#composite cladding

Photo

Mid-sized elegant attached three-car garage photo

0 notes

Photo

Contemporary Landscape Kent

This is an illustration of a decked, mid-sized contemporary backyard.

#composite cladding#low maintenance decking#composite decking ashford#contemporary garden design#composite cladding ashford#anti-slip decking

0 notes

Photo

Contemporary Landscape

This is an illustration of a sizable, decked contemporary backyard.

0 notes

Photo

Landscape - Contemporary Landscape

An example of a large contemporary backyard landscaping with decking.

#plastic decking#composite cladding#wpc decking#ecoscape decking#composite decking suppliers#landscape

0 notes

Text

Fire-Rated Materials in Architecture: Eurobond FR ACP

In the world of modern architecture, ensuring the safety of buildings and their occupants is paramount. Fire safety is a critical concern, and one key component of achieving this goal is the use of fire-rated materials. Among these materials, Eurobond FR (Fire-Retardant) Aluminum Composite Panels (ACP) stands out as an exceptional choice for architects and builders.

Understanding Fire-Rated Materials

Fire-rated materials are those that are specifically designed to resist the spread of fire, providing valuable time for occupants to evacuate a building and for firefighters to respond. These materials are rigorously tested and certified to meet fire safety standards and building codes.

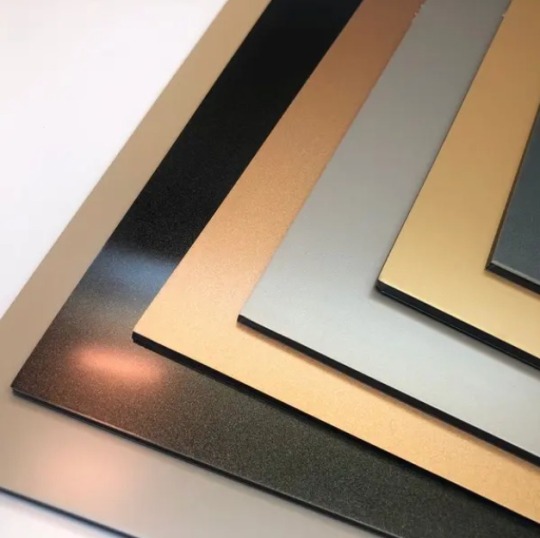

Eurobond FR ACP: A Brief Introduction

Eurobond FR ACP is a type of cladding material that combines the aesthetics of aluminum with exceptional fire-resistant properties. This product is designed to meet the highest industry standards for fire safety while offering a wide range of design possibilities. Here's why it's gaining popularity in architectural circles:

1. Fire-Resistance

Eurobond FR ACP is designed to be fire-retardant, meaning it slows down the spread of flames in the event of a fire. The core material in Eurobond FR ACP is specially formulated to withstand high temperatures, limiting the potential for the ACP to ignite or contribute significantly to the fire's progression.

2. Code Compliance

Architects and builders can have confidence in Eurobond FR ACP because it complies with stringent fire safety regulations and standards. These panels typically undergo rigorous testing to determine their fire performance, and the results are used to assign specific fire-resistance ratings, such as Class A, B, or C, to the material.

3. Versatile Design

One of the remarkable features of Eurobond FR ACP is its adaptability to various architectural styles and design aesthetics. It is available in a wide array of colors, finishes, and textures, allowing architects and designers to incorporate it seamlessly into their projects. Eurobond FR ACP's design versatility makes it an attractive option for both contemporary and traditional designs.

4. Durability

In addition to fire resistance, Eurobond FR ACP is known for its durability and weather resistance. It can withstand harsh environmental conditions, such as UV exposure and extreme temperatures, without compromising its structural integrity. This longevity ensures that the material maintains its fire-resistant properties over time.

5. Sustainability

Sustainability is an ever-increasing concern in the construction industry. Eurobond FR ACP contributes to environmental sustainability by being recyclable and energy-efficient. Its fire-resistant properties also add an extra layer of safety, protecting the environment from potential fires.

Applications of Eurobond FR ACP

Eurobond FR ACP is used in various architectural applications, including:

Exterior Cladding: Eurobond FR ACP is often used as an exterior cladding material, providing a visually appealing facade while ensuring fire safety.

Interior Walls: It can also be used for interior wall coverings, where fire resistance is crucial, such as in commercial kitchens or high-rise buildings.

Signage and Signboards: Its versatility in terms of finishes and colors makes it a popular choice for signage and signboards.

Ceilings and Partitions: Eurobond FR ACP can be applied to ceilings and partitions, enhancing the overall fire safety of a space.

Conclusion

Fire-rated materials like Eurobond FR ACP play a vital role in ensuring the safety and longevity of architectural projects. As architects and builders strive to create aesthetically pleasing yet secure structures, the use of Eurobond FR ACP becomes a valuable choice. Its fire-resistant properties, code compliance, design flexibility, and durability make it a worthy addition to any construction project, contributing to the safety and appeal of the built environment.

#eurobond acp#acp sheet#acp panel#eurobond#eurobond acp panels#aluminium composite panels#building materials#fire retardant acp#acp cladding#acp panels#fire rated material#Eurobond FR ACP#Eurobondacp#fireproof acp#fireproof acp sheet and acp panel

2 notes

·

View notes

Text

The Benefits of Copper Composite Panel

Copper composite panel 100% recyclable, sustainable, eco-friendly, fireproof and durable but also uniquely alluring. This is a major USP that makes it stand apart. Equipped with a glossy finish, these sheets have a red-orange tone which allows it to undergo oxidation. To know more, visit here: https://www.quora.com/What-are-the-benefits-of-a-copper-composite-panel/answer/Pradip-152

0 notes

Video

youtube

Wall and Ceiling Cladding - WPC “U” Profile - Composite Tube for Indoor ...

0 notes

Text

issuu

Are you looking for luxury marble in London? View our exquisite collection, which features timeless beauty and outstanding quality. Our meticulously sourced marbles promise sophistication and refinement, elevating interiors with their luxurious appeal. Choose the ideal option to add timeless elegance and style to your spaces.

#Premium marble London#White Marble London#High quality Slate London#Exquisite Limestone London#High quality Quartzite London#man made composite quartz London#travertine London#Marble Stair London#Marble Floor London#Marble for Stair Cladding London#Quality Granite London

0 notes

Text

HOW TO INSTALL COMPOSITE CLADDING

Different composite vertical cladding designs use a variety of installation systems, here at Wallong we have chosen what we believe to be the quickest, easiest and securest way to install our SQB-15621 overlap composite cladding. We have created a short article explaining what you'll need to consider when installing the composite cladding.

For installing the composite cladding installation guide, please click here. Let's start at the beginning and guide you step by step through the whole process:

Required Tools for Installing Composite Cladding

Chop Saw

Any wood cutting blade can be used but fine teeth are recommended for a professional finish.

Circular Saw

Power Mitre Saw can also be useful for efficiency and bevelled edges

Jig Saw

Hand Drill - 3mm and countersink drill bits, used for simple straight cuts, radius edges and for intricate shapes.

Drills

Used for creating clearance holes using appropriate-sized wood drill bits depending on the size of the fixing. It also could be used for screwing fixings through clearance holes to firmly secure

Objects

Other tools: Tape Measure, Carpentry Square, Spirit Level, Safety Glasses and relevant Personal Protection Equipment, Calculating Material Requirement

Tools for WPC Composite Wall Cladding

To decide how much wood plastic composite cladding you will need, you can either follow your layout or follow the method below. Please email our team for any assistance with this process, we are happy to offer a quote based on your quantity.

Except for the cladding, you will also need to fix joists, fascia boards and fixing screws. Below are our quantity recommendations:

Joists: Require 3-3.5m per square meter of Cladding

Fascia Boards: Depending on the dimension and situation of your installation are

Fixing screws: Require 15 pcs per square meter cladding

Installation Steps of Composite Cladding

Step 1: Fix the joists according to marked distance. The best span between each joist should be 300-400mm.(Remark: the first joist should be installed min. 20mm from the floor)

Step 2: Screw starting clips to make sure the first cladding board is straight, so the cladding lines up perfectly.

Step 3: Put the first cladding onto the level starters, then pre-drill a hole on the cladding, the length of holes is suggested to be 15mm, and the width is depended on the cap of the screw ( Noted: The cap of the nail should be larger than the width. ) The span between holes should be 300-400mm to allow expansion & contraction.

Step 4: Once secure the first one, place the next cladding board in place and repeat this process, checking the level before each board is fixed. The screw will be invisible during the installation. Fix all boards until the top (or side for vertical) edge of the wall, you may be required to shape boards around doors and windows.

Finishing Steps of Composite Cladding

Install a Fascia Board to finish off and cover the last cladding board.

Remark: Both of these WPC timber products can be cut to size and require pre-drilling and screwing down to joists.

If you have any further questions feel free to see more installation details or contact one of our technical team at [email protected].

0 notes

Text

Aluminum composite panels (ACM) are a type of composite material made from two thin sheets of aluminum bonded to a polyethylene core. They are lightweight, durable, and easy to maintain. ACM panels are often used in exterior applications, such as cladding, roofing, and signage.

Here are some of the benefits of using ACM panels:

Lightweight. ACM panels are lightweight, which makes them easy to install and maintain.

Durable. ACM panels are durable and can withstand the elements.

Easy to maintain. ACM panels are easy to maintain and do not require regular cleaning or painting.

Versatile. ACM panels can be used in a variety of applications, including cladding, roofing, signage, and insulation.

Cost-effective. ACM panels are a cost-effective option for a variety of applications.

If you are looking for a material for an exterior application, ACM panels are a good option. They are lightweight, durable, easy to maintain, and versatile.

Please call or fill out our online form to request an estimate or ask general questions about our services. We are excited to serve you!

(718) 517-9178

https://www.skywindowsnj.com/

#aluminumcompositepanels#acppanels#compositepanels#aluminiumcompositepanels#exteriorpanels#cladding#roofing#signage#insulation#cost-effective#lightweight#contractor#brooklyn windows#window installation nyc#design#nyc windows#Aluminum composite panels

0 notes

Photo

Sydney Deck

medium-sized side yard with a second-story deck and wood railing

0 notes

Text

Why Are ACPs A Popular Choice For Wall Cladding

ACPs are a versatile and sustainable cladding material that can be used to improve the energy efficiency, noise levels, security, indoor air quality, and maintenance costs of a building. They are a popular choice for wall cladding in a wide range of commercial, industrial, and residential buildings.

0 notes

Photo

Deck Side Yard

A medium-sized side yard with a second-story wood railing deck

0 notes

Text

Aluminium Composite Panels: Revolutionizing the Building Industry

Versatility in Design

One of the standout features of ACP sheets is their incredible versatility. Available in an extensive range of colors, finishes, and textures, ACPs allow architects and designers to experiment with styles and aesthetics that were previously hard to achieve. Whether it’s a sleek, contemporary facade or a traditional, rustic look, ACPs provide the flexibility to create visually striking buildings. The ability to mimic materials like wood, stone, and metal further expands the creative possibilities.

Lightweight and Durable

ACPs are significantly lighter than traditional building materials such as concrete or steel. This lightweight nature simplifies transportation and installation, leading to reduced labor costs and faster construction timelines. Despite being lightweight, ACPs boast impressive durability. Their structure—comprising two thin layers of aluminum enclosing a non-aluminum core—ensures resistance to weathering, corrosion, and UV radiation. This durability helps maintain the building's appearance and structural integrity over time, reducing the need for frequent repairs and replacements.

Cost-Effective

In an industry where cost efficiency is paramount, ACPs offer a compelling solution. They generally have a lower initial cost compared to other cladding materials and their long lifespan reduces maintenance and replacement expenses. The ease of installation further cuts down on labor costs, making ACPs an economical choice for many construction projects.

Energy Efficiency

With growing awareness around energy consumption and environmental impact, ACPs play a crucial role in enhancing energy efficiency. The core material of ACPs provides excellent thermal insulation, reducing heat transfer and helping to maintain a stable indoor temperature. This improved thermal performance can significantly cut down on energy usage for heating and cooling, leading to lower utility bills and a reduced carbon footprint.

Sustainability

Sustainability is no longer a niche concern; it's a central focus in construction today. ACPs contribute to sustainable building practices in several ways. Often made from recycled materials, they are also recyclable at the end of their lifecycle, promoting a circular economy. Their energy-efficient properties align with green building standards, making them an ideal choice for environmentally conscious projects.

Fire Resistance

Safety is a non-negotiable aspect of construction, and ACPs offer robust fire resistance. By incorporating special fire-retardant cores, ACPs can meet stringent fire safety regulations, which is particularly important for high-rise buildings and public structures. This fireproof quality, combined with their aesthetic and functional benefits, makes ACPs a preferred choice for many architects and builders.

Ease of Maintenance

Maintaining the exterior of a building can be costly and labor-intensive. ACPs require minimal maintenance compared to other materials. They are resistant to dust and pollution and can be easily cleaned with simple solutions. This low maintenance requirement not only keeps buildings looking new for longer but also reduces the overall cost of upkeep.

Innovative Applications

ACPs are not just limited to exterior cladding. They are increasingly being used in interior applications, such as partitions, false ceilings, and modular kitchens. Their flexibility and aesthetic appeal make them suitable for various design projects. Moreover, ACPs are finding their way into the creation of corporate signage, exhibition stands, and even automotive body parts, showcasing their wide-ranging utility.

Enhanced Acoustic Performance

In urban environments where noise pollution is a concern, ACPs offer enhanced acoustic performance. The core material can help dampen sound, creating a quieter and more comfortable indoor environment. This acoustic benefit makes ACPs an excellent choice for buildings in bustling city areas.

Customization and Branding

For commercial buildings, ACPs offer significant customization potential. Businesses can select specific colors and finishes that align with their brand identity, creating a cohesive and recognizable look. This is particularly beneficial for retail stores, corporate offices, and hospitality venues where visual identity plays a crucial role.

Weather Resistance

Buildings are subjected to various weather conditions, and ACPs are designed to withstand these challenges. They are resistant to rain, wind, and extreme temperatures, making them suitable for diverse climates. This weather resistance ensures that buildings maintain their structural integrity and appearance regardless of environmental conditions.

Retrofitting and Renovation

ACPs are not only ideal for new constructions but also for retrofitting and renovation projects. Older buildings can be given a modern facelift with ACP cladding, enhancing their aesthetic appeal and energy efficiency. This ability to easily retrofit buildings makes ACPs a versatile option for extending the life and functionality of existing structures.

Innovation in Manufacturing

The manufacturing process of ACPs is continuously evolving, leading to improved quality and new product offerings. Innovations such as nano-coatings that enhance self-cleaning properties or advanced fire-retardant cores are examples of how ACP technology is advancing. These innovations ensure that ACPs remain at the forefront of building materials.

Enhanced Safety and Regulation Compliance

As building regulations become more stringent, especially concerning fire safety and environmental impact, ACP manufacturers have adapted to meet these standards. By using fire-retardant materials and adhering to strict quality controls, ACPs help builders and architects comply with local and international regulations, ensuring the safety and legality of their projects.

Contribution to Modern Architecture

ACPs have played a significant role in the evolution of modern architecture. Their ability to create sleek, smooth surfaces and clean lines has contributed to the minimalist and contemporary aesthetic that defines many modern buildings. Landmarks, commercial complexes, and residential buildings alike benefit from the modern touch that ACPs provide.

Conclusion

Aluminium Composite Panels are undoubtedly revolutionizing the building industry. They offer an unparalleled combination of aesthetic versatility, durability, cost-effectiveness, and sustainability. Their ability to enhance energy efficiency, provide fire resistance, and reduce maintenance needs makes them a preferred choice for modern construction projects.

As manufacturing techniques advance and the focus on sustainable building practices grows, the role of ACPs in reshaping the building industry will likely continue to expand. Whether for new constructions or renovations, ACPs offer an innovative solution that meets the demands of contemporary architecture and construction. Their widespread adoption across various applications underscores their significance in creating buildings that are not only visually appealing but also safe, efficient, and sustainable.

In a world where construction demands are constantly evolving, ACPs stand out as a material that meets these challenges head-on, proving to be a cornerstone in the future of building design and technology.

#eurobond acp#acp sheet#eurobond#acp panels#eurobond acp panels#aluminium composite panels#acp panel#eurobondacp#acp cladding#building materials

1 note

·

View note

Text

Sustainable, Colour-Dynamic & Durable Copper Cladding offers an eco-friendly solution for architectural design. Utilizing recycled copper, it provides lasting vibrancy with customizable color options. Its durability ensures longevity, making it a versatile and environmentally conscious choice for building exteriors.

0 notes

Text

Biochar Cladding in Construction

Introduction

Biochar Cladding is a carbon-negative building material made from the pyrolysis of biomass. It can be used as cladding or insulation, offering improved thermal performance and reducing the building’s carbon footprint. Biochar can be utilized as a supplement for plaster or concrete blocks at a ratio of up to 80% when combined with mud, limestone, and cement mortar. This mixing…

View On WordPress

#air purification#Biochar Cladding#biomass pyrolysis#carbon footprint#Carbon Gold#carbon sequestration#carbon-negative building material#cementitious composites#construction#Eco-friendly Construction#electromagnetic shielding#humidity regulation#insulation#noise reduction#Pacific Biochar#plastics#research#sustainable building practices#thermal performance#water purification

1 note

·

View note