#glue spreader rollers manufacturers

Text

Glue spreader rollers: Importance and Benefits for the manufacturing industry

In this industrial blog, we are going to highlight the glue spreader roller, its importance and benefits, and its advantages for the industry.

Before we take a deep dive into the business-centric subject, it makes sense to learn the basics of the roller.

What is a glue spreader roller?

A roller that has found usage in the manufacturing industry is designed for spreading glue. It is a cylindrical product engineered by using a sturdy core rod and well-fitted with brackets, bearings, and a solid frame. Coming to thickness and dimensions, the product is available in various standard dimensions. At the same time, a few glue spreader rollers manufacturers in India hold professional expertise to deliver custom-designed solutions. In the ensuing sections, we will talk about this vital feature of glue Spreader Rollers in India

With the emergence of innovative technology, glue spreader rollers’ manufacturing process has changed noticeably. It is in the interest of the manufacturing industry. Gluespreader rollers manufacturers in India are drawing benefits from the innovative technology. Bottlenecks that were persisting in the rollers have been addressed. Subsequently, the modern manufacturing industry rollers are more efficient.

Salient features of the glue spreader roller

A quality-driven industrial roller in Ahmedabad, India is recognized for a wide range of unique features. These include:

Requires less maintenance

Resistant to abrasion

Resistant to chemicals

High tensile strength

Resistant to wear and tear

Resistant to scratching and bumping

Width remains static

Excellent coefficient of friction

Quickly compensates for small changes that occur in the machine's precision

Always prefer a quality-driven product

Here it’s important to mention that quality matters a lot. A quality-driven product requires less maintenance and is durable. As a result, you don’t have to spend additional money on maintenance. Being an owner of a company, you require a quality-driven product, a product that requires less maintenance. Your production team doesn’t have to think time and again about the maintenance of the product. This allows them to focus on the production part, their primary goal.

Glue Spreader Rollers in India are known for quality and effectiveness. Yet don’t leave any stone unturned when you decide to purchase glue spreader rollers for your manufacturing company.

Application

Let’s now shift our focus towards the application segment of this blog. As the name indicates, the glue spreader roller is essentially designed for spraying the adhesive.

Used in spraying the adhesive

Industry

This technically sound product is designed for the Plywood-based industry.

Custom-designed glue Spreader Rollers in India

A few leading companies in Ahmedabad, India hold competency to design custom-designed solutions. Their team holds professional expertise in developing products in accordance with your industrial requirement, their team will develop rollers for your company. Every minute detail is shared with you for your reference. Unless the layout is approved by you and your production team, it is not permitted for production.

Let’s connect for a mutually beneficial partnership

Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credit.

"Excellence means setting benchmarks, without telling others", this adage has been at the center of our corporate strategy. Starting with mere two industrial rollers in the beginning, over the years we have grown to produce more than 100 types of industrial rollers.

Are you looking for glue spreader rollers? Don’t go further. End your search with Arvind Rubbers.

9 notes

·

View notes

Text

How do I apply marine adhesive?

Careful planning and close attention to detail are necessary while applying marine adhesive. The general procedures for using marine adhesive are as follows:

1.) The surface should be clean, dry, and free of dust, grime, and grease before you apply the marine adhesive. To properly clean the surface, use a cleaning agent that has been advised by the adhesive's producer.

2.) Apply the glue: On one of the surfaces you want to bond, spread a thin, even layer of marine adhesive. The glue can be applied with a spreader, roller, or brush. Apply enough adhesive to completely cover the surface.

3.) After applying the glue, assemble the components that you want to connect together. you prevent any misalignment, make sure you thoroughly align the components. For a few minutes, apply pressure on the components to ensure a solid bond.

4.) Allow the adhesive to cure: Per the manufacturer's directions, permit the adhesive to cure. Depending on the type of adhesive and the surrounding circumstances, this could take several hours or even longer.

5.) Cleaning: Use a solvent suggested by the manufacturer to remove any extra glue. Make sure to properly dispose of any garbage.

When using maritime adhesive, keep in mind to always read and adhere to the manufacturer's directions precisely. Additionally, before handling the glue, put on the appropriate safety gear, such as gloves and goggles. Buy water resistant wood glue for your wooden surfaces to enhance the productivity of your assets.

0 notes

Text

Glue Roller Applicator | Glue Spreader Roller Price

BKG Corrugating Rolls is an eminent Flute roller provider in India.BKG Corrugating Rolls Manufacturer, supplier, and exporter of best quality glue spreader rollers. We are making available superior quality glue spreader machine. We offer Glue Applicator Roller at the best price.

0 notes

Text

Cao Su Viet Industrial Rubber Products

Viet Rubber Co.,Ltd specializes in manufacturing all kinds of rubber products such as rubber roller, rubber sleeve, corona sleeve, seal & gasket, diaphragm, damping, etc.. based on NR, NBR, XNBR, HNBR, CR, SBR, EPDM, Viton, Silicone, Polyurethane, Hypalon.

cao-su-viet-industrial-rubber-products-lmt155

Feeding Wheels

cao-su-viet-industrial-rubber-products-lmt155

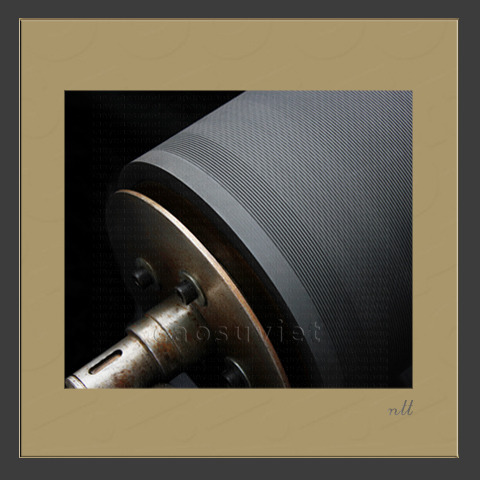

Glue spreader roller wood working machine

caosuviet | lmt

0 notes

Photo

whatsapp:+8618769900191

wechat: +8619953900191

email: [email protected]

www.lymhmachinery.com

Hello dear... This is Mark Zhai from Linyi Jianzhong Machinery CO., Ltd, and we have more than 20 years' experience in woodworking machines and plywood production lines.

Our Plywood machine production including: 1. 4ft*8ft wood log debarker/barker for peeling and rounding; 2. 4*8ft veneer peeling machine/wood veneer slicing machine for processing wood into veneer, it has two types, one is spindleless peeling machine which has single side driving and double sides driving, common speed and fast speed, another is spindle peeling machine, especially for peeling big diameter’s wood, these two types veneer peeling machine can peel kinds of hardwood and soft wood, and make sure veneer thickness is balance and accurate; 3. veneer core dryer machine, which remove the abundant moisture, we have press veneer dryer, and roller dryer; 4. glue spreader machine/coating machine, which has 3feet 6feet 4feet 8feet, has single side and double sides; 5. plywood veneer paving machine line, which paving veneer into plywood size, it is convenient for making plywood; 6. plywood hydraulic cold press machine/pre-press machine, has 400t, 500t or according to your needs to produce; 7. plywood hydraulic hot press machine/thermal oil or steam heating press machine, has 400t 500t 600t 800t 1200t 1600t or customized according to your needs, and has 10 layers, 12layers, 15layers, 18layer, 20layers, 25layers, 30layers; 8. automatic sawing machine/dd saw/plywood edge cutting machine/plywood edge trimming machine for repair the four sides of plywood, it is easy operate and high efficiency, is one necessary machine for plywood making; 9. High-precision plywood sanding machine for polishing and calibrating, we have wide belt, two heads or three heads, and have different weight and power, it will be manufactured according to your conditions. 10. plywood turnover machine/over turn board machine, usually used with plywood sanding machine, its angle is 180°, save labor; 11. lift table/scissor lift/lift platform, usually for plywood hot press machine, sanding machine, glue spreader, and dd saw, its max height can be 2m, can loading 3-4t.

#plywood machine manfacturer#plywood machine#plywood machinery#plywood machines#Plywood Veneer#plywood#woodworking machines#wood working machine

0 notes

Text

Glue Spreader Machine

We are leading Glue Spreader Machine. It is commercial model & is suitable for all type of plywood industires. The is simple in working & machine is fitted with four rollers. Rollers are fitted with double ball bearing Brackets. Heavy Duty M.S. Fabricated Frame & Body.

Glue Spreader Machine

With thumping feet, we are marching ahead in the domain as manufacturer and exporter of Glue Spreader Machine and Heavy Duty Glue Spreader.

http://www.jamunaengineering.com/Glue-Spreader.html

Contact Person : Mr. Sandeep Singh Sehmi (Director)

Phone No. : +91-1732-252531

E-mail : [email protected]

Fax : +91-1732-252530

Address : Workshop Road, Near I.T.I., Yamunanagar - 135001, Haryana, India

0 notes

Text

Manufacturing industries in plenty count on industrial rollers

The title of the article says it all! Industrial rollers are the backbone of the manufacturing sector. Industries cutting across domains and verticals rely on the product to perform a wide range of applications flawlessly.

Scientific innovation and evolution have played a critical role in shaping the transformation of rollers, from leather, wood, and metal, the product has gone for a sweeping change. Metal and rubber bonding has been instrumental in the evolution of an innovative range, the rubber roller or the industrial rubber roller. Metal remains at the nucleus, while rubber endures the brunt of the surface contact and force of friction.

In this concise blog, I’m striving to bring forth the significance and unique features of industrial rubber rollers. I’m quite sure; the humble attempt will expand the knowledge base of many!

What's the industrial roller

An industrial is a metallic shaft, cylindrical in shape. The shaft could be made up of aluminum, steel, and hosts of other materials. The metallic shaft is provided with the requisite covering. Based on the covering, the industrial rollers are named. A metallic shaft with a rubber covering is called a rubber roller.

Types of industrial rollers

Depending on the metallic coating, industrial rollers have been classified into various types, these include a Rubber Roller, Ebonite Roller, Guide Roller, Teflon coated Roller, Glue spreader Roller, HCP Roller, and Nip Noller among others.

Quality parameters

Industrial rollers are identified with impeccable features. The industrial Rollers manufacturers, India adhere to a stringent quality policy to ensure quality as per the market standards. A few of the prominent parameters include:

It should be stable and non-reactive

The material of the roller should be firm and stable

The surface of the roller should be uniform

Precision driven dimension should be there

Performance should be measured on industry parameters

Industrial Applications

Industrial rollers are phenomenal. They are being leveraged to perform a wide range of industrial applications, including:

Gravure printing (Printing)

Flexo graphic printing (Printing)

Solventless lamination (Lamination)

Eliminates wrinkle

Removes slack edges

Dye stuff

Rubber roller

The evolution of rubber rollers has been a defining moment for the manufacturing industry. Their characteristics are suitable for a wide gamut of industries. The rubber roller is an obvious choice for the manufacturing industry. Rightly so. While metal is inclined to corrosion, on other hand, rubber is resistant to corrosion and harsh weather conditions. Since the rubber is agile in nature, it withstands heavier weights.

Here are a few unique features of the product:

Doesn’t undergo any chemical reactions, therefore the shaft shape remains intact

Resistant to distortion. Comes back to its original shape

Embedded with high friction coefficient, makes it ideal for industry

Surface quality is resistant to scratching

Doesn’t require any specific professional training to use and install

Printing Rubber Rollers

The industrial roller is tailor-made for gravure printing and flexo printing to name a few. The printing rubber rollers are being leveraged in several industries, including paper, textile, and printing among others.

Source: https://arvind-rub-web-controls-limited.blogspot.com/2021/06/industrial-rollers-are-backbone-of.html

14 notes

·

View notes

Text

Durable and affordable range of Glue Spreader Rollers

Glue spreader roller the most prominent part of plywood industry are manufactured, supplied and exported by Arvind rubbers. We are the dealer of affordable and high-quality glue spreader roller from Ahmedabad.

Features:

Our glue spreader rollers are available in both standard and customized sizes. Mainly used to spray the adhesive in the plywood industry these Sturdy rollers are known for their unmatched quality and durable finish standard. The rollers manufactured by us are super easy to install and offer excellent speed without needing high maintenance.

Source:

https://arvind-rub-web-controls-limited.blogspot.com/2019/10/durable-and-affordable-range-of-glue.html

7 notes

·

View notes

Text

Glue Spreader Rollers for Plywood Industry

Arvind rubber is one of the most trusted manufacturers, supplier and exporter of Glue spreader rollers in India. This roller is widely used in the plywood industry. The rollers are well-fitted with brackets and bearings and solid frame.

Customized range:

We deal in a wide range of glue spreader rollers. Our rollers are designed as per the client’s requirement. Thickness and dimensions may vary as per the use. Our international quality rollers are known for their durability and long life.

Source:

https://arvind-rub-web-controls-limited.blogspot.com/2019/06/glue-spreader-rollers-for-plywood.html

7 notes

·

View notes

Photo

glue spreader machine for plywood making coating machine

whatsapp: +8618769900191

wechat: +8619953900191

email: [email protected]

web: www.lymhmachinery.com

Hello dear... This is Mark Zhai from Linyi Jianzhong Machinery CO., Ltd, and we have more than 20 years' experience in woodworking machines and plywood production lines.

Our Plywood machine production including: 1. 4ft*8ft wood log debarker/barker for peeling and rounding; 2. 4*8ft veneer peeling machine/wood veneer slicing machine for processing wood into veneer, it has two types, one is spindleless peeling machine which has single side driving and double sides driving, common speed and fast speed, another is spindle peeling machine, especially for peeling big diameter’s wood, these two types veneer peeling machine can peel kinds of hardwood and soft wood, and make sure veneer thickness is balance and accurate; 3. veneer core dryer machine, which remove the abundant moisture, we have press veneer dryer, and roller dryer; 4. glue spreader machine/coating machine, which has 3feet 6feet 4feet 8feet, has single side and double sides; 5. plywood veneer paving machine line, which paving veneer into plywood size, it is convenient for making plywood; 6. plywood hydraulic cold press machine/pre-press machine, has 400t, 500t or according to your needs to produce; 7. plywood hydraulic hot press machine/thermal oil or steam heating press machine, has 400t 500t 600t 800t 1200t 1600t or customized according to your needs, and has 10 layers, 12layers, 15layers, 18layer, 20layers, 25layers, 30layers; 8. automatic sawing machine/dd saw/plywood edge cutting machine/plywood edge trimming machine for repair the four sides of plywood, it is easy operate and high efficiency, is one necessary machine for plywood making; 9. High-precision plywood sanding machine for polishing and calibrating, we have wide belt, two heads or three heads, and have different weight and power, it will be manufactured according to your conditions. 10. plywood turnover machine/over turn board machine, usually used with plywood sanding machine, its angle is 180°, save labor; 11. lift table/scissor lift/lift platform, usually for plywood hot press machine, sanding machine, glue spreader, and dd saw, its max height can be 2m, can loading 3-4t.

#glue spreader machine for plywood making#glue spreader for plywood making glue coating for plywood making#4feet glue spreader glue spreader#8ft Veneer Glue Spreader 8ft single glue spreader 8ft double glue spreader#2700mm glue spreader#600mm1400mm2700mm single /double surface glue spreader#glue spreader#hot glue#4roller glue spreader#plywood veneer glue spreading machine#glue coater machine#wood gumming machine#wood veneer glue spreader#8feet double glue spreader#plywood core veneer drying machine for plywood making#plywood veneer glue spreader#glue blender for chipboard#gluing spreader machine for panel board production#glue coater#double side glue spreader#plywood making glue spreader machine#2700mm single glue spreader#2700mm double glue spreader#8ft glue spreader#9ft glue spreader#woodworking machines#woodworking machine roller glue spreader for plywood coreboard

0 notes

Video

2600mm veneer rotary peeling machine for wood veneer peeling line veneer slicing machine

whatsapp: +8618769900191

wechat:+8619953900191

email: [email protected]

web: www.lymhmachinery.com

Hello dear... This is Mark Zhai from Linyi Jianzhong Machinery CO., Ltd, and we have more than 20 years' experience in woodworking machines and plywood production lines.

Our Plywood machine production including: 1. 4ft*8ft wood log debarker/barker for peeling and rounding; 2. 4*8ft veneer peeling machine/wood veneer slicing machine for processing wood into veneer, it has two types, one is spindleless peeling machine which has single side driving and double sides driving, common speed and fast speed, another is spindle peeling machine, especially for peeling big diameter’s wood, these two types veneer peeling machine can peel kinds of hardwood and soft wood, and make sure veneer thickness is balance and accurate; 3. veneer core dryer machine, which remove the abundant moisture, we have press veneer dryer, and roller dryer; 4. glue spreader machine/coating machine, which has 3feet 6feet 4feet 8feet, has single side and double sides; 5. plywood veneer paving machine line, which paving veneer into plywood size, it is convenient for making plywood; 6. plywood hydraulic cold press machine/pre-press machine, has 400t, 500t or according to your needs to produce; 7. plywood hydraulic hot press machine/thermal oil or steam heating press machine, has 400t 500t 600t 800t 1200t 1600t or customized according to your needs, and has 10 layers, 12layers, 15layers, 18layer, 20layers, 25layers, 30layers; 8. automatic sawing machine/dd saw/plywood edge cutting machine/plywood edge trimming machine for repair the four sides of plywood, it is easy operate and high efficiency, is one necessary machine for plywood making; 9. High-precision plywood sanding machine for polishing and calibrating, we have wide belt, two heads or three heads, and have different weight and power, it will be manufactured according to your conditions. 10. plywood turnover machine/over turn board machine, usually used with plywood sanding machine, its angle is 180°, save labor; 11. lift table/scissor lift/lift platform, usually for plywood hot press machine, sanding machine, glue spreader, and dd saw, its max height can be 2m, can loading 3-4t.

#2600mm veneer rotary peeling machine for wood veneer peeling line#veneer peeling#Plywood Veneer#plywood veneer machine#plywood veneer paving machine production line#plywood machine#plywood machinery#plywood machines#core veneer peeling machine line#core veneer peeling line#wood log cutting machine#veneer slicing machine#wood slicing machine#wood slicpper machine for veneer making#woodworking#clipping#wood veneer peeling rotary slicing machine#veneer peeling and clipping combined machine#Wood Slicing vertical veneer slicer machine ARO veneer machine#Wood Veneer Rotary Peeling Machine#spindle less veneer rotary lathe#plywood manufacturing process#wood rotary veneer clipper rotary veneer lathe rotary veneer cutting machine#8 feet spindleless wood log veneer rotary peeling lathe machine#4ft rotary veneer lathe#1300mm Wood veneer cutting machine#2600mm Wood veneer cutting machine#wood log cutting machine 8ft spindle wood veneer peeling machine CNC Spindle less Veneer Peeling combined clipping machine#rotary veneer clipper#rotary veneer lathe

0 notes

Video

youtube

plywood manufacturing process

Here is the process of making Triplex /Multiple plywood/building Wood Plywood /Furniture plate/ Plywood timber companies, Start scraping at Rotary, Fresh Dryer, Repair Place, Fresh Joint, Glue spider, Cold Press, Hot Press, Finishing, Shipping, for those of you who have never known possible Video this can add your insight and hopefully useful

my email is [email protected] [email protected] mobile: 0086 18769900191, wechat:008615966433391

Full automatic plywood making machine production line-

Jianzhong

machinery

Hello dear... This is Mark Zhai from Linyi Jianzhong Machinery CO., Ltd, and we have 20 years' more experience in woodworking machines and lines, if you are interested in our plywood machine, please feel free to let me know, web: www.lymhmachinery.com. Email: [email protected].. Mobile: 8618769900191

Used Plywood Machine

Shandong Linyi JIANZHONG Woodworking Machinery Manufacturing CO.,LTD

From veneer gluing to sanding,you can see how Chinese people to produce plywood!

It is a video for who want to establish a plywood factory,just seeing and hoping you can like it!

Производство фанеры Plywood

Производство фанеры Plywood

Plywood machine log rotary peeling Lathe machine,Automatic peeling production line,

Log Debarker Machine / Log Roundup Machine

DEBARKER MACHINE & ROUND-UP MACHINE JEC1400. THIS IS THE NEWEST MODEL LOG DEBARKER FOR SPINDLELESS CORE VENEER PEELING & ROTARY LOG PEELING MACHINE. IT CAN BE INSTEAD OF ROSSER HEAD LOG DEBARKER. IT CAN BARK THE SKIN OF THE LOG AND THEN MAKE THE LOG ROUND, IT WILL BE MORE CONVENIENT FOR SPINDLE LESS VENEER PEELING LATHE & OTHER PEELING MACHINE TO PEEL THE LOG. THE TOOL CARRIAGE IS DRIVEN BY HYDRAULIC CYLINDER, SO CAN MAKE THE ENOUGH EXTRUDING PRESSURE TO HOLD THE LOG CAN BARK IT. THE OPERATOR ONLY NEEDS TO CONTROL THE HANDLE IN THE FRONT CONTROL PANEL, THEN CAN ADJUST THE TOOL CARRIAGE FORWARD AND BACK. PARAMETER MODEL JEC1400 LENGTH OF THE BALDE(MM) 1400 MAX. DEBARKING LENGTH(MM) 1400 HYDRAULIC STATION POWER(H.P) 3 MAIN MOTER(H.P) 15 DIMENSION OF DEBARKING MACHINE(MM) 2800× 1795× 1350

my email is [email protected] [email protected] mobile: 0086 18769900191, wechat:008615966433391

Plywood Flooring - An inexpensive alternative to hardwood floors (

Plywood flooring? Check out this inexpensive alternative to traditional wood flooring that you can do for half the cost. This is part one of this project, more to come soon!!!

Ever wondered how plywood is made?

my email is [email protected] [email protected] mobile: 0086 18769900191, wechat:008615966433391

film faced plywood production process

surface overlaid laminated board production line

Melamine press/Pre-lamination board machine/Melamine presses

Auto loading machine for plywood hot press /plywood loader for hot press

Breath (Press) Type Veneer Dryer

Breath (press) type veneer dryer is the economic veneer dryer which can be used for processing core and face veneer for plywood industry. It adopts the priciple like hot press machine (plywood machine). The one drying section, which will has 3 working cycle; during the cycles the machine will exhaust the hot steam ( made from the moisture in the veneer) and leak the water out from the small groove on the surface of the platen. It is different with some steel pipe type one. Through using this machine, the veneer will be dried into the rated moisture and the final workpiece will be more flat than other one; it occupies little space. If you need more details about this machines, pls feel free to contact me!

my email is [email protected] [email protected] mobile: 0086 18769900191, wechat:008615966433391

The first step in the hardwood plywood manufacturing process—the dryer—is one of the most crucial for producing quality inner-plies. Timber Products Company's Medford Complex general manager John Wasniewski explains how important it is that every piece of softwood veneer is dried to the correct moisture content level to insure quality and performance. As attractive as it is versatile, hardwood plywood reflects nature's understated beauty alongside technological breakthroughs. Timber Products Company has pioneered hardwood plywood manufacturing, and we create products that are unrivaled in quality, craftsmanship and environmental responsibility.

my email is [email protected] [email protected] mobile: 0086 18769900191, wechat:008615966433391

Hardwood Plywood Series - The Drying Process

Veneer Jointing and Bonding-Production Process of Construction Plywood

Hot Pressing-Production Process of Concrete Forming Plywood

How It's made — Plywood production line

Making Thin High Quality Plywood

Manufacturing plywood boards

Veneer Jointing and Bonding-Production Process of Construction Plywood

automatic full sets plywood equipment production line

plywood hot press ,plywood cold press,plywood glue spreader ,plywood core veneer composer ,plywood veneer paving machine,plywood veneer sewing machine,plywood cutting saw machine ,plywood turnover machine,plywood sanding line machine,plywood lift table ,veneer peeling machine ,log debarker ,ect ,plywood equipment production line ,

my email:[email protected]

whatsapp:008618769900191

Plywood machine log rotary peeling Lathe machine,Automatic peeling production line,

Plywood machine: glue spreading,high quality hot press, cold press, CNC automatic four sides saws(DDS),High-precision sanding machine, spindleless or spindle peeling machine, veneer drying machines, lifts-platform For MDF / particle line: Drum chipper,ring flaker,dryer machine, screener,glue blender,forming machine,multi rollers prepress,hot press,mats cross saw,cooling start,edge trimming saw,4 heads polishing sander plywood machine service centre supply for you: 1. 4 feet or 8 feet veneer peeling machine 2. full of plywood machine, including: glue/cold press/hot press/DD SAW/ sanding machine and so on 3. full of mdf production line and partical board line. 4.Auto block board production line. 5. produce fancy plywood technology 6.produce melamine plywood technology 7.produce melamine paper technology 8.Full set of incense equipment 9.Woodworking engraving equipment 10.Furniture surface treatment equipment we not only export machine and equipment.We also provide technical services for 7X24.

face veneer dryer machine, fire wood veneer drying machine, dryer machine for face veneeer

we upload this machine's working video for promote our machine, if you are interested in our machine, please feel free to contact with us, my email is [email protected] [email protected] mobile: 0086 18769900191, wechat:008615966433391

Face veneer dryer machine, veneer drying machine for sell

this is jack lee from china geelong machinery manufacture company limited, and we are face veneer, core veneer dryer machine producer, glad to have an opportunity to cooperate with you, my email is [email protected] what's app: 008618769900191 008615966433391 if you are interested in our machine, please feel free to contact with me, my website: www.lymhmachinery.com

8ft Spindle Veneer Peeling Lathe Max Dia 1000 -2000 mm

Spindle Veneer Peeling Lathe for 2600mm logs , thickness 0.2-3.0 mm , max diameter up to 2000 mm , for hardwood . Contact me by phone no./ whatsapp : 008618769900191 +8615966433391 ,email :[email protected] if you are interested .

2600mm spindle less face veneer peeling lathe--- whatsapp: 0086

18769900191 008615966433391

Yimeng jianzhong Machinery Manufacturing Co.,Ltd is specializing in manufacture spindle less veneer peeling machine, wood debarking machine and other plywood machines in China. There is a wide variety of our products, including 2ft, 4ft, 5ft, 6ft, 8ft ,9ft and 10ft, special demands also can be meet. If you have such requirement, welcome to contact us.

my email is [email protected] [email protected] mobile: 0086 18769900191, wechat:008615966433391

8ft spindleless lathe peeling 0 3mm face veneer

Veneer Peeling Machine-Professional Veneer Peeling Machine Factory 8ft spindleless lathe peeling 0 3mm face veneer

Yimeng jianzhong Machine Co., Ltd. Contact: whatsapp:008618769900191 wechat:008615966433391

E-mail: [email protected]

Rotary plywood log spindleless veneer peeling machine

Hello dear...This is Mark Zhai from China yimeng jianzhong wood machinery co., ltd, and we are plywood veneer peeling machine supplier, glad to have an opportunity to cooperate with you, if you have further questions about our machine, please feel free to contact with me via email: [email protected] [email protected] mobile: 0086 18769900191, wechat:008615966433391

spindle-less face veneer rotary peeling machine M-

008618769900191 wechat:008615966433391

Quality high quality wood spindle peeling machine / face veneer slicing machine ... Diameter of peeler log mm Maximum Length: 1300-2600mm(4ft-8ft); Max Processing Dia: 350mm Rotary cutting ... Quality Spindle less peeling machine/lathe/ Veneer peeling machine/ ... Quality manufacture 8ft spindless veneer peeler/log peeling machine Manufacturer By jianzhong wood machinery co.,ltd, M- 008618769900191 www.lymhmachinery.com AN ISO 9001: 2008 E-mail: [email protected] website: www.lymhmachinery.com Manufacturer of – Core Dry Machines Core Dry is an automatic system for rapid drying Machine Veneer generated by peeling machine Hydraulic Power Unit Electric Panel Plywood Machine Hydraulic press Peeling Machines Core Dry machines Hydraulic Ply Press Bioler Machine spindle-less 8 ft face veneer rotary peeling machine

waste plywood jointing machine,veneer splicing machine

waste plywood jointing machine woodworking machine,log debarking rounding and peeling cutting machine all in one plywood making machine log peeling machine line log debarker CNC veneer peeling lathe,veneer clipper,rotary log peeling machine spindle less log peeling machine automatic peeling cutting veneer and unload the rest roller automatic

my email is [email protected] [email protected] mobile: 0086 18769900191, wechat:008615966433391

Hydraulic hot press machine/plywood heat hot press machine

hydraulic heat press machine/plywood hot press machine ,hydraulic hot press for plywood/ hot press machine made in china. plywood production line..

my email is [email protected] [email protected] mobile: 0086 18769900191, wechat:008615966433391

Auto loading machine for plywood hot press /plywood loader for hot press

Hot press dryer for plywood veneer --

CHINA

Continuous veneer dryer Mesh belt veneer dryer N --Decks Mesh belt veneer dryer Veneer dryer with N layers Net-belt veneer dryer Veneer dryer machine Stainless steel mesh-belt veneer dryer Veneer roller dryer Roller type veneer dryer Mesh-roller combined veneer dryer Thanks for your attention to our JIANZHONG WOOD MACHINERY, our main business is Plywood Machinery, more information from our , any matters pls contact us freely. Company name: JIANZHONG WOOD MACHINERY Website: www.lymhmachinery.com Contact number: 008618769900191 wechat:008615966433391E-mail:[email protected]

Veneer Jointing and Bonding-Production Process of Construction PlywoodVeneer Jointing and Bonding-Production Process of Construction Plywood

poplar veneer core prdouction design for good quality plywood

Poplar core veneer stitching machienry ,smooth surface ,less gaps ,good quality plywood only

Core bulider/veneer stitching machine /veneer splicing machine from China

Automatic Core bulider/veneer stitching machine /veneer splicing machine from China factory direct . This machine is used for splicing the core veneer into longer veneer with thread and glue ,this machine is widely used for veneer production plant ,very popular in Southeast Asia countries like Vietnam ,Malaysia, Indonesia ,India and Thailand etc . *Automatic model ,PLC computer control ,only need one operator ,labor saving . *High precise test ,making minimum waste ,guarantee the maximum profit *Servo accurate position system . *Using TAIWAN DELTA ,German SIEMENS ,JAPAN MITSUBISHI parts ,high quality guaranteed . Website:

www.lymhmachinery.com

Contact Person:Mark Zhai Contact whatsapp and wechat number: 008618769900191 wechat:008615966433391 E-mail:www.lymhmachinery.come�fDn9�Lg

0 notes

Video

youtube

glue spreader 4feet glue spreader glue spreader

whatsapp:+8618769900191

wechat :+8615966433391

[email protected]

Plywood Manufacturing Process

600mm,1400mm,2700mm single /double surface glue spreader

8ft Veneer Glue Spreader 8ft single glue spreader 8ft double glue spreader

8feet glue spreader 8feet single glue spreader 8feet double glue spreader

2700mm glue spreader 2700mm single glue spreader 2700mm double glue spreader

wood veneer glue spreader/plywood veneer machine

glue spreader for woodworking

Heavy Duty Double side Four roller Glue spreader for plywood core veneer

Heavy Duty Double side Four roller Glue spreader for plywood core veneer

wood veneer glue spreader/double surface gluing machine

Panels Machinery Wood Core Veneer Glue Spreading Plywood Glue Spreader

#glue spreader#4feet glue spreader glue spreader#Plywood Manufacturing Process#600mm1400mm2700mm single /double surface glue spreader#8ft Veneer Glue Spreader 8ft single glue spreader 8ft double glue spreader#2700mm glue spreader#8feet single glue spreader#8feet double glue spreader#2700mm single glue spreader#2700mm double glue spreader#wood veneer glue spreader#plywood veneer machine#glue spreader for woodworking

0 notes