#roller conveyor

Text

figure status update - real world task | source

#talos gifs#stim gifs#stim#robot stim#robotics#robotcore#robotkin#metallic#metal#mechanical#technology#silver#white#black#grey#gray#blue#plastic#crates#roller conveyor#im pertty sure thats what thats called#gif ids#id in alt

45 notes

·

View notes

Text

Are you looking for best Industrial Roller Manufacturer in India?

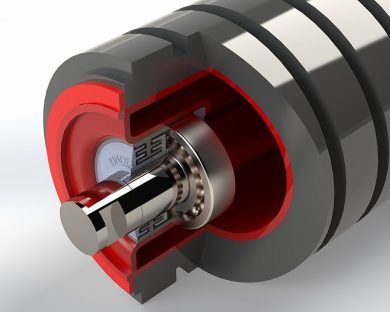

Industrial rollers is a cylindrical or cylindrical-like component used in various industrial applications. Industrial rollers are used in a variety of situations, including conveyor systems, printing presses, feeding machines, bending machines, and stamping presses.

These rollers come in different shapes, sizes, materials, and designs, used for its specific industrial application, processes and requirements.

We are Leading manufacturer of rollers, Industrial Rollers.

We are Supplier and Exporter of Conveyor Rollers, Conveyor Accessories, Conveyor Idler Roller, Taper Roller, Rubber Rollers, Teflon Roller, PP Coated Roller, Food Grade Coated Roller, Polyurethane Rollers, Nylon Roller, Textile Roller, Sugar Mill Roller, Paper Mill Roller, Silicone Rubber Coated Roller, Sponge Roller (Paint Roller), Plastic Roller (PVC Roller), Idler Rollers, Natural Rubber Roller, Ebonite Rubber Rollers, Hard Chrome Plated Roller.

Industrial Rollers Supplier and Exporter in Noida, Bengaluru, Coimbatore, Maharashtra, Punjab, Rajasthan, Gujarat, Goa, Chhattisgarh, Madhya Pradesh, South Africa, Oman, US, UK.

For More Details

Click here: https://www.jekminindustries.com/

0 notes

Text

Mineral Water Bottling Plant, Mineral Water Bottling Plant Manufacturer - kceindia.com

Mineral Water Bottling Plant : We are Mineral Water Bottling Plant Manufacturer, Mineral Water Bottling Plant Supplier in Navi Mumbai, India. Call Now.

Mineral Water Bottling Plant, Industrial Water Bottling Plant, Mineral Water RO Plant, Mineral Water Plant, Mineral Water Plant Machine, Mineral Water Packaging Plant, Mineral Water System, Industrial Mineral Water Plant, Mineral Water Treatment Plant, Packaged Drinking Water Plant, Fully Automatic Bottle Filling Machine, Fully Automatic Bottle Blowing Machine, SS Vessel, SS Storage Tanks, SS Housing For Filter, SS Membrane Housing, SS Piping, Dosing Pump, Roller Conveyor, Ozonation Generator, Post Filtration System, Leather Softeners, Water Softeners in Sanpada, navi mumbai, mumbai, india.

#Mineral Water Bottling Plant#Industrial Water Bottling Plant#Mineral Water RO Plant#Mineral Water Plant#Mineral Water Plant Machine#Mineral Water Packaging Plant#Mineral Water System#Industrial Mineral Water Plant#Mineral Water Treatment Plant#Packaged Drinking Water Plant#Fully Automatic Bottle Filling Machine#Fully Automatic Bottle Blowing Machine#SS Vessel#SS Storage Tanks#SS Housing For Filter#SS Membrane Housing#SS Piping#Dosing Pump#Roller Conveyor#Ozonation Generator#Post Filtration System#Leather Softeners#Water Softeners in Sanpada#navi mumbai#mumbai#india

0 notes

Text

Băng tải đóng gói sản phẩm là gì ?

Băng tải gói sản phẩm là một loại hệ thống băng tải được sử dụng trong quy trình đóng gói hàng hóa trong ngành công nghiệp. Chức năng chính của băng tải này là chuyển sản phẩm từ điểm xuất phát đến các máy đóng gói hoặc các trạm đóng gói khác, giúp tối ưu hóa quy trình đóng gói và tăng cường hiệu suất.

=> Xem Thêm: https://bangtaihaanh.vn/bang-tai-dong-goi-san-pham.html

1 note

·

View note

Text

Advantages of Roller Conveyors in Material Handling

A roller conveyor is a material handling system comprising parallel-mounted rollers on frames, forming a continuous surface for the efficient movement of goods within industrial environments. It can be powered by external motors or gravity, making it versatile for various applications like parcel sorting, assembly line transportation, and pallet handling in warehouses. Roller conveyors are known for their simplicity, low maintenance, and ability to handle diverse materials, providing a cost-effective solution for streamlined material handling.

Uses of Roller Conveyors:

Parcel and Package Sorting: Roller conveyors find extensive use in parcel and package sorting facilities. The gravity-driven rollers allow for a smooth and controlled movement of packages, aiding in the efficient sorting of items based on size, destination, or other criteria.

Assembly Line Dynamics: Roller conveyors play a vital role in assembly lines, where the systematic movement of components is crucial for the manufacturing process. Their ability to transport items without the need for external power makes them ideal for gravity-fed applications, contributing to the optimization of assembly line workflows.

Pallet Handling in Warehouses: Warehouses benefit from roller conveyors for handling pallets and larger loads. These conveyors provide a reliable means of transporting heavy items over short or long distances, contributing to the streamlined operations of material distribution within a facility.

Dynamic Material Accumulation: Roller conveyors can be designed to allow for the accumulation of materials without the need for external power. This feature is particularly useful in scenarios where temporary halts or buffering are required in the material handling process.

Advantages of Roller Conveyors:

Simple and Low-Maintenance Design: The straightforward design of roller conveyors, often driven by gravity, contributes to their low maintenance requirements. With fewer components prone to wear and tear, these conveyors offer a cost-effective solution for material handling needs.

Versatility in Material Handling: Roller conveyors are versatile and can handle a wide range of materials, from small packages to larger items. Their adaptability makes them suitable for various industries, contributing to the flexibility and efficiency of material handling operations.

Energy Efficiency: Gravity-driven roller conveyors operate without the need for external power, relying on the natural force of gravity for movement. This not only reduces energy consumption but also aligns with the growing emphasis on sustainable and eco-friendly practices in industrial settings.

Customizable Configurations: Roller conveyors can be easily customized to suit specific material handling requirements. Whether it’s the roller spacing, conveyor length, or the addition of curves, businesses can tailor these systems to optimize the flow of materials within their unique operational contexts.

Conclusion:

In conclusion, roller conveyors stand as silent champions in the realm of material handling, offering a reliable and efficient solution for various industries. Their simple design, low-maintenance requirements, and adaptability make them indispensable tools in the pursuit of streamlined logistics. As industries continue to evolve, roller conveyors are likely to remain at the forefront, contributing to the ongoing transformation of material handling processes.

#roller conveyor#roller conveyor manufacturer#roller conveyor supplier#roller conveyor manufacturer in India#roller conveyor supplier in India

1 note

·

View note

Text

Rolling Into Efficiency: Unleashing the Power of Yontro Roller Conveyors

In the fast-paced world of material handling, efficiency is the key to success. At Yontro, we understand the critical role that conveyor systems play in streamlining operations, reducing manual labor, and optimizing productivity. Introducing our flagship product, the Yontro Roller Conveyor – a game- changer in the world of material handling.

Unrivaled Efficiency in Motion

The Yontro Roller Conveyor is not just a conveyor; it’s a precision-engineered solution designed to meet the diverse needs of modern industries. Whether you’re moving small packages, heavy boxes, or irregularly shaped items, our roller conveyors provide a seamless and efficient transport mechanism. The secret lies in our commitment to quality and innovation.

Key Features That Set Us Apart:

1. Customization for Every Need: Our roller conveyors are not one-size-fits- all. We understand that different industries have different requirements. That’s why our conveyors are customizable to meet the specific needs of your operation. From roller spacing to conveyor length, we tailor our solutions to your unique challenges.

2. Versatility at Its Core: Yontro Roller Conveyors are versatile, capable of handling a wide range of products. Whether you’re in manufacturing, distribution, or logistics, our conveyors can be adapted to suit your industry’s demands. Straight or curved, gravity-powered or motorized – we’ve got you covered.

3. Smart Design for Streamlined Operations: Our engineers have meticulously designed the Yontro Roller Conveyor with user convenience in mind. Easy installation, minimal maintenance, and smooth operation are hallmarks of our design philosophy. Reduce downtime and keep your operations running seamlessly with our intelligent conveyor systems.

4. Enhanced Safety Measures: We prioritize safety as much as efficiency. Our roller conveyors are equipped with safety features to protect both your products and your workforce. From proper guarding to emergency stop mechanisms, we’ve incorporated the latest safety standards into our designs.

The Yontro Advantage:

When you choose Yontro Roller Conveyors, you’re choosing a partner in efficiency. Our commitment to quality, innovation, and customer satisfaction sets us apart in the competitive world of material handling solutions. Join the countless businesses that have experienced the Yontro advantage and elevated their operations to new heights.

Ready to Roll? Contact Us Today!

Discover the power of Yontro Roller Conveyors for yourself. Contact Yontro today to discuss your specific requirements and let us tailor a conveyor solution that transforms your material handling processes. Efficiency, versatility, and reliability – experience it all with Yontro.

Roll into the future with Yontro Roller Conveyors – where efficiency meets innovation!

0 notes

Text

Titan material handling Pvt. Ltd provide Roller Conveyor, Roller Conveyor at best cost, It Is the best Roller Conveyor, Roller Conveyor manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

#Roller Conveyor#Roller Conveyor Manufacturer#Roller Conveyor Manufacturer in Pune#Roller Conveyor Manufacturer in India#Powerised Roller Conveyor#Gravity Roller Conveyor#Andhra Pradesh#Visakhapatnam#SriCity#Guntur#Goa#Margao#Haryana#Gurugram#Faridabad#Gujarat#Ahmedabad#Ankleshwar#Bharuch#Gandhinagar#Jamnagar#Rajkot#Vadodara#Himachal Pradesh#Baddi#Karnataka#Bangalore#Belagavi#Tumkur#Manglore

0 notes

Text

Chain Driven Roller Conveyor is a versatile material handling solution. Its robust design and durable chain-driven rollers ensure smooth movement of goods in warehouses and production lines. This conveyor system offers reliability, efficiency, and flexibility, making it an essential tool for various industries.

#roller conveyor#roller conveyor system#conveyor roller manufacturer#mesh conveyor belt#wire mesh conveyor#wire mesh conveyor belt#conveyor manufacturer#conveyor manufacturer in india#conveyor system manufacturer in india#screw conveyor

0 notes

Text

Roller Conveyor Manufacturers and Suppliers In India

Our roller conveyors are manufactured using high quality raw materials and are designed to meet the requirements of our customers. We have a wide range of products that can be customized according to your specific needs and specifications.more info visit our website.>https://www.conveline.com/blog/conveyor-systems-in-food-beverage-industry

#roller conveyor#gravity roller conveyor#roller conveyor system#conveyor rollers for sale#conveyor roller manufacturer#conveyor roller price#small conveyor rollers#steel conveyor rollers#industrial conveyor rollers#conveyor rollers near me

0 notes

Text

Titan material handling Pvt. Ltd provide Mobile Conveyor, Movable Conveyor at best cost, It Is the bestMobile Conveyor, Movable Conveyor manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

0 notes

Text

Four-Wheel Overhead Conveyors system

Four-wheel overhead conveyors have revolutionized the manufacturing and logistics industries by providing a highly efficient and versatile material handling solution.

VISIT- https://alineconveyors.com/

Efficient and Space-Saving Design

The four-wheel overhead conveyor system is engineered with efficiency in mind. By utilizing overhead space, it minimizes floor clutter, allowing for smooth movement of materials without obstructing personnel or vehicles. The compact design optimizes space utilization and enables seamless integration with existing production layouts, maximizing overall productivity.

Flexible and Customizable Configurations

One of the major advantages of four-wheel overhead conveyors is their adaptability to diverse applications. These systems can be customized with different track layouts, curvatures, and inclines to meet specific material handling requirements. From simple point-to-point transfers to complex multi-level installations, the flexibility of four-wheel conveyors ensures efficient and tailored solutions.

Enhanced Material Flow and Accessibility

With their elevated position, four-wheel overhead conveyors facilitate smooth material flow throughout the production floor. By transporting items overhead, they eliminate potential ground-level obstacles and bottlenecks, providing unobstructed access to workstations, assembly lines, and storage areas. This streamlined workflow reduces handling time and enhances operational efficiency.

Increased Safety and Ergonomics

Four-wheel overhead conveyors prioritize safety by keeping materials off the ground, minimizing the risk of accidents or damage. Additionally, these conveyors can be equipped with ergonomic features such as adjustable heights and ergonomic handling tools, reducing strain on workers and promoting a safer and healthier work environment.

Conclusion

In conclusion, four-wheel overhead conveyors offer numerous advantages in terms of efficiency, flexibility, safety, and ergonomics. Their ability to optimize material flow, conserve space, and adapt to different configurations make them indispensable tools for a wide range of industries. By implementing these conveyors, businesses can enhance productivity and streamline their operations effectively.

#conveyor belts#conveyorsystem#manufacturing#roller conveyor#folexin#folexinbuy#folexinprice#folexinscam#hypocbdskinspray

0 notes

Text

youtube

How to Do Belt Installing of Batch Asphalt Mixing Plant?

The asphalt plants or asphalt mixing plant is one plant that is used for mixing the dry warm aggregate, padding and asphalt for homogeneous mixture at the required temperature. And it is widely used to the construction of highway, city road and parking lot.

The major components of a batch asphalt mixing plant are the cold- feed system, asphalt cement supply system, aggregate dryer, mixing tower, and emission-control system.

The main activity of an asphaltbatch type mixing plant is that it heats up aggregates and then mixes them with bitumen and other adhesive substances to generate hot mix asphalt. The quantity and nature of the aggregate are dependent on the specific requirements.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#concrete#asphalt plant#asphaltplant#heavy equipment#construction#mobile asphalt drum mix plant#conveyor belts#conveyorsystem#roller conveyor#screw conveyor#conveyorize#belt conveyor#Youtube

1 note

·

View note

Text

Packing Lines and Conveying Systems

Unipack is been catering the industries in packaging and conveying since more than two decades. We are equipped with up to date high-tech machinery and well experienced professionals which give us an added advantage over the contemporaries and many other players in this field. With high quality need based machinery we strive to ensure maximum customer satisfaction.

Since its inception in the year 1988, Unipack is been associated with production of packaging machines and conveying systems to cater the needs of different industries. We specialise in manufacturing of Filling Machines, Heat Sealing Machines, Capping Machines, Taping Machines, Conveyors, Coding Conveyors etc.

#Belt Conveyor#Slat Conveyor#Roller Conveyor#Aging Conveyor for LED Testing#Z Elevator#Chyawanprash Filling Machine#Oil Filling Machine#Screw Capping Machine#Liquid Filling Machine#Assembly Line Belt Conveyor#Packing Belt Conveyor#Bucket Elevator#Slat Chain Conveyor

1 note

·

View note

Text

Ultimate Guide to Selecting Conveyor Rollers for Efficiency

Whether you're upgrading an existing conveyor system or starting from scratch, selecting the right conveyor rollers is crucial for maximising productivity and minimising downtime. In this ultimate guide, we'll walk you through everything you need to know to choose the perfect conveyor rollers for your application.

Understanding the Basics

Before diving into the specifics of selecting conveyor rollers for sale, it's essential to grasp the fundamentals of how they function within a conveyor system.

Conveyor rollers are cylindrical tubes or shafts that support and guide conveyor belts, allowing them to move items from one point to another with minimal friction. These rollers come in various sizes, materials, and designs, each tailored to specific applications.

Types of Conveyor Rollers

When it comes to selecting conveyor rollers, one size does not fit all. Different types of rollers are available, each offering unique benefits depending on the application. Some common types include:

Gravity Rollers

Conveyor rollers often include gravity rollers, which rely on the force of gravity to move items along the conveyor line. These rollers are ideal for transporting lightweight packages or products with a smooth, flat bottom.

Powered Rollers

Powered rollers, on the other hand, are driven by motors or other power sources, providing greater control over the movement of goods. They're suitable for heavier loads or applications that require precise speed and positioning.

Tapered Rollers

Tapered rollers are designed to help facilitate the movement of curved or irregularly shaped items along the conveyor line. They feature a conical shape that allows for smoother transitions between sections of the conveyor system.

Idler Rollers

Idler rollers are non-powered rollers that support the weight of the conveyor belt and the items being transported. They're essential for maintaining proper tension and alignment within the conveyor system.

Factors to Consider

Choosing the right conveyor rollers for sale involves considering several key factors to ensure optimal performance and longevity. Here are some essential considerations:

Load Capacity

One of the most critical factors to consider is the weight of the items being transported. Select conveyor rollers that can support the anticipated load without compromising efficiency or safety.

Material Compatibility

The material composition of the conveyor rollers should be compatible with the items being transported. For example, corrosive or abrasive materials may require rollers made from durable materials such as stainless steel or polyurethane.

Environmental Conditions

Take into account the operating environment of your conveyor system. Factors such as temperature extremes, humidity, dust, and exposure to chemicals can affect the performance and lifespan of conveyor rollers.

Maintenance Requirements

Consider the maintenance needs of the conveyor rollers. Choose rollers that are easy to clean and maintain to minimise downtime and prolong the life of your conveyor system.

Making the Right Choice

With so many options available, selecting the right conveyor rollers can seem like a daunting task. However, by carefully considering your specific needs and requirements, you can make an informed decision that maximises efficiency and productivity.

Whether you're in the market for gravity rollers, powered rollers, tapered rollers, or idler rollers, there are conveyor rollers for sale to suit every application and budget.

Conclusion

Conveyor rollers are the backbone of any conveyor system, playing a crucial role in ensuring smooth and efficient transportation of goods and materials. By understanding the different types of rollers available and considering factors such as load capacity, material compatibility, environmental conditions, and maintenance requirements, you can select the perfect rollers for your application.

With the right conveyor rollers in place, you can streamline your operations, improve productivity, and ultimately, boost your bottom line.

0 notes

Text

#Construction Equipment Market#Construction Equipment#Forklifts#Cranes#Conveyors#Hoists#Concrete Mixer & Pavers#Construction Pumps#Road Rollers#Backhoe Loaders#Skid Steer Loaders#Crawler/Track Loaders#Wheeled Loaders#Motor Graders#Bulldozers#Trencher#Motor Scrappers#Earth Moving Equipment#Concrete and Road Construction Equipment#Material Handling Equipment

0 notes

Text

Conveyor Roller Systems | Damon

In the bustling world of manufacturing and logistics, efficiency is the name of the game. Every minute counts, every movement matters. It’s in this environment that conveyor roller systems emerge as unsung heroes, silently but efficiently carrying out the heavy lifting of material handling. Let’s delve into how these unassuming systems play a crucial role in enhancing productivity across various industries.

Streamlined Material Flow: Picture a bustling warehouse or a manufacturing floor. Without conveyor roller systems, the scene would be chaotic, with workers constantly shuttling between stations, carrying loads of materials. But with these systems in place, materials move seamlessly from one point to another, eliminating bottlenecks and streamlining the entire process.

Reduced Manual Labor: Gone are the days of back-breaking manual labor. Conveyor roller systems automate the tedious task of moving materials, freeing up human resources for more skilled and value-added tasks. This not only improves worker morale but also reduces the risk of injuries associated with manual handling.

Optimized Space Utilization: In today’s world where real estate comes at a premium, every square inch counts. Conveyor roller systems are designed to make the most out of available space by facilitating vertical integration and efficient layout designs. This optimization leads to higher storage capacity and better utilization of floor space.

Flexibility and Customization: One size does not fit all, especially in the world of manufacturing. Conveyor roller systems offer a high degree of flexibility and customization, allowing businesses to tailor solutions according to their specific needs. Whether it’s adjusting speed, accommodating different types of materials, or integrating with existing machinery, these systems can be fine-tuned to meet diverse requirements.

Enhanced Safety: Safety is paramount in any workplace. Conveyor roller systems are equipped with various safety features such as emergency stop buttons, guardrails, and sensors to prevent accidents and ensure a secure working environment for all personnel involved.

In essence, Conveyor Roller Systems are the unsung heroes of the manufacturing and logistics world, quietly but effectively driving efficiency, productivity, and safety across industries. As technology continues to evolve, these systems will undoubtedly play an even more integral role in shaping the future of material handling.

More Info Contact Us

Website https://www.damon-group.com.au/

Facebook https://www.facebook.com/damon.australia/

Youtube video Urlhttps://www.youtube.com/channel/UClI-8HJ0s314pTINMVICTjA

Ph: 3 9333 7034

Mail id: [email protected]

Working Time: Monday to FRiday 9.00 am - 6.00 pm.

0 notes