#nonstickcoatingprocess

Text

3D Surface Etching Transforms Journey in Mould Manufacturing

Fueled by innovation and perfection, manufacturing evolves. A recent thrilling development is the fusion of mold-making artistry.

#laserengravingservicesindelhi#mouldengravingexpertsindelhi#ptfecoatingprocess#laserengraverformouldindelhi#nonstickcoatingprocess#tefloncoatingservices

0 notes

Text

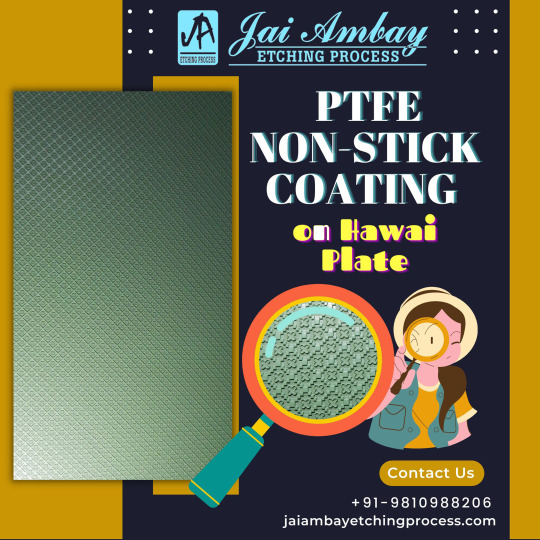

PTFE non-stick coating service provider on hawai plate

We can provide PTFE non-stick coating service provider on Hawai plates. For more inquiries contact us at 9810988206 or Visit: www.jaiambayetchingprocess.com.

#nonstickcoatingprocess#lasermarkingservices#nonstickcoating#Metaletchingservices#etchingservices#ecoating#tefloncoatingservices#Ptfenonstickcoating#ptfecoatingprocess#ptfecoatingservices#waterbasedcoating

0 notes

Text

Learn how PTFE coating is used in nonstick cookware | Blog

In this blog, we learn about what is PTFE coating and how does nonstick coating works. Understand the uses of PTFE on nonstick kitchen vessels and how to use it safely.

#Blogonptfecoating#whatisptfecoating#nonstickcoatingprocess#lasermarkingservices#nonstickcoating#laserengravingservices#Metaletchingservices#etchingservices#tefloncoatingservices#Ptfenonstickcoating#ptfecoatingprocess#ptfecoatingservices

0 notes

Text

E-Coating services in Delhi - Jai Ambay Etching Services

Jai Ambay Etching Process Provides top quality e-coating services. For further information about our services visit our website to see what we are capable of.

#ecoatingservices#ecoatingservicesinDelhi#PTFEcoatingservicesinDelhi#foodgradecoating#bestnonstickcoatingservices#Tefloncoatingformetal#PTFEtefloncoatingservices#TeflonnonstickcoatingservicesinDelhi#Teflonnonstickcoatingservices#nonstickcoatingprocess#bestptfecoatingserviceinDelhi#tefloncoatingservices

0 notes

Text

Contact Us for Best Etching, Engraving, and coating process

We offer 3D laser engraving, chemical etching, mold texturing, non-stick coating, blasting services, and more in Delhi. Call us now to get the latest price.

#nonstickcoatingprocess#mouldpolishingprocess#lasermarkingservicesinDelhi#laserengravingservices#Metaletchingservices#etchingservices#MouldTexturingindelhi#LaserTexturingindelhi#PTFECoatingOnMouldindelhi#Foodgradecoatingonwaffleplatedelhi

0 notes

Link

Teflon is used for the inner coating material of non-stick cookware. It prevents food from sticking to the pans during cooking. That's why Teflon is the material of choice to coat surfaces on non-stick cookware.

#TeflonCoatinginDelhi#bestptfecoatingserviceinDelhi#ptfecoatingprocess#tefloncoatingservices#nonstickcoatingprocess#PTFECoatingOnMouldinDelhi#ecoatingservicesindelhi#PTFEcoatingservicesinDelhi

0 notes

Link

Manufacturer and Suppliers of Coatings Services - Non-stick Coating Services, Food Grade PTFE Coating offered by Jai Ambay Etching Process, Delhi and Noida.

#TeflonCoatinginDelhi#bestptfecoatingserviceinDelhi#PTFEcoatingprocess#tefloncoatingservices#nonstickcoatingprocess#PTFECoatingOnMouldinDelhi#ecoatingservicesindelhi#PTFEcoatingservicesinDelhi#foodgradecoating#bestnonstickcoatingservicesdelhi#tefloncoatingformetal#PTFEtefloncoatingservices#Teflonnonstickcoatingservicesindelhi#Teflonnonstickcoatingservices#Nonstickcoatingteflon#Topetchingprocesscompany

0 notes

Link

Learn about the fundamentals of PTFE nonstick coating. An easy-to-understand explanation of the fundamentals of PTFE nonstick coating, including the benefits, applications, and common misunderstandings about PTFE.

#Basicfactsofprfecoating#TopMetaletchingservices#MetaletchingservicesnearNoida#TeflonCoatinginDelhi#blogonptfecoating#benefitsofptfe#metaletchingindelhi#nonstickcoatingprocess

0 notes

Link

#Moldpolishingservices#Laserengravingonmould#mouldengravingExpertsinDelhi#bestptfecoatingserviceinDelhi#3dlaserengravingdelhi#etchingservicesdelhi#etchingofmetalsindelhi#metaletchingindelhi#nonstickcoatingprocess#lasermarkingservicesinDelhi#3DSurfaceEtching#TeflonCoatinginDelhi

0 notes

Link

Jai Ambay frequently performs general or routine maintenance on such goods to ensure that they function properly and to avoid costly breakdowns and repairs.

#Moldpolishingservices#Laserengravingonmould#mouldengravingExpertsinDelhi#bestptfecoatingserviceinDelhi#3dlaserengravingdelhi#etchingservicesdelhi#etchingofmetalsindelhi#metaletchingindelhi#NonstickCoatingProcess#lasermarkingservicesinDelhi#Metaletchingservices#etchingservices#LaserTexturingindelhi#PTFECoatingOnMouldindelhi#bestchemicaletchingservicesindelhi

0 notes

Link

Jai Ambay offers shot and sandblasting among our extensive range of services. In this blog, We discuss sand and shot blasting, and the difference between them.

#BlastingServices#SandBlastingservices#ShotBlastingServicesinDelhi#3DSurfaceEtching#3dlaserengravingdelhi#etchingservicesdelhi#etchingofmetalsindelhi#metaletchingindelhi#nonstickcoatingprocess#lasermarkingservicesinDelhi#EmbossingDie#laserengravingservices

0 notes

Link

Jai Ambay Etching Process offers mold polishing services at discounted wholesale prices. Are you curious about our services? Contact us now!

#Moldpolishingservices#Laserengravingonmould#mouldengravingExpertsinDelhi#bestptfecoatingserviceinDelhi#3dlaserengravingdelhi#etchingservicesdelhi#etchingofmetalsindelhi#nonstickcoatingprocess#lasermarkingservicesinDelhi#MouldTexturingindelhi#MetalMouldPolishingdelhi#mouldpolishingprocess#laserengravingservices#metaletchingservices#etchingservices#PTFECoatingOnMouldindelhi#bestchemicaletchingservicesindelhi#bestlaserengravingserviceindelhi#ecoatingservicesindelhi#SandblastingServices#ShotBlastingServicesinDelhi#LaserMarkingservices#bestnonstickcoatingservicesdelhi#PTFEcoatingservices#Nonstickcoatingteflon#LaserMouldTexturing#ptfecoatingprocess

0 notes

Text

Reasons Why You Should Use Non-Stick Coating Services

Taking care of our equipment is the most important thing, be it high profile industry equipment or our regular kitchenware. Using food-grade kitchenware that is also easy to operate is the real task. A lot of people resort to non-stick kitchenware for its effortless usage. If you are also planning to get your equipment or kitchenware coated in non-stick materials then here's why you are absolutely on the right track!

1. Long-lasting vessels

When you go for additional coatings on your utensils, naturally the interior of the vessels gets secured with an external material. This new coat, being non-stick, is also very durable. This increases the shelf life of your coated vessels, making them last longer than they usually would. You can also always have them recoated and enhance their life even more.

2. Highly non-reactive

The materials used to coat are generally made up of stainless steel, tin or enamel which makes them non-reactive. You should always opt for such vessels because they are the safest when it comes to cooking liquids.

Ingredients from the food can react with the elements from the vessels when they are not coated. This can result in certain chemical reactions altering the nutritional values of the food you are consuming. When a non-reactive vessel is used, you can rest assured that your food comes to your plate as it is.

3. High resistance

Such coatings are also highly resistant to external elements like water and moisture. This further lengthens their life and makes them long-lasting. Elements like wind, moisture and water cause your equipment to be corroded easily. When you apply an additional coat, it protects the equipment from damage.

4. Safe

Equipment that is coated by other materials does not get damaged due to the coats. All the coating service providers make sure that no damage is caused to any of the equipment because of the coating. It's all the goodness and no harm!

5. Low friction

This is a special benefit for industrial equipment. Coatings of your apparatus can also act as a softening lubricant. The surfaces that have been coated with non-stick materials will easily slide over each other creating lesser friction. This also minimizes the risk for corrosion and abrasion.

Well, now you know why you should choose non-stick coatings. It is easy to use, clean and gives good quality! So stop thinking, and start coating!

#NonstickCoatingProcess#PTFECoatingOnMouldindelhi#tefloncoatingservice#usesofnonstickcoating#whyshouldusenonstickcoatingservices#3dlaserengraving#bestlaserengravingserviceindelhi#laserengravingservices#LaserTexturingindelhi#bestchemicaletchingservicesindelhi

0 notes

Link

In this article, we will discuss laser engraving and laser etching. There is a lot of ambiguity between them. Take a peek at what laser engraving & etching are.

#laserengravingservicesinDelhi#chemicaletchinginDelhi#laserengraverformouldindelhi#logolasermarkingserviceproviderindelhi#mouldengravingExpertsinDelhi#TopmetaletchingservicesDelhi#MetaletchingservicesnearNoida#TeflonCoatinginDelhi#bestptfecoatingserviceinDelhi#engravingservicesinDelhi#3dsurfaceetching#3dlaserengravingdelhi#etchingservicesdelhi#etchingofmetalsindelhi#metaletchingindelhi#ptfecoatingprocess#tefloncoatingservice#ecoatingservices#nonstickcoatingprocess#mouldpolishingprocess#lasermarkingservices#Metaletchingservices#etchingservices#LaserTexturingindelhi#PTFECoatingOnMouldindelhi#Laserengravingonmould#bestchemicaletchingservicesindelhi#bestlaserengravingserviceindelhi

0 notes

Link

importanceofptfecoating Importance of PTFE coating in Indian Manufacturing industry ! Blog

Learn about the importance of PTFE coating and how it’s used in Indian manufacturing industries. This blog will give you an idea of how efficient and versatile your items may become after being coated with PTFE.

#importanceofptfecoating#applicationofptfe#benefitsofptfe#ptfe#ptfecoating#blogonptfecoating#bestchemicaletchingservicesindelhi#bestlaserengravingserviceindelhi#Topetchingprocesscompany#ptfecoatingservices#tefloncoatingservices#laserengravingservices#lasermarkingservices#nonstickcoatingprocess

0 notes

Link

Jai Ambay Etching Process offers 3D surface etching services in Delhi. They collaborate with clients on projects that require texturing in a mould cavity.

#3DSurfaceEtching#3dlaserengravingdelhi#etchingservicesdelhi#etchingofmetalsindelhi#metaletchingindelhi#ptfecoatingprocess#tefloncoatingservice#nonstickcoatingprocess#mouldpolishingprocess#lasermarkingservices#Metaletchingservices#lasermarking#logolasermarkingserviceproviderinDelhi

0 notes