#large scale 3d printing service

Text

#custom 3d printing near me#custom 3d printing services#custom 3d printing#3d print service near me#3d printing companies near me#3d printing cost#online 3d printing#3d printing online services#3d print vase#fused deposition modeling#3d printer service near me#large 3d printing services#sls 3d printing service#fused deposition modeling 3d printer#large industrial 3d printer#rapid prototyping 3d printing#3d scanning services cost#3d scale model maker#High resolution 3d scanning#Industrial 3d scanning#Reverse engineering services#Rapid Prototyping#Scale modeling#3d printing services#large 3d printing#best 3d printing service#large format 3d printing#3d model printing service#sls printing service#large scale 3d printing service

0 notes

Link

The market for 3D printing software and services is being driven by new and improved technologies as well as the ease of developing custom products such as engine parts, prototypes, and artistic items for industries, including automotive, aerospace, and healthcare. Rapid product development at a low cost is a key factor augmenting demand for additive manufacturing worldwide.

Computer-aided design (CAD) or 3D object scanners are used in this technology to take precise measurements of the product to be custom designed. As per industry players, 3D software are programs required to operate 3D printers for creating models using 3D printing techniques.

Request for the Sample of this Report at: https://bisresearch.com/requestsample?id=1176&type=download

#3D Printing Software and Services Market#3D Printing Software and Services Market Size#3D Printing Software and Services Market Share#3D Printing Software and Services Market Trends#3D Printing Software and Services Market Forecast#3D Printing Software and Services Market Analysis#3D Printing Software and Services Market Overview#3D Printing Software and Services#3d printing service#3d printing machine#3d printer design software#3d technology#3d printing materials#large scale 3d printer#metal 3d printer#3d printing software

0 notes

Text

Custom Vehicle Wraps With 3D Effects

Utilize your vehicle as a mobile billboard and gain more impressions for less money than with traditional marketing strategies. Full vehicle wraps also enable you to utilize every surface of the car or truck for an attractive design that stands out.

vehicle branding near me should carefully prepare the paint surface of your vehicle in order to ensure there are no rust spots or dents underneath the wrap, and to avoid rushed painting jobs which look unprofessional and potentially damage its integrity.

3D graphics

Vehicle wraps can create lasting impressions and be an effective marketing investment for local businesses of any size - be they solar panel suppliers, restaurants, pet care specialists or hotels. At Caliber Signs and Imaging we have done vehicle wrappings for solar panel suppliers, restaurants, pet care experts hotels among others - so whether your goal is brand recognition or brand awareness we have your solution!

There is an assortment of colors from which to choose, but it is essential that the design can be read at high speeds on the road. Sans serif fonts may make reading your message easier.

Roland DG TrueVIS series printers and GR2 series vinyl cutters from Roland DG offer reliable digital large format printing that delivers premium graphics for vehicle wraps, providing color accuracy, media versatility and productivity benefits that professionals require in vehicle graphics work.

3D logos

An effective logo conveys who and what your organization stands for to the world, prompts people to recall your product, and helps potential customers evaluate if your offering fits with them. Logos do this through colors, shapes and other design elements.

Car wraps are a cost-effective and eye-catching way to promote your business and create mobile billboards, turning vehicles into moving billboards that reach millions every day. In fact, research indicates that just one vehicle with wrap advertising could reach up to 80,000 people daily! Don't overlook this type of advertisement for making an impactful statement about who you are!

A wrap can be as complex or straightforward as desired, as long as it serves its function and can easily be read. 3D effects should be used sparingly so as not to detract from its message, and design elements should be easily scaled for different sizes, applications and environments - plus the capability of being printed on different types of media in different colors and formats.

3D text

Vehicle wraps are an efficient way for companies and organizations to promote their services or products. A vehicle wrap can transform an assortment of trucks into an organized fleet or serve as a mobile billboard for local businesses - unlike traditional print advertisements which typically yield few impressions for their dollar spent.

Use the 3D Text plugin to add a 3D effect to any text on your stage. While its default settings should work just fine, experiment with its various contour options until you achieve exactly the look you desire.

3D Text offers several customizable bevel controls to add characteristic edge styles, as well as repeat its width and angle for greater visual effects. Furthermore, different materials can be applied to face, back, sides and bevel areas of text for even more flexibility when creating visuals effects.

3D shapes

Custom vehicle wraps can add a memorable and eye-catching visual to any car, from rock bands and celebrities who don't shy away from attention to those seeking a personalized tribal graphic effect. The process involves applying high-performance cast vinyl directly to a car's paint surface before laminating this film to protect the design against abrasion.

Experts use special measures to create vehicle wraps. First they measure the hood, bumpers, and fenders before adding three inches of extra material (bleed) so that their prints will fit seamlessly during installation.

Make your wrapping business stand out by offering special effects like metallics and matte finishes, adding textures such as carbon fiber, honeycomb, crocodile skin or emulsion - these techniques will ensure customers' vehicles stand out.

2 notes

·

View notes

Text

Printing Services Singapore: Quality, Efficiency, and Innovation

In the vibrant business hub of Singapore, where innovation and excellence are the norm, printing services play a pivotal role in supporting the diverse needs of companies across various industries. From small startups to multinational corporations, businesses rely on printing services to bring their ideas to life, communicate their messages effectively, and leave a lasting impression on their target audience. Let's delve into the world of printing services in Singapore and explore how they embody the principles of quality, efficiency, and innovation.

1. Quality That Speaks Volumes

In Singapore's competitive marketplace, quality is non-negotiable. Printing services in Singapore pride themselves on delivering exceptional quality in every aspect of their work, from vivid colors and sharp details to durable materials and impeccable finishes. Whether it's business cards, brochures, posters, or packaging, businesses can trust that their print materials will reflect the highest standards of quality, professionalism, and craftsmanship.

2. Efficiency at Its Best

Time is of the essence in business, and printing services in Singapore understand the importance of efficiency. With state-of-the-art equipment, streamlined processes, and a commitment to meeting deadlines, printing companies in Singapore ensure that projects are completed promptly and to the highest standards. Whether it's a last-minute rush job or a large-scale printing project, businesses can rely on Singapore's printing services to deliver results with speed and efficiency.

3. Innovation Driving Progress

Innovation is the lifeblood of Singapore's printing industry, driving progress and pushing boundaries in technology, creativity, and sustainability. From digital printing and 3D printing to personalized printing and augmented reality experiences, printing services in Singapore are at the forefront of innovation, offering cutting-edge solutions that meet the evolving needs of businesses in a rapidly changing world. By embracing innovation, printing companies in Singapore empower businesses to stay ahead of the curve and stand out in the marketplace.

4. Tailored Solutions for Every Need

One size does not fit all when it comes to printing services, and Singapore's printing companies understand the importance of offering tailored solutions that meet the unique needs of each client. Whether it's a small batch of custom invitations or a large-scale marketing campaign, printing services in Singapore offer a wide range of options, from paper types and finishes to printing techniques and delivery methods, ensuring that every project is executed with precision and attention to detail.

5. Sustainable Practices for a Better Future

As sustainability becomes increasingly important to businesses and consumers alike, printing services in Singapore are committed to implementing eco-friendly practices that minimize environmental impact. From using recycled materials and eco-friendly inks to reducing waste and energy consumption, printing companies in Singapore are taking proactive steps to promote sustainability and contribute to a greener, more sustainable future for all.

Conclusion: Elevating Business Success Through Printing Services

In conclusion, printing services in Singapore embody the principles of quality, efficiency, and innovation, serving as indispensable partners in the success of businesses across all sectors. With their unwavering commitment to delivering exceptional quality, efficiency, and innovation, printing companies in Singapore empower businesses to communicate their messages effectively, differentiate themselves in the marketplace, and achieve their goals with confidence. Whether it's through traditional print materials or cutting-edge digital solutions, printing services in Singapore play a vital role in helping businesses thrive in the dynamic and competitive landscape of Singapore's business ecosystem.

0 notes

Text

Revolutionizing Manufacturing: Exploring the Benefits Offered By 3D Printer Manufacturing Companies

In the ever-evolving landscape of manufacturing, additive manufacturing has emerged as a game-changer, with several companies at the forefront of innovation. This article delves into the benefits offered by 3D printers, showcasing how their advancements contribute to revolutionizing the manufacturing industry.

Cutting-Edge Technological Innovation: 3d printer manufacturing companies are at the forefront of technological innovation. Their commitment to cutting-edge advancements ensures that businesses have access to state-of-the-art 3D printing solutions that continually push the boundaries of what is possible.

Diverse Range of Printing Materials : One of the key benefits lies in the diverse range of printing materials offered by top 3D printers. From traditional plastics to advanced metals and composite materials, these machines provide a versatile selection that caters to a wide array of manufacturing needs.

Precision and Accuracy in Printing: Precision and accuracy are paramount in manufacturing, and additive manufacturing companies in India, excel in delivering high-quality 3D printers. These printers are engineered to produce intricate and precise components and parts to meet the stringent standards required in various industries.

Scalability for Large-Scale Production: To ensure 3D printing scalability is to choose the right 3D printer. Industrial 3d printer manufacturers design printers and systems that can seamlessly integrate into production lines, offering efficiency and cost-effectiveness for mass manufacturing.

Customization and Design Flexibility:3D printing process allows for unparalleled customization, and industrial 3d printer companies capitalize on this by providing design flexibility. Businesses can create unique, tailor-made components and prototypes, fostering innovation and meeting specific project requirements.

Streamlined Prototyping Processes:The technologies in most of the advance 3D printers today, enable businesses to streamline the prototyping process, reducing development time and costs. This agility is particularly advantageous for industries where quick iterations are crucial.

Environmental Sustainability:3D printers prioritize environmental sustainability through reduced energy use. Through the use of eco-friendly materials and efficient printing processes, these machines contribute to reducing waste and minimizing the environmental impact of manufacturing.

User-Friendly Interfaces and Software Integration:Accessibility is key, and most of the manufacturers ensure that their 3D printers come with user-friendly interfaces. Additionally, they often integrate seamlessly with advanced software solutions, enhancing the overall user experience and making 3D printing more accessible to a broader audience.

Continuous Research and Development:The commitment to continuous research and development sets the 3D printing technology apart. The additive manufacturing companies in India, invest heavily in R&D. Their investment in R&D ensures that they stay ahead of industry trends, introducing new features, materials, and printing capabilities to meet evolving market demands.

Global Support and Service Networks:Top 3D printer manufacturers establish global support and service networks. This ensures that businesses using their technology have access to timely support, maintenance, and upgrades, fostering a reliable and long-term partnership.

Industry-Leading Reliability and Durability:Reliability and durability are non-negotiable when it comes to additive manufacturing. 3D printers are engineered to withstand rigorous use, providing businesses with a robust and dependable solution for their manufacturing needs.

In conclusion, the benefits offered by 3D printing machines extend far beyond the capabilities of traditional manufacturing methods. From technological innovation to customization and environmental sustainability, most companies are driving a transformative shift in the manufacturing landscape, empowering businesses to embrace a future where possibilities are limitless.

0 notes

Text

Contract Packaging Services Restricted Overview Discover And Update Company Info Gov Uk

One of the principle advantages of contract packaging is improved efficiency and cost-effectiveness. By outsourcing packaging tasks to specialised firms, businesses can save on labor costs, as they don't need to rent and prepare their very own packaging employees. Additionally, contract packaging firms typically have access to bulk purchasing discounts on packaging materials, which can further scale back costs. There are various kinds of contract filling services out there available in the market. Some corporations provide liquid filling services, where they fill bottles or containers with liquids corresponding to beverages, cleansing products, or personal care products. Other firms focus on dry filling, the place they fill luggage or containers with powders, granules, or stable merchandise.

As your flexible supply chain associate, we've an answer to swimsuit your needs. Our facility has the potential to supply plain or printed corrugated cardboard packaging on-site. This can even scale back freight costs of transport cardboard outers from one provider to another. Packaging Assembly – Fulfillment of all packaging meeting, including any further supplies you may need such as sticker placement, coupon or handbook inclusion, and careful product placement. In our BRC grade AA rated factory in the North-West of England we now have large dedicated zones for each contract sachet manufacture and contract packing.

Timelines of planning, scheduling and finishing our orders have all the time been great and we’ve been extremely happy with the quality of the product. The Finishing Line was instrumental in ensuring that we were able to distribute over 150,000 testing kits every month throughout England as a half of the Government's COVID-19 REACT study. Their information and expertise supplied us with the utmost confidence of their ability. I’ve labored with Evolve for 2 years now, they have all the time understood my needs extremely nicely and I’ve been very happy with their account management. And you’ll all the time know precisely what has gone where and when it arrived, thanks to our strong processes and tracking technology.

This type of packaging can even embody foil blistering for tablets and capsules, as nicely as liquid complement filling into bottles. If wanted, our group can even handle the manufacturing of thermoplastic packaging and branding or printing on foil blisters. If you might have supplies such as powders or different non-liquids, we can repack them for you.

Our ArtiosCAD software program permits EPI engineers to create exact structural designs and animated 3D modeling, and to provide prototype cartons on our digital plotter/cutter. At Complete Co-packing Services Limited we concentrate on contract packing, warehousing and distribution. We supply a confidential service for the packing of natural and non-organic dried meals, powders, granules, liquids, tablets and capsules.

Consider your budget actually and punctiliously, as it’s simple to underestimate how much packaging can value. If the contract packer has experience and offers a high-quality service, it should be capable of assess the way to modify your project to maintain it within your price range. If you're a start-up company, then please be happy to provide us a name, we are always happy to help. By analysing market trends and consumer behaviour, Colman Packaging anticipates future packaging wants and develops solutions that keep purchasers forward of the curve.

#contract packaging#contract packaging uk#contract packaging company#contract packaging services#fast packaging service#contract packing#contract packaging solutions

0 notes

Text

Understanding Mold Making Services: From Prototyping to Mass Production

Continuing from the previous article

Importance of Precision and Accuracy

Precision and accuracy are paramount in mold making. Even minor deviations from the intended specifications can result in defective parts or products, leading to waste, rework, and increased production costs. Therefore, meticulous attention to detail and adherence to tight tolerances are critical throughout the mold-making process to ensure consistent, high-quality results.

Materials Used in Mold Making

The choice of materials for mold making depends on various factors, including the type of product being manufactured, the production volume, and the desired characteristics of the finished mold. Common materials used in mold making include:

Metals (e.g., aluminum, steel) for durable, long-lasting molds suitable for high-volume production.

Plastics (e.g., epoxy, silicone) are used for cost-effective, flexible molds that are ideal for prototyping and low-volume production.

Composites (e.g., fiberglass, carbon fiber) for lightweight, high-strength molds capable of withstanding demanding manufacturing environments.

Each material offers unique advantages and considerations in terms of strength, durability, thermal conductivity, and moldability, which must be carefully evaluated to determine the most suitable option for a given application.

Types of Mold-Making Services

Prototyping Mold-Making Services

Prototyping molds plays a crucial role in the product development process by enabling the creation of initial versions of a product for testing, validation, and refinement. These molds are designed to produce prototypes quickly and cost-effectively, allowing designers and engineers to iterate on designs and make necessary modifications before proceeding to mass production.

Process and Technologies

Prototyping molds employ various advanced manufacturing technologies to rapidly create prototypes with precision and accuracy. Some common techniques include:

3D Printing: Additive manufacturing processes such as stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM) are widely used for producing prototype molds directly from digital designs. 3D printing offers fast turnaround times and the ability to create complex geometries with minimal tooling costs.

CNC Machining: Computer numerical control (CNC) machining utilizes computer-controlled cutting tools to remove material from a solid block or billet, resulting in highly accurate prototype molds. CNC machining is suitable for producing prototypes from a wide range of materials, including metals, plastics, and composites.

Silicone Molding: Silicone molding, also known as rapid tooling or soft tooling, involves creating a silicone mold directly from a master pattern or 3D-printed model. This flexible and cost-effective method allows for producing small-batch prototypes with intricate details and fine surface finishes.

Mass Production Mold-Making Services

Mass production molds are designed for high-volume manufacturing, allowing businesses to replicate products consistently and efficiently on a large scale. These molds are engineered to withstand continuous production demands while maintaining tight tolerances and dimensional accuracy.

Characteristics

Mass-production molds are characterized by their durability, precision, and suitability for high-volume production. Key features of mass-production molds include:

Durability: Mass-production molds are typically constructed from robust materials such as hardened steel or aluminum to withstand the rigors of prolonged use and repeated molding cycles without experiencing excessive wear or degradation.

Precision: Mass production molds are engineered with precision-machined cavities and cores to ensure uniformity and consistency in the molded parts. Tight tolerances are maintained to meet the strict quality standards required for mass-produced components.

High-Volume Capability: Mass production molds are optimized for rapid cycle times and efficient material utilization, allowing for producing large quantities of parts within a short timeframe. This scalability makes them ideal for industries with high demand and production volumes

0 notes

Text

Mass Customization: Transforming Industries with Personalized Products and Experiences

Share Post:

LinkedIn

Twitter

Facebook

Reddit

In today’s consumer-driven marketplace, mass customization, also known as made-to-order, has emerged as a powerful strategy for businesses to meet the diverse needs and preferences of individual customers while maintaining the efficiencies of large-scale production. Mass customization combines the benefits of mass production with the personalization of custom-made goods, allowing companies to offer tailored products and experiences at scale.

Understanding Mass Customization

It refers to the ability to produce goods or services that are customized to meet the specific needs, preferences, and requirements of individual customers, while still leveraging the efficiencies of mass-production techniques. Unlike traditional mass production, which focuses on producing large quantities of standardized products, mass customization allows for variations in design, features, and specifications to accommodate diverse customer preferences.

The Shift Towards Personalization

The rise of mass customization can be attributed to several factors, including advancements in technology, changes in consumer behavior, and increasing demand for personalized products and experiences. Consumers today value individuality, uniqueness, and self-expression, leading to a growing preference for products that reflect their personal tastes and lifestyles. Customization enables businesses to cater to this demand by offering customized options that resonate with customers on a personal level.

Benefits of Mass Customization

Customization offers numerous benefits for both businesses and consumers, including:

1. Enhanced Customer Satisfaction

By offering personalized products and experiences, businesses can increase customer satisfaction and loyalty, leading to repeat purchases and positive word-of-mouth.

2. Greater Market Differentiation

Mass customization allows businesses to differentiate themselves from competitors by offering unique and innovative products that cannot be replicated easily.

3. Improved Inventory Management

With customization, businesses can reduce excess inventory and waste by producing goods on-demand or in small batches, minimizing the need for large stockpiles of finished goods.

4. Increased Revenue and Profitability

Personalized products often command higher prices and profit margins than standard offerings, leading to increased revenue and profitability for businesses.

5. Deeper Customer Insights

Customization initiatives generate valuable data and insights into customer preferences, behaviors, and purchasing patterns, which can be used to inform future product development and marketing strategies.

Strategies for Implementing Customization

To successfully implement customization initiatives, businesses should consider the following strategies:

1. Invest in Technology

Leverage advanced technologies, such as 3D printing, computer-aided design (CAD), and artificial intelligence (AI), to streamline the customization process and reduce production costs.

2. Offer Flexible Options

Provide customers with a range of customization options, including colors, sizes, features, and materials, to accommodate diverse preferences and tastes.

3. Simplify the Process

Make the customization process intuitive, user-friendly, and accessible to customers, minimizing complexity and barriers to entry.

4. Integrate Customer Feedback

Solicit feedback from customers throughout the customization process to ensure that their needs and preferences are being met effectively.

5. Collaborate with Customers

Involve customers in the design and development process, allowing them to co-create products that are tailored to their individual requirements.

6. Emphasize Quality and Value

Ensure that customized products meet high standards of quality and craftsmanship, providing customers with exceptional value and satisfaction.

Industries Embracing Mass Customization

2. Automotive: Customized cars, motorcycles, and bicycles with personalized features, colors, and accessories.

3. Technology: Personalized electronics, gadgets, and devices with customizable specifications and configurations.

4. Home Goods: Custom furniture, home decor, and appliances designed to fit specific spaces and aesthetic preferences.

5. Food and Beverage: Personalized food and beverage products, such as customized meal kits, beverages, and confections.

Sustainability and Environmental Impact

Mass customization can contribute to sustainability efforts by minimizing waste and reducing the environmental impact of production processes. By producing goods on-demand or in small batches, businesses can avoid overproduction and excess inventory, leading to fewer unsold products ending up in landfills. Additionally, customization enables customers to choose eco-friendly materials, reduce packaging waste, and opt for products that align with their values and sustainability preferences.

Brand Loyalty and Customer Engagement

Offering personalized products and experiences can strengthen brand loyalty and deepen customer engagement. When customers feel actively involved in the design process and have the opportunity to create products that reflect their unique identities, they develop stronger emotional connections to the brand. This emotional bond can lead to increased brand advocacy, word-of-mouth referrals, and long-term customer relationships built on trust and mutual understanding.

Supply Chain Optimization and Efficiency

It requires a flexible and agile supply chain capable of responding quickly to changing customer demands and preferences. By leveraging digital technologies and real-time data analytics, businesses can optimize their supply chains to support customization initiatives efficiently. This includes streamlining production processes, improving inventory management, and enhancing collaboration with suppliers and manufacturing partners to ensure the timely delivery of customized products.

Personalized Marketing and Customer Insights

It generates valuable data and insights that can inform targeted marketing strategies and personalized customer experiences. By analyzing customer preferences, purchase history, and customization choices, businesses can tailor marketing messages, promotions, and product recommendations to individual customers’ interests and preferences. This personalized approach enhances the relevance and effectiveness of marketing efforts, driving higher conversion rates and customer satisfaction.

Continuous Innovation and Adaptation

Mass customization encourages continuous innovation and adaptation to evolving market trends and consumer preferences. By closely monitoring customer feedback and market trends, businesses can identify emerging opportunities and adapt their customization offerings accordingly. This iterative process of innovation enables businesses to stay ahead of competitors, anticipate customer needs, and introduce new and innovative products that resonate with target audiences.

Integration of Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) technologies holds immense potential for advancing customization capabilities. AI-driven customization algorithms can analyze vast amounts of customer data to identify patterns, trends, and preferences, enabling businesses to offer more accurate and personalized recommendations. Machine learning algorithms can also optimize production processes, predict demand fluctuations, and automate decision-making to improve efficiency and responsiveness.

Conclusion

Mass customization represents a paradigm shift in the way businesses interact with customers and deliver products and experiences. By combining the efficiency of mass production with the personalization of custom-made goods, customization enables businesses to meet the diverse needs and preferences of individual customers while driving innovation, sustainability, and brand loyalty. As technology continues to evolve and consumer expectations evolve, businesses that embrace customization will be well-positioned to thrive in an increasingly competitive and dynamic marketplace.

0 notes

Text

Additive-X Ltd

Previously known as Express Group Ltd and then GoPrint3D, we renamed to Additive-X in 2020 – a demonstration of our commitment to growing as an additive manufacturing company. Our roots lie in printer spare parts and repair, as well as a commitment to providing flexible customer service, reliable technical support, and training that goes above and beyond.

But our latest vision is to democratise the manufacturing industry by providing small and large-scale additive manufacturing solutions. It’s our firm belief that 3D printing has the power to reshape the manufacturing landscape, empowering businesses and individuals alike to realise their creative goals.

Business hours: Mon - Fri: 9am - 5:30pm

Contact Us;

Address: College Business Park, Kearsley Road, Ripon, North Yorkshire, HG4 2RN

Phone;

Sales - 01765 694 007

Technical - 01765 694 030

Business Email;

Sales - [email protected]

Technical - [email protected]

Website: https://additive-x.com

1 note

·

View note

Text

Innovative Solutions: Exploring the Versatility of Plastic Extrusion Products

Different types of plastics are essential to a lot of contemporary sectors and are also used in homes in the form of many different products. Reputable companies provide plastic extrusion products that can be manufactured through large-scale product production. The goods are used in mechanical parts, automobiles, doors, windows, and many other locations. The plastic goods produced by this process are commonly used in barrier rails as well. PVC fence has also become increasingly popular recently, and this process is actually used to make the smaller pieces.

In a similar vein, parking spaces are available for cars at warehouses so they may load and unload goods. In all such situations, the rubber dock bumpers wholesale become vital and prevent harm to the car or the building's structure. Actually, a wide range of items may be created using this technique and technology known as plastic extrusion. Because of the high quality of the items produced, there is a strong demand for the extrusion process and leading manufacturers are able to fulfill large quantity demands as well.

A Look at Additional Services Provided by Top Extrusion Brands

Colour Matching: Occasionally, a certain colour must be used in the production of plastic goods. The best-in-class colour-matching technology may be used for this and this is required for most products made of plastic.

3D Printing: Prototyping has changed dramatically as a result of 3D printing, which allows one to create a 3D model and test its needs without having to pay for the necessary tools.

In-House Tool Making: Tools are required for many different purposes and leading companies are able to make tooling products in less time and expense.

Leading extrusion brands are capable of handling any task, from in-house tool manufacturing to laboratory testing. Speak with the top businesses to discuss your needs and learn more about the project you need to do.

Source

0 notes

Text

Empowering Creativity, One Layer at a Time: Explore 3D Printing in India

3D printing is at the pioneer of technological advancement in an creative world, providing countless resources to unleash creativity. With each layer seriously created, we enable people and businesses to realise their major audacious ideas. With the help of our 3D printing services, dreamers, designers, and entrepreneurs can turn ideas into tangible facts in India, stimulating exploration. From prototypes to customised goods, we offer the know-how and resources to successfully arrange the complexities of additive manufacturing. Come along on an creative trip with us, and let’s work together to create a future that is only constrained by our combined creativity.

A successful ecosystem of designers, engineers, and entrepreneurs eager to realise the transformative possible of 3D printing technology has led to a memorable surge in its adoption in India. There has never been a greater need for dependable and easily popular 3D printing services as companies try to stay ahead in a market that is becoming more and more cut-throat.

Businesses are using 3D printing to oversimplify their production processes, cut costs, and quicken creation cycles in a variety of industries, including consumer goods, automotive, and aerospace. Businesses can access state-of-the-art technology and knowledge to bring their ideas to life with accuracy and efficacy by collaborating with reputable 3D print services providers.

The advent of online 3D printing stages has revolutionised the way that people and companies can investigate the possible of additive manufacturing. These platforms are easily popular and convenient. Users only need to upload their designs, choose the materials and specifications they want, and a some clicks will bring their creations to life with unpaired accuracy and speed.

The benefits of online 3D printing in India go beyond practicality; they signify a basic change in our understanding of design and manufacturing. Online 3D printing stages enable creators of all backgrounds to realise their ideas, nevertheless of skills or location, by democratising access to advanced manufacturing capabilities.

Also, by reducing waste and maximising material usage through on-demand production, online 3D printing in India provides a acceptable alternative to conventional manufacturing methods. This gets rid of the need for large-scale supply storage, which not only helps the environment but also saves businesses money.

Online 3D print services in India provides an infinite amount of resources for anyone interested in using it, be it a startup trying to rapidly iterate on prototypes, a designer hoping to customise products for your clients, or a hobbyist avid to unleash your creativity. With an comprehensive selection of materials, finishes, and printing technologies at your disposal, you can realise your ideas with unmatched accuracy and quality.

0 notes

Text

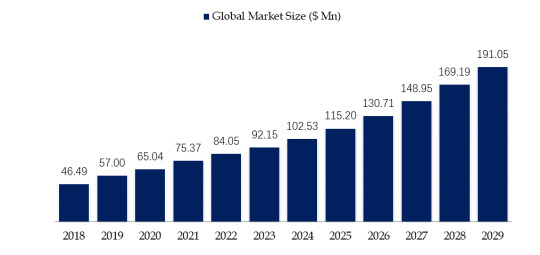

The global 3D Printed Insoles market size is projected to reach USD 191 million by 2029

3D Printed Insoles Market Summary

According to the new market research report "Global 3D Printed Insoles Market Report 2023-2029", published by QYResearch, the global 3D Printed Insoles market size is projected to grow from USD 84.05 million in 2022 to USD 191.05 million by 2029, at a CAGR of 12.92% during the forecast period.

3D printed insoles are customized insoles manufactured using 3D printing technology to provide foot support, reduce pressure, improve comfort, and adapt to individual foot shapes. While traditional insoles typically use relatively standard design and manufacturing methods, 3D printing technology allows insoles to be custom manufactured based on an individual's foot anatomy, gait and comfort needs.

Figure. Global 3D Printed Insoles Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global 3D Printed Insoles Market Report 2023-2029.

Main drivers:

There is an increasing demand for personalized and customized products. 3D printing technology allows manufacturing to be customized according to each person's foot shape and needs, meeting consumers' requirements for comfort and uniqueness, and providing consumers with a unique product experience.

Foot health is closely related to overall health. Many people face foot problems such as plantar pain, abnormal arches, etc. 3D printed insoles can be customized based on medical recommendations to provide better support and relief, and can also be used for personalized support during the recovery process. Therefore, it has broad application prospects in the medical field.

3D printing technology continues to advance, and printing accuracy and material selection are constantly improving. This makes it more feasible to create more ergonomic insoles. 3D printing technology can achieve on-demand manufacturing, reduce material waste, and is more environmentally friendly than traditional manufacturing methods.

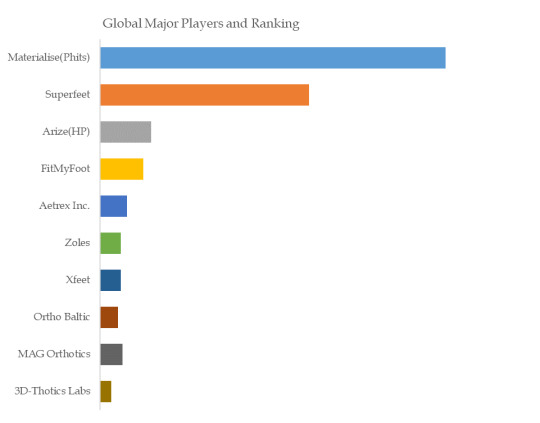

Figure. 3D Printed Insoles, Global Market Size, The Top Five Players Hold 56% of Overall Market

Based on or includes research from QYResearch: Global 3D Printed Insoles Market Report 2023-2029.

In terms of manufacturers, globally, the core manufacturers of 3D printed insoles mainly include Materialize (Phits), Superfeet, Arize (HP), FitMyFoot, Aetrex Inc., Zoles, Xfeet, Ortho Baltic, MAG Orthotics, etc. In 2022, the world's first-tier manufacturers mainly include Materialize (Phits) and Superfeet; the second-tier manufacturers include Arize (HP) and FitMyFoot.

Based on end-use, it can be divided into medical uses and non-medical uses. Medical use will account for the largest share in 2022, accounting for 87.09%, and the share is expected to reach 82.98% in 2029. In the medical field, 3D printed insoles play an active role, providing patients with foot health solutions through customized design and manufacturing. These medical insoles not only provide pain relief but also help support and improve foot structure to promote overall health.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Digitising Services UK: Revolutionizing Industries with Precision and Efficiency

In today's fast-paced digital age, businesses across various industries are continually seeking ways to enhance their operations, streamline processes, and stay ahead of the competition. One such transformative solution that has gained significant momentum is digitising services. From embroidery to vector graphics, digitising services UK are revolutionizing traditional practices, offering unparalleled precision, efficiency, and versatility.

Introduction to Digitising Services

Digitising services entail the conversion of physical content into digital formats, allowing for easier storage, manipulation, and distribution. Whether it's transforming intricate embroidery designs into digital patterns or converting hand-drawn sketches into scalable vector graphics, digitising services play a pivotal role in modernizing workflows and unlocking new possibilities.

Types of Digitising Services

Embroidery Digitizing

Embroidery digitizing involves the conversion of artwork or logos into stitch files that embroidery machines can interpret. This process enables businesses in the fashion and textile industries to create intricate and customizable designs with impeccable accuracy.

Vector Digitizing

Vector digitizing focuses on converting raster images, such as photographs or illustrations, into vector graphics composed of scalable geometric shapes. This method ensures that graphics remain crisp and clear regardless of size, making it ideal for branding, signage, and digital printing.

Image Digitizing

Image digitizing encompasses a broader spectrum, including the conversion of photographs, paintings, and drawings into digital formats. This versatile service enables artists, photographers, and marketers to digitize their visual assets for online sharing, editing, and preservation.

Benefits of Digitising Services

Digitising services offer a plethora of advantages, making them indispensable for businesses and individuals alike.

Precision and Accuracy

By digitizing designs and images, businesses can achieve unparalleled precision and consistency in their output. Whether it's replicating intricate patterns or fine-tuning graphical elements, digitising services ensure that every detail is faithfully preserved.

Cost-effectiveness

Traditional methods of design and reproduction often incur substantial costs, especially when dealing with complex or large-scale projects. Digitising services streamline processes, minimize material wastage, and reduce labor costs, making them a cost-effective solution for businesses of all sizes.

Time-saving

The manual creation of designs and artwork can be a time-consuming endeavor, often requiring hours or even days of meticulous work. Digitising services automate repetitive tasks, accelerate production timelines, and enable rapid iterations, allowing businesses to meet tight deadlines without compromising quality.

Applications of Digitising Services

Digitising services find applications across a diverse range of industries and disciplines, including:

Apparel Industry

In the fashion and apparel industry, digitising services are instrumental in creating intricate embroidery designs for garments, accessories, and promotional merchandise. From corporate logos to personalized monograms, digitized embroidery adds a touch of elegance and professionalism to branded products.

Marketing and Branding

In marketing and branding, digitising services play a crucial role in translating brand identities into visual assets that resonate with target audiences. Whether it's digitizing logos for online use or creating custom illustrations for marketing campaigns, digitised graphics enhance brand visibility and recognition across digital channels.

Architectural Designs

In architecture and interior design, digitising services facilitate the creation of detailed floor plans, renderings, and 3D models. By digitizing architectural drawings and sketches, designers can visualize concepts, communicate ideas effectively, and streamline the design-to-construction process.

How Digitising Services Work

Digitising services typically involve the following steps:

Input: Clients provide the desired artwork, design, or image to be digitized.

Conversion: Skilled digitizers use specialized software to convert the input into a digital format compatible with the intended output medium.

Editing: Fine-tuning and adjustments are made to ensure optimal quality and compatibility.

Output: The digitized file is delivered to the client in the desired format, ready for use in production or distribution.

Choosing the Right Digitising Service Provider

Selecting the right digitising service provider is crucial for achieving optimal results. Consider the following factors:

Experience and Expertise: Look for providers with a proven track record and expertise in your specific industry or niche.

Quality Assurance: Ensure that the provider employs stringent quality control measures to deliver consistently high-quality results.

Customer Support: Opt for providers that offer responsive and reliable customer support to address any queries or concerns promptly.

Trends in Digitising Services

Customization

With the rise of e-commerce and personalized products, there is a growing demand for customized digitising services tailored to individual preferences and requirements. From bespoke embroidery designs to personalized illustrations, customization is driving innovation in digitising services.

Automation

Advancements in artificial intelligence and machine learning are enabling automation in digitising services, streamlining workflows, and enhancing efficiency. Automated digitising tools can analyze and process complex designs with speed and accuracy, reducing manual intervention and minimizing errors.

Sustainability

As environmental consciousness continues to grow, sustainability is becoming a key focus area in digitising services. From eco-friendly materials to energy-efficient processes, digitising service providers are adopting sustainable practices to minimize their carbon footprint and promote environmental stewardship.

Challenges in Digitising Services

Despite their numerous benefits, digitising services also present certain challenges that businesses need to address:

Quality Control: Maintaining consistent quality across different digitising projects can be challenging, especially when dealing with intricate designs or diverse materials.

Compatibility Issues: Ensuring compatibility between digitised files and various production processes or software platforms can pose technical challenges.

Security Concerns: Protecting intellectual property rights and sensitive data from unauthorized access or infringement is a constant concern in digitising services.

Future of Digitising Services

The future of digitising services is poised for exciting developments, driven by technological advancements and evolving industry trends. Some key areas of focus include:

Emerging Technologies: Innovations such as augmented reality (AR), virtual reality (VR), and 3D printing are opening up new possibilities for digitising services, enabling immersive and interactive experiences.

Potential Advancements: From automated design generation to real-time collaboration tools, the future of digitising services holds promise for greater efficiency, creativity, and accessibility.

Conclusion

Digitising services have emerged as a cornerstone of modern business operations, offering unparalleled precision, efficiency, and versatility across diverse industries. From apparel and marketing to architecture and beyond, the transformative impact of digitising services in the UK is evident in the seamless integration of digital technologies into traditional workflows. As technology continues to evolve and innovate, the future of digitising services holds boundless potential for driving creativity, sustainability, and growth.

0 notes

Text

The Evolution of Laser Machines in Modern Industry

In the realm of modern manufacturing, precision is paramount. From intricate medical devices to robust automotive components, the demand for accuracy and efficiency drives innovation. Among the array of technological marvels revolutionizing production processes, laser machine stand out as beacons of precision, offering unparalleled capabilities across diverse industries.

Laser machines, once confined to the realm of science fiction, have seamlessly integrated into the fabric of contemporary manufacturing. These devices harness the power of light amplification by stimulated emission of radiation (LASER) to perform a myriad of tasks with remarkable accuracy and speed. From cutting and engraving to welding and marking, the versatility of laser machines knows no bounds.

One of the most compelling aspects of laser machines is their ability to operate across a broad spectrum of materials. Whether it's metals, plastics, ceramics, or even organic substances, lasers can manipulate these materials with surgical precision. This versatility has made laser machines indispensable in industries ranging from aerospace and electronics to jewelry design and healthcare.

In the automotive sector, laser cutting has revolutionized the production of complex components. High-powered lasers slice through metal with unparalleled precision, allowing for intricate designs and tight tolerances. This not only streamlines the manufacturing process but also enhances the performance and durability of automotive parts.

Similarly, in the field of medicine, laser technology has ushered in a new era of minimally invasive procedures. Laser cutting and welding techniques enable the fabrication of intricate medical devices with unmatched precision. From stents and catheters to surgical instruments and implants, these advancements have significantly improved patient outcomes while minimizing trauma and recovery time.

The electronics industry also benefits immensely from laser technology, particularly in the realm of microelectronics. Laser ablation and patterning enable the precise etching of circuit boards and semiconductor materials, facilitating the production of smaller, more efficient electronic devices. Additionally, laser marking provides a permanent, high-resolution method for branding and labeling electronic components.

In the realm of consumer goods, laser engraving has emerged as a popular choice for adding custom designs and personalization to products. From engraved jewelry and personalized electronics to intricate artwork on various materials, laser engraving offers limitless creative possibilities. This has fueled the growth of boutique businesses and custom manufacturing services catering to discerning consumers seeking unique and personalized products.

Beyond traditional manufacturing applications, laser technology is also making significant strides in emerging fields such as additive manufacturing (3D printing). Laser sintering and melting techniques enable the precise layer-by-layer deposition of metal powders, opening up new avenues for rapid prototyping and on-demand manufacturing.

However, the evolution of laser machines is not without its challenges. As technology advances, so too do the demands for higher precision, faster speeds, and increased automation. Innovations such as fiber lasers, ultrafast lasers, and adaptive optics are pushing the boundaries of what's possible, but researchers and engineers continue to explore new avenues for improvement.

Moreover, as laser technology becomes more accessible and affordable, the democratization of manufacturing capabilities is underway. Small businesses and entrepreneurs now have access to laser cutting and engraving services that were once exclusive to large-scale industrial operations. This democratization promises to fuel innovation and creativity across a diverse range of industries and applications.

In conclusion, laser machines have emerged as indispensable tools in modern manufacturing, offering unparalleled precision, versatility, and efficiency across diverse industries. From automotive and aerospace to healthcare and consumer goods, the applications of laser technology are boundless. As technology continues to advance and barriers to entry diminish, the future of manufacturing looks brighter than ever, illuminated by the brilliance of laser machines.

1 note

·

View note

Text

Future Of Manufacturing: Unraveling the Benefits of Additive Manufacturing

The industrial landscape is undergoing a profound transformation, and at the heart of this evolution are industrial 3D printer manufacturers. This article explores the myriad benefits of choosing industry leaders in the realm of industrial 3D printing, showcasing how these manufacturers are shaping the future of manufacturing and engineering.

Cutting-Edge Technology and Innovation:Industrial 3D printer manufacturers in India, lead the way in cutting-edge technology and innovation. Their commitment to continuous improvement ensures that businesses have access to the latest advancements, pushing the boundaries of what can be achieved with industrial 3D printing.

High-Speed and High-Volume Production: One of the standout benefits is the ability to achieve high-speed and high-volume production. 3D printer manufacturing companies, design systems that cater to the demands of industrial-scale manufacturing, offering unparalleled efficiency and throughput.

Materials Diversity and Specialization: 3D printing machines enable part production using diverse range of materials tailored for industrial applications. From advanced metals to high-performance polymers, the use of diverse materials coupled with advance technology opens new possibilities for manufacturing robust and specialized components.

Precision and Accuracy at Scale: Precision and accuracy are critical in industrial settings, and leading manufacturers excel in delivering high-precision prints at scale. The industrial-grade printers are engineered to meet the stringent tolerances required for manufacturing components used in various industries.

Customization for Complex Components: Industrial 3D printing allows for intricate and complex designs. Businesses can achieve bespoke solutions that meet specific performance and functionality requirements.

Advanced Prototyping and Iterative Design: Rapid prototyping is a hallmark benefit offered by industrial 3D printer manufacturers. Businesses can streamline the prototyping and design iteration process, allowing for quick adjustments and improvements without the need for extensive tooling or manufacturing changes.

Cost-Efficiency Through Additive Manufacturing: Industrial 3D printing embraces additive manufacturing principles, significantly improving cost-efficiency. By building up layers of material, manufacturers reduce material waste,additive manufacturing lowers production costs, and achieve economic advantages in large-scale manufacturing.

Integration with Industry 4.0 Technologies: 3D printing is one of the fundamental technologies of Industry 4.0. The systems often seamlessly integrate with other smart manufacturing technologies, allowing businesses to create interconnected and efficient production ecosystems.

Sustainability and Environmental Considerations: Sustainability is a growing concern, technology, and processing in 3D printers address this by offering eco-friendly solutions, with the use of biodegradable materials and reduced wastage of plastic polymers.

Additive manufacturing companies in India are committed to following sustainable practices through their 3d printing machines. Using recyclable materials and minimizing waste, aligns with the broader push for environmentally conscious manufacturing.

Global Support Networks and Maintenance Services: Top industrial 3D printer manufacturers establish global support networks. This ensures that businesses around the world have access to reliable support, maintenance services, and timely upgrades, fostering long-term partnerships.

Industry-Leading Reliability and Durability: Reliability and durability are paramount in industrial applications, and top manufacturers prioritize these aspects. Their industrial 3D printers are built to withstand the rigors of continuous operation, providing businesses with robust and dependable solutions.

In conclusion, industrial 3D printers are catalysts for change in the manufacturing landscape. From innovation and customization to sustainability and cost-efficiency, their contribution is reshaping how industries approach production and engineering challenges, paving the way for a future where industrial possibilities are limitless.

0 notes