#lockouttagout

Text

Electrical Plug Lockout Device Large Isolation and Lockout Solution

Plug Lockouts are a simple solution for locking out Industrial Electrical Plugs. These Electrical Plug Lockouts prevent electrical plugs from being inserted into sockets. It is used when the plug is not under the exclusive control of the person performing service or maintenance.

Manufactured from sturdy polystyrene/ABS, these units have been developed to completely enclose electrical plugs to prevent a machine from being energized. The plug completely sits inside the unit with the cable being fed through an access hole.

E-Square introduced Electrical Plug Lockout devices (ES-LPLO) to accommodate a large variety of plug shapes and sizes. The large unit of our plug lockout is suitable for standard and larger electrical plugs, including 3 phase connectors.

Feature:

- This Large plug lockout is applicable for 220V-500V plugs

- Inner dimension: 155 H x 86 D x 84 W mm with 8.5 to 19 mm diameter holes for cable. These holes can be customized/ Extended upto a certain limit, if required.

To get more information about product, visit - https://www.safetylock.net/product/plug-lockout-device-large-es-lplo/

#PlugLockout#ElectricalPlugLockout#PlugLockoutDevice#LockoutTagout#LockoutTagoutManufacturer#LOTO#LockoutDevice#LOTODevices#LockoutTagoutSupplier#LockoutTagoutExporter#ESquare#ESquareAlliance

0 notes

Text

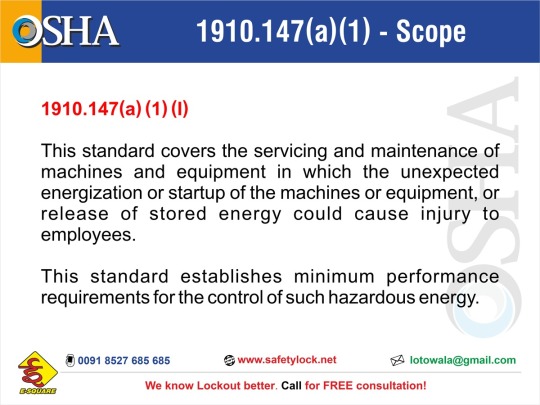

OSHA 29 CFR 1910.147 Standard: Scope (a)(1)

OSHA 29 CFR 1910.147 Standard: Scope (a)(1) The main aim of this Standard1910.147(a)(1) is to protect the employees from hazardous energy sources on machines during maintenance from:

· Unexpected energization or startup of the machines and equipment:

Employees servicing or maintaining machines may be exposed to serious physical harm or death if hazardous energy is not properly controlled. Unexpected energization includes- sudden, accidental, unintentional or careless startup or release of hazardous energies that pose a serious threat to employees.

· Release of Stored Energy that can cause injury to employees:

Any energy can become hazardous if stored energy builds to a dangerous level or is suddenly released. Turning the power off or removing the energy source doesn’t guarantee that the equipment is safe.

If workers service or perform maintenance without relieving chemicals, gases, liquids and vapors or remove springs, wheels or elevated parts, Batteries and capacitors, Pressurized or moving gases, then their sudden release could cause serious injury to personnel.

The Standard establishes minimum performance requirements for the control of hazardous energy sources:

· Identifying energy sources that can cause harm

· De-energize the equipment by turning it off from the main source.

· Dissipate stored energy by releasing the energy after de-energization.

The goal of every safety program, should be to protect the employees from the release of hazardous energies that can cause injury to them, while performing maintenance. The OSHA Lockout Tagout standard set forth in1910.147 covers the servicing and maintenance of machines, equipment and processes in general industries. Check OSHA Guidelines- https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#OSHA#OSHAGuidelines#OSHAStandard#OSHALockoutTagout#LockoutTagout#LOTO#LockoutTagoutProcedure#HazardousEnergySources#ESquare#ESquareAlliance

1 note

·

View note

Text

Best Practices for Mobile App Testing

Mobile app testing is a critical process that ensures that the app works as intended and delivers the best user experience. It's essential to perform thorough testing before launching the app to the market to avoid negative reviews and low ratings.

At Ioninks, we follow best practices for mobile app testing to ensure the quality of the app. Here are some tips on how to conduct effective mobile app testing:

1. Start with a plan: Before testing the app, create a test plan that outlines the testing goals, requirements, and test scenarios. This plan will serve as a guide and help you stay organised throughout the testing process.

2. Choose the right devices: Test the app on various devices to ensure compatibility and consistent performance across different platforms. It's crucial to test the app on both older and newer devices to ensure that it works well on all types of hardware.

3. Test on real devices: Emulators can be useful, but it's always better to test on real devices. This way, you can get a more accurate representation of how the app will work in the real world.

4. Use automation tools: Automated testing can save a lot of time and effort. Use automation tools to test repetitive tasks and scenarios, allowing your team to focus on more critical aspects of the app.

5. Test for security: Security is a critical concern for mobile apps. Ensure that the app's security measures are sufficient by conducting penetration testing and vulnerability assessments.

6. Involve end-users: Finally, involve end-users in the testing process. Ask for feedback, conduct surveys, and make changes based on their input. This way, you can ensure that the app delivers the best possible user experience.

In conclusion, following best practices for mobile app testing is crucial to ensure the quality of the app. At Ioninks, we believe that thorough testing is essential for a successful app launch. By implementing these tips, you can ensure that your app works as intended and delivers an excellent user experience.

0 notes

Text

Safety Gate Valve Lockout Device- LUKKO SAFETY

The "Safety Gate Valve Lockout Device" is introduced by Lukko Safety, a major producer of lockout tagout devices in India. This novel lockout mechanism is intended to give an extra degree of security by successfully locking gate valves, preventing unauthorised entry, and ensuring worker safety in working conditions.

The "Safety Gate Valve Lockout Device" is made of resilient components that make it impervious to deterioration, pollutants, and severe environment, making it excellent for usage in a variety of industries such as oil and gas, manufacturing, and chemical plants. The vivid red colour and clear labelling make it very visible, indicating that the valve's position has been sealed and not be played with.

This lockout mechanism is straightforward to set up and has a distinctive adjustable design that accommodates most gate valves. The gadget is simple to put together and requires no equipment, providing a rapid and reliable lockout operation. It has a durable locking mechanism that resists interference and keeps the valve locked in the off mode unless correctly opened by authorised personnel.

The "Safety Gate Valve Lockout Device" is also compatible with a variety of lockout padlocks, providing extra security. It can be used with other lockout tagout devices to produce a full lockout sequence that complies with regulatory criteria.

Using the "Safety Gate Valve Lockout Device" fosters a safe working culture by preventing inadvertent or unauthorised use of gate valves, which can result in significant casualties or equipment damage. It assists businesses in complying with safety standards and requirements, resulting in a safer working environment for employees.

Lukko Safety is a well-known brand in lockout tagout products, with a focus on quality and safety. The "Safety Gate Valve Lockout Device" is a dependable, long-lasting, and effective way to secure gate valves and prevent unauthorised entry. Select Lukko Safety for all of your lockout tagout requirements to ensure the safety of the premises. Order the "Safety Gate Valve Lockout Device" immediately to protect your employees and equipment!

1 note

·

View note

Text

"Ensure safety first! Introducing our Lockout-Tagout system—your key to preventing accidents and securing #SafetyFirst#LockoutTagout ⚠️

Visit us: https://www.softdesigners.co.in/loto-lockout-tagout-system-in-manufacturing/

#lotosystem#innovation#safety#Ehs#softdesigners

0 notes

Text

Online Lockout Tagout Training and LOTO Courses | E-Square Training Academy

To support your workplace LOTO safety training needs, E-Square Training Academy offers variety of online lockout tagout training courses and programs. Our 20 years of experience in Lockout Tagout makes us experts at enabling you to gain insight into your LOTO program and into your business.

Training is an essential part of every employer’s health and safety program and several studies highlight that effective training and re-training for Lockout Tagout plays a pivotal role in preventing lockout tagout related injuries and fatalities.

We help health and safety practitioners, business owners and workers to stay safe, compliant and productive through our extraordinary, high impact, and experiential breakthrough training programs. E-Square Training Academy offers a variety of innovative and friendly training programs. Our training programs are based on internationally accepted most stringent standards on hazardous energy management to ensure optimum safety levels.

All of our training programs are based on OSHA’s Resource for development and delivery of training recommended ADDIE model for training development.

We offer:

On-site Lockout Tagout Training

Virtual-Live Training

Online LOTO Courses

Industry Specific LOTO Training

For more information about Lockout Tagout Training and Online Courses, visit - https://www.lototrainingcourses.com

#lototrainingcourses#lockouttagoutcourse#lockoutagouttraining#onlinelockoutagouttraining#lockoutagoutcourses#lototraining#lotocoursesonline#onlinelotocourses#lockouttagoutprogram#esquarealliance#esquaretrainingacademy#esquareacademy#esquare#lockouttagout#onlinelototraining#onlinelockouttagoutcourses

1 note

·

View note

Text

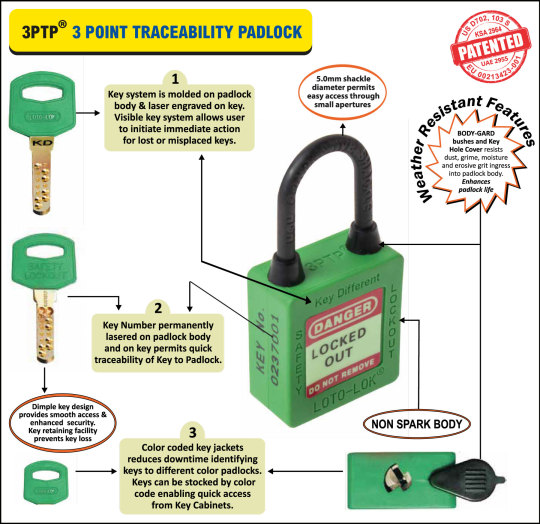

LOTO PADLOCKS – THE 3PTP™ (3 Point Traceability Padlock)

The ubiquitous plastic padlock used for immobilizing a wide range of energy sources in lockout tagout programs has come a long way in 30 years from the date when OSHA enforced energy isolation guidelines on industry to prevent injuries and fatalities in the workplace.

The metamorphosis of the LOTO padlock over the past few years has led to several additional features being inculcated along with a higher degree of tamper resistance and traceability by various manufacturers.

https://www.lotosafetyproducts.com/product-category/lockout-tagout/safety-lockout-padlocks/

https://www.lotosafetyproducts.com/product/plastic-lockout-padlocks/

https://lockouttagoutmuscatoman.com/product/premium-plastic-safety-lockout-padlocks-2/

CONSIDER THIS:

For over 2 decades, the market was dominated by 2 American brands who made plastic padlocks which had little or no information other than a number lasered on the key.

Additional features viz: individual names, logos and key number engraving on padlock body were customized at additional costs to be incurred by the buyer.

The key system of the padlock, ie: Keyed Different OR Keyed Alike OR Master Keyed was generally recorded in the system but did not appear anywhere on the padlock. In the event of key loss or misplacement informed decisions could not be made on whether the lock had to be destroyed or if a spare key was available.

Padlock covers to protect dust, dew and grit ingress were available as an additional product from some manufacturers.

https://www.lotosafetyproducts.com/product-category/lockout-tagout/safety-lockout-padlocks/

https://www.lotosafetyproducts.com/product/plastic-lockout-padlocks/

https://lockouttagoutmuscatoman.com/product/premium-plastic-safety-lockout-padlocks-2/

THE 3PTP STORY:

As a relative newbie in the LOTO scene in 2011, we were always brainstorming on how we could add value and address gaps to provide additional features out-of-the-box to save downtime on tracing keys to locks, knowing the key system without having to refer to documents as well as retrieving keys quickly from cabinets to open locks during the re-energization process.

The 3 Point Traceability Padlock (3PTP) was born from various inputs derived from end user interactions.

The features we inculcated into the padlock helped save substantial downtime and increased the life of the padlock with it’s weather protection features.

Key system molded on body and one side of key – KD (Keyed Different), KA (Keyed Alike), KD+MK (Keyed Different + Master Keyed).

Key number lasered on padlock body and key enabling quick key to lock tracing.

Key jacket matching padlock color resulted in saving substantial downtime when tracing keys from cabinets.

A sliding key cover which prevented dust, grime, dew and grit ingress into the cylinder.

2 additional rubber bushes which if needed could be installed on the shackle to prevent ingress into the plastic body of the padlock.

SUCCESS LIES IN THINKING FROM THE CUSTOMER VIEWPOINT:

The patented 3PTP padlocks were launched in 2012 and over time ended up establishing the gold standard for energy isolation padlocks. The popularity increased over time leading to most customers specifying the 3PTP features as a minimum standard for their LOTO programs thereby forcing the competition to comply.

Not content to rest on our laurels, we kept working on improvements to make a more aesthetic + higher tamper resistance padlock.

REVAMPING THE 3PTP OVER A DECADE:

Steel chrome plated shackle changed to SS304 to prevent corrosion in chemical / saline atmospheres.

Normal plastic non-conductive shackle re-engineered with a stainless steel metal insert. The 3PTP had a 5.0mm shackle diameter as standard which was more susceptible to breaking than the standard 6.0mm version on other brands. To enhance the cut / break resistance, we inserted a SS304 metal rod internally and molded over with a hard bearing PA6 nylon end to end.

Colors were revamped from slightly darkish to a more brighter range thereby increasing visibility.

The individual box packing was redesigned with a transparent window allowing color and key number visibility without having to remove the padlock.

* The author of this blog is Qaid Zohar – Director at LOTO Safety, Dubai. This blog is written to educate interested parties on Lockout Tagout products.

#LockoutTagout#cablelockout#arcflash#architecture#ppe#ppe equipment#padlock#3ptp padlock#lotosafety#safetyproducts#safety#uae#oman#lotolok#cable#protection#mechnical#electrical#thermal

0 notes

Video

From the archives, in 2018 I posted this video about working safe and being safe. The man’s hands clenched on the conductors from being electrocuted. Luckily, his co-workers knew what to do by not becoming a part of the problem. Comment below ⬇️ on what safety measures should have been taken⚡️ #electrical #electrician #lockouttagout #safety #shock #bluecollar #worksafebesafe Repost from @hvac_refer_guy (at Tag a Friend) https://www.instagram.com/p/CT2IH1rBIP7/?utm_medium=tumblr

0 notes

Photo

Thanks @t_raw1230 for this submission. I do agree that this is a valiant effort in trying to be safe but this certainly isn’t how you lock out. A for effort. #electrical #electrician #loto #lockout #lockouttagout @accuratesafetyco let’s work on LOTO instead of ladder safety for now. https://www.instagram.com/p/B46kfFOn-jL/?igshid=1idjddc1hety6

0 notes

Text

Preserving Lives and Assets - The Art of Effective Lockout Tagout Implementation

Efficient lockout tagout procedures can enhance your unit's productivity and efficiency. The process of implementing lockout tagout involves critical aspects related to safely de-energising machines or equipment.

A proactive technique for maintenance safety is much needed in today’s fast-paced world. Regulatory compliances, safety processes and enforced guidelines create a sense of safety and protection for both employees and employers.

#LockoutTagoutImplementation#LockoutTagout#LOTOInstallation#LOTO#LOTOProcedure#ESquare#EsquareAlliance

0 notes

Photo

RAAH SAFETY suppliers for Key and Padlock Storage Cabinets

Key and padlock storage and management system

A key cabinet is an important part of any management system which involves the use of large numbers of keys. These cabinets can be configured to store and record the removal and return of important keys and padlocks.

We also supply key view cabinets, system key cabinets, padlock storage cabinets, deep system key cabinets, keystore value cabinets, free standing key cabinet, portable key cabinet, emergency key cabinets, deep padlock cabinet – high capacity, padlock control center with 18 hooks, padlock control center – 8 hooks, high-view padlock storage cabinet 30 LC, high-view padlock storage cabinet 48 LC, emergency key box spare glass, select access portable key safe 5400D, emergency key box seals, emergency key box hammer, select access wall mounted key safe 5401D, select access wall mounted key safe 5403D and select access wall mounted key safe 5412D

For more information visit https://raahsafety.com/key-and-padlock-cabinets.html

For more information kindly visit us at www.raahsafety.com and for any enquiries email us at [email protected] #KeyandPadlock

0 notes

Text

Brady Compact Lockout Tagout Padlock Personal Safety Kit - 123143 Click quickl http://rover.ebay.com/rover/1/711-53200-19255-0/1?ff3=2&toolid=10039&campid=5338274770&item=142940267515&vectorid=229466&lgeo=1

0 notes

Text

1. Describe lockout/tagout procedures2. List and describe the 7 “principles of

1. Describe lockout/tagout procedures2. List and describe the 7 “principles of

1. Describe lockout/tagout procedures2. List and describe the 7 “principles of learning”3. What training is requiring for Personal Protective Equipment.4. Describe “risk assessment”.5. What is a gate (as it pertains to machine guarding”6. Describe a robots “work envelop”7. List 8 things a slip and fall prevention program should address.8. What are 4 causes of falls?9. What are 4 kinds of…

View On WordPress

0 notes

Link

LOTO Safety Requisites Trading L.L.C is a comprehensive solution provider in Lockout Tagout, Arc Flash PPE and Electrical safety equipment. We supply an extensive range of products for Energy Isolation procedures and the accompanying PPE prescribed by OSHA Standards.

#lockout#oman#tagout#lockouttagout#arcflash#safety#safetyproducts#cablelockout#cable#cablelock#valvelock#uae#electrical#ppe equipment#ppe kits#ppe

1 note

·

View note

Link

By Ethan Davis Lockout: The application of a lock, chains, or other appropriate apparatus, and a danger identification tag to de-energize electrical equipment and/or process system to ensure that the equipment or system cannot be activated. Note: OSHA regulations require that locks be used to secure equipment whenever possible. Chains can be wrapped around valve handles and then locked in such a way that the valve cannot be operated. Tags alone can be used when it is not possible to use a lock. Tagout: The application of a danger identification tag when a physical lockout or de-energizing i...

0 notes