#plastic extrusion Melbourne pelmet rubber

Text

Drive Safely- Install Top-grade Pelmets & Plastic Extrusion in Melbourne

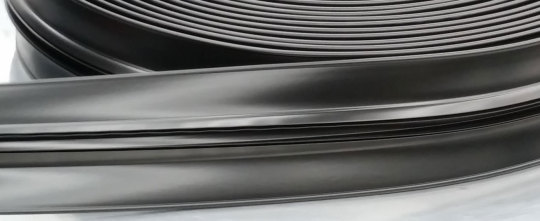

Buy high-quality and durable plastic extrusion in Melbourne from trustworthy Australian manufacturers and suppliers to keep commercial vehicles and drivers safe from harsh weather. Generally, people search for high-quality rubber-made extrusions as they are highly useful for many different types of vehicles. Reputable manufacturers offer rubber products that are highly resistant to ozone, UV light, and other harmful elements. Exposed metal, plywood, windows, doors, glass, plastic, fibreglass, and other surfaces can all be well-sealed and protected by using these extrusions.

Furthermore, those who drive for long journeys frequently search for pelmet rubber for vehicle windows. High-quality pelmets are usually made to regulate the amount of light that enters the required space and mounting rubber-made pelmets prevents not only light but dust and other harmful particles inside the vehicle. It produces a calm and relaxing indoor environment by obstructing light and helps to drive mindfully. Many vehicle owners additionally search for windscreens to shield them from hot, intense sunlight and shifting weather conditions.

Advantages of Installing Extrusions and Pelmets

In general, if anyone purchases from reputable manufacturers, they get many advantages and offers with warranties. As they use state-of-the-art equipment and tools, they can make specialised items for corporate needs. They focused to construct with the best possible eco-friendly materials to maintain a sustainable and non-allergenic environment.

Additionally, all-in-one extrusion manufacturing and selling businesses offer customer-oriented products with extra colour-matching services, 3D printing, and in-house customised tool development to save time and money.

Finally, if anyone is interested to get high-quality and durable rubber extrusions or pelmets, they must get in touch with reputable suppliers.

Source

0 notes

Text

Purchase High-quality Surface Sealing Products & Plastic Extrusion in Melbourne

To obtain reliable and high-quality items, look for reputable Australian producers and suppliers of multipurpose plastic extrusion in Melbourne. Extrusions constructed from high-quality rubber have a wide variety of applications. Products made of rubber that are ozone, UV, and weatherproof are available from reputable producers. These extrusions are also very effective for sealing a wide range of surfaces, including plywood, windows, doors, exposed metal, glass, plastic, fibreglass, and other surfaces.

In contrast, commercial vehicle window pelmet rubber is popularly searched by vehicle owners. They also look for windscreens that can protect them from harsh sunshine, heat, and changing weather. Additionally, consumers purchase PVC fencing, barrier rail, and uPVC window items from reputable retailers and assured poly tubes for pool coving and posts.

In addition, numerous manufacturers produce PVC pipes to use in pool coving, pool fencing, posts, PVC fencing, barrier rail, and other items. They also put a lot of effort into offering the best rigid edging, flexible edging, glazing wedges and channels, bottom door seals, seating blocks, and soft furnishings.

Advantages of Buying Extrusions and Dock Bumpers:

Reputable manufacturers offer products with guarantees.

They produce specialised items in accordance with corporate requirements using cutting-edge machinery and tools.

They use eco-friendly materials of the highest quality in their products.

A lot of companies offer additional 3D printing services.

Customized tools and services created in-house assist companies in delivering the highest quality services in the appropriate amount of time and money.

They offer excellent customer service and workmanship.

Therefore, people must contact reliable providers if they need to buy high-quality and long-lasting rubber extrusions or docks.

Source

1 note

·

View note

Text

Looking for High-quality Plastic Extrusion in Melbourne? Purchase from Well-known Manufacturers

Large to small-scale businesses often search for plastic extrusion in Melbourne to get the exact match extrusions of their varieties of uses. Numerous trustworthy Australian manufacturers and suppliers deliver high-quality plastic, PVC, and rubber-made extrusions for different uses. Exposed metal, plywood, windows, doors, glass, plastic, fibreglass, and other surfaces can all be sealed very well with these extrusions.

In contrast, they also supply commercial vehicles and truck pelmet rubber for windows to protect windscreens and prevent air leakage. Reputable manufacturers offer rubber products that are resistant to ozone, UV light, and the elements.

Many of them supply a variety of products including bottom door seals, glazing wedges and channels, bumper protection systems, flexible and stiff edging systems, truck pelmet rubber, pool coving and posts, setting blocks, soft furnishings, barrier rail, a large number of different types of dies, and uPVC window items are all made of plastic.

Specialized plastic extrusion is typically used to make composite windows, vinyl fences, freezer gaskets, and vehicle window pelmets.

Production is made easier by the process' frequent cross-sectioning and large volume.

Importance of Using Extrusions:

One of the most important benefits of the plastic extrusion process is increased flexibility. The best rigid edging, flexible edging, glazing wedges and channels, bottom door seals, seating blocks, and soft furnishings are beneficial to use to protect edges from scratching, air leaking, and frictional damage. Reputable manufacturers offer items with warranties and they use state-of-the-art workmanship making specialised items in compliance with corporate needs. They construct their items with the best possible eco-friendly materials.

Additional Advantages of Renowned PVC and Rubber Product Manufacturers:

Several manufacturers offer in-house developed, customised tools and services to help businesses and provide the greatest quality services in the right amount of time and money. They also provide extra 3D printing service stop-notch customer service and craftsmanship.

Meanwhile, businesses must contact well-known manufacturers to get top-quality products with the exclusive numbers that they need.

Source

0 notes

Text

Buy Plastic Extrusions from Manufacturers: Check Advantages!

When it comes to purchasing plastic extrusions, it is beneficial to choose reputable manufacturers in Melbourne for a variety of reasons. Renowned manufacturers provide long-lasting high-quality extrusion products manufactured by plastic and rubber. These businesses generally invest in high-quality raw materials that ensure the durability and performance of their products.

Pros of Buying Extrusions from Renowned Manufacturers:

Renowned manufacturers prioritise quality, client happiness, and industry compliance, giving them a dependable alternative for their customers for a variety of purposes. Buyers can benefit from a wide range of top-notch products and customer-centric services by purchasing from a respected manufacturer in Melbourne.

Certain Melbourne manufacturers offer a varied product line that includes flexible edging systems, stiff edging, truck pelmet rubber, bumper safeguards, glazing wedge and channels, bottom door seals, setting blocks, soft furnishings and a large selection of dies. With over two thousand dies on hand, some manufacturers may already have the ideal product to meet specific requirements.

Choose a reputable manufacturer to provide top-quality products with outstanding customer service. Reputable manufacturers prioritise client satisfaction and have a customer-focused approach. They respond quickly to questions, have transparent communication, and address client concerns promptly.

Furthermore, these manufacturers conform to Australian standards and ensure compliance with industry benchmarks and regulations for their products and services.

How to Find a Renowned Manufacturer Locally?

When looking for a reputable manufacturer in the local area, it is important to examine a few vital aspects. They should research the manufacturer's industry reputation, and seek companies with a proven track record of producing high-quality items.

Additionally, they should check their customer feedback and comments might provide information about the manufacturer's dependability and customer happiness.

It is important to check the manufacturer's knowledge and skills in the extrusion manufacturing field as well. Experienced manufacturers have expertise and abilities to the table, ensuring top-notch product manufacturing.

Finally, contact their customer service to check transparency in communication and pricing, and ask them for a quotation for your needs.

Source

0 notes

Text

Plastic Extrusion in Melbourne: Understand the Multiple Benefits and the Importance Offered by Them!

Very thin plastic sheets and films may also be made using the plastic extrusion in Melbourne moulding method. These are also quite adaptable and employed in a variety of industries. Examples include glass replacement materials, machine guards, window glazing, and packaging for things like drink bottles and medicine blister packs. Last but not least, the method is perfect for producing lengthy cross-section objects like vinyl siding, signage, or windscreen wiper blades.

Uses of Plastic Extruded Products are Important

Products created from pelmet rubber, which includes pressing molten plastic through a die into a form with a predetermined cross-section, are significant, according to verified research. It is essential for use in both commercial and domestic products and is a successful method for producing a range of forms. Since they need to be melted form a solid state and subsequently resolidified, only thermoplastics may be extruded. Due to its properties, this type of plastic is appropriate for recycling both scrap materials and old goods.

Explore the Multiple Advantages of a Curtain Pelmet

Insulation: By putting a barrier across the window and the room, curtain pelmets assist keep the space warm in the cooler months and cool in the summer by reducing draughts.

Window pelmets: They may help block out light and noise, improving the comfort and sleeping environment in your room.

Visual Appeal: Curtain pelmets give your space a polished look by adding a touch of sophistication and elegance.

Benefits and Drawbacks of Extrusion Moulding

Both plastic moulding techniques have benefits and drawbacks. Extrusion moulding, on the other hand, has advantages like cheaper manufacturing costs since extra plastic can be recovered and used again.

Additionally, because the plastic stays heated and flexible for a longer period of time, the procedure enables modifications to be made after extrusion. In conclusion, plastic producers create high-quality plastic goods using plastic extrusion technology. Anyone seeking these things can get in touch with a nearby plastic extrusion company.

Source

0 notes

Text

Choose Trusted Services for Plastic Extrusion in Melbourne to Manufacture Products

In recent years, industries have seen growth in utilisation of plastic extrusion in Melbourne that helps to produce precise outcomes. Qualified manufacturers mentioned that in order to mould the plastic into the desired shape and size for the inventory, the proper amount of pressure is necessary. Further, renowned companies offer plastic films, pipe work, dyes, tubing, rods, and other plastic related production. They also assist with custom made plastic product inventory so one could get their specifications depending on industrial requirements.

Benefits of Choosing Reliable Pelmets for Trucks & Trailers:

The main purpose of installing pelmet rubber in trucks, trailers and heavy vehicles is to provide protection from curtain roller mechanism. Expert manufacturers inspect the transport vehicle and provide pelmet according to available size, shape and colour requirements. This will not only enhance overall vehicle appeal but also provide protection from external elements that might cause destruction.

Basically, high quality pelmet can withstand adverse weather conditions, harmful toxic substances and can lock firmly for holding on to the grip. Renowned companies offer premium quality rubber material that is durable, reliable and would last for longer period without compromising on angles. Moreover, it will also provide proper framing for trucks and trailers without compromising on transport truck outlook as well as safety.

Generally, professional suppliers are knowledgeable enough to advice customers over queries and recommend them appropriate type of pelmet that fulfils the criteria. Numerous studies believe that rubber pelmet can mould into any shape and size depending on the vehicle’s exterior body to complete the appeal while protecting from harsh components.

Perks of Opting for Plastic Extrusion Profile & Products:

Expert manufacturers offer wide range of services that include colour matching, 3D printing and in house tool creation allowing customers to obtain all the answers they require at once.

They conduct one on one with customers to better understand their needs for plastic production and create solutions that are tailored according to industries.

The code of conduct also provide tools for impact and weather testing so they can assess the reliability of stainless steel as well as plastic manufacturing.

One should enquire with the best company in the area, if they are seeking for plastic extrusion services!

Source

0 notes

Text

Buy High-quality Industrial Extrusion and Tubes: Contact Plastic Tube Manufacturers in Melbourne

Industrial-level plastic tube manufacturers produce high-quality plastic and rubber tubes and extrusion which have a wide range of applications and practical advantages that make them indispensable in industrial and commercial settings.

Plastic tubes are commonly used for pneumatic and hydraulic systems, electrical conduit, irrigation, and HVAC systems, among others. They also offer excellent insulation properties, making them ideal for protecting wires and cables from moisture and other environmental factors.

Industrial Uses of Plastic Tubes and Extrusion:

Plastic tubes come with excellent durability and resistance features to various chemicals, making them suitable for transporting corrosive substances or hazardous materials.

These tubes and extrusions are also highly flexible, allowing for easy bending and routing in tight spaces, which makes them ideal for complex installations.

Additionally, these tubes are lightweight, cost-effective, and easy to install, providing significant cost savings compared to traditional metal or glass alternatives.

In addition to tube and extrusion, these manufacturers also produce top-quality flexible and rigid types of rubber t edging highly useful for small to large-scale industries. Many customers can also find rubber-made pelmets and rigid edging from them.

Flexible rubber edging is known for its elasticity, allowing it to bend and conform to different shapes and sizes, making it ideal for applications that require flexibility, such as in the automotive, aerospace, and medical industries.

On the other hand, rigid rubber tubing, offers stability and strength, making it suitable for applications that require rigidity and durability, such as in construction, industrial, and marine industries.

When it comes to purchasing rubber tubing, it is crucial for businesses to buy from recognized manufacturers. They ensure the quality and reliability of their rubber tubing, adhering to industry standards and regulations.

They invest in research and development, use high-quality materials, and have strict quality control processes in place to ensure the consistent performance and durability of their products.

Purchasing from recognized manufacturers also provides businesses with access to technical support, product customization options, and reliable after-sales service.

Overall, plastic tubes and extrusion provide a reliable and efficient solution for various industrial and commercial applications, making them a vital component in many industries.

Therefore, businesses should invest in reliable manufacturers to prevent costly downtime, reduce maintenance costs, and ensure the safety and reliability of the end product or system.

Source

0 notes

Text

Check 3D Printing & Testing Procedure for Quality Plastic Extrusion in Melbourne

The importance of extrusion in framing and other pertaining works cannot be overstated. Metal and plastic extrusion in Melbourne is used to complete the manufacturing jobs. Plastic flexible edging systems fit better than other hardened extrusions. Thus the demand for these protective materials is increasing.

Many reputed manufacturers are developing plastic extrusion products such as bumper protection, truck pelmet rubber, bottom door seals, soft furnishing, and many more. Whether you want to fix a glass into a frame or waterproof a joint, these elastic materials are literally useful.

The procedure followed by reputed industries to make extrusion:

Colour Matching- Sometimes to develop the stuff creatively, one needs a colourful pelmet for perfect matching finishing. Renowned industries don't let their clients disappoint, they match colour by computer software and produce exact matching tubes.

3D Printing- Developing factories print one sample for large quantity production by 3D printing technology. This can be seen as testing so thereafter changes can also be done as per requirement. Thereafter, its Q.U.V weather testing, impact testing etc. is done in the laboratory so that its quality can be ascertained.

Tool Production- When the final sample gets approval then companies do production on a big scale. These types of products can be used for different purposes in many places. The created product can be marketed as a new type of tool.

If you need to get any type of custom plastic extrusion made then tell your requirement to a reliable manufacturing unit. Time and money can be saved by testing the flexibility and durability of the sample.

Source

0 notes

Text

Require Perfect Plastic Component for Industry? Contact Leading Plastic Manufacturers in Melbourne

Plastic is the go-to material for producing a wide range of complicated products used in numerous industries. Leading plastic manufacturers in Melbourne offer a range of services in plastic manufacturing. With the rise of manufacturing the demand for plastic has seen exponential growth. From truck pelmets rubber to bumper protection systems everything can be developed using plastic. Plastic is generally quite durable compared to any other material while offering significant flexibility.

UPVC has been quite popular among other plastics due to its rigidity. Leading brands offer a lot of UPVC extrusion profiles and thus one can choose from the many products developed. UPVC as a material has been preferred by many industrial units over the years due to it being environmentally friendly. The material has been widely used as a replacement for wood especially in cases of frames for windows.

Catalogue of Services Offered by Leading Manufacturers

Colour Matching: - There are many instances when a certain component of a specific colour is required. A leading firm has the technology of manufacturing components with the exact specific colour.

3D Printing: - This has been in quite a craze due to its ability to develop products for testing before manufacturing a product and is widely used for reducing tooling costs.

In House Tool Making: - Leading brands can develop tools customised to customers’ specific requirements with the in-house development team.

Final Thoughts

Modern plastic manufacturing methods allow one to have a great degree of customisation. The products that are developed by leading brands can be modified to suit customers’ needs. Reach out to the leading brands to have a look over their catalogue or contact them.

Source

0 notes

Text

Know the Secret Behind Purchasing Objects from Plastic Manufacturers in Melbourne

If a person wants to purchase cost-effective products, they can contact the best plastic manufacturers in Melbourne. People can contact them if they're going to make tools and objects made through the plastic extrusion process. Manufacturers use advanced machines to produce materials having continuous shapes in high quantity. People can make products like pipes, fencing materials, cable wires, window frames, insulation of cables, etc., from the manufacturing units.

A person can contact the manufactures to purchase table edging made of synthetic materials. These additions give proper finishing to the object and prevent the deterioration of wooden objects. These thin bands help to make the tables solid and durable. Additionally, this layering enhances the appearance of the house and is available at very affordable rates. Companies offer flexible materials which a person can install on the object having any shape. People can buy different colour and types of products from reputed companies.

Why should you purchase products from the manufacturers?

Saves money – if a person purchases an object directly from the company, they can receive it at a very nominal price. This difference in rate happens because they do not have to give commission to the middlemen, saving a lot on transportation.

Saves time – the companies produce objects at a tremendous speed, and people receive their ordered commodities within few hours. They can make materials of different thickness and lengths at one go. Additionally, people can produce a pipe of hundred meters within a half-hour, but the same procedure with an ordinary machine requires more time. Furthermore, a person can get bulk production if they contact reputed companies in their locality.

High quality – companies install heavy-duty machines to produce better quality products at an affordable price. The people at the production unit can combine two pipes in the barrel containing different raw materials to enhance the final objects' quality.

Plastic is one of the greatest inventions in the history of humankind. If a person knows its proper application and disposal, they can benefit them and nature in numerous ways. People can efficiently recycle high-grade plastic objects. Products made of this human-made material are very durable and can last up to several years without showing any signs of damage. Manufacturers offer a wide range of products such as truck pelmet rubber, bumper protection systems, glazing wedges and channels, bottom door seals, setting blocks, soft furnishings, dies, barrier rail and uPVC window products, PVC fencing products, pool coving and posts etc.; people can purchase ones according to their needs.

Source

0 notes

Text

Achieve Versatility and Cost-Effectiveness through Plastic Extrusion in Melbourne

Plastic extrusion in Melbourne is a popular method to create different type and size of plastic items. It proves to be a boon for both manufacturers and customers as this method of extrusion can easily create complex shapes and sizes. This process involves conversion of plastic materials from solid to liquid, to c and recreated into finished products. In simpler words, the workers melt plastic to give a shape that can be used in day-to-day life or as part of huge equipment.

You can easily find reputable manufacturers practising this method and offering a variety of products such as flexible garden edging, truck pelmet rubber, glazing wedges, and many more. Manufactures uses consistent cross-sectioning with the help of a tool named die. This tool is used to press the melted plastic for providing correct shape.

The methodology of consistent cross sectioning provides a high amount of flexibility to the manufacturers. As long as consistent cross sectioning remains the same, achieving the complex shapes are easy. The best aspect of extrusion is that it allows minor alterations, even after the completion of the process. The plastics still stands hot after freshly leaving the extruder, which allows the post-extrusion manipulation. It is beneficial for most of the manufacturers as they can create a wide variety of products such as shoes, rollers, and dies. They use hot plastic to get the desired shape products, as per the requirement. It allows the manufacturing of items with mix plastic attributes.

The resultant products from plastic extrusion are affordable as compare to other moulding processes. This process used thermoplastic, which continuously goes through melting and hardening. Unlike other methods, plastic extrusion does not allow the discarding of leftover materials as they are instantly reused. It reduces the raw materials and consequently the prices of disposals. If you are interested in using the product made from this method, have a detailed discussion about your requirements with reputable manufacturers.

Source

0 notes