#custom-gasket-manufacturer

Text

Quality Matters: How to Identify Reliable Rubber Molded Parts Manufacturers

For premium rubber molded parts, turn to Rubber-MoldedProducts, the industry-leading Rubber Molded Parts Manufacturers renowned for quality and innovation. Our meticulously crafted parts boast superior performance and longevity, meeting the rigorous demands of your applications. From custom designs to standardized solutions, we offer versatility without compromising on excellence. Experience the difference with Rubber-MoldedProducts, your trusted partner for top-tier rubber molded parts.

#Custom-Gasket-Manufacturer#Custom-Rubber-Molded-Products#Rubber-Molded-Parts-Manufacturers#Rubber-Mold-Manufacturers

0 notes

Text

Custom Silicone gaskets

Custom silicone gaskets provide a snug seal for various applications. Tailored to fit specific needs, these durable gaskets resist heat and pressure, ensuring reliable performance. Ideal for diverse industries, they offer a cost-effective solution for effective sealing.

epdm gasket manufacturers

If you're in search of reliable EPDM gasket manufacturers, look no further. Our company specializes in custom rubber silicone molds, ensuring you get precisely what you need. Trust us for quality craftsmanship and tailored solutions to meet your requirements seamlessly.

0 notes

Text

What Are The Benefits Of Using Rubber Seals & Gaskets?

Rubber gaskets are elastic components that are utilized for mechanically sealing the minute gaps between two joints or surfaces. Some examples of these surfaces are mating surfaces of the automotive cylinder head fittings and piping, engine block, door edges, tank cover and rim, frames, and so more.

Rubber gaskets are helpful in sealing surfaces by flowing in and filling the existing irregularities in the surfaces of parts that are commonly rigid. The sealing effect is the result of the parts that exert pressure or compressive forces. It helps in deforming the gasket plastically.

Understanding the Role of Rubber Gaskets

The natural sealing capability of rubbers is imparted to the elastomer nature. Rubbers, whether they are synthetic or natural, are derived from the family of materials referred to as elastomers. Elastomers can be regarded as classes of polymers having a high elastic nature developed with the help of cross-linking longer polymer chains into the respective amorphous structure.

The intermolecular forces that exist between the respective polymer chains tend to be relatively weak. This enables them to be easily reconfigured when stress is applied. Due to this property, elastomer gaskets are capable of easily conforming to the surface profiles. It helps in the creation of a tighter seal. Get the best out of the custom rubber extrusions manufacturers.

Read originally published on – https://www.santopseal.com/what-are-the-benefits-of-using-rubber-seals-gaskets/

#custom rubber extrusions#custom rubber extrusions supplier#extruded rubber bulb seal#extruded rubber gasket#extruded rubber seals#rubber extrusion profiles#rubber u channel extrusion#santoprene profile extrusion#santoprene extrusion suppliers#santoprene tpv manufacturers#santoprene tpv suppliers#tpe custom extruded rubber gaskets and seals#tpe extruded rubber clamping profiles#tpe extruded rubber seals manufacturers#tpe extrusion rubber suppliers#tpv custom extruded rubber gaskets and seals#trim seals and rubber extrusions

0 notes

Text

The Heart of Boiler Systems: Exploring the Role of IBR Fitting and Flanges

Boiler systems serve as the backbone of numerous industrial processes, powering everything from heating and hot water supply to steam generation in various manufacturing operations. Within these systems, ensuring safety, efficiency, and reliability is paramount, and this is where IBR (Indian Boiler Regulations) fitting and flanges play a pivotal role. As a trusted distributor in Vadodara and a leading dealer in Gujarat, Tubetrading is dedicated to providing top-quality IBR fitting and flanges to industries across the region. In this blog post, we'll delve into the significance of IBR fitting and flanges in boiler systems, explore their crucial functions, and highlight the expertise of Tubetrading in supplying these essential components.

Understanding IBR Fitting and Flanges

IBR fitting and flanges are integral components of boiler systems that ensure seamless operation and compliance with safety standards mandated by the Indian Boiler Regulations. These regulations are designed to safeguard the integrity of boiler components, prevent accidents, and promote efficient energy utilization. IBR fitting and flanges are manufactured according to stringent specifications outlined by the IBR to guarantee durability, reliability, and performance in demanding industrial environments.

The Role of IBR Fitting and Flanges in Boiler Systems

1. Pressure Regulation: IBR fitting and flanges are designed to withstand high-pressure environments commonly found in boiler systems. They play a crucial role in regulating and controlling the flow of fluids, gases, and steam within the system, ensuring optimal pressure levels for efficient operation.

2. Sealing and Joint Integrity: Proper sealing and joint integrity are essential to prevent leaks and maintain the integrity of boiler systems. IBR fitting and flanges are equipped with robust sealing mechanisms, such as gaskets and O-rings, to create a tight seal between interconnected components, minimizing the risk of leaks and ensuring system integrity.

3. Connection and Interoperability: IBR fitting and flanges serve as connection points between various components of boiler systems, including pipes, valves, and vessels. Their standardized dimensions and configurations enable seamless interoperability, facilitating efficient assembly, maintenance, and repair of boiler systems.

4. Compliance and Certification: Compliance with IBR regulations is mandatory for all boiler components used in India. IBR fitting and flanges undergo rigorous testing and certification processes to ensure compliance with safety standards and regulatory requirements, providing peace of mind to industries reliant on boiler systems.

Tubetrading: Your Trusted Supplier of IBR Fitting and Flanges in Gujarat

As a reputable distributor and dealer of IBR fitting and flanges in Vadodara and Gujarat, Tubetrading prides itself on delivering superior-quality products and exceptional service to its customers. Here's why industries trust Tubetrading for their IBR fitting and flanges needs:

1. Extensive Product Range: Tubetrading offers an extensive range of IBR fitting and flanges, including elbows, tees, reducers, bends, and flanges in various sizes, materials, and specifications. Whether you need standard or customized components, we have the expertise and resources to meet your requirements.

2. Quality Assurance: At Tubetrading, quality is our top priority. We partner with reputable manufacturers who adhere to strict quality control measures and comply with IBR regulations. Our products undergo thorough inspection and testing to ensure they meet the highest standards of performance, reliability, and safety.

3. Expert Guidance: With years of experience in the industry, the team at Tubetrading possesses in-depth knowledge of IBR fitting and flanges and their applications in boiler systems. We provide expert guidance and technical support to help our customers select the right components for their specific needs, ensuring optimal performance and efficiency.

4. Timely Delivery: We understand the importance of timely delivery to our customers' operations. With our efficient logistics network and inventory management systems, we strive to fulfill orders promptly and ensure on-time delivery of IBR fitting and flanges to our customers across Gujarat.

Conclusion

In conclusion, IBR fitting and flanges are the heart of boiler systems, playing a critical role in ensuring safety, efficiency, and compliance with regulatory standards. As a trusted distributor and dealer in Vadodara and Gujarat, Tubetrading is committed to supplying top-quality IBR fitting and flanges to industries across the region. With our extensive product range, quality assurance, expert guidance, and timely delivery, we are your reliable partner for all your IBR fitting and flanges needs. Contact Tubetrading today to learn more about our products and services and discover how we can support your boiler system requirements.

#IBR Fitting and Flanges distributor in Gujarat#IBR fitting and flanges distributor in Vadodara#IBR fitting and flanges dealer in Gujarat#IBR fitting and flanges#Gujarat#Maharashtra#Rajasthan#Madhya Pradesh#Daman#Uttar Pradesh

7 notes

·

View notes

Text

What Are Mechanical Keyboard PCBs?

Mechanical keyboards have gained immense popularity due to their tactile feedback and durability. However, behind their satisfying keypresses lies a crucial component - the Printed Circuit Board (PCB). In this guide, we delve into the inner workings of mechanical keyboard PCBs, exploring their functions, features, and the key role they play in keyboard layouts.

The Role of a Mechanical Keyboard PCB

At its core, a mechanical keyboard PCB acts as the central nervous system of the keyboard, facilitating communication between the keys and the computer. Each key is linked to a specific switch on the PCB, and when a key is pressed, the switch sends an electrical signal to the PCB, which then translates it into a digital signal that the computer understands. This seamless interaction is what allows you to type, game, or perform any other function on your computer using your keyboard.

Features Supported by Mechanical Keyboard PCBs

Beyond basic key input, modern mechanical keyboard PCBs offer a range of advanced features that enhance the user experience. These include:

Stabilizers: Some PCBs support screw-in or clip-in stabilizers for larger keys like the spacebar and enter key. These stabilizers provide a more uniform and stable keypress.

Hot-swap Sockets: Certain PCBs come with hot-swap sockets, allowing you to easily replace switches without the need for soldering. This feature is particularly useful for users who enjoy customizing their keyboard's feel and sound.

RGB Lighting: Many mechanical keyboard PCBs support RGB lighting, allowing for customizable backlighting effects. This feature adds a vibrant and aesthetic element to your keyboard setup.

Mounting Options for Mechanical Keyboard PCBs

Mechanical keyboard PCBs can be mounted in several ways, each affecting the typing experience:

Top Mount: In this configuration, the PCB is secured to the top of the keyboard case, providing a sturdy typing platform.

Tray Mount: Tray-mounted PCBs are secured to the bottom of the keyboard case. While this mounting style is common, it can lead to uneven typing due to tension from the screws.

Gasket Mount: This mounting method involves using foam pieces between the PCB and plate. It provides a cushioned typing experience, reducing typing fatigue.

Keyboard Layout Support

One of the most appealing aspects of mechanical keyboard PCBs is their flexibility in supporting various layouts. Common layouts include:

60%

65%

75%

TKL (Tenkeyless)

100%

These layouts vary in size and key configuration, catering to different user preferences. Moreover, enthusiasts can design and create their own PCBs using online PCB makers, allowing for limitless customization possibilities.

Conclusion

In conclusion, mechanical keyboard PCBs are the backbone of any keyboard build, dictating its functionality and layout. Understanding the role and features of a PCB is crucial for anyone looking to build or customize their mechanical keyboard. By familiarizing yourself with the intricacies of mechanical keyboard PCBs, you can create a personalized typing experience that suits your preferences and style.

3 notes

·

View notes

Text

Rubber Elastomer Washers

Specializing in quick turnaround of thin-gauge components, Mercer Gasket & Shim provides world-class laser chopping providers for applications where precision is a high precedence and quality is essential. Metal gaskets is a term often used to describe any measurement of gasket, shim or washer that is manufactured from elemental metals or alloys such as metal, brass or titanium. Specialist metal alloys such as Inconel, which is composed of nickel, chromium and iron, have properties suited to processes that endure excessive pressures or temperatures. They have offered superior performance and products for our doors as properly and lots of of weird requests from us making an attempt to care for our prospects. The employees are very hardworking and professional and can do what it takes to get the job done.

Goodrich Gasket delivers premium quality gaskets that ensures performance, safer operation and reliability. Regardless the kind, the gaskets are personalized to specifically go nicely with the client specifications and space of utility to speed up the efficiency with usage of the best materials. Polyurethane products often are called “urethanes”, they're a particularly numerous product as a end result of multiple ways it can be configured during manufacturing. Polyurethane materials are a fantastic selection when pondering of your next sealing product utility.

Custom Gasket Manufacturing also presents custom rubber molding and extrusion companies for extra complicated, 3D geometries. It’s necessary to notice that rubber just isn't a single material, however instead a broad class of elastomers with totally different bodily traits. Industrial purchasers should contemplate any needed corrosion and temperature resistance properties and select a rubber accordingly. Available in 10 metre rolls, metre lengths, strips, washers or cut to order in normal or non commonplace gaskets. Industrial Gaskets manufactures commonplace Imperial rubber washers as nicely as Metric rubber washers.

Mercer Gasket & Shim is provided with new, state-of-the-art router slicing tools. Mercer Gasket & Shim’s waterjet cutting service presents a fast, versatile, and correct technique for fabricating advanced or difficult components while maintaining the integrity of the material. We proceed to attempt to boost and increase the range of companies we provide our prospects. AG’s extrusion services embody using injection, cold and hot becoming a member of strategies which allows us to offer a variety of sections, sizes and shapes made from a big selection of materials. Our big selection of standard items at the aspect of our varied methods of manufacture will ensure you get the right seal every time, reduced lead times assured. A gasket is a mechanical seal that fills the area between two mating surfaces, generally to prevent leakage from or into the joined objects whereas underneath compression.

Today, it is established as a quantity one supplier of piping systems for the safe and dependable transport of liquids and gases. Despite the constant change, customer-centric innovation and sustainability stay the defining values for GF Piping Systems. Often used as a seal for steam and scorching valves, taylor ring gaskets are reduce from a variety of sheet metals and fashioned into corrugated concentric rings.

As a manufacturer of a broad range of flange gaskets, including metallic gaskets, semi-metallic gaskets, and sheet gaskets, we pride ourselves on helping our customers supply the best product for any utility. At Mercer Gasket & Shim, our staff has the information to promptly and accurately finish any custom gasket order. In addition, we are geared up with cutting-edge equipment to precisely manufacture gaskets from numerous materials. We are additionally committed to offering the very best quality gaskets to our clients by adhering to relevant industry standards and specifications. Our expert group of engineers at Mercer Gasket & Shim aids customers all throughout the whole gasket production course of.

metallic gaskets

We additionally provide custom gasket solutions to ensure that you get the most effective answer for your needs. Our in depth range includes, 100% Pure, Expanded and Modified PTFE products available in sheet, tape, completed components, gaskets and washers. Covering a wide range of applications, our brands include Gylon, Klinger’s Topchem & Teflex.

#durlon sealing products#durlon gaskets#industrial gaskets#sheet gaskets#metallic gaskets#sustainable gasket materials#high-quality gaskets#PTFE sheet gaskets

2 notes

·

View notes

Photo

Back in a former life, I had an addiction that I loved beyond sanity. Here’s the story of it.

2002 2003 2004 2005 2006 2007 2008 2009 pt1 2009 pt2 2009 Redux

This is the final spec list for my glorious, insane Brutal Truth.

Nissan Skyline BCNR33 GT-R (Type 2) manufactured in April 1996. JDM non V-Spec vehicle retailed through Osaka Nissan Prince in May/June 1996. Imported to the

UK in June 1997. Remained in original JDM spec without speedometer conversion until August 2002. Only the steering wheel & white dial sets were fitted in Japan.

Nismo RB26N1 bare engine: [N1 water pump (improved flow & less cavitation)/Reinforced cylinder block head bolt boss/Increased sump capacity (6L 20w60)/1.2mm oil restrictor]

N1 head with 0.5mm overbore (2598cc)

Cryogenically hardened N1 crankshaft

Wossner forged & cryogenically hardened pistons

Abbey Motorsport reinforced & cryogenically hardened con-rods

ACL Race Series conrod & crankshaft bearings

Tomei sump baffle kit

Tomei high flow (larger drive gears) oil pump

HKS 1.2mm metal head gasket

Tomei Procam Spec 2 cam kit (270 degree inlet & outlet with 10.25mm lift)

HKS V-Cam System Step 1 Type B (variable 248-278 degree inlet; replaces Procam inlet camshaft)

HKS vernier cam pulleys

HKS kevlar reinforced timing belt

Trust metal intake & throttle gaskets

HKS front pipe & decat gaskets

GReddy Iridium 08 Racing sparkplugs

Mocal 19-row oil cooler & Abbey Motorsport remote oil filter assembly

Abbey Motorsport catch tank & washer reservoir with SFS breather hoses

Abbey Motorsport Pro Alloy large radiator

Tomei fuel pump, fuel regulator & 600cc injectors

A’PEXi Power Intake induction kit

A’PEXi GT Spec intercooler (237x610x136mm) & hard pipe kit

HKS GT-SS turbos

HKS twin AFM delete kit

Tomei turbo elbows

HKS downpipes

HKS Silent Hi-Power exhaust

Abbey Motorsport 80mm decat pipe

Mine’s VX-ROM

HKS F-Con V Pro

HKS EVC 6 boost controller (1.6 bar)

AEM wideband lambda sensor

Splitfire DI Super Direct Ignition System

HKS Circle Earth kit

HKS GD Max twin-plate clutch (with lightened flywheel)

Abbey Motorsport rebuilt transfer box

Abbey Motorsport rebuilt gearbox with cryogenically hardened gear set, modified Nissan synchromesh upgrade and OS Giken strengthening plate

Abbey Motorsport rebuilt rear diff

Nismo gearbox mounts

Nismo Solid Shift gear stick (10% short shift)

Omex Shift Light Sequential

Sunsei SE-135 solar panel trickle charger mounted on a custom aluminium riser between the rear parcel shelf speaker enclosures.

Team Dynamics Equinox alloys 19x9.5, ET+15 in silver with polished stainless steel rim.

Falken FK452 265/30/19 Y-rated tyres

Cusco brake master cylinder brace

Cusco rear steering delete kit

Cusco front & rear upper suspension links

AST Sport Line 1 full suspension kit with UK spring setup

Nismo stainless steel braided brake hoses

StopTech 355mm rotor 4 pot caliper front brake kit

StopTech 355mm rotor 2 pot caliper rear brake kit with Abbey Motorsport modified pad retainers

Ferodo DS2500 brake pads front & rear

Bomex AD-390 front splitter

Nismo R34 smoked front indicators in custom aluminium mounting plates finished in crackle black

Nissan Xenon headlamp units

Border Racing Aero Fenders (vented front wings) with silver GT emblems from a R32 Skyline

Nismo smoked side repeaters

Top Mix one-off FRP twin blade rear spoiler on custom aluminium mounting plates

Entire exterior resprayed in BMW black (code 086) base and lacquer

Nissan Motorsport International carbon fibre B-pillar plates

PIAA carbon effect silicon wipers, front pair with spoilers, rear without

Nismo white face dial sets (dashboard & centre console) in carbon fibre panels

AEM AFR gauge mount replaces the lighter socket

HKS EVC display mounted on custom carbon fibre plate replacing the ashtray

Lighter socket relocated to the fog light switch panel

Nissan Momo steering wheel (with airbag)

Dressycar Nismo harness pads

Redline Automotive leather gearstick & handbrake gaiters

Abbey Motorsport carbon fibre door sill trims

Carbon fibre boot sill trim

Inlet plenum and sundry induction pipework finished in powder grey

Trust clear cam pulley cover

HKS Kansai Service carbon fibre spark plug cover

Right hand cam cover finished in crackle black

Nismo radiator & washer reservoir caps

HKS Kansai Service front strut brace finished in high gloss black

GReddy aluminium slam panel finished in crackle black

Tein bonnet dampers with black sleeves

Custom made one-off Cobra Misano Lux front seats: [Alcantara (colour code 9189) outers/Alcantara (colour code 9182) centre panels/One-piece carbon fibre backs/Sidewinder bases on custom subframes adapted by Abbey Motorsport/Cobra logo in silver thread on the headpads/GT-R logo beneath the grommets on seat backs]

JVC KD-AVX2 multi-media DVD/CD receiver with built-in 3.5” widescreen monitor

2x JL Audio Evolution VR600-CXi 6” speakers (front)

2x JL Audio Evolution TR650-CXi 6.5” speakers (rear)

Multiple and interlaced Thatcham rated security systems.

500 bhp. 520 ft/lb.

Ludicrously, hilariously, unbelievably fast.

Hope you enjoyed this little trip down memory lane with me. Cheers! JM.

(Photo by N. Liassides.)

#r33#bcnr33#skyline#gt-r#nissan skyline#Abbey Motorsport#HKS#Bomex#Tomei#A'PEXi#GReddy#Nismo#RB26N1#Mocal#Team Dynamics

12 notes

·

View notes

Text

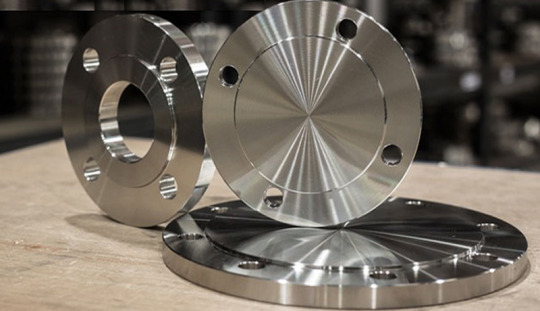

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

How Do Glass Door Display Chillers benefit the end user?

In this blog, we are going to highlightCommercial Display Fridge, its importance, prominent features, and applications among others.

Before we move forward, it makes sense to understand the machine.

So, what is a Commercial Display Fridge?

It is a technically sound machine designed for storing and persevering edibles, beverages, and medicines among others. It is also famous as Glass Door Display Chillers across the industry circles.

Unique features of a quality-driven Glass Door Display Chillers

Let’s now focus on the prominent features of the machine. As an owner of a hotel or shopping complex, you require a flawless machine that delivers excellent results. Here is a list of salient features of a quality-driven machine:

Better Display Area

Large storage with Display

Temperature retaining

Customized size

Energy efficient

Uniform Temperature

Easy maintenance

Easy assemble & dismantle

Temperature: 2 to 8 ° C

Technical specifications

Technical specifications vary from company to company. More or less, the basics remain the same. Here is the technical specifications of a Glass Door Display Chiller manufactured by Bharat Refrigerations:

Glass Door Frame Size: 1401 mm x 1840 mm

Single Door Opening Size: 600 mm x 1720 mm.

Customized glass doors (hinged type) with magnetic door gasket for air-tight seal.

Minimum 2 Glass Door.

Floor Insulation: Aluminium Chequered plate.

Digital temperature controller with digital display.

Insulated perimeter frames designed with forward facing for easy service and maintenance from front of the door.

Energy efficient frame that reduces heat loss by 30% with its added insulation

Double layer vacuumed tempered glass to prevent moisture.

For the specific arrangement of products.

Adjustable Stainless Steel Shelves for specific arrangements of merchandise.

Provision for special demands such as glass doors, special flooring, silent condensing unit, Shelves, etc.

Long durability and perfect construction with a balanced refrigeration system

Applications

The automatic machine is designed to safely store and preserve a wide range of edibles, beverages, and medicines among others, including Chocolates, Soft drinks, Milk, Pastry, Cake, Ready to eat, etc.

Commercial use

As the name indicates, the machine is designed for commercial use. Generally, set between 2 and 8°C, the machine is used in a wide range of setups and commercials including Cinema halls, Multiplexes, Hotels, Restaurants, Shopping malls, Corporate Towers, etc.

Keep your requirement in view

Before taking the final decision to buy the product, don’t forget to keep in view your custom requirements. Factors like the average amount of food prepares every day, the number of raw materials, you would like to store, space designed for refrigerators, etc. should be considered. It’s important to list down your different requirements, before reaching a conclusion.

Custom-designed Glass Door Display ChillersIndian market isn’t short of

Commercial Display Fridge manufacturers

, however, don’t trust blindly. An inferior quality product wouldn’t meet your requirements, leading to wastage of items stored. Subsequently, it makes sense to buy the product only from reputed manufacturers.

Conclusion

The picture is no hazier, given the content of this blog. Buying an excellence-drivenGlass Door Display Chillers is always a tough decision, especially when the market is flooded with many companies and brands. Considering the expertise of Bharat Refrigerations, you can trust their quality-driven range of Commercial Display fridges.

9 notes

·

View notes

Video

youtube

4D105-3 Engine O-Ring Rubber21-2230 07000-03090 07000-03022 6130-21-2220.

China Guangzhou Mingyi Seal Manufacturing Factory produces customized various engine overhaul and refurbishment kits, metal interface gaskets, thermostat gaskets, copper gaskets, applied in various professional fields, such as: construction machinery excavators, bulldozers, agricultural machinery herbicides, cutting Engine, marine machinery engine repair and refurbishment kit gaskets, involving models: Kubota, Isuzu, Caterpillar, Hyundai, Detroit, Mitsubishi, Toyota, Cummins, Perkins, Nissan, Hino, Volvo, Komatsu, Yanmar, etc. For the car series, the factory aims to solve the engine overhaul and refurbishment sealing performance, and develops various materials; viscosity; products with different thicknesses, aiming to solve and prolong the performance and life of the engine, provide various engine overhaul gaskets, For example: cylinder gaskets, intake manifold gaskets; exhaust manifold gaskets; metal interface gaskets; valve cover gaskets; O-rings; crankshaft front and rear oil seals; side cover gaskets; oil pan gaskets; valve stem oil seals ; Oil pump oil seals gaskets; Timing gaskets, custom flange wound gaskets, copper gaskets, etc.

Mob:+8613802755679(Whatsapp/Wechat/Skype )

E-Mail:[email protected]

Web:engines-gasket-manufacturer.com

Store :http://www.mingyiseal.com/

2 notes

·

View notes

Text

Boost Your Equipment Performance with a Top Custom Gasket Manufacturer

Discover unparalleled performance upgrades for your machinery with the expertise of a top custom gasket manufacturer. Our precision-engineered solutions ensure optimal functionality and durability, empowering your equipment to excel in any application. Trust in the expertise of our experienced team to elevate your machinery's performance to new heights. Partner with us, the leading custom gasket manufacturer, and unlock the full potential of your equipment today.

0 notes

Link

#tpe custom extruded rubber gaskets and seals#tpe extruded rubber seals manufacturers#tpe extrusion rubber suppliers#santoprene tpe extruded profiles#santoprene tpe extruded gaskets#santoprene tpe extruded tubing#santoprene tpe seals manufacturer#santoprene tpe manufacturers#santoprene tpe suppliers#custom tpe extrusion seal strip

0 notes

Text

Innovations Driving the High Pressure Seal Market to Reach US$ 11.5 Billion by 2034

The global high pressure seal market is poised for significant growth between 2024 and 2034, driven by various factors such as increasing industrialization, technological advancements, and the growing demand for high-performance sealing solutions across multiple industries. This article explores the market landscape, key trends, challenges, and future outlook of the high pressure seal market.

The global High Pressure Seal industry, valued at US$ 5.7 billion in 2023, is projected to experience significant growth over the next decade. With an estimated compound annual growth rate (CAGR) of 6.7% from 2024 to 2034, the industry is expected to reach a value of US$ 11.5 billion by the end of 2034. This substantial increase reflects the dynamic expansion and evolving opportunities within the sector, highlighting its robust potential for future development and investment.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=37535

Market Segmentation

By Service Type:

Gasket Seals

Mechanical Seals

O-rings

Others

By Sourcing Type:

OEM (Original Equipment Manufacturer)

Aftermarket

By Application:

Pumps

Valves

Compressors

Others

By Industry Vertical:

Oil & Gas

Chemical

Pharmaceutical

Manufacturing

Others

By Region:

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Regional Analysis

North America and Europe are expected to hold significant market shares, owing to the presence of established industries and stringent regulations regarding leakage prevention and environmental protection.

The Asia Pacific region is projected to witness the highest growth rate, driven by rapid industrialization in countries like China, India, and Southeast Asian nations.

Market Drivers and Challenges

Drivers:

Increasing demand for high pressure seals in various industries to prevent leaks and ensure operational efficiency.

Technological advancements leading to the development of innovative sealing solutions.

Growing awareness about the importance of maintaining a safe working environment and reducing environmental impact.

Challenges:

High initial investment required for implementing high pressure sealing solutions.

Concerns regarding the compatibility of seals with different operating conditions and fluids.

Intense competition among market players leading to pricing pressures.

Market Trends

Adoption of advanced materials such as fluoropolymers and thermoplastics for manufacturing high pressure seals, enhancing their performance and durability.

Integration of IoT (Internet of Things) technology for real-time monitoring and predictive maintenance of sealing systems.

Shift towards customized sealing solutions to meet specific application requirements and regulatory standards.

Future Outlook

The high pressure seal market is expected to witness continued growth in the coming years, driven by ongoing industrialization, globalization, and the need for efficient sealing solutions across various sectors. Market players are likely to focus on innovation, product diversification, and strategic partnerships to gain a competitive edge in the market.

Key Market Study Points

Market dynamics including drivers, restraints, opportunities, and challenges.

Competitive landscape analysis highlighting key players, their market share, and strategies.

Market segmentation based on service type, sourcing type, application, industry vertical, and region.

Technological advancements and their impact on market growth.

Regulatory landscape and its influence on market trends and developments.

Competitive Landscape

The high pressure seal market is highly competitive, with several global and regional players vying for market share. Key players include:

John Crane

Flowserve Corporation

AESSEAL plc

EagleBurgmann

Parker Hannifin Corporation

Recent Developments:

Launch of new sealing solutions catering to specific industry requirements.

Strategic acquisitions and partnerships to expand product portfolio and geographic presence.

Investments in research and development to enhance product performance and reliability.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Comprehensive Guide to SORF Flange Dimensions and Specifications

Choosing the correct flange for your piping system is essential for ensuring reliability and performance. Slip-On Raised Face (SORF) Flanges are a popular choice due to their versatility and ease of installation. This comprehensive guide will cover the dimensions and specifications of SORF flanges, highlighting their importance and applications in various industries.

For high-quality SORF flanges and expert assistance, visit Renine Metalloys.

Understanding SORF Flanges

Slip-On Raised Face (SORF) Flanges are designed to slide over the pipe end and are welded in place. The raised face design enhances the gasket's surface contact area, providing a better seal. SORF flanges are known for their simplicity and cost-effectiveness, making them a preferred choice in many industrial applications.

Key Dimensions of SORF Flanges

Understanding the critical dimensions of SORF flanges ensures proper fit and function within piping systems. The following are essential dimensions to consider:

Outside Diameter (OD)

The outside diameter of a SORF flange varies with the flange's size and pressure class. This measurement is crucial for compatibility with other piping components.

Bolt Circle Diameter (BCD)

The bolt circle diameter is the diameter of the circle formed by the centers of the bolt holes. This dimension ensures the flange aligns correctly with the mating flange or equipment.

Number of Bolt Holes

The number of bolt holes depends on the flange's size and pressure rating. These holes must match the bolt pattern of the mating component to ensure a secure connection.

Bolt Hole Diameter

The bolt hole diameter determines the size of bolts that can be used with the flange. Compatibility with the bolts used in the piping system is essential.

Raised Face Height

The raised face height is the elevation of the raised portion around the bore of the flange. This feature provides a better sealing surface for the gasket, enhancing connection reliability.

Thickness

Flange thickness affects its strength and pressure rating. Thicker flanges can handle higher pressures and provide increased durability.

Applications of SORF Flanges

Petrochemical Industry

In the petrochemical industry, SORF flanges are used in pipelines transporting various chemicals and hydrocarbons. Their secure and reliable connections are crucial for this sector.

Oil and Gas Industry

The oil and gas industry extensively uses SORF flanges in pipelines, refineries, and offshore platforms. These flanges offer excellent sealing capabilities necessary for handling volatile substances.

Water Treatment

SORF flanges are used in water treatment facilities' pipelines and systems, providing secure connections to prevent leaks and ensure efficient processing.

Power Generation

Power plants use SORF flanges in piping systems to handle steam, water, and other fluids. The flanges' robustness and reliability are vital in high-stress environments.

Why Choose Renine Metalloys for SORF Flanges?

At Renine Metalloys, we offer a wide range of high-quality SORF flanges that meet international standards. Our products are designed to deliver superior performance and durability, ensuring the efficiency and reliability of your piping systems.

Our Commitment

Renine Metalloys is committed to providing top-notch products and services. Our SORF flanges are manufactured using the best materials and state-of-the-art technology, ensuring they meet the highest industry standards.

Custom Solutions

We understand that different projects have unique requirements. Renine Metalloys offers custom solutions to meet your specific needs, ensuring you get the perfect flange for your application.

Understanding the dimensions and specifications of SORF Flanges is crucial for their proper application in your projects. For high-quality flanges and expert guidance, visit Renine Metalloys. Our extensive range of products and commitment to quality make us a trusted partner in the industry. Explore our offerings and find the right solutions for your needs today.

#SORF Flange Dimensions#Slip-On Raised Face Flanges#SORF Flange Specifications#Industrial Flange Guide#SORF Flange Applications#High-Quality SORF Flanges#Renine Metalloys Flanges

0 notes

Text

Rubber Gasket Manufacturer In Pune - Fairdeal Rubber

Fairdeal Rubber is a leading rubber gasket manufacturer in Pune. Fairdeal Rubber, established in 1982, is a prominent manufacturer and supplier.

Fairdeal Rubber is a leading rubber gasket manufacturer in Pune, India. The company has been in the business for several years and has established itself as a trusted supplier of high-quality rubber gaskets for various industries.

One of the key factors that set Fairdeal Rubber apart from its competitors is its commitment to innovation and technology. The company has invested heavily in research and development, which has enabled it to develop a range of advanced rubber gasket solutions that meet the needs of its customers. For example, Fairdeal Rubber has developed a patented process for preparing Patiromer, a crosslinked polymer that is used in the treatment of hyperkalemia. This process is designed to be commercially viable and to produce a high-quality product that meets the needs of the pharmaceutical industry.

Fairdeal Rubber is also committed to sustainability and environmental responsibility. The company has implemented a range of measures to reduce its carbon footprint and to promote the use of eco-friendly materials. In addition to its commitment to innovation and sustainability, Fairdeal Rubber is also dedicated to quality and customer satisfaction. The company has implemented a rigorous quality control system that ensures that every rubber gasket that it produces meets the highest standards of quality and performance. This system includes regular testing and inspection of raw materials, as well as thorough testing of finished products before they are shipped to customers.

Product Range:

Fairdeal Rubber offers a diverse range of rubber gaskets, including rectangular gaskets, rubber flange gaskets, cooker gaskets, and tri-clover gaskets.

These gaskets are made from various materials such as silicone rubber, known for its exceptional resistance to high temperatures and harsh chemicals.

Additional Products:

Apart from rubber gaskets, Fairdeal Rubber also provides other industrial rubber products like rubber washers, seals, and O-rings.

These products are crafted from materials like Viton, silicone, and nitrile rubber, chosen for their specific properties and applications.

Quality Control:

Fairdeal Rubber's commitment to quality is evident in its rigorous quality control system.

Every batch of raw materials and finished products undergoes thorough testing to ensure they meet the highest standards of quality and performance.

Sustainability Efforts:

Fairdeal Rubber is dedicated to sustainability and environmental responsibility.

The company has implemented measures to reduce its carbon footprint and promote the use of eco-friendly materials, such as 100% non-asbestos rubber gaskets.

Innovation and Technology:

Fairdeal Rubber stands out for its commitment to innovation and technology.

The company has invested significantly in research and development, leading to the development of advanced rubber gasket solutions like the patented process for preparing Patiromer.

In conclusion, Fairdeal Rubber is a leading rubber gasket manufacturer in Pune that is committed to innovation, sustainability, quality, and customer satisfaction. The company's patented processes, eco-friendly materials, rigorous quality control system, and customized solutions make it a trusted partner for businesses in a wide range of industries.

#Rubber O Ring Manufacturer in Pune#Rubber Gasket Manufacturer in Pune#Silicone Gasket Manufacturer in Pune#Sms Union Gasket Manufacturer in Pune#Manhole Gasket Manufacturer in Pune

1 note

·

View note

Text

Science of Resilience: Silicone Compression Molding Techniques Unveiled

Silicone compression molding reaches new heights of excellence with Rubber-MoldedProducts. Harnessing advanced technology and expertise, we deliver silicone products of unparalleled quality and resilience. Whether for medical devices or consumer electronics, our compression molding techniques ensure precise manufacturing, meeting the most stringent standards. Partner with us for silicone solutions that redefine durability and performance in diverse industries.

#Custom Rubber Molding#Silicone Compression Molding#Custom Gasket Manufacturing#Custom Rubber Extrusion

0 notes