#stainless steel enclosure manufacturers

Text

Understanding the Types of Enclosures

Enclosures serve a vital purpose in countless industries. They protect delicate equipment from physical damage, dust, moisture, and even extreme temperatures. But with so many varieties available, choosing the right enclosure can be a challenge. This guide dives into various enclosure types, their applications, and how Bartakke Electrofab can fulfill your specific needs.

General Purpose Enclosures:

Floor Standing Enclosures: These sturdy enclosures, as the name suggests, stand upright on the floor. Ideal for housing heavy equipment or when space is a premium on walls. They offer a variety of sizes and configurations to accommodate diverse needs.

Wall Mount Enclosures: Space-saving solutions perfect for lighter equipment. Mounted directly on walls, they free up valuable floor space and provide easy access for maintenance or monitoring.

Environmental Protection Enclosures:

Stainless Steel Enclosures: Built to withstand harsh environments, stainless steel enclosures offer superior corrosion resistance. They are ideal for applications exposed to moisture, chemicals, or extreme temperatures, making them popular in the food processing, pharmaceutical, and marine industries.

NEMA Rated Enclosures: Developed by the National Electrical Manufacturers Association (NEMA), these enclosures are assigned specific ratings that indicate their level of protection against dust, water, and corrosion. Understanding NEMA ratings is crucial for selecting an enclosure suitable for your environment. For instance, a NEMA 4X enclosure offers superior protection against outdoor elements like rain, sleet, and windblown dust.

Specialty Enclosures:

Control Panel Enclosures: Designed specifically to house electrical control panels, these enclosures often feature features like hinged doors for easy access and transparent viewing windows for monitoring. Additionally, they may have provisions for mounting DIN rail components for organized and efficient control panel layout.

Custom Enclosures: When standard options don't meet your specific requirements, custom enclosures provide the perfect solution. Bartakke Electrofab offers complete customization capabilities, allowing you to specify the size, material, ventilation, and access points to create an enclosure that seamlessly integrates with your application.

Key Considerations When Choosing an Enclosure:

Environment: Consider the surrounding conditions like temperature, humidity, dust, and potential exposure to liquids or chemicals.

Size and Weight: Ensure the enclosure is large enough to comfortably house your equipment while considering weight limitations, especially for wall-mounted options.

Accessibility: Think about how often you will need to access the equipment and choose an enclosure with appropriate access doors or panels.

Ventilation: Proper ventilation is crucial for heat dissipation, particularly for equipment that generates significant heat.

Material: Select a material that offers the necessary protection based on the environment and desired features. Consider factors like corrosion resistance, strength, and weight.

Bartakke Electrofab is a leading manufacturer of a comprehensive range of enclosures. We offer a vast selection of floor-standing, wall-mount, and specialty enclosures, including NEMA-rated and stainless steel options. Additionally, our team is adept at designing and building custom enclosures to your exact specifications.

Whether you require a standard enclosure or a unique solution, Bartakke Electrofab has the expertise and capabilities to fulfill your needs. Contact us today to discuss your project requirements and explore how our enclosures can safeguard your valuable equipment.

#control panel enclosure manufacturers#customized enclosures manufacturers#stainless steel enclosure manufacturers#bartakke electrofab

0 notes

Text

Laser Cutting and Sheet Metal Fabrication Services - RP Lasertech

At RP Lasertech, we believe a great product is a result of an in-depth understanding of the customer’s requirements, transforming imaginations into practical realities, and manufacturing products that set the benchmark of innovative engineering.

#cnc metal cutting#stainless steel fabricators#metal manufacturing company#sheet metal fabrication company#sheet metal enclosure

2 notes

·

View notes

Text

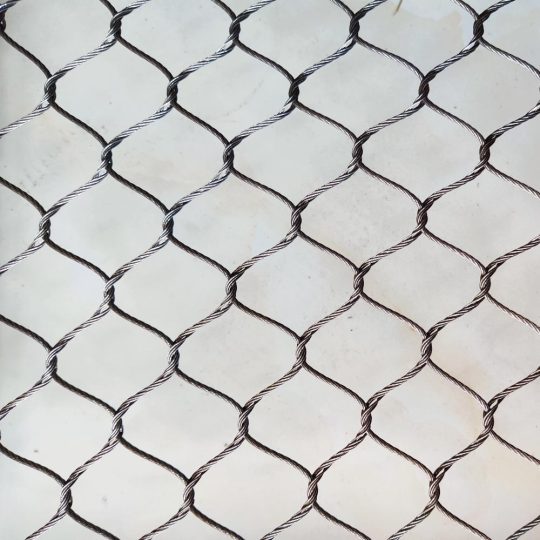

Zoo Mesh: The Perfect Solution for Animal Enclosures

As animal lovers, we all want to ensure that our furry friends are safe and secure in their enclosures. Whether it's for a zoo, aviary, or any other animal enclosure, choosing the right mesh is crucial to ensure the safety and well-being of the animals. That's where Hebmetalmesh comes in - we are a factory that specializes in providing high-quality zoo mesh, animal enclosure mesh, and aviary mesh. In this blog post, we'll explore the benefits of using Hebmetalmesh products for your animal enclosures.

Why Choose Hebmetalmesh?

At Hebmetalmesh, we understand the importance of providing a safe and secure environment for animals. That's why we use only the highest quality materials to manufacture our products. Our zoo mesh, animal enclosure mesh, and aviary mesh are made from stainless steel wire rope, which is strong, durable, and resistant to corrosion. Our products are also designed to be flexible and easy to install, making them the perfect solution for any animal enclosure.

Benefits of Using Hebmetalmesh Products

Safety: Our zoo mesh is designed to be strong and durable, ensuring that animals cannot escape from their enclosures. It also provides a barrier between animals and visitors, ensuring the safety of both parties.

Durability: Our products are made from stainless steel wire rope, which is resistant to corrosion and can withstand harsh weather conditions. This ensures that our products last longer and require less maintenance.

Flexibility: Our products are designed to be flexible and easy to install, making them the perfect solution for any animal enclosure. They can be customized to fit any size or shape of enclosure, ensuring a perfect fit every time.

Aesthetics: Our zoo mesh is not only functional but also aesthetically pleasing. It provides a clean and modern look to any animal enclosure, enhancing the overall appearance of the exhibit.

Products Offered by Hebmetalmesh

We offer a wide range of products to suit any animal enclosure needs. Our products include:

Zoo Mesh: Our zoo mesh is perfect for creating enclosures for large animals such as lions, tigers, and bears. It is strong and durable, ensuring that animals cannot escape.

Animal Enclosure Mesh: Our animal enclosure mesh is designed for smaller animals such as monkeys, birds, and reptiles. It provides a safe and secure environment for these animals.

Aviary Mesh: Our aviary mesh is perfect for creating enclosures for birds of all sizes. It is designed to be strong and durable, ensuring that birds cannot escape.

Recommendation

At Hebmetalmesh, we take pride in providing high-quality products that are designed to meet the needs of our customers. We believe that our zoo mesh, animal enclosure mesh, and aviary mesh are the perfect solutions for animal enclosures of all kinds. We recommend our products to anyone who is looking for a safe, durable, and aesthetically pleasing solution for their animal enclosures.

Conclusion

Choosing the right mesh is crucial to ensure the safety and well-being of animals in their enclosures. At Hebmetalmesh, we offer high-quality zoo mesh, animal enclosure mesh, and aviary mesh that are designed to meet the needs of our customers. Our products are strong, durable, flexible, and aesthetically pleasing, making them the perfect solution for any animal enclosure. We recommend our products to anyone who is looking for a safe and secure environment for their furry friends.

More Ideas

ZOO MESH – A BETTER ZOO ENCLOSURE AND AVIARY NETTING

Types of Zoo Mesh Order with Different Panels and Meshes All In One

Black Oxide Zoo Mesh Order with Different Panels and Meshes All In One

#zoo mesh#aviary mesh#zoo fencing#animal enclosure mesh#Animal fence#Aviary wire mesh#Aviary netting

43 notes

·

View notes

Photo

Back in a former life, I had an addiction that I loved beyond sanity. Here’s the story of it.

2002 2003 2004 2005 2006 2007 2008 2009 pt1 2009 pt2 2009 Redux

This is the final spec list for my glorious, insane Brutal Truth.

Nissan Skyline BCNR33 GT-R (Type 2) manufactured in April 1996. JDM non V-Spec vehicle retailed through Osaka Nissan Prince in May/June 1996. Imported to the

UK in June 1997. Remained in original JDM spec without speedometer conversion until August 2002. Only the steering wheel & white dial sets were fitted in Japan.

Nismo RB26N1 bare engine: [N1 water pump (improved flow & less cavitation)/Reinforced cylinder block head bolt boss/Increased sump capacity (6L 20w60)/1.2mm oil restrictor]

N1 head with 0.5mm overbore (2598cc)

Cryogenically hardened N1 crankshaft

Wossner forged & cryogenically hardened pistons

Abbey Motorsport reinforced & cryogenically hardened con-rods

ACL Race Series conrod & crankshaft bearings

Tomei sump baffle kit

Tomei high flow (larger drive gears) oil pump

HKS 1.2mm metal head gasket

Tomei Procam Spec 2 cam kit (270 degree inlet & outlet with 10.25mm lift)

HKS V-Cam System Step 1 Type B (variable 248-278 degree inlet; replaces Procam inlet camshaft)

HKS vernier cam pulleys

HKS kevlar reinforced timing belt

Trust metal intake & throttle gaskets

HKS front pipe & decat gaskets

GReddy Iridium 08 Racing sparkplugs

Mocal 19-row oil cooler & Abbey Motorsport remote oil filter assembly

Abbey Motorsport catch tank & washer reservoir with SFS breather hoses

Abbey Motorsport Pro Alloy large radiator

Tomei fuel pump, fuel regulator & 600cc injectors

A’PEXi Power Intake induction kit

A’PEXi GT Spec intercooler (237x610x136mm) & hard pipe kit

HKS GT-SS turbos

HKS twin AFM delete kit

Tomei turbo elbows

HKS downpipes

HKS Silent Hi-Power exhaust

Abbey Motorsport 80mm decat pipe

Mine’s VX-ROM

HKS F-Con V Pro

HKS EVC 6 boost controller (1.6 bar)

AEM wideband lambda sensor

Splitfire DI Super Direct Ignition System

HKS Circle Earth kit

HKS GD Max twin-plate clutch (with lightened flywheel)

Abbey Motorsport rebuilt transfer box

Abbey Motorsport rebuilt gearbox with cryogenically hardened gear set, modified Nissan synchromesh upgrade and OS Giken strengthening plate

Abbey Motorsport rebuilt rear diff

Nismo gearbox mounts

Nismo Solid Shift gear stick (10% short shift)

Omex Shift Light Sequential

Sunsei SE-135 solar panel trickle charger mounted on a custom aluminium riser between the rear parcel shelf speaker enclosures.

Team Dynamics Equinox alloys 19x9.5, ET+15 in silver with polished stainless steel rim.

Falken FK452 265/30/19 Y-rated tyres

Cusco brake master cylinder brace

Cusco rear steering delete kit

Cusco front & rear upper suspension links

AST Sport Line 1 full suspension kit with UK spring setup

Nismo stainless steel braided brake hoses

StopTech 355mm rotor 4 pot caliper front brake kit

StopTech 355mm rotor 2 pot caliper rear brake kit with Abbey Motorsport modified pad retainers

Ferodo DS2500 brake pads front & rear

Bomex AD-390 front splitter

Nismo R34 smoked front indicators in custom aluminium mounting plates finished in crackle black

Nissan Xenon headlamp units

Border Racing Aero Fenders (vented front wings) with silver GT emblems from a R32 Skyline

Nismo smoked side repeaters

Top Mix one-off FRP twin blade rear spoiler on custom aluminium mounting plates

Entire exterior resprayed in BMW black (code 086) base and lacquer

Nissan Motorsport International carbon fibre B-pillar plates

PIAA carbon effect silicon wipers, front pair with spoilers, rear without

Nismo white face dial sets (dashboard & centre console) in carbon fibre panels

AEM AFR gauge mount replaces the lighter socket

HKS EVC display mounted on custom carbon fibre plate replacing the ashtray

Lighter socket relocated to the fog light switch panel

Nissan Momo steering wheel (with airbag)

Dressycar Nismo harness pads

Redline Automotive leather gearstick & handbrake gaiters

Abbey Motorsport carbon fibre door sill trims

Carbon fibre boot sill trim

Inlet plenum and sundry induction pipework finished in powder grey

Trust clear cam pulley cover

HKS Kansai Service carbon fibre spark plug cover

Right hand cam cover finished in crackle black

Nismo radiator & washer reservoir caps

HKS Kansai Service front strut brace finished in high gloss black

GReddy aluminium slam panel finished in crackle black

Tein bonnet dampers with black sleeves

Custom made one-off Cobra Misano Lux front seats: [Alcantara (colour code 9189) outers/Alcantara (colour code 9182) centre panels/One-piece carbon fibre backs/Sidewinder bases on custom subframes adapted by Abbey Motorsport/Cobra logo in silver thread on the headpads/GT-R logo beneath the grommets on seat backs]

JVC KD-AVX2 multi-media DVD/CD receiver with built-in 3.5” widescreen monitor

2x JL Audio Evolution VR600-CXi 6” speakers (front)

2x JL Audio Evolution TR650-CXi 6.5” speakers (rear)

Multiple and interlaced Thatcham rated security systems.

500 bhp. 520 ft/lb.

Ludicrously, hilariously, unbelievably fast.

Hope you enjoyed this little trip down memory lane with me. Cheers! JM.

(Photo by N. Liassides.)

#r33#bcnr33#skyline#gt-r#nissan skyline#Abbey Motorsport#HKS#Bomex#Tomei#A'PEXi#GReddy#Nismo#RB26N1#Mocal#Team Dynamics

12 notes

·

View notes

Text

2023 Cost vs. Value Report: 5 Best and 5 Worst Home Renovations ROI in the Los Angeles area

When it comes to home renovations, it's important to consider not only the immediate benefits of the project but also its potential resale value. The annual Cost vs. Value Report by Remodeling magazine analyzes the average cost of various renovation projects and estimates their potential return on investment (ROI) in the current housing market. In the Pacific region of the US, Los Angeles is a particularly popular area for home renovations. Let's take a look at the top 5 home renovation projects with the highest recuperation rate and the bottom 5 with the lowest recoup rate in the Los Angeles, CA area according to the 2023 Report. Some of these projects may be confirmation of what you know and some may shock you. If you have questions about a Huntington Beach home renovation call me.

Top 5 renovation projects with the highest recoup rate:

Manufactured stone veneer: The project involves replacing the existing vinyl siding on the bottom third of the street-facing facade of the house with manufactured stone veneer. The average cost of the project is $12,989, and it has an estimated ROI of 109.8%.

garage door replacement: This project involves replacing an existing garage door with a new four-section garage door with heavy-duty galvanized steel tracks. The average cost of the project is $3,776, and it has an estimated ROI of 107.3%.

Entry door replacement (steel): this project involves replacing an existing entry door with a new 20-gauge steel entry door with clear dual-pane half-glass panel, jambs, and an aluminum threshold with composite stop. The average cost of the project is $1,981, and it has an estimated ROI of 94.5%.

Minor kitchen remodel: This project involves replacing cabinet fronts with shaker-style wood panels and drawer fronts, installing new hardware, replacing laminate countertops with new ones, and installing a new stainless steel sink and faucet. The average cost of the project is $27,772, and it has an estimated ROI of 88.4%.

Siding replacement (vinyl): this project involves replacing the existing siding with new foam-backed insulated vinyl siding, including all trim. The average cost of the project is $18,929, and it has an estimated ROI of 84.9%.

Bottom 5 renovation projects with the lowest recoup rate:

Backup Power Generator: This project involves installing a new standby generator to provide backup power during outages. The average cost of the project is $17,500, and it has an estimated ROI of 41.6%.

Home office remodel: This project involves converting a spare bedroom into a home office with custom cabinets, a laminate desktop, and recessed overhead lighting. The average cost of the project is $38,582, and it has an estimated ROI of 43.5%.

Sunroom Addition: This project involves adding a 200-square-foot sunroom with a new foundation and footings, vinyl windows with insulated glass, and a sliding door. The average cost of the project is $113,238, and it has an estimated ROI of 47.4%.

Major kitchen remodel: This project involves gutting the kitchen and replacing everything, including cabinets, countertops, appliances, flooring, and lighting. The average cost of the project is $81,700, and it has an estimated ROI of 47.5%.

Bathroom Addition: This project involves adding a new 6-by-8-foot bathroom to an existing space, including a fiberglass shower with a glass enclosure, a toilet, and a vanity with a solid-surface countertop. The average cost of the project is $49,782, and it has an estimated ROI of 52.4%.

When planning a home renovation project in the Los Angeles, CA area, it's important to consider not only your personal preferences and needs but also the potential resale value of the project. As seen in the 2023 Cost vs. Value Report, certain projects tend to recoup a higher percentage of their cost than others. This doesn't mean that you should always choose the highest recoup rate projects, as personal preference, location, and other factors may also come into play.

However, it's always a good idea to weigh the potential return on investment against the upfront cost when deciding on a renovation project. It's also important to keep in mind that the cost and ROI estimates provided in the report are just averages, and your actual cost and ROI may vary depending on factors such as the size of your home, the quality of materials used, and the contractor you hire.

Therefore, it's always a good idea to get multiple quotes from licensed and experienced contractors and to do your research before making a decision. With careful planning and execution, a home renovation project can not only improve your living space but also add value to your home.

Also don't forget to call me for what your Huntington Beach home value is to see if it makes sense to sell now with these upgrades and remodels.

Mr. Huntington Beach Real Estate

315 7th St D Huntington Beach, CA 92648

949-310-4110

10 notes

·

View notes

Text

Electrical Enclosure Market Insights: Comprehensive Global Forecast (2023-2032)

The global demand for Electrical Enclosures was valued at USD 49514.2 million in 2023 and is expected to reach USD 80168.1 million in 2032, growing at a CAGR of 5.50% between 2024 and 2032.

The electrical enclosure market is experiencing robust growth, driven by the increasing demand for reliable and safe housing for electrical and electronic components across various industries. These enclosures are essential for protecting sensitive equipment from environmental hazards, such as dust, water, chemicals, and physical impacts, thereby ensuring the safety and functionality of electrical systems. The market is witnessing significant advancements due to rapid industrialization, urbanization, and the expansion of infrastructure projects worldwide. The rise in automation and the adoption of advanced technologies in manufacturing processes have further fueled the need for high-quality electrical enclosures to safeguard sophisticated machinery and control systems.

In terms of materials, metal and non-metal enclosures are the primary segments. Metal enclosures, particularly those made of stainless steel and aluminum, are preferred for their durability, strength, and excellent shielding properties against electromagnetic interference. On the other hand, non-metal enclosures, typically made from plastics like polycarbonate and fiberglass-reinforced polyester, are gaining traction due to their lightweight, corrosion resistance, and cost-effectiveness. These materials also offer greater flexibility in design and are easier to install, making them suitable for a wide range of applications, from industrial to commercial and residential settings.

The market is also driven by stringent safety regulations and standards set by governmental and regulatory bodies, which mandate the use of protective enclosures to prevent electrical hazards. This has led to increased adoption in sectors such as energy and power, telecommunications, transportation, and healthcare. In the energy sector, the growing deployment of renewable energy sources like wind and solar power requires robust enclosures to protect equipment from harsh outdoor conditions. Similarly, in the telecommunications industry, the expansion of 5G networks necessitates advanced enclosures to house critical network components.

The electrical enclosure market, while poised for growth, faces several significant challenges that could impact its expansion and development. These challenges stem from various factors, including technological advancements, regulatory complexities, market competition, and environmental considerations.

Technological Complexity: As industries evolve and adopt more sophisticated technologies, the design and manufacturing of electrical enclosures must keep pace. Enclosures need to accommodate a wide range of electrical and electronic components, often with varying requirements for ventilation, cooling, and access. Integrating advanced features such as IoT and smart sensors into enclosures adds another layer of complexity, requiring specialized expertise and increased R&D investment.

Stringent Regulatory Standards: The electrical enclosure market is governed by numerous safety and quality standards, which vary across different regions and industries. Ensuring compliance with these diverse and often stringent regulations can be challenging for manufacturers, particularly those operating in multiple markets. Non-compliance can lead to significant penalties, product recalls, and damage to brand reputation.

Cost Pressures: The cost of raw materials, particularly metals like stainless steel and aluminum, can fluctuate significantly, impacting the overall production costs of electrical enclosures. Additionally, incorporating advanced technologies and ensuring regulatory compliance can further drive up manufacturing costs. These cost pressures can make it difficult for manufacturers to maintain competitive pricing while ensuring high-quality products.

Environmental and Sustainability Concerns: There is an increasing focus on environmental sustainability, which affects the electrical enclosure market in several ways. Manufacturers are under pressure to use eco-friendly materials and sustainable production processes. Ensuring that enclosures are recyclable or made from recycled materials can add to the complexity and cost of production. Moreover, disposing of old or obsolete enclosures in an environmentally responsible manner presents an ongoing challenge.

Customization and Diversification Demands: Customers across different industries often have specific and varied requirements for electrical enclosures, necessitating a high degree of customization. This demand for customized solutions can complicate production processes and supply chain management. Balancing the need for bespoke designs with efficient mass production is a significant challenge for manufacturers.

Market Competition: The electrical enclosure market is highly competitive, with numerous global and local players vying for market share. Intense competition can lead to price wars, squeezing profit margins and making it difficult for companies to invest in innovation and quality improvements. Differentiating products in such a crowded market requires continuous innovation and effective marketing strategies.

Supply Chain Disruptions: The global supply chain for materials and components used in electrical enclosures can be vulnerable to disruptions due to geopolitical tensions, natural disasters, and other unforeseen events. These disruptions can lead to delays, increased costs, and difficulties in meeting customer demands. Ensuring a resilient and flexible supply chain is crucial for maintaining steady production and delivery schedules.

Rapid Technological Changes: The pace of technological advancements in the electrical and electronics industry means that enclosure designs need to be frequently updated to accommodate new components and technologies. Staying ahead of these changes requires continuous investment in research and development, which can strain resources, especially for smaller manufacturers.

Key Players:

Schneider Electric SE

Legrand SA

Hubbell Inc.

Emerson Electric Co.

ABB Ltd

Eaton Corporation

Eldon Holding AB

AZZ Inc.

Austin Electrical Enclosures

Siemens AG

Pentair PLC

Rittal GmbH & Co. Kg.

Adalet (Scott Fetzer Company)

More About Report- https://credenceresearch.com/report/electrical-enclosure-market

The key findings of the study on the electrical enclosure market highlight several crucial insights that underscore the market's dynamics, growth drivers, and potential challenges. These findings provide a comprehensive understanding of the factors influencing the market and its future trajectory:

Rising Demand for Industrial Automation: The proliferation of industrial automation and the adoption of advanced technologies in manufacturing processes are key drivers for the market. The need to protect sophisticated machinery and control systems from environmental hazards is boosting the demand for high-quality electrical enclosures.

Diverse Material Preferences: There is a growing preference for both metal and non-metal enclosures. Metal enclosures, especially those made from stainless steel and aluminum, are valued for their durability and excellent shielding properties. Non-metal enclosures, made from materials like polycarbonate and fiberglass-reinforced polyester, are gaining popularity due to their lightweight, corrosion resistance, and cost-effectiveness.

Technological Advancements: The integration of smart technologies and IoT into electrical enclosures is a notable trend. Smart enclosures equipped with sensors for real-time monitoring of environmental conditions and equipment status are becoming increasingly popular, particularly in industrial automation and smart grid applications.

Regulatory Influence: Stringent safety regulations and standards imposed by governmental and regulatory bodies are significantly influencing the market. Compliance with these regulations is essential, driving the adoption of protective enclosures across various sectors such as energy, telecommunications, and transportation.

Growth in Renewable Energy Sector: The growing deployment of renewable energy sources like wind and solar power is driving the demand for robust electrical enclosures. These enclosures are essential for protecting equipment in harsh outdoor conditions, supporting the growth of the renewable energy sector.

Customization and Personalization: The demand for customized and personalized electrical enclosures is on the rise. Customers across different industries require tailored solutions to meet specific needs, driving manufacturers to offer a wide range of customizable options.

Geographic Insights: The market shows significant growth potential across various regions, with North America, Europe, and Asia Pacific leading the charge. The Asia Pacific region, in particular, is witnessing rapid industrial growth, urbanization, and infrastructural development, making it a lucrative market for electrical enclosures.

Environmental and Sustainability Concerns: Increasing focus on environmental sustainability is influencing the market. Manufacturers are emphasizing the use of eco-friendly materials and sustainable production practices, responding to the growing demand for environmentally responsible products.

Competitive Landscape: The market is highly competitive, with numerous global and local players striving to capture market share. Companies are focusing on innovation, quality, and strategic partnerships to differentiate their products and expand their market presence.

Challenges and Risks: Despite positive growth prospects, the market faces challenges such as technological complexity, regulatory compliance, cost pressures, supply chain disruptions, and the need for continuous innovation. Addressing these challenges requires strategic planning and investment.

Segmentation-

By Material:

Metal (Steel, Stainless Steel, Aluminum)

Non-metallic (Plastic, Fiberglass, Polycarbonate)

Others

By Product Type:

Dust-Tight Enclosures

Water-Tight Enclosures

Hazardous Environment Enclosures

Free-Standing Enclosures

Wall-Mounted Enclosures

Floor-mounted/Pedestal Enclosures

Others

By Mounting Type:

Flush-Mounted Enclosures

Surface-Mounted Enclosures

Others

By Industry Vertical:

Industrial

Commercial

Energy and Power

Oil and Gas

IT and Telecommunication

Healthcare

Browse the full report – https://credenceresearch.com/report/electrical-enclosure-market

Browse Our Blog: https://www.linkedin.com/pulse/electrical-enclosure-market-projections-global-industry-m8dpf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Supplier of SS Sheets in Chennai

Meghmani Metal Industries is a Manufaturer and Supplier of SS Sheets in Chennai, Tamil Nadu, India.

Established in 2011, Meghmani Metal Industries has steadfastly emphasized customer satisfaction and environmental stewardship throughout its operations.

We offer a comprehensive array of stainless steel products, including plates, coils, bars, pipes, tubes, flanges, valves, fittings, fasteners, channels, and flats, meticulously crafted to fulfill a wide spectrum of industrial requirements.

Stainless Steel Sheets are versatile and essential components across various industries, prized for their durability, corrosion resistance, and aesthetic appeal.

Our sheets are manufactured through a process involving hot rolling, cold rolling, or annealing, resulting in different surface finishes and thicknesses to suit diverse applications.

Stainless steel sheets find extensive use in cladding, roofing, and decorative elements due to their sleek, modern appearance and ability to withstand harsh weather conditions.

Their reflective surfaces can create striking visual effects, enhancing the overall ambiance of commercial and residential spaces alike.

SS sheets serve as foundational materials for fabricating machinery, equipment enclosures, and storage tanks.

These sheets are used to construct countertops, food processing equipment, and storage containers, ensuring compliance with regulatory requirements and maintaining the integrity of consumable products.

Meghmani Metal Industries is a Manufaturer and Supplier of SS Sheets in Chennai and places like Advadi, Kanagam, Ennore, Chetpet, Minjur, Kolathur, Mylapore, Ennore, Adyar, MRC Nagar, Pallikaranai, Egattur, Nesapakkam, Perungalathur, Kottivakkam, Kazhipattur.

If you have any queries or would like more information, please get in touch with us.

View Product: https://meghmanimetal.com/ss-sheets-plates-coils/

Read the full article

#Advadi#Adyar#Chennai#Chetpet#Egattur#Ennore#ExporterofSSSheets#India#Kanagam#Kazhipattur#Kolathur#Kottivakkam#ManufacturerofSSSheetsinAhmedabad#Minjur#MRCNagar#Mylapore#Nesapakkam#Pallikaranai#Perungalathur#SSSheetsinChennai#SSSheetsinIdia#SSSheetsinTamilNadu#SupplierofSSSheets#SupplierofSSSheetsinChennai#SupplierofSSSheetsinIndia#TamilNadu

0 notes

Text

Pros Offered By a Weatherproof Junction Box

Sometimes weatherproof electrical box is required on the exterior of your property, whether at home or business, to the point where a specific style of box and accompanying accessories can be acquired. If you want to make a waterproof connection outside, a weatherproof junction box is the best option.

Weatherproof junction boxes are an excellent choice for protecting parts from dangerous exterior components. These boxes are normally sealed enclosures designed for placement on roof overhangs, outside walls, decks, and other surfaces. These boxes are used to mount lighting fixtures and outside receptacles.

Weatherproof junction boxes must feature an exterior fixture or a cover suited for wet environments, however this varies by application. They are often IP (Ingress Protection) or NEMA-rated (National Electrical Manufacturers Association) to endure a wide range of environmental conditions such as extreme cold or heat, UV radiation, wetness, and strong winds.

Benefits of weatherproof junction boxes

Durable

As previously said, weatherproof electrical boxes and weatherproof gang box are constructed with durable materials that will function properly regardless of the weather conditions. Weatherproof junction boxes constructed of stainless steel are resistant to a variety of environmental issues, resulting in a long and reliable product life.

Shock resistant

Depending on the material chosen to construct a weatherproof electrical box, it can provide some degree of impact resistance. Polycarbonate enclosures, in particular, can provide shock resistance due to their great dimensional stability.

Protect against extreme weather fluctuations

When junction boxes are exposed to extreme cold and hot temperatures or UV radiation, they can degrade and lose their capacity to protect your electrical elements. Nonetheless, weatherproof junction boxes can successfully address this immediate weather issue since they are made of high-quality materials that can survive harsh weather conditions. These junction boxes come in a variety of durable materials, including polycarbonate, aluminum, FRP (fiber-reinforced polyester), and stainless steel.

Protect against accidental damage

Weatherproof junction boxes safeguard against unintentional damage to the elements caused by heat, loose connections, sparks, and short circuits. Furthermore, these enclosures protect the wires from dust, grime, and moisture. A reliable and robust weatherproof power junction box is essential, especially if you want to protect your electrical components from the multiple harsh elements encountered in outdoor environments.

1 note

·

View note

Text

Enhancing Cleanroom Efficiency with Pass Boxes from Modular Clean Room India

In cleanroom environments, maintaining a contamination-free space is critical. A vital component in achieving this is the pass box. Modular Clean Room India offers top-quality pass boxes designed to enhance the efficiency and safety of cleanroom operations. Discover our full range of cleanroom solutions at [clean room manufacturer and supplier in chennai](clean room manufacturer and supplier in chennai).

What is a Pass Box?

A pass box is an enclosure installed in cleanrooms to facilitate the transfer of materials between areas of different cleanliness levels. This ensures minimal contamination risk, maintaining the integrity of the cleanroom environment.

Types of Pass Boxes

Modular Clean Room India provides two main

types of pass boxes:

1.Static Pass Box

- Ideal for transferring non-living materials between cleanrooms or between a cleanroom and an uncontrolled environment.

- Features interlocking doors that prevent simultaneous opening, ensuring no contamination breach.

2. Dynamic Pass Box

- Designed for transferring both living and non-living materials.

- Equipped with a built-in HEPA filtration system to continuously clean the air inside the pass box, reducing particulate contamination.

Key Features of Pass Boxes from Modular Clean Room India

Our pass boxes are designed with several advanced features:

-Stainless Steel Construction: Durable and

easy to clean.

- Interlocking Mechanism: Prevents cross-contamination by ensuring only one door can be opened at a time.

- UV Sterilization: Integrated UV lights sterilize the internal surfaces, further minimizing contamination risks.

- Seamless Design:Smooth, rounded corners avoid particle accumulation and facilitate easy cleaning.

Benefits of Using Pass Boxes

- Enhanced Cleanroom Efficiency:Streamlines material transfer, reducing personnel movement and contamination risks.

- Cost-Effective: Lowers operational costs by maintaining a contamination-free environment.

- Safety and Compliance: Helps maintain compliance with stringent cleanroom standards and regulations.

Applications of Pass Boxes

Pass boxes are essential in various industries, including:

- Pharmaceuticals: Ensures contamination-free transfer of drugs and medical equipment.

- Biotechnology: Facilitates safe transfer of biological samples and reagents.

- Microelectronics: Protects sensitive electronic components from particulate contamination.

- Food and Beverage: Maintains hygienic conditions during the transfer of food products and packaging materials.

Why Choose Modular Clean Room India?

At Modular Clean Room India, we are committed to pr

oviding top-of-the-line cleanroom solutions tailored to your specific needs. Our pass boxes are designed with precision, incorporating the latest technology to ensure optimal performance. Visit our website [modularcleanroomindia.com](clean room manufacturer and supplier in chennai) to learn more about our offerings and how we can help enhance your cleanroom operations.

Conclusion

Pass boxes play a vital role in maintaining the integrity of cleanroom environments. By choosing the right pass box, you can significantly improve the efficiency and safety of your cleanroom operations. Modular Clean Room India is your trusted partner in achieving the highest standards of cleanliness and contamination control. Explore our products and services today at [clean room manufacturer and supplier in chennai](clean room manufacturer and supplier in chennai).

By following this article format, you can effectively highlight the importance and benefits of pass boxes in cleanroom environments while promoting Modular Clean Room India's website and services.

#modularcleanroomindia.com#modularcleanrooms#manufacturer#supplier#chennai#india#operation theatre#theatre

0 notes

Text

Transforming Spaces with 3D Metal Tiles: The Future of Interior Design

In the ever-evolving landscape of interior design, the advent of 3D metal tiles has marked a significant milestone. These innovative tiles offer a striking combination of durability, versatility, and aesthetic appeal, making them an increasingly popular choice for both residential and commercial spaces.

Understanding 3D Metal Tiles

3D metal tiles are crafted using advanced manufacturing techniques that allow for intricate designs and patterns to be embedded directly into the metal surface. This process not only enhances the visual depth of the tiles but also creates a tactile experience that traditional flat tiles cannot match. Materials commonly used include stainless steel, aluminum, and copper, each bringing its unique properties and finishes to the table.

The manufacturing process often involves techniques such as stamping, laser cutting, and embossing, which enable the creation of complex and detailed patterns. These methods ensure that the tiles are not only aesthetically pleasing but also robust and long-lasting.

Applications in Interior Design

The versatility of 3D metal tiles makes them suitable for a variety of applications. In kitchens, they can serve as a stunning backsplash that not only adds a modern touch but also stands up to heat and moisture. Bathrooms can benefit from their water-resistant properties, providing a stylish yet practical solution for walls and shower enclosures. In commercial settings, 3D metal tiles can transform reception areas, conference rooms, and retail spaces, creating an impression of sophistication and cutting-edge design.

Moreover, these tiles are increasingly being used in accent walls, fireplace surrounds, and even ceilings. Their reflective properties can enhance lighting effects, making spaces appear larger and more vibrant. Outdoor applications, such as facades and garden features, are also possible due to the durability of the materials used.

Advantages Over Traditional Tiles

Compared to traditional ceramic or porcelain tiles, 3D metal tiles offer several advantages. Their durability ensures a long lifespan, making them a cost-effective investment over time. Additionally, metal tiles are easier to clean and maintain, as they resist stains and do not require sealing. The ability to recycle metal tiles also adds an eco-friendly aspect, aligning with sustainable design practices.

The heat resistance of metal tiles makes them ideal for areas exposed to high temperatures, such as around stoves and fireplaces. They are also less prone to cracking or chipping compared to ceramic tiles, ensuring that they remain in pristine condition for longer periods.

Installation and Maintenance

Installing 3D metal tiles requires precision and expertise. It is recommended to engage professionals to ensure a seamless finish. The process typically involves preparing the substrate, applying adhesive, and carefully placing the tiles to maintain alignment and pattern consistency. Proper installation ensures that the tiles are securely attached and can withstand daily wear and tear.

Maintenance is relatively straightforward; regular wiping with a soft cloth and mild detergent is usually sufficient to keep the tiles looking their best. For areas exposed to heavy use or moisture, periodic checks for signs of wear can help maintain their pristine condition. Avoiding abrasive cleaners and harsh chemicals will preserve the finish and prevent tarnishing.

Design Trends and Future Outlook

As design trends continue to evolve, 3D metal tiles are expected to remain at the forefront of interior design innovations. Their ability to combine functionality with artistic expression makes them an ideal choice for modern, industrial, and contemporary styles. Emerging trends include the use of mixed metals, integrating different finishes and colors to create unique, multi-dimensional effects.

In conclusion, 3D metal tiles represent a perfect blend of form and function, offering endless possibilities for interior design. Their unique aesthetic and practical benefits make them a valuable addition to any space, promising to remain at the forefront of design trends for years to come. Whether for residential or commercial applications, these tiles can transform ordinary spaces into extraordinary ones, elevating the overall aesthetic and value of the property.

#bespoke metal tiles#3d metal tiles#metal tiles#interior tiles#exterior tiles#tiles supplier#bespoke metal tiles

0 notes

Text

Industry-Wise Role of Enclosures

Enclosures might seem like simple boxes, but they play a critical role in safeguarding sensitive components across industries. From harsh outdoor environments to delicate manufacturing processes, enclosures provide tailored protection against dust, moisture, impact, and other hazards. Let's explore the industry-specific applications of enclosures and why partnering with reputable manufacturers like IP65 enclosure box manufacturers, custom enclosure manufacturers, and control panel enclosure manufacturers is essential.

Electrical and Electronics

Control Panels: Control panel enclosures are the heart of any electrical system, housing critical components like switches, circuit breakers, and relays. They require robust construction to withstand vibrations, temperature changes, and potential electrical faults.

Industrial Automation: In highly automated facilities, enclosures protect programmable logic controllers (PLCs), sensors, and other sensitive electronics from dust, debris, and electromagnetic interference (EMI). Look for enclosures with appropriate IP ratings and EMI shielding for optimal protection.

Outdoor Electronics: Weatherproof enclosures are essential for outdoor electronic equipment, from security systems to traffic control devices. IP65-rated enclosures provide reliable protection against rain, snow, and harsh sunlight.

Manufacturing

Machinery: Manufacturing environments often contain airborne contaminants like metal shavings, oil mist, and chemicals. Enclosures protect the control systems and electronics of machinery, ensuring reliable operation and minimizing downtime.

Washdown Areas: In food processing and other industries with strict hygiene standards, enclosures must withstand frequent washdowns with high-pressure water and cleaning agents. Stainless steel enclosures with high IP ratings are ideal for these demanding applications.

Hazardous Environments: Industries that handle flammable or explosive materials require specialized enclosures designed to prevent sparks or explosions. Seek out enclosures with certifications like ATEX or IECEx.

Telecommunications and Networking

Outdoor Equipment: Telecommunications equipment such as cell towers and remote antennas often require protection from the elements. Weatherproof enclosures ensure uninterrupted service in all weather conditions.

Data Centers: Network cabinets and server racks are specialized enclosures that provide physical security, airflow management, and cable organization for critical IT infrastructure.

Why Choose the Right Enclosure Manufacturer

IP Ratings: Ensure the enclosure's dust and water resistance meets your specific needs. Look for IP65 enclosure box manufacturers for superior protection.

Customization: Many applications require unique modifications. Custom enclosure manufacturers can tailor solutions to your exact equipment and environmental requirements.

Materials: Choose the right material (e.g., steel, stainless steel, aluminium, polycarbonate) based on strength, corrosion resistance, and cost considerations.

Certifications: Verify relevant safety and performance certifications, particularly for hazardous locations.

Enclosures are not just a matter of convenience; they are an investment in the longevity and reliability of your valuable equipment. By understanding the specific requirements of your industry and partnering with experienced manufacturers, you can find the perfect enclosure solution to ensure years of trouble-free operation.

#control panel enclosure manufacturers#customized enclosures manufacturers#bartakke electrofab#stainless steel enclosure manufacturers

0 notes

Video

youtube

Biomass Pellet Machine Inside Structure, Pellet Production Line, 4-30mm Pellets Diameter, 1-5t/h

Today Let's see the pellet machine's inside structure.

First you can see the ring die and pressed rollers of our pellet machines are made of high-alloy wear-resistant material, and also can be equipped with stainless steel material for customer to choose.

The ring die matrix is placed vertically, and adopts the upper and lower 2layers' design to reduce the wear cost and at the same time form the rebound effect of the second-layer high enclosure and increase the output.

We are a pellet machine manufacturer. We are producing pellet machine and complete lines already for 18 years, and our key machines are biomass pellet machine, wood pellet mill, wood chipper, wood crusher, wood hammer mill, rotary dryer, pellet cooler and the complete lines. The output is from several kgs to several tons per hour.

If any interest, feel free to connect us.

#biomasswoodpelletmachine #pelletmachinesuppliers #biomassenergy #biomasspellet #pelletmachine #manufacturing #biomassfuel #ricehusk #ricehuskpellet #waste #wasteclothes #wastereuseideas #wastepaper #wasterubber #inctroduction waste #feedpelletmachine #feedpelletmaker #feedpelletmills #organicfertilizer #msw #rdf #JNSHARE 4-30mmpelletsdiameter #1-5tons/h #ringdiepelletmachine #flatdiepelletmachine

TEL/Wechat/ Whatsapp: +86 15053177578

Email: [email protected]

[email protected]

web: www.jnshare.com

www.pelletmill.cn

0 notes

Text

North american aluminum framed sliding glass shower door

Leak-Free guarantee and no silicone on show design

Easy-glide quick-release door runners for ease of cleaning

We have a huge and extensive range of shower enclosures which includes pivot, Bifold, sliding doors and corner entry, quadrants, Double sliding enclosures,single sliding enclosures, frameless shower enclosures, framed shower enclosures ,Wet rooms & many more

Modern appearance design, light and delicate charm

Certified tempered clear glass, aluminium finish hardware, clear premium leak-seal strips, durable steel supports, you just drop in your relaxing shower time

Company Name:Kaipunuo Sanitary Ware Co., Ltd.

Web:https://www.showercabinfactory.com/product/shower-enclosure/stainless-steel-series/1.html

ADD:Pinghu xindai sanitary ware city

Phone:86-13515739471

Fax:86-057385219605

Email:[email protected]

Tip:314200

Profile:Kaipunuo Sanitary Ware Co., Ltd., a professional manufacturer of shower products, established in 1997 in Pinghu, Zhejiang province, China, which integrates design, produce, sales and customer service vertically for our customers in more than 20 countries all over the world.

0 notes

Text

Plastic Filter and Stainless-Steel Housing System | MFTECH

Introducing the innovative technology of active metal brazing and ASME vessel filter housing solutions with superior performance and high efficiency by MFTECH. As a prominent display provider in Korea and overseas, has extensive experience in plastic injection and molding. The company manufactures and supplies plastic enclosures that contain No. 222, No. 226, and No. 334 filters. Entire product quality control of all shipping goods makes large-scale PRODUCT TRACKING practicable. To address the high-purity filtration needs of customers in many industries, including semiconductors and screens, petrochemicals, and food and pharmaceuticals, MFTECH undertakes thorough manufacturing process management and quality control from initial design to final shipment of all filter housings.

UPK PVC HOUSING:

CPVC injection housing for high flow #334 filter

foot print minimization, easy ring-nut fastening

High flow filter housing with 65A piping

transparent bowl, CPVC bowl selection (optional)

UPK PP HOUSING:

P.P. injection housing for high-rate #334 filters

foot print minimization, easy Ring-nut fastening

handle type without open tool

Ring-nut (optional), high-flow filter housing capable of piping 65A

Bowl-down, Bowl-up exclusive product lineup (optional)

UPKS PVC HOUSING:

CPVC injection housing for high-rate #226 filter

foot print minimization, easy ring-nut fastening

filter housing with up to 40A piping

transparent bowl, CPVC bowl selection (optional)

If you are looking for multi round housing in Korea, you can find it on MFTECH

Click here to contact MFTECH

View more: Plastic Filter and Stainless-Steel Housing System

0 notes

Text

Curved Track Sliding System Manufacturers

Artify Your Space Today with Core's Sleekly Stylish Curved Track Sliding Systems: Revolutionizing Modern Design and Functionality Altogether !

Core Architectural Hardware as one of the most trusted and reliable Curved Track Sliding System Manufacturers & Suppliers in Delhi, India, have been serving in the industry since ages with remarkable working performance. Thoroughly providing luxurious shower sliding and cubicle hardware, today we'll let you take a look at our freshly designed Curved Track Sliding System!

Our Curved Track Sliding Systems represent a significant innovation in architectural and interior design, offering both aesthetic appeal and practical functionality. These systems are increasingly popular in various applications, from residential homes to commercial spaces. This article explores the key features, benefits, and applications of curved track sliding systems.

Let's get into some Key Features of Curved Track Sliding Systems:

Design Flexibility:

One of the most appealing aspects of Core's Curved Track Sliding Systems is their design flexibility. Unlike traditional straight-track systems, Curved Tracks can be customized to fit a wide range of architectural designs and spatial configurations. This adaptability allows for the creation of unique, flowing spaces that enhance the overall aesthetic of a room or building.

Smooth Operation:

Advanced engineering in our Curved Track Sliding Systems ensures that the systems operate smoothly and quietly. High-quality materials and precision manufacturing contribute to the seamless movement of doors or panels along the curved tracks, reducing noise and increasing user satisfaction.

Durability and Strength:

Curved Track Sliding Systems are designed to withstand frequent use and heavy loads. This unique system is constructed from robust materials like fresh stainless steel, ensuring longevity and reliability even in high-traffic areas.

Versatility:

These systems can accommodate various types of sliding elements, including glass doors, wooden panels, and metal partitions. Pre-equipped to surpass all the issues that may appear, Core is your foretell best Curved Track Sliding System Supplier in Delhi. This versatility makes them suitable for diverse applications, from elegant room dividers to secure enclosures.

Enhanced Aesthetic Appeal:

Our Curved Track adds a touch of elegance and sophistication to any space. They break away from the rigid lines of traditional sliding systems, offering a more organic and fluid visual effect. This makes them ideal for contemporary designs where smooth, flowing lines are desired.

Space Optimization:

Core's Curved Track Sliding Systems are excellent for optimising space. They allow for more efficient use of available area, especially in rooms with unconventional shapes or where maximizing floor space is crucial. By following the natural contours of a room, they can create a more open and airy environment.

All in all, you can trust Core Architectural Hardware for your overall Architectural Hardware needs as we are here to support you as the best Curved Track Sliding Systems Manufacturers in India.

Our Curved Track Sliding Systems are a game-changer in modern design, offering unparalleled flexibility, functionality, and aesthetic appeal as Core Architectural Hardware have been entitled as the topmost Curved Track Sliding System Suppliers across India, we make sure to ensure to serve you with high quality products and convenient customer services. We are available to furnish your needs 24/7! To explore our magnanimous range of Architectural Glass Hardware products, you may reach out to us at: Click here for more information: https://corehardware.co.in/curved-track-sliding-system.php

0 notes