#plasticcutting

Text

"Cutting-edge precision: Where metal meets laser at Omnific Solutions in Navi Mumbai's MIDC, shaping your vision with unmatched accuracy!"

@omnificsolution

#LaserCutting#LaserCuttingServices#PrecisionCutting#CustomFabrication#MetalFabrication#AcrylicCutting#WoodCutting#PlasticCutting#LaserEngraving#CNCcutting#SheetMetal#Manufacturing#Engineering#MumbaiManufacturing#NaviMumbaiServices#IndustrialServices#InnovationInMetal#DesignAndCut#PrototypeServices#midcindustrialarea

0 notes

Text

CNC Machining

In the present globe, where material high quality is one of the most crucial variable of all, picking the best-quality plastic products is something that is extremely important. This is because of the crucial price tags that are required for the production of such types of plastic materials.

Engineers have actually been building high-quality materials for mechanical design given that its creation. Products like fibers, wood, fiberglass, polymers, and polyurethane products are all instances of crafted plastic items which are made use of in mechanical engineering. These sort of engineering materials use various advantages to the designers in terms of engineering style. For instance, in the case of fiberglass, it has actually been recognized to be one of one of the most durable and flexible plastics which have actually shown to function well with high temperature. The residential properties of fiberglass have actually been also included in the production of synthetic textiles.

Even though fiberglass is a strong product, it is understood to be fairly delicate when based on severe temperatures. Some sorts of fibers which are taken into consideration to be tough, such as polyvinyl chloride (PVC) and also polypropylene (PP), are susceptible to melt-off if exposed to high temperature. If they do happen to melt, they have a tendency to transform fragile and also break quickly. Many different types of artificial fibers, made from nylon as well as polyester, have been utilized for printing applications in the past. Nonetheless, there are different types of manufacturing processes which make them much less durable than the ones made use of for other types of plastic products. This is because, when using the previously mentioned materials, high temperature is unavoidable.

The reasons for this are the extreme temperature level extremes. For instance, when printing an item, the color will develop at heat and after that transform weak and also break. When revealed to heat, the material will trigger a lot of stress and anxiety and fatigue which causes poor performance. An engineer will certainly locate it essential to know exactly how to generate the very best high quality plastic materials. The essential requirements of great performance can be satisfied by using materials like polyurethane, which is one of the most prominent plastic materials for engineering.

Polyurethane, which is a favorite among most of the engineers, is also known to be more tough and resilient to handling warm than nylon or polypropylene. This is the reason why polyurethane has come to be the most popular kind of plastic materials for engineering. Polymers do not need a heat to develop due to the fact that the procedure occurs within the manufacturing procedure. Actually, polymers and plastics was available in a variety of sizes. They are usually used various chain reactions as well as are really flexible as well as effective.

When it pertains to mechanical engineering, it is required to research just how to generate solid and also long lasting materials. It has been observed that polyurethane has actually been extensively utilized by mechanical engineers in designing the chassis of vehicles and various other such items. http://performanceplastic.pro/california/

Actually, polyurethane has actually proven to be really adaptable and also durable so it is very much reliable in the development of the wheels and also the body of autos. There are various other types of polymers and plastic materials which are made use of in mechanical design.

youtube

0 notes

Text

CNC Machining

In the here and now world, where worldly quality is the most crucial factor of all, picking the best-quality plastic materials is one thing that is vital. This is because of the crucial price that are needed for the manufacturing of such kinds of plastic products.

Designers have actually been building premium materials for mechanical design since its creation. Products like fibers, timber, fiberglass, polymers, and polyurethane products are all instances of crafted plastic products which are made use of in mechanical design. These kinds of engineering products use various advantages to the engineers in terms of engineering layout. For example, when it comes to fiberglass, it has been understood to be one of one of the most long lasting as well as flexible plastics which have confirmed to function well with heat. The residential properties of fiberglass have been likewise included in the development of synthetic textiles.

Even though fiberglass is a strong product, it is known to be fairly delicate when based on extreme temperature levels. Some kinds of fibers which are taken into consideration to be difficult, such as polyvinyl chloride (PVC) as well as polypropylene (PP), are vulnerable to melt-off if exposed to heat. If they do occur to melt, they often tend to turn fragile and also break conveniently. Several kinds of synthetic fibers, made from nylon and also polyester, have actually been used for printing applications in the past. Nonetheless, there are different kinds of manufacturing processes which make them much less sturdy than the ones used for various other kinds of plastic items. This is because, when utilizing the previously mentioned materials, heat is inevitable.

The factors for this are the extreme temperature level extremes. For instance, when publishing an item, the dye will create at heat and afterwards turn weak and break. When exposed to heat, the product will certainly create a great deal of stress and tiredness which brings about poor performance. A designer will find it required to know how to produce the most effective high quality plastic materials. The required requirements of great performance can be met by utilizing materials like polyurethane, which is among the most preferred plastic materials for engineering.

Polyurethane, which is a preferred among the majority of the engineers, is also known to be more sturdy and also resistant to dealing with warmth than nylon or polypropylene. This is the reason why polyurethane has ended up being one of the most preferred sort of plastic materials for design. Polymers do not call for a heat to create since the procedure occurs within the production procedure. As a matter of fact, polymers and plastics came in a variety of sizes. They are generally used various chemical reactions and also are very adaptable and effective.

When it pertains to mechanical engineering, it is necessary to study how to produce solid and sturdy products. It has been observed that polyurethane has been commonly made use of by mechanical engineers in developing the chassis of cars and various other such items. http://plasticsheet.net/los-angeles-county/

As a matter of fact, polyurethane has actually verified to be really adaptable and also sturdy so it is significantly efficient in the creation of the wheels as well as the body of autos. There are other types of polymers and plastic products which are utilized in mechanical design.

youtube

1 note

·

View note

Text

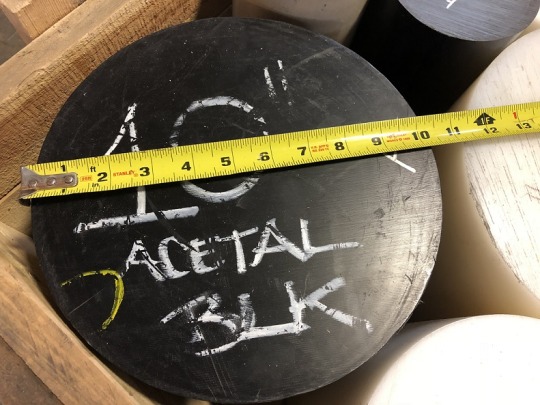

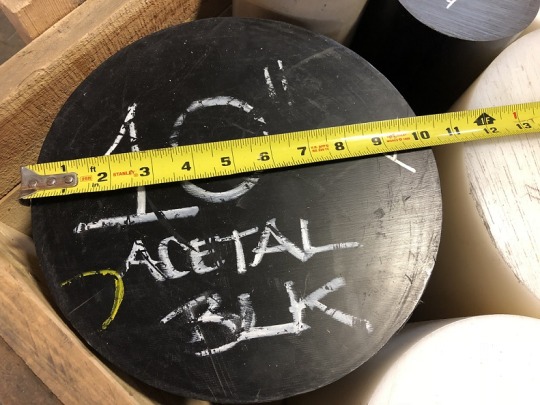

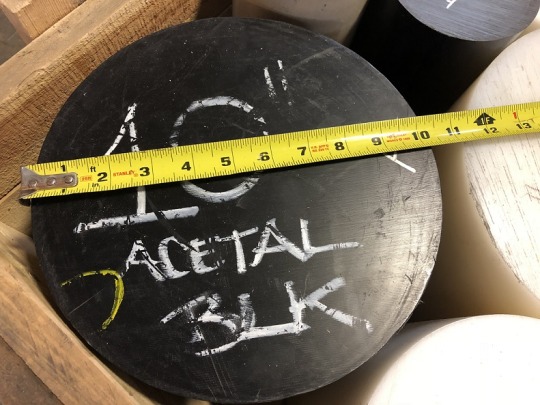

CNC Basic Cutting

In today world, where material high quality is one of the most essential aspect of all, selecting the best-quality plastic products is something that is vital. This is because of the weighty price that are needed for the manufacturing of such kinds of plastic products.

Engineers have been developing premium products for mechanical design since its beginning. Products like fibers, timber, fiberglass, polymers, and also polyurethane products are all instances of engineered plastic items which are made use of in mechanical engineering. These sort of design materials provide various benefits to the designers in terms of engineering style. As an example, when it comes to fiberglass, it has been recognized to be among one of the most durable as well as flexible plastics which have actually verified to function well with heat. The homes of fiberglass have actually been also incorporated in the development of synthetic materials.

Even though fiberglass is a solid product, it is known to be rather sensitive when subjected to extreme temperatures. Some types of fibers which are considered to be tough, such as polyvinyl chloride (PVC) as well as polypropylene (PP), are vulnerable to melt-off if exposed to heat. If they do happen to thaw, they tend to turn weak and also break easily. Many different kinds of synthetic fibers, made from nylon and polyester, have actually been used for printing applications in the past. Nonetheless, there are various kinds of making processes that make them less durable than the ones made use of for other types of plastic items. This is because, when utilizing the aforementioned products, high temperature is inevitable.

The reasons for this are the extreme temperature level extremes. For example, when publishing a product, the color will certainly create at high temperature and afterwards turn breakable and also break. When exposed to high temperature, the material will certainly trigger a great deal of anxiety as well as tiredness which leads to inadequate efficiency. A designer will certainly discover it needed to recognize how to create the best high quality plastic materials. The required demands of excellent performance can be met by utilizing materials like polyurethane, which is among the most prominent plastic materials for engineering.

Polyurethane, which is a preferred among the majority of the designers, is additionally recognized to be extra durable as well as durable to managing heat than nylon or polypropylene. This is the reason why polyurethane has come to be one of the most prominent type of plastic materials for design. Polymers do not require a high temperature to form since the process takes place within the manufacturing procedure. As a matter of fact, polymers and plastics can be found in a variety of sizes. They are normally used numerous chain reactions and are really adaptable as well as powerful.

When it comes to mechanical design, it is necessary to study how to produce strong as well as resilient materials. It has actually been observed that polyurethane has been commonly made use of by mechanical engineers in creating the chassis of vehicles and various other such products. http://copolymeracetalsheetandrod.pro/orange-county/

In fact, polyurethane has actually proven to be really flexible and sturdy so it is very much reliable in the creation of the wheels and the body of automobiles. There are various other types of polymers and also plastic products which are made use of in mechanical engineering.

youtube

0 notes

Video

youtube

REDSTAR I PELLETS CUTTER I CUTTER I DOUBLE SPEED PELLETS CUTTER I CUTTER...

#plastic#plasticrecycling#plasticcutting system#plastic pellets video#Wasteplastic#wasterecycling#waste#wastewashing#wasteplasticrecycling

1 note

·

View note

Text

Tremendous Growth exhibited in the laser cutting machine market

The laser cutting machine market was valued at 3.02 billion Dollars in 2015 worldwide. The growing trend of automation inside the manufacturing sector and the escalating demand for the end-use industry are predicted to supplement the need for these machines in the coming days.

Cutting materials like steel or plastic with absolute precision is possible with the use of laser cutting machines. It’s a crucial manufacturing instrument necessary for industries to manufacture parts with complex geometry. These components mainly being for the automotive industry, machine industry, consumer electronics, and other manufacturing industries.

The laser cutting industry has witnessed different phases of advancements in power, quality and thickness of cutting material & efficiency in the past few decades. Hence, cutting thin and thick metals at higher speeds is a quality possessed by the machines of today.

With the utilisation of laser cutting, it’s possible to cut varied materials including metallic, non-metallic and artificial substances of miscellaneous thickness. During the method, a laser beam is passed through the material to cut it accurately. Depending on the actual content, lasers could be produced through vaporisation, thermal stress cracking, melt and blow & cold cutting, or other techniques. It’s also possible to control the laser with a mess of reflective surfaces. Precision is the pivotal quality that lasers offer. A laser-cut part is more has smoother edges and excels in terms of accuracy. Since there’s less operator involvement in laser cutting, the chances of human error also comparatively low. Another economic advantage of laser cutting is that the time required for the operation is minimal when compared to standard cutting.

Growing urbanisation, high adoption of laser cutting machines by end-users, and rise in investments by manufacturers are the driving forces that have profoundly impacted the laser machine market.

The rise in globalisation has led to an extensive demand among consumers for final products to the micron level. Moreover, the end-use segment is widely adopting these machines to supply high-quality products quickly and efficiently. The widespread trend of automation is warranting manufacturers to automate various processes, including laser cutting machine industry.

Industrialisation being among the foremost reasons for the Growth in laser cutting market has sky-rocketed demand for laser cutting machines from developing economies like India, South Korea, China, South Africa, and Brazil. This reason will further fuel the demand for laser cutting machines over the forecast period.

Stable Growth of automobile industry is one of the first components, which is impacting the worldwide laser cutting machine market. Production capabilities of automobiles have witnessed a significant increase in the past decade in Asian countries like China and India. This increase in the automobile industry will potentially benefit the laser cutting market and help it advance further.

Soaring need for accurate and precise shapes in electrical equipment, electronics sector, and industrial tools is further expected to proliferate the demand for laser cutting machines in the coming future. Developing economies will be highly benefited with the addition of these machines.

Laser cutting machine market is predicted to surpass 5.7 billion dollars by 2022. The rise in production requirements in various industries and decrease in human involvement for improving the metal quality facilitate the necessity for automation in manufacturing industries. Laser cutting machines fulfil these requirements.

Laser cutting machines are taking the world by storm and will only keep getting popular amongst businesses in the coming future. To buy or know more about laser cutting machines, visit us at https://www.asianlaser.in/.

#lasermachine#lasertag#lasertechnology#lasercutting#lasermarket#lasertrend#steelcutting#plasticcutting

0 notes

Video

Aluminum cutting with STYLECNC cnc router. The cnc router for wood can also be used for all the soft metal cutting, wood or plastic cutting. #aluminum #stylecnc #woodcutting #aluminumcutting #aluminum #plasticcutting #cncrouter (在 Jinan Style Machinery Co.,Ltd) https://www.instagram.com/p/B5H_fv9FuJk/?igshid=1rfhb049h4if1

0 notes

Text

CNC Milling

In today world, where worldly top quality is the most essential factor of all, picking the best-quality plastic materials is one thing that is paramount. This is as a result of the weighty cost that are required for the production of such sorts of plastic products.

Designers have been developing premium products for mechanical engineering because its creation. Materials like fibers, timber, fiberglass, polymers, and also polyurethane materials are all instances of engineered plastic items which are made use of in mechanical engineering. These sort of design materials supply various advantages to the engineers in terms of engineering design. As an example, when it comes to fiberglass, it has been recognized to be among one of the most durable as well as versatile plastics which have proven to work well with heat. The homes of fiberglass have been also integrated in the creation of synthetic fabrics.

Despite the fact that fiberglass is a strong product, it is known to be rather delicate when subjected to severe temperature levels. Some types of fibers which are thought about to be tough, such as polyvinyl chloride (PVC) and also polypropylene (PP), are vulnerable to melt-off if subjected to high temperature. If they do occur to thaw, they have a tendency to transform fragile as well as break quickly. Several types of artificial fibers, made from nylon as well as polyester, have been made use of for printing applications in the past. Nevertheless, there are different sorts of making processes which make them less resilient than the ones utilized for other types of plastic products. This is because, when utilizing the aforementioned products, high temperature is inescapable.

The factors for this are the severe temperature extremes. As an example, when publishing an item, the dye will certainly develop at heat and afterwards turn fragile and break. When subjected to high temperature, the product will certainly create a lot of stress as well as fatigue which results in bad efficiency. An engineer will locate it necessary to recognize exactly how to generate the very best high quality plastic products. The essential needs of great efficiency can be fulfilled by utilizing products like polyurethane, which is one of the most prominent plastic products for design.

Polyurethane, which is a favorite among most of the designers, is additionally understood to be much more sturdy and also resilient to handling warmth than nylon or polypropylene. This is the reason why polyurethane has actually ended up being the most prominent kind of plastic materials for engineering. Polymers do not call for a heat to create due to the fact that the process takes place within the manufacturing process. As a matter of fact, polymers and also plastics came in a range of sizes. They are generally used numerous chain reactions as well as are very flexible and also powerful.

When it concerns mechanical design, it is required to research how to produce solid and durable materials. It has actually been observed that polyurethane has actually been widely made use of by mechanical engineers in developing the framework of cars and also various other such items. http://performanceplastic.pro/california/the-complete-idiots-guide-to-copolymer-acetal-rod-revealed/

As a matter of fact, polyurethane has confirmed to be really flexible as well as durable so it is very much effective in the creation of the wheels and the body of autos. There are various other sorts of polymers as well as plastic materials which are made use of in mechanical design.

youtube

0 notes