection, acoustic and moisture. If you need advice we are always on hand. We supply plasterboard from all the trusted manufacturers such as British Gypsum, Knauf and Siniat. Nationwide supplies offer nationwide delivery to your site or home. If you prefer to collect to can collect from one of our nationwide collection points.

We have nationwide collection points.

Because of the wide variety of products every collection point does not stock every

single product.

If you want to collect a product contact one of our friendly staff on 0330 390 9222

to find out the nearest collection point

When your order has been placed we will confirm by phone or email the full address

of your collection point.

For more information on our services, to enquire about any of our products or to find out more about our delivery services please don’t hesitate to contact us. Contact Us 0330 390 9222 , www.nationwidebm.co.uk ,[email protected]

2 notes

·

View notes

Text

Enhance Your Projects with Plastics Source: Acrylic Mirrors, Polycarbonate Sheeting in Canada

Plastics Source is your one-stop shop for a variety of high-quality plastic materials, perfect for bringing your design ideas to life. Whether you’re a professional contractor, hobbyist, or DIY enthusiast, they offer a comprehensive selection to suit your needs. This article explores some of their most popular products, including acrylic mirrors, solid polycarbonate sheets, multi wall polycarbonate sheets, and blue plexiglass sheets.

Acrylic Mirrors from Plastics Source in Canada

A lightweight and shatter-resistant alternative to traditional glass mirrors, acrylic mirrors from Plastics Source are ideal for various applications.

Safety: They are particularly suitable for areas with high foot traffic or where safety is a concern, such as childcare facilities, gyms, and dance studios.

Versatility: Acrylic mirrors can be cut, drilled, and shaped to fit your specific requirements. They are also available in various sizes and thicknesses, making them perfect for signage, displays, and decorative purposes.

Durability: The vacuum metalizing process used in their creation makes them scratch-resistant and easy to maintain.

Solid Polycarbonate Sheets

Solid polycarbonate sheets are known for their exceptional strength and clarity.

Impact Resistance: Virtually unbreakable, they can withstand significant impact, making them ideal for applications such as machine guards, safety windows, and vandal-resistant glazing.

Weatherproof: Polycarbonate sheets are UV-resistant and can endure harsh weather conditions without degrading.

Lightweight: They offer significant weight savings compared to glass, simplifying installation and handling.

Multiwall Polycarbonate Sheets

Featuring a unique hollow channel construction, multi wall polycarbonate sheets provide excellent light diffusion and insulation properties.

Light Transmission: They allow natural light to permeate while offering UV protection.

Insulation: The air gaps within the channels create a thermal barrier, improving energy efficiency in buildings.

Applications: Multiwall sheets are commonly used for skylights, greenhouses, and roofing applications.

Blue Plexiglass Sheets

Blue plexiglass sheets, also known as acrylic sheets, offer a vibrant pop of color for various projects.

Versatility: These sheets can be cut, drilled, and shaped for signage, displays, craft projects, and more.

Light Diffusion: Plexiglass offers excellent light transmittance, making it ideal for applications that require colored light effects.

Durability: Resistant to scratches and chemicals, plexiglass sheets ensure long-lasting performance.

Trending FAQs About Acrylic Mirrors in Canada

What is the difference between acrylic and plexiglass?

There is virtually no difference between acrylic and plexiglass. Plexiglass is a brand name for acrylic, and both terms are widely used in the industry.

Can I cut acrylic mirrors at home?

While possible, cutting acrylic mirrors requires specialized tools and techniques for a clean and precise finish. Plastics Source may offer cutting services or recommend professional assistance.

How thick should a polycarbonate sheet be for a greenhouse roof?

The ideal thickness for a polycarbonate greenhouse roof depends on factors like size, snow load, and wind rating. Consulting Plastics Source or a structural engineer is recommended for proper selection.

Do I need to pre-drill holes in plexiglass sheets?

Yes, pre-drilling holes in plexiglass sheets is crucial to prevent cracking or shattering during installation. Plastics Source may offer pre-drilled sheets or drilling services.

How can I clean acrylic mirrors and plexiglass sheets?

Use a soft microfiber cloth with mild soap and water to clean acrylic mirrors and plexiglass sheets. Avoid harsh chemicals or abrasive cleaners that can damage the surface.

Conclusion

Plastics Source empowers your creativity with a vast selection of high-quality plastic materials. From acrylic mirrors and polycarbonate sheets to blue plexiglass and more, they cater to diverse project needs. Their knowledgeable staff is available to assist you in choosing the perfect product for your application.

Contact Plastics Source Today

Visit their website or contact Plastics Source to explore their comprehensive product catalog and discuss your project requirements with their friendly and professional team.

0 notes

Text

The Impact of Polycarbonate Sheets in Karnataka

Polycarbonate sheets have revolutionized the construction and roofing industry, offering a versatile and durable solution for a wide range of applications. In Karnataka, a state known for its rapid urbanization and infrastructure development, the demand for polycarbonate sheets is on the rise. As businesses and homeowners seek innovative roofing solutions that balance functionality, aesthetics, and sustainability, polycarbonate roofing in Karnataka emerges as a preferred choice. Among the frontrunners in this domain is RoofMyWorld, a leading provider of high-quality polycarbonate sheets and roofing solutions tailored to the needs of Karnataka's diverse clientele.

Understanding the Appeal of Polycarbonate Sheets in Karnataka

Polycarbonate sheets are renowned for their exceptional properties, including high impact resistance, transparency, and thermal insulation. These qualities make them ideal for a myriad of applications, ranging from industrial roofing and greenhouse construction to skylights and architectural accents. In Karnataka, where climatic conditions vary from urban centers to rural areas, the versatility of polycarbonate sheets is particularly advantageous.

"polycarbonate sheet in Karnataka" reflects the growing interest in this innovative building material across the state. Businesses, architects, and homeowners alike are increasingly turning to polycarbonate roofing in Karnataka as a cost-effective and sustainable alternative to traditional materials.

The Rise of Polycarbonate Roofing in Karnataka's Construction Landscape

Karnataka's construction sector is witnessing a paradigm shift, with a greater emphasis on eco-friendly and energy-efficient building practices. Polycarbonate roofing has emerged as a frontrunner in this regard, offering numerous advantages over conventional roofing materials such as metal, concrete, and asbestos.

RoofMyWorld has been at the forefront of popularizing polycarbonate roofing in Karnataka, catering to the evolving needs of builders, developers, and homeowners. With a comprehensive range of polycarbonate sheets designed for diverse applications, RoofMyWorld empowers clients to create sustainable and visually striking structures that stand the test of time.

Advantages of Polycarbonate Roofing in Karnataka's Climate

Karnataka's climate presents unique challenges, including high temperatures, heavy rainfall, and intense sunlight. Polycarbonate roofing addresses these challenges effectively, offering superior UV protection, weather resistance, and thermal insulation.

By incorporating polycarbonate roofing in Karnataka construction projects, builders and homeowners can mitigate heat buildup, reduce energy consumption for cooling, and enhance indoor comfort levels. Additionally, the lightweight nature of polycarbonate sheets makes them easy to install and transport, contributing to cost savings and logistical efficiency.

Tailored Solutions for Diverse Applications

One of the key strengths of RoofMyWorld lies in its ability to offer customized solutions tailored to the specific requirements of clients across Karnataka. Whether it's a commercial warehouse requiring durable roofing solutions or a residential project seeking to maximize natural light, RoofMyWorld's team of experts collaborates closely with clients to deliver optimal outcomes.

From multiwall polycarbonate sheets in karnataka ideal for greenhouse construction to corrugated polycarbonate panels suitable for industrial roofing, RoofMyWorld offers a comprehensive range of products designed to meet the diverse needs of Karnataka's construction industry.

Embracing Sustainability with Polycarbonate Roofing

Sustainability is a driving force behind the growing popularity of polycarbonate roofing in Karnataka. Unlike traditional roofing materials that contribute to environmental degradation, polycarbonate sheets are recyclable and possess a significantly lower carbon footprint.

RoofMyWorld is committed to promoting sustainable building practices by advocating for the widespread adoption of polycarbonate roofing in Karnataka. By choosing polycarbonate sheets over conventional options, clients not only reduce their environmental impact but also contribute to a greener and more sustainable future for Karnataka and beyond.

Conclusion: Redefining Roofing Solutions with RoofMyWorld

As Karnataka's construction landscape evolves, the demand for innovative and sustainable roofing solutions continues to grow. Polycarbonate roofing, with its myriad benefits and applications, emerges as a frontrunner in this dynamic market.

RoofMyWorld stands at the forefront of this revolution, empowering clients across Karnataka to embrace the versatility, durability, and sustainability of polycarbonate sheets. By leveraging advanced technologies, unparalleled expertise, and a commitment to customer satisfaction, RoofMyWorld is redefining roofing solutions one project at a time.

In the competitive realm of polycarbonate sheet in Karnataka, RoofMyWorld emerges as not just a supplier but a trusted partner dedicated to transforming visions into reality. As Karnataka embarks on a journey towards sustainable development and innovation, RoofMyWorld remains committed to leading the way with cutting-edge polycarbonate roofing solutions.

0 notes

Text

PUF Insulated Roofing Sheets

When it comes to roofing solutions, PUF insulated roofing sheets offer a perfect blend of durability, energy efficiency, and aesthetic appeal. Whether you are constructing a new building or renovating an existing one, PUF insulated roofing sheets provide an excellent option for a wide range of applications. In this article, we will explore the benefits of PUF insulated roofing sheets and why they are an ideal choice for roofing sheets in Karnataka.

1.What are PUF Insulated Roofing Sheets?

PUF (Polyurethane Foam) insulated roofing sheets are made by sandwiching a layer of rigid foam insulation between two layers of metal sheets. The foam insulation provides excellent thermal insulation properties, making PUF insulated roofing sheets highly energy-efficient. These roofing sheets are lightweight, durable, and easy to install, making them suitable for a variety of roofing applications.

2.Benefits of PUF Insulated Roofing Sheets:

Energy Efficiency: PUF insulated roofing sheets offer superior thermal insulation properties, helping to keep your building cool in summer and warm in winter. This can lead to significant energy savings on heating and cooling costs.

Durability: The combination of metal sheets and rigid foam insulation makes PUF insulated roofing sheets extremely durable and long-lasting. They are resistant to corrosion, weathering, and pests, making them ideal for both residential and commercial applications.

Lightweight: PUF insulated roofing sheets are lightweight compared to traditional roofing materials, which makes them easier to handle and install. This can result in faster installation times and lower labor costs.

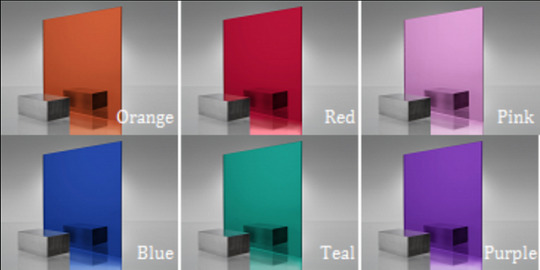

Versatility: PUF insulated roofing sheets are available in a variety of profiles, colors, and thicknesses to suit different roofing requirements. Whether you need roofing sheets for residential, industrial, or agricultural buildings, there is a PUF insulated roofing sheet to meet your needs.

3.Applications of PUF Insulated Roofing Sheets:

Residential Buildings: PUF insulated roofing sheets are an excellent choice for residential buildings due to their energy efficiency, durability, and aesthetic appeal. Whether you are building a new home or renovating an existing one, PUF insulated roofing sheets can help you create a comfortable and stylish living space.

Commercial Buildings: PUF insulated roofing sheets are widely used in commercial buildings such as warehouses, factories, shopping malls, and office complexes. Their superior thermal insulation properties make them ideal for buildings that require temperature control and energy efficiency.

Agricultural Buildings: PUF insulated roofing sheets are also commonly used in agricultural buildings such as poultry farms, dairy farms, and greenhouses. Their excellent insulation properties help to create a comfortable and conducive environment for livestock and plants, while also reducing energy costs.

4.Why Choose Roofing Sheets in Karnataka?

Karnataka experiences a diverse climate with hot summers and moderate to heavy rainfall during the monsoon season. As a result, it is essential to choose roofing materials that can withstand these weather conditions while providing effective thermal insulation. PUF insulated roofing sheets are an ideal choice for roofing sheets in Karnataka due to the following reasons:

Thermal Insulation: The superior thermal insulation properties of PUF insulated roofing sheets help to keep buildings cool during the hot summer months, reducing the need for artificial cooling and lowering energy costs.

Weather Resistance: PUF insulated roofing sheets are resistant to corrosion, weathering, and pests, making them well-suited to the diverse climatic conditions of Karnataka.

Aesthetic Appeal: PUF insulated roofing sheets are available in a variety of colors and profiles, allowing you to choose a roofing solution that complements the architectural style of your building.

5. Promote Your Business with RoofMyWorld:

If you are looking for high-quality PUF insulated roofing sheets in Karnataka, look no further than RoofMyWorld. We are a leading provider of roofing solutions, offering a wide range of PUF insulated roofing sheets to suit your specific requirements. Our roofing sheets are manufactured using the highest quality materials and state-of-the-art technology to ensure superior performance and durability.

In addition to PUF insulated roofing sheets, we also offer a comprehensive range of roofing accessories, including ridge vents, flashing, gutter systems, and insulation materials. Whether you are a homeowner, builder, or contractor, we have the products and expertise to help you complete your roofing project on time and within budget.

Conclusion:

PUF insulated roofing sheets Roofmyworld, offer a range of benefits, including energy efficiency, durability, and aesthetic appeal. Whether you are building a new home, renovating an existing one, or constructing a commercial or agricultural building, PUF insulated roofing sheets provide an ideal roofing solution. If you are in Karnataka and looking for high-quality roofing sheets in karnataka , contact RoofMyWorld today to learn more about our products and services.

0 notes

Text

PUF Insulated Roofing Sheets

When it comes to roofing solutions, PUF insulated roofing sheets offer a perfect blend of durability, energy efficiency, and aesthetic appeal. Whether you are constructing a new building or renovating an existing one, PUF insulated roofing sheets provide an excellent option for a wide range of applications. In this article, we will explore the benefits of PUF insulated roofing sheets and why they are an ideal choice for roofing sheets in Karnataka.

1.What are PUF Insulated Roofing Sheets?

PUF (Polyurethane Foam) insulated roofing sheets are made by sandwiching a layer of rigid foam insulation between two layers of metal sheets. The foam insulation provides excellent thermal insulation properties, making PUF insulated roofing sheets highly energy-efficient. These roofing sheets are lightweight, durable, and easy to install, making them suitable for a variety of roofing applications.

2.Benefits of PUF Insulated Roofing Sheets:

Energy Efficiency: PUF insulated roofing sheets offer superior thermal insulation properties, helping to keep your building cool in summer and warm in winter. This can lead to significant energy savings on heating and cooling costs.

Durability: The combination of metal sheets and rigid foam insulation makes PUF insulated roofing sheets extremely durable and long-lasting. They are resistant to corrosion, weathering, and pests, making them ideal for both residential and commercial applications.

Lightweight: PUF insulated roofing sheets are lightweight compared to traditional roofing materials, which makes them easier to handle and install. This can result in faster installation times and lower labor costs.

Versatility: PUF insulated roofing sheets are available in a variety of profiles, colors, and thicknesses to suit different roofing requirements. Whether you need roofing sheets for residential, industrial, or agricultural buildings, there is a PUF insulated roofing sheet to meet your needs.

3.Applications of PUF Insulated Roofing Sheets:

Residential Buildings: PUF insulated roofing sheets are an excellent choice for residential buildings due to their energy efficiency, durability, and aesthetic appeal. Whether you are building a new home or renovating an existing one, PUF insulated roofing sheets can help you create a comfortable and stylish living space.

Commercial Buildings: PUF insulated roofing sheets are widely used in commercial buildings such as warehouses, factories, shopping malls, and office complexes. Their superior thermal insulation properties make them ideal for buildings that require temperature control and energy efficiency.

Agricultural Buildings: PUF insulated roofing sheets are also commonly used in agricultural buildings such as poultry farms, dairy farms, and greenhouses. Their excellent insulation properties help to create a comfortable and conducive environment for livestock and plants, while also reducing energy costs.

4.Why Choose Roofing Sheets in Karnataka?

Karnataka experiences a diverse climate with hot summers and moderate to heavy rainfall during the monsoon season. As a result, it is essential to choose roofing materials that can withstand these weather conditions while providing effective thermal insulation. PUF insulated roofing sheets are an ideal choice for roofing sheets in Karnataka due to the following reasons:

Thermal Insulation: The superior thermal insulation properties of PUF insulated roofing sheets help to keep buildings cool during the hot summer months, reducing the need for artificial cooling and lowering energy costs.

Weather Resistance: PUF insulated roofing sheets are resistant to corrosion, weathering, and pests, making them well-suited to the diverse climatic conditions of Karnataka.

Aesthetic Appeal: PUF insulated roofing sheets are available in a variety of colors and profiles, allowing you to choose a roofing solution that complements the architectural style of your building.

5. Promote Your Business with RoofMyWorld:

If you are looking for high-quality PUF insulated roofing sheets in Karnataka, look no further than RoofMyWorld. We are a leading provider of roofing solutions, offering a wide range of PUF insulated roofing sheets to suit your specific requirements. Our roofing sheets are manufactured using the highest quality materials and state-of-the-art technology to ensure superior performance and durability.

In addition to PUF insulated roofing sheets, we also offer a comprehensive range of roofing accessories, including ridge vents, flashing, gutter systems, and insulation materials. Whether you are a homeowner, builder, or contractor, we have the products and expertise to help you complete your roofing project on time and within budget.

Conclusion:

PUF insulated roofing sheets Roofmyworld, offer a range of benefits, including energy efficiency, durability, and aesthetic appeal. Whether you are building a new home, renovating an existing one, or constructing a commercial or agricultural building, PUF insulated roofing sheets provide an ideal roofing solution. If you are in Karnataka and looking for high-quality roofing sheets in karnataka , contact RoofMyWorld today to learn more about our products and services.

0 notes

Text

Colour Coated Sheet in Karnatka

In the dynamic landscape of Karnataka's construction industry, where innovation and efficiency are paramount, the adoption of modern building materials plays a pivotal role in shaping the architectural narrative of the state. Among these materials, colour coated sheets have emerged as a versatile and durable solution for roofing and cladding applications across various sectors. This article delves into the significance of colour coated sheets in Karnataka, highlighting their multifaceted benefits and widespread usage in the construction sector, particularly in roofing applications.

The Rise of Colour Coated Sheets in Karnataka:

Colour coated sheets, also referred to as pre-painted or pre-coated sheets, have garnered considerable attention in Karnataka's construction industry due to their exceptional attributes and adaptability to diverse environments. These sheets are typically made from galvanized steel or aluminum substrates, coated with a layer of paint or polymer to enhance their aesthetic appeal and durability.

In Karnataka, the utilization of colour coated sheets has witnessed a steady rise, driven by factors such as rapid urbanization, infrastructural development, and the quest for sustainable building solutions. Builders, architects, and homeowners alike are increasingly turning to colour coated sheets for their roofing needs, recognizing the numerous advantages they offer over traditional roofing materials.

Advantages of Colour Coated Sheets:

The popularity of colour coated sheets in Karnataka can be attributed to several key advantages they offer:

Durability and Weather Resistance: Colour coated sheets are engineered to withstand the vagaries of Karnataka's climatic conditions, including heavy rainfall, intense sunlight, and high humidity. The protective coating acts as a shield against corrosion, rust, and UV radiation, ensuring long-term durability and performance even in the harshest environments.

Aesthetic Versatility: With a wide array of colors, textures, and finishes available, colour coated sheets provide architects and designers with unparalleled creative freedom. Whether it's blending seamlessly with the natural surroundings or making a bold architectural statement, these sheets can be customized to suit the aesthetic preferences of any project, from traditional to contemporary designs.

Ease of Installation: Colour coated sheet in karnataka are lightweight and easy to handle, facilitating quick and hassle-free installation. Their modular design and interlocking profiles ensure seamless fitting, reducing labor costs and construction time. This makes them an ideal choice for both new construction projects and renovation endeavors across Karnataka.

Energy Efficiency: Some variants of colour coated sheets come with thermal insulation properties, helping to regulate indoor temperatures and reduce energy consumption. By minimizing heat transfer through the roof, these sheets contribute to enhanced energy efficiency, particularly in regions like Karnataka, where summers can be sweltering.

Low Maintenance: Once installed, colour coated sheets require minimal maintenance compared to traditional roofing materials. Routine cleaning and occasional inspections are usually sufficient to keep them in optimal condition, saving both time and resources over the lifespan of the structure.

Colour Roofing Sheets in Karnataka:

In Karnataka, the demand for reliable and cost-effective roofing solutions has led to the widespread adoption of colour roofing sheets in karnataka across residential, commercial, industrial, and agricultural sectors. These sheets are extensively used in a variety of applications, including:

Residential Roofing: Colour roofing sheets are a popular choice for residential roofing projects in Karnataka, ranging from individual houses and apartments to housing complexes and gated communities. Their durability, aesthetic appeal, and ease of installation make them an attractive option for homeowners looking to enhance the value and longevity of their properties.

Commercial and Industrial Buildings: In urban centers like Bengaluru, Mysuru, and Hubballi, colour roofing sheet in karnataka find extensive usage in commercial and industrial buildings such as warehouses, factories, workshops, and retail outlets. Their ability to provide reliable weather protection and structural integrity makes them well-suited for these applications, where durability and performance are paramount.

Agricultural Structures: In rural areas of Karnataka, where agriculture forms the backbone of the economy, colour roofing sheets are widely used for roofing agricultural structures such as barns, sheds, poultry farms, and storage facilities. Their resistance to corrosion, moisture, and environmental factors makes them an ideal choice for protecting agricultural assets and livestock.

Conclusion: Advancing Karnataka's Infrastructure with Colour Coated Sheets

In conclusion, colour coated sheets have emerged as a game-changer in Karnataka's construction industry, Roofmyworld, offering a winning combination of durability, aesthetics, and performance that is unmatched by traditional roofing materials. Whether it's enhancing the skyline of Bengaluru with sleek commercial complexes or safeguarding rural farmsteads from the elements, these sheets have become an integral part of the state's architectural landscape.

As Karnataka continues to witness rapid urbanization and infrastructural development, the demand for innovative building materials like colour coated sheets is expected to soar further. With ongoing advancements in technology and manufacturing processes, these sheets will continue to evolve, meeting the evolving needs and aspirations of builders, architects, and homeowners across the state.

In this journey towards progress and prosperity, colour roofing sheet in karnataka are poised to play a pivotal role in shaping Karnataka's infrastructure and skyline, contributing to its growth and development in the years to come. As such, they represent not just a roofing solution but a symbol of Karnataka's unwavering commitment to building a brighter, more resilient future for generations to come.

0 notes

Text

Marucool is renowned for its commitment to quality. They use the best material for heat insulation.When you purchase a double-bubble insulation sheet from them, you can trust that you're getting a product that meets high standards of durability and performance.

#thermal reflective roof insulation#heat resistant insulation materials#double bubble insulation sheet

0 notes

Text

Best Thermal Insulation Sevice

We have high-quality thermal insulation services available from Jaipur, India. Heat Insulation, Steel Buildings, Metal Roof, Concrete Roof, Asbestos Roof Sheets, Under Deck, Cold Storage, Refrigerators & Mobile containers, Porta Cabin, False Ceiling, Cold Storage, Poultry Farm, Heat insulation, PEB Insulation, Thermal Insulation, Live Stock Insulation All types of Roofing, Claddings (walls), Ceilings, HVAC, Building Insulation, Industrial, Commercial, and Institutional & M This thermal insulation can be used in a variety of ways and is beneficial to the environment.

We provide thermal insulation services to metro cities such as Delhi, Mumbai, Kolkata, Chennai, Bangalore, Hyderabad, Ahmedabad, Surat, Pune, Kanpur, Indore, Jaipur, Vadodara, Nagpur, Lucknow, Patna, Jabalpur, Madurai, Kochi, Nashik, Rajkot, Gorakhpur, Amravati, Sangli, Jamnagar, Chandigarh, Aurangabad, Nellore, Faridabad, Gurugram, These thermal insulation are made of high-quality materials and have a long lifespan.

Visit us on for more information.

NASA's spacesuits use air bubble films to make them radiation resistant and keep astronauts warm, and AR-FF Fighters use proximity (aluminized) suits for protection from the amount of heat and cool temperature.

• Due to higher documented R values in varying thicknesses, all products are strongly recommended by industrial and commercial building preparers.

• All products are 12 degrees cooler in the summer and 8 degrees warmer in the winter.

Materials for Roof Thermal Insulation Thermal Wrap Sheet Thermal Aluminium Wrap Sheet Thermal Reflective Insulation Bubble Thermal Wrap Sheet Bubble Insulation in Sheet Metalized Sheet Metalized Sheet Metalized Sheet Metalized Sheet Metalized Sheet Metalized Sheet Reflective Insulation Sheet Thermal Wrap Super Roof Insulation Material Thermal Insulation Sheet Thermal Roof InsulationRegular and prompt delivery to all major cities in India, including Mumbai Delhi Bangalore Hyderabad Ahmedabad Chennai Kolkata Pune Surat Jaipur Lucknow Kanpur Nagpur Thane Indore Bhopal Visakhapatnam Chinchwad and Pimpri Patna Vadodara Ghaziabad Ludhiana Agra Nashik Faridabad Meerut Rajkot Dombivali & Kalyan Varanasi Vasai Virar Srinagar Aurangabad Dhanbad Amritsar Navi Mumbai is a city in India. Allahabad Ranchi Haora Coimbatore Jabalpur Vijayawada Gwalior Jodhpur Madurai Raipur Kota Guwahati and Chandigarh are two cities in Assam. Solapur Dharwad and Hubli Bareilly Moradabad Mysore Gurgaon Aligarh Jalandhar Tiruchirappalli Salem, Bhubaneswar Bhayander and Mira Thiruvananthapuram Bhiwandi Saharanpur Gorakhpur Guntur Amravati Bikaner Noida Jamshedpur Bhilai Nagar is a neighbourhood in Bhilai, India. Warangal Cuttack Firozabad Kochi Bhavnagar Dehradun Durgapur Nanded Asansol Waghala Kolapur Ajmer Gulbarga Jamnagar Ujjain Loni Siliguri Jhansi Ulhasnagar Nellore Jammu Sangli Miraj Kupwad Belgaum Mangalore Ambattur Tirunelveli Malegoan Gaya Jalgaon Udaipur Maheshtala.

#thermal insulation#thermal insulation material#Colour Coated Roofing Sheets#insulated roofing sheets#insulation sheet#thermal sheeting insulation#heat insulation#thermal insulation materials in buildings#insulation sheet for roof#roof insulation#thermal insulation sheet manufacturers in india#insulation material#thermal insulation sheet

0 notes

Text

AusFoam: Adaptable Marvels

youtube

The Australian foam industry is a dynamic force, offering versatile options for various applications. From flexible foams with different grades to sturdy foam varieties serving industries like sign writing and construction, and dense cellular materials boasting buoyancy and thermal insulation properties, the foam sector is an essential component of modern manufacturing.

Foams That's Very Flexible

Manufactured in diverse grades, flexible foams cater to a range of needs. The industry standard code, such as 16-100, denotes the density and hardness of the foam. Foams with higher density have a longer lifespan but come at a higher cost, while hardness, measured in Newtons, signifies the 'feel' of the foam. This flexibility allows for tailored solutions, from packaging to comfortable cushions.

Rigid Foams

The foam industry extends its reach by providing sturdy foam varieties, which are crucial in sign writing, building, and construction. Materials like polystyrene (EPS and XPS), PIR, and rigid polyurethanes serve diverse industries, enhancing structural integrity and insulation. EPS, with its closed-cell and resilient nature, finds applications in thermal insulation systems, decorative surfaces, packaging, and stage sets.

Closed Cell Foams

Crafted from polyethylene or ethyl vinyl acetate co-polymers, dense cellular materials exhibit buoyancy, waterproof properties, lightweight composition, and exceptional thermal insulation characteristics. Their applications span expansion joints, packaging, impact absorption, thermal insulation, and backing rod. These foams, resistant to common chemicals, are ideal where durability and performance are crucial.

Environmental Considerations and Innovation

With the growing focus on global sustainability, the foam industry is aligning with environmental goals. Innovations in materials and manufacturing processes, along with recycling initiatives and eco-friendly alternatives, ensure the industry's continued growth while minimizing ecological impact.

In conclusion, the foam sector in Australia is known for its adaptability and innovation, providing essential materials for diverse applications. From flexible foams to sturdy and dense cellular materials, these materials have become integral to daily life, showcasing the flexibility and creativity within the Australian manufacturing landscape.

https://ausfoamadaptablemarvels502.blogspot.com/2024/04/ausfoam-adaptable-marvels.html

foam WA

insulation foam WA

Polystyrene WA

buy styrofoam sheets

EPS Perth

closed cell foam WA

https://commercialmetalroofrestoration777.blogspot.com/

https://commercialmetalroofrestoration777.blogspot.com/2024/04/commercial-metal-roof-restoration.html

https://learnmassagetherapylosangeles468.blogspot.com/2024/04/all-on-4-dental-implants-encinitas.html

https://www.tumblr.com/stulovecorners/748860880082632704

https://caringfortreesvital954.blogspot.com/

0 notes

Text

Comprehensive Guide to Color Roofing Sheets: Styles, Benefits, and Selection Tips

Color roofing sheets offer a blend of aesthetic appeal and functional performance, making them a popular choice in both residential and commercial construction. This guide details the types, benefits, and practical tips for selecting and using color roofing sheets.

Understanding Color Roofing Sheets

What are Color Roofing Sheets?

Explanation of the materials (typically metal or polycarbonate) and the color coating process.

Overview of the common finishes and colors available.

Types of Color Roofing Sheets

Metal Sheets: Aluminum, steel, copper, and their benefits in roofing applications.

Polycarbonate Sheets: Lightweight and durable options suitable for different climatic conditions.

Specialty Coated Sheets: Sheets treated for enhanced UV resistance, thermal insulation, or reflective properties.

Benefits of Using Color Roofing Sheets

Aesthetic Appeal: The role of color in enhancing architectural beauty and complementing exterior designs.

Durability and Protection: How these sheets withstand environmental factors like rain, sun, and wind.

Energy Efficiency: Reflective coatings that contribute to reducing cooling costs by reflecting sunlight.

Ease of Installation: The lightweight nature and design of color roofing sheets make them easy to install and maintain.

Applications of Color Roofing Sheets

Residential Buildings: Enhancing curb appeal and matching thematic exterior designs.

Commercial Structures: Use in malls, warehouses, and factories for both protection and aesthetic consistency.

Agricultural Facilities: Ideal for barns and storage buildings due to their durability and cost-effectiveness.

Choosing the Right Color Roofing Sheets

Color Matching: Tips on choosing colors based on the surrounding environment and building architecture.

Material Selection: How to decide between different materials based on climate, budget, and building use.

Quality and Warranty: Importance of selecting high-quality sheets that come with reliable warranties and after-sales support.

Installation Tips for Color Roofing Sheets

Preparation and Tools Needed: Overview of the tools and preparation steps required for a successful installation.

Installation Process: Step-by-step guide on how to properly install roofing sheets to ensure longevity and performance.

Maintenance Recommendations: Regular cleaning and inspection practices to maintain the aesthetic and functional integrity of the roofing.

Conclusion Color roofing sheets are not just practical but also enhance the visual appeal of any structure. Understanding their types, benefits, and installation can help homeowners and builders make informed decisions that align with their construction needs and aesthetic desires.

More Read: Roofing Sheet | Color Roofing Sheets

0 notes