#flexiblepipe

Photo

Arçek Automotive DAF SPARE PARTS, IVECO SPARE PARTS, MAN SPARE PARTS, MERCEDES SPARE PARTS, RENAULT SPARE PARTS, SCANIA SPARE PARTS, VOLVO SPARE PARTS, CALIPER REPAIR KITS, CALIPER, AUTOMATIC SLACK ADJUSTER, FLEXIBLE PIPE, WATER PUMP Detaylar için sitemizi ziyaret edin------> www.otomotivmagazin.com Visot our site for details-------> www.automotivesparepartsturkey.com #otomotiv #otomotivyedekparça #automotive #automotivesparepartsturkey #dafspareparts #ivecospareparts #mercedesspareparts #renaultspareparts #scaniaspareparts #volvospareparts #caliperrepairkits #calipers #automaticslackadjuster #flexiblepipe #waterpump #waterpumps #truckspareparts #treyler #truck @arcekexport @otomotivmagazin https://www.instagram.com/p/BtqbLsEAjqR/?utm_source=ig_tumblr_share&igshid=1v690vzo6yozn

#otomotiv#otomotivyedekparça#automotive#automotivesparepartsturkey#dafspareparts#ivecospareparts#mercedesspareparts#renaultspareparts#scaniaspareparts#volvospareparts#caliperrepairkits#calipers#automaticslackadjuster#flexiblepipe#waterpump#waterpumps#truckspareparts#treyler#truck

1 note

·

View note

Photo

From VIP conduit pipes to all types of accessories you can now buy at Eleczo.com

#Eleczo#Bangalore#bengaluru#pvcpipes#conduitpiepes#flexiblepipes#electricalpipes#lelectricalsafety#electricalproducts#electricalindustry

1 note

·

View note

Text

Thermoplastic Hose Pipe Manufacturer - Dks Enterprises

https://dksenterprises.in/thermoplastic-hose.php

Contact Us : 09711764803 / 09873197789 / 011-40831403

#suctionhosepipe #safetyfirst #digitalmarketing #bansari #industrialhosepipe #bansarineterprise #garden #cpvcpipe #firesafety #flexiblepipe #valve #hose #fire #safeindia #dogsofinstagram #sieverttorch #tconnector #coupling #dog #tconnect #bully #hosepipefittings #lpgconnection #firefighter #torchburners #gasconnection #likeus #inktober #msme #entrepreneur

0 notes

Text

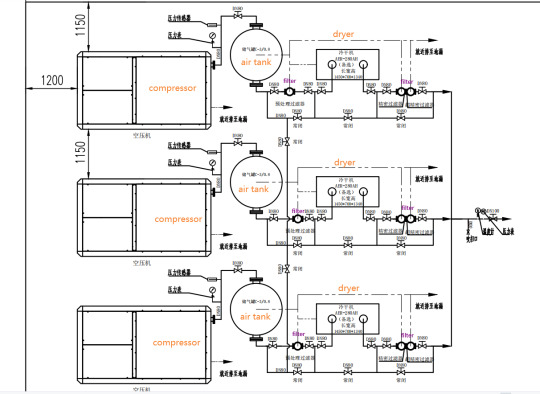

The latest FSTpipe aluminum alloy superpipe application case sharing:

Optical fiber manufacturing, optical communication equipment manufacturing industry

The air compressor room uses DN80 pipes and DN100 summary pipes, which are connected to the workshop stainless steel welded pipes through flanges.

#pipework #pipeworks #airpipingsystem #compressorroom #pressurecontrol #flexiblepipe #airleak#clampconnection #installationwork #tools #airtools #manufacturing

#compressedair #compressed #airpipe #dn100 #followus #dn80 #comment #100mm #pipingsystem

0 notes

Link

PVC flexible pipe connectors, pvc flexible pipe sizes, pvc flexible pipe coupling, resistant to weather flexible pipe conditions, High Quality flexible pipe.

0 notes

Text

Extending Design Life, Improving Integrity of Flexible Pipe

Chris Saunders, MCS

As exploration moves into ever deeper and more complex fields, the need for flexible pipe increases. Given that the use of flexible pipe is relatively recent and the analysis is therefore fairly limited, its integrity has largely been monitored by visual inspections carried out by ROV operations.

Visual inspection shows only the damage already done. It does not provide preventative measure to reduce the risk of failure. Emerging new technologies, such as annulus testing, can improve the integrity of flexible pipe, reduce costs, and extend their original design life.

During 2002, UKOOA issued guidance entitled “Monitoring methods and integrity assurance for unbonded flexible pipe.” Since then, as the use of flexible pipe has increased, a number of lessons have been learned in management and on-going operation of flexible pipes.

Growth in the use of flexible pipe.

These guidelines should be updated to include the data on reasons for failure and lessons learned. This would allow the industry to challenge the inspection strategies currently used as well as to identify emerging technologies as alternative solutions.

Given the advances in flexible pipe analysis, some of which were developed under the RealLife JIP, MCS demonstrated that through proper asset management, flexible pipe technology service life can be extended beyond the original design criteria. Similarly, flexible pipe previously considered damaged and in need of early replacement may be justified for extension to beyond original design life.

Since the mid-1980s, there has been exponential growth in the use of flexible pipe. Given that most flexible pipe systems are designed with a 20-25 year service life, only a small percentage in operation are close to this service life.

Should flexible pipe failure rates follow the typical “bath-tub” analysis curve, it is possible that the type and quantity of flexible pipe damage/failure mechanisms will increase in the future.

Percent of flexible pipes nearing the end of service life.

Examining the main causes of damage shows the percentage of “internal sheath pull-out” incidents is down. This is due to a historical failure mode associated with early PVDF design structures, identified around 1995, and subsequently designed out.

There also has been a reduction in the number of “aged internal pressure sheath” incidents. This can be explained by improved industry knowledge regarding the recommended operating restrictions for polymers.

Another significant variation is related to “external sheath damage” where there has been a marked increase in the number of occurrences. This is difficult to explain in terms of changes in flexible pipe operation. However, one explanation is the increase in vacuum testing and other monitoring and inspection techniques for the annulus which make it possible to identify external sheath damage.

A significant proportion of external sheath damage occurs during installation. There is clear potential for this to be improved with better installation procedures.

Main causes of damage to flexible pipe.

To date, general visual inspection (GVI) of flexible pipe has been key in maintaining its integrity. However, operators are increasingly questioning the value of frequent GVI to their integrity management strategy.

The main advantages of GVI are the ability to confirm general layout and configuration, to identify gross riser/ancillary equipment damage, and to provide inspection results which can be clearly interpreted.

The main disadvantages are that it is difficult to identify small outer sheath leaks, annulus flooding from venting systems is not identified, no inspection of internal layers is possible, there are environmental limits (especially shallow work), limited inspection contractor expertise for flexible pipe, and a requirement for ROV support vessel or DSV when vessel costs and availability are real issues.

External sheath damage would appear to be the most obvious damage to be spotted by periodic GVI. However, the reality of flexible pipe operation means that it is only possible to identify reasonably large areas of damage from the video footage. In conjunction with this, experience has shown that relatively small areas of damage can cause significant problems.

In addition to this, it is MCS’ experience that areas of potential damage are routinely identified during GVI but upon closer inspection are only surface staining. This has a significant cost implication for the operator, who will invariably have to undertake close visual inspection (CVI) using either diver or ROV.

The second reason for flexible pipe damage is aging of the internal pressure sheath. GVI can only identify damage that has already reached the point where it can be difficult to manage. For example, when fluid release by the pressure sheath has aged to an extent where is visible externally, it makes the pipe unserviceable.

There is a need for GVI with flexible pipe systems due to regulatory requirements and to identify other damage/failure mechanisms such as those associated with ancillary equipment, e.g. loss of mid-water arch buoyancy, buoyancy clamp slippage, tether failures, etc.

The main areas of concern with ancillary components are the bend stiffener, buoyancy module, mid-water arches, clamps, and tethers. Even here, data quality can be increased and costs can be reduced with innovative approaches. For example, the FPSO turret area is difficult for an ROV to inspect due to surface waves, currents, and congestion. An alternative might be to deploy a fixed controllable camera below the turret. This allows inspection as frequently as desired and without ROV support.

Operators spend £30,000 and £200,000 ($61,411 and $409,410) per flexible per annum on GVI. This variation is due to a number of reasons, including:

Small number of flexible pipes in the field which can increase the costs of vessel mobilization per riser

Level of integrity management strategy optimization. An optimized integrity management strategy allows the operator to target inspection in the high risk locations most frequently

Uptake of alternative integrity management tools instead of GVI

Age of the asset

Operator / regulator attitude to risk.

Depending on the operator strategy in use, it is possible for operators to reduce their annual inspection costs for flexible pipe. This can be achieved by:

Developing and maintaining an integrated integrity management strategy, which incorporates the use of focused GVI and alternative assessment / inspection techniques

Using GVI in high value reward situations, where the data recovered can be used to identify specific types of damage, e.g. ancillary equipment

Considering integrity management at the asset procurement and design stage to incorporate available online monitoring techniques which are difficult and expensive to retrofit

Using previous operational experience at the design stage

Development and use of detailed inspection manuals for the inspection contractor, providing examples of as-built state, as last-observed state, typical anomalies, and definition of records required for each type of new anomaly.

One significant way manage to the integrity of flexible pipe can be by assessing the annulus environment. There are a number of techniques to accomplish this, including vacuum testing, pressure build-up testing, gas sampling, and online monitoring. Each provides benefits and levels of information. Increasingly, combinations of these strategies are being adopted. The key to all these techniques is that they measure the flexile pipe annulus properties to identify changes such as the presence of seawater/water, H2S and CO2 composition, gas permeation rates, and “unflooded” volume in the annulus. Through the correct analysis of this data, it is possible to determine the presence of external sheath damage, topside flooding, and pressure sheath aging which then can direct further investigation.

There are limitations to annulus testing such as the potential to pull water in to the annulus and the perceived inability to assess riser systems with hog and sag bends. But these are minimal compared to the value of knowing whether or not there is a breech in the external sheath.

It still is important to confirm the layout of flexible pipe subsea. However, this does not necessarily require the level of GVI which is currently being employed. To demonstrate that the layout has not changed significantly, a survey from an increased distance covering a number of flexibles may be sufficient. Equally, it is common practice during GVI on flexible pipe to survey both sides of the structure. If external sheath damage is being assessed by alternative techniques, it could be argued that this is not necessary. This alone would reduce GVI time for flexibles by 50%.

Operators look to extend the life of flexible pipe assets. To determine whether life extension is feasible, analysis of the flexible pipe history is required. This generally includes assessment of fatigue (in which annulus condition is of paramount importance), polymer aging (based upon coupon samples, operating pressures and temperatures and chemical injection data), and anomalies identified from GVI.

Given a proper asset integrity management strategy, that is, one in which data is collected diligently and anomalies are identified and understood, there is potential to use the methodologies defined as part of the RealLife JIP to derive an accurate assessment of flexible pipe fatigue damage rate. This generally results in an extension to previously calculated fatigue lives. The single caveat to this is that the methodologies that were used to calculate fatigue life at the design stage must have incorporated the effects of resonant frequency response on the flexible pipe system. Using RealLife methods with a proper asset integrity management results in an accurate and balanced value for the flexible pipe fatigue life.

Source: http://www.offshore-mag.com/articles/print/volume-67/issue-11/construction-installation/extending-design-life-improving-integrity-of-flexible-pipe.html

0 notes

Link

IPLUK offers Plastic Ducting which is made for plastic industry along with this Flexible Pipe. These Plastic Ducting is with different features used for various applications in UK.

0 notes

Text

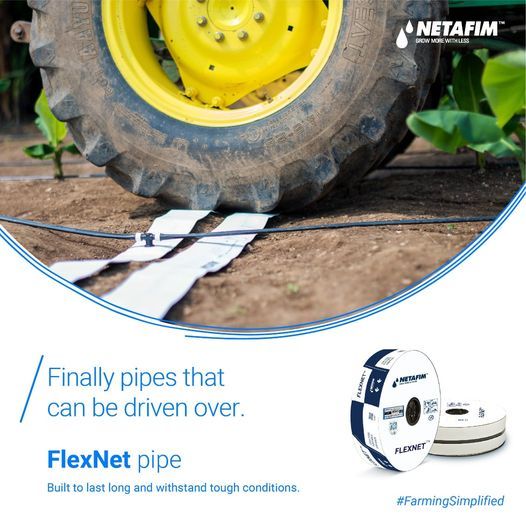

FlexNet - Netafim Flexible Pipes - Netafim India

FlexNet - Netafim Flexible Pipes - Netafim India

Netafim India, a leading smart irrigation solution provider, has launched FlexNet. FlexNet Flexible Pipe is the newest innovation in sub-mainline distribution pipe from Netafim. FlexNet is the only leak-proof flexible piping in the industry.

FlexNet™ Benefits:

FlexNet™ is a prudent choice! A little investment translates into several sustainable benefits that keep you away from the hassles of investing in changing pipes time and again.

visit us https://www.netafimindia.com/products-and-solutions/product-offering/flexible-and-pe-pipes/flexnet/

0 notes

Text

Flexible Pipe : HDPE Pipe

HISTORY

High Density Polyethylene (HDPE) is a versatile plastic that has many practical uses, not the least of which is for the fabrication of pipe.

English chemists Reginald Gibson and Eric Fawcett created a solid form of polyethylene in 1935. This discovery was first used commercially was an insulating material for radar cables during World War II.

In 1953, Karl Ziegler of the Kaiser Wilhelm institute invented high density polyethylene.

In 1955 HDPE was first used as a pipe. For his invention of HDPE, Ziegler won the Nobel Price for Chemistry in 1963.

CHARACTERISTIC

The number one characteristic that sets HDPE apart from other pipe types is that it can be made to be flexible. This quality opens HDPE pipe up to a different world of applications than rigid pipe.

Another quality of HDPE is that it can melted and re-solidified a limitless number of times without losing any of its favorable qualities. For this reason, most HDPE pressure pipe is made to be 'butt welded'. This is where the ends of two sections of pipe are melted and then pushed and held together, forming a single pipe.

These two characteristics make HDPE pipe the perfect candidate to be installed via directional drill. Long lengths of HDPE are welded together and then installed under roads, creeks, rivers, etc by a Horizontal Directional Drill (HDD) rig.

SIZES

HDPE pipe is given a Dimension Ratio (DR) rating. The DR Rating is the outside diameter / minimum wall thickness. DR ratings range from DR 32.5 (50 PSI working pressure) to DR 7 (265 PSI working pressure).

All HDPE pressure pipe is given a DR rating, but there are different outside diameter standards. The standards used are IPS (Iron Pipe Size), DIPS (Ductile Iron Pipe Size) and CTS (Copper Tube Size).

So for the sake of example, let's look at 8" HDPE IPS pipe. All DR ratings for 8" IPS will have the same Outside Diameter (OD). The only difference is in the wall thickness and Inside Diameter (ID). 8" DR 32.5 pipe has a wall thickness of only 0.265". 8" DR 7 pipe, however, has a wall thickness of 1.232", thus the much higher pressure rating (50 psi compared to 265 psi).

Keep checking back to this site for size charts, which will be added soon.

USES

There is an HDPE product that can be applied to just about any situation. There are a few things that should be noted, though. Because most HDPE is a flexible product, it is not commonly used in sanitary sewer gravity installations. This is because the flexible properties of the pipe can cause dips in the gravity runs.

There are several manufacturers that produce a corrugated rigid pipe product that is primarily used for storm drainage.

Corrugated HDPE storm pipe is extremely common and is second only to reinforced concrete pipe for storm drainage use.

Like PVC, HDPE pipe can be color coated to match installation requirements. Typically for pressure installations, HDPE is black with a color coated stripe.

material is taken from http://www.all-about-pipe.com/HDPE-Pipe.html

0 notes

Text

Flexible Pipe

Extending design life, improving integrity of flexible pipe

Chirs Saunders, MCS

As exploration moves into ever deeper and more complex fields, the need for flexible pipe increases. Given that the use of flexible pipe is relatively recent and the analysis is therefore fairly limited, its integrity has largely been monitored by visual inspections carried out by ROV operations.

Visual inspection shows only the damage already done. It does not provide preventative measure to reduce the risk of failure. Emerging new technologies, such as annulus testing, can improve the integrity of flexible pipe, reduce costs, and extend their original design life.

During 2002, UKOOA issued guidance entitled “Monitoring methods and integrity assurance for unbonded flexible pipe.” Since then, as the use of flexible pipe has increased, a number of lessons have been learned in management and on-going operation of flexible pipes.

Growth in the use of flexible pipe.Click here to enlarge image

These guidelines should be updated to include the data on reasons for failure and lessons learned. This would allow the industry to challenge the inspection strategies currently used as well as to identify emerging technologies as alternative solutions.

Given the advances in flexible pipe analysis, some of which were developed under the RealLife JIP, MCS demonstrated that through proper asset management, flexible pipe technology service life can be extended beyond the original design criteria. Similarly, flexible pipe previously considered damaged and in need of early replacement may be justified for extension to beyond original design life.

Since the mid-1980s, there has been exponential growth in the use of flexible pipe. Given that most flexible pipe systems are designed with a 20-25 year service life, only a small percentage in operation are close to this service life.

Should flexible pipe failure rates follow the typical “bath-tub” analysis curve, it is possible that the type and quantity of flexible pipe damage/failure mechanisms will increase in the future.

Percent of flexible pipes nearing the end of service life.Click here to enlarge image

Examining the main causes of damage shows the percentage of “internal sheath pull-out” incidents is down. This is due to a historical failure mode associated with early PVDF design structures, identified around 1995, and subsequently designed out.

There also has been a reduction in the number of “aged internal pressure sheath” incidents. This can be explained by improved industry knowledge regarding the recommended operating restrictions for polymers.

Another significant variation is related to “external sheath damage” where there has been a marked increase in the number of occurrences. This is difficult to explain in terms of changes in flexible pipe operation. However, one explanation is the increase in vacuum testing and other monitoring and inspection techniques for the annulus which make it possible to identify external sheath damage.

A significant proportion of external sheath damage occurs during installation. There is clear potential for this to be improved with better installation procedures.

Main causes of damage to flexible pipe.Click here to enlarge image

To date, general visual inspection (GVI) of flexible pipe has been key in maintaining its integrity. However, operators are increasingly questioning the value of frequent GVI to their integrity management strategy.

The main advantages of GVI are the ability to confirm general layout and configuration, to identify gross riser/ancillary equipment damage, and to provide inspection results which can be clearly interpreted.

The main disadvantages are that it is difficult to identify small outer sheath leaks, annulus flooding from venting systems is not identified, no inspection of internal layers is possible, there are environmental limits (especially shallow work), limited inspection contractor expertise for flexible pipe, and a requirement for ROV support vessel or DSV when vessel costs and availability are real issues.

External sheath damage would appear to be the most obvious damage to be spotted by periodic GVI. However, the reality of flexible pipe operation means that it is only possible to identify reasonably large areas of damage from the video footage. In conjunction with this, experience has shown that relatively small areas of damage can cause significant problems.

In addition to this, it is MCS’ experience that areas of potential damage are routinely identified during GVI but upon closer inspection are only surface staining. This has a significant cost implication for the operator, who will invariably have to undertake close visual inspection (CVI) using either diver or ROV.

The second reason for flexible pipe damage is aging of the internal pressure sheath. GVI can only identify damage that has already reached the point where it can be difficult to manage. For example, when fluid release by the pressure sheath has aged to an extent where is visible externally, it makes the pipe unserviceable.

There is a need for GVI with flexible pipe systems due to regulatory requirements and to identify other damage/failure mechanisms such as those associated with ancillary equipment, e.g. loss of mid-water arch buoyancy, buoyancy clamp slippage, tether failures, etc.

The main areas of concern with ancillary components are the bend stiffener, buoyancy module, mid-water arches, clamps, and tethers. Even here, data quality can be increased and costs can be reduced with innovative approaches. For example, the FPSO turret area is difficult for an ROV to inspect due to surface waves, currents, and congestion. An alternative might be to deploy a fixed controllable camera below the turret. This allows inspection as frequently as desired and without ROV support.

Operators spend £30,000 and £200,000 ($61,411 and $409,410) per flexible per annum on GVI. This variation is due to a number of reasons, including:

Small number of flexible pipes in the field which can increase the costs of vessel mobilization per riser

Level of integrity management strategy optimization. An optimized integrity management strategy allows the operator to target inspection in the high risk locations most frequently

Uptake of alternative integrity management tools instead of GVI

Age of the asset

Operator / regulator attitude to risk.

Depending on the operator strategy in use, it is possible for operators to reduce their annual inspection costs for flexible pipe. This can be achieved by:

Developing and maintaining an integrated integrity management strategy, which incorporates the use of focused GVI and alternative assessment / inspection techniques

Using GVI in high value reward situations, where the data recovered can be used to identify specific types of damage, e.g. ancillary equipment

Considering integrity management at the asset procurement and design stage to incorporate available online monitoring techniques which are difficult and expensive to retrofit

Using previous operational experience at the design stage

Development and use of detailed inspection manuals for the inspection contractor, providing examples of as-built state, as last-observed state, typical anomalies, and definition of records required for each type of new anomaly.

One significant way manage to the integrity of flexible pipe can be by assessing the annulus environment. There are a number of techniques to accomplish this, including vacuum testing, pressure build-up testing, gas sampling, and online monitoring. Each provides benefits and levels of information. Increasingly, combinations of these strategies are being adopted. The key to all these techniques is that they measure the flexile pipe annulus properties to identify changes such as the presence of seawater/water, H2S and CO2 composition, gas permeation rates, and “unflooded” volume in the annulus. Through the correct analysis of this data, it is possible to determine the presence of external sheath damage, topside flooding, and pressure sheath aging which then can direct further investigation.

There are limitations to annulus testing such as the potential to pull water in to the annulus and the perceived inability to assess riser systems with hog and sag bends. But these are minimal compared to the value of knowing whether or not there is a breech in the external sheath.

It still is important to confirm the layout of flexible pipe subsea. However, this does not necessarily require the level of GVI which is currently being employed. To demonstrate that the layout has not changed significantly, a survey from an increased distance covering a number of flexibles may be sufficient. Equally, it is common practice during GVI on flexible pipe to survey both sides of the structure. If external sheath damage is being assessed by alternative techniques, it could be argued that this is not necessary. This alone would reduce GVI time for flexibles by 50%.

Operators look to extend the life of flexible pipe assets. To determine whether life extension is feasible, analysis of the flexible pipe history is required. This generally includes assessment of fatigue (in which annulus condition is of paramount importance), polymer aging (based upon coupon samples, operating pressures and temperatures and chemical injection data), and anomalies identified from GVI.

Given a proper asset integrity management strategy, that is, one in which data is collected diligently and anomalies are identified and understood, there is potential to use the methodologies defined as part of the RealLife JIP to derive an accurate assessment of flexible pipe fatigue damage rate. This generally results in an extension to previously calculated fatigue lives. The single caveat to this is that the methodologies that were used to calculate fatigue life at the design stage must have incorporated the effects of resonant frequency response on the flexible pipe system. Using RealLife methods with a proper asset integrity management results in an accurate and balanced value for the flexible pipe fatigue life.

Author’s note

This article presents some data updating the previous industry guidelines published by UKOOA. This data is based on the authors’ experience and does not capture all knowledge available throughout the industry.

Given that it is estimated that approximately three times more information is available today compared to that used in 2001/2002, it is recommended that the industry consider updating these documents to reflect current industry thinking.

This should include a worldwide update on types of failure and percentage occurrence and challenge the inspection strategies previously recommended along with identifying new emerging techniques.

About the author

Chris Saunders joined MCS in July 2005 from Bureau Veritas where he gained experience in offshore projects working as a consultant. Before Bureau Veritas, he completed a MEng in Engineering Acoustics and Vibration, specializing in structural dynamics.

Saunders currently heads the Integrity Management team at MCS in Aberdeen where he recently presented a paper at Offshore Europe 07, questioning the value of general visual inspections in the integrity of flexible pipe.

Source: http://www.offshore-mag.com/articles/print/volume-67/issue-11/construction-installation/extending-design-life-improving-integrity-of-flexible-pipe.html

0 notes

Photo

Easy To Lay Quick To Install | Netafim FlexNet pipes | Netafim India

FlexNet – the industry’s only leak-proof flexible pipe that doesn't crack, bend or entangle.

The drip line also stays in place.

0 notes

Text

Pneumatic Hose Pipe Manufacturer - Dks Enterprises

https://dksenterprises.in/pneumatic-hose-pipe.php

Contact Us : 09711764803 / 09873197789 / 011-40831403

#suctionhosepipe #safetyfirst #digitalmarketing #bansari #industrialhosepipe #bansarineterprise #garden #cpvcpipe #firesafety #flexiblepipe #valve #hose #fire #safeindia #dogsofinstagram #sieverttorch #tconnector #coupling #dog #tconnect #bully #hosepipefittings #lpgconnection #firefighter #torchburners #gasconnection #likeus #inktober #msme #entrepreneur

0 notes

Photo

Easy To Lay Quick To Install | FlexNet Pipe | Netafim India

FlexNet – the industry’s only leak-proof flexible pipe that is quick and easy to instal.

You will cut your labour cost by installing and moving them a lot faster!

Visit https://www.netafimindia.com/products-and-solutions/product-offering/flexible-and-pe-pipes/flexnet/

#Lightweight #pipes #Flexiblepipes

0 notes

Text

Long time not sharing project status.

here share one project which will start by tomorrow.

pipe and fittings just reached today on site.

FSTpipe can accept orders by project and stock.

If you have any project need piping, do not hesitate to inquiry for support on piping system drawing and quote.

#air #piping #pipingtips #pipingtechniques #pipingskills #industrialdesign #industrysupply #constructionmanagement #pipework #pipeworks #airnetpipingsystem #compressorroom #pressurecontrol #flexiblepipe #airleak #salesfunnel #airnetpipingsystem #pushfittings #installationwork #tools #airtools

0 notes

Photo

Trust is built through long-term understanding,

It needs to pass the test of time and all kinds of hardships before it can be delivered completely.

Whether it’s love or business,

Without trust, it won't last long.

Trust, only once,

Lost, there will be no more,

It was broken and couldn't be put together.

If you believe, get along well,

Don't try, don't deceive.

If you don’t believe it, tell it directly,

Don't act, don't calculate.

Trust as gold, cherish it.

#air #piping #pipingtips #pipingtechniques #pipingskills #industrialdesign #industrysupply #FSTpipe #constructionmanagement #pipework #pipeworks #airnetpipingsystem #compressorroom #pressurecontrol #flexiblepipe #airleak #salesfunnel #airnetpipingsystem #pushfittings #installationwork #tools #airtools

0 notes

Link

PVC flexible pipe connectors, pvc flexible pipe sizes, pvc flexible pipe coupling, resistant to weather flexible pipe conditions, High Quality flexible pipe.

0 notes