#best erp for small manufacturing business

Text

Overcoming Common Challenges in ERP Implementation for Manufacturing

In the dynamic and constantly changing environment of the industrial sector, enterprises must maintain flexibility and strive for competitiveness. Enterprise Resource Planning (ERP) software is a pivotal instrument that facilitates manufacturers in attaining their objectives. Enterprise Resource Planning (ERP) systems provide a broad range of integrated applications that are specifically developed to optimise operational processes, enhance productivity, and facilitate organisational expansion. Nevertheless, despite their considerable potential, ERP for manufacturing industry projects frequently encounter typical obstacles that can impede their achievement.

This blog post aims to examine the world of ERP for manufacturing industry, focusing on the most effective ERP solutions suitable for manufacturing enterprises of varying scales, encompassing both large-scale operations and small-scale organisations. Furthermore, we will explore the common challenges that manufacturers face during the adoption of the best ERP software for manufacturing companies and offer practical strategies for overcoming these difficulties.

The Power of ERP for Manufacturing:

Prior to delving into the complexities and remedies associated with the adoption of Enterprise Resource Planning (ERP), it is essential to comprehend the profound impact that ERP systems have on the manufacturing sector.

· ERP for Manufacturing Industry:

The manufacturing industry is characterised by intricate procedures, a wide range of product offerings, and complicated supply chain dynamics. Enterprise Resource Planning (ERP) demonstrates its exceptional capabilities in this context. Enterprise Resource Planning (ERP) systems for manufacturing encompass the integration of several operational tasks, such as production planning, inventory management, quality control, and finance management, under a unified and interconnected platform. The integration described herein provides manufacturers with the capability to access real-time visibility into their operations, hence facilitating data-driven decision-making and improving overall efficiency.

· Best ERP for Manufacturing Industry:

When it comes to the selection of ERP software for the manufacturing industry, it is imperative to carefully evaluate a system that is in line with the unique requirements of the organisation. Prominent enterprise resource planning (ERP) solutions catering to the manufacturing industry encompass SAP S/4HANA, Oracle ERP Cloud, Microsoft Dynamics 365, and STERP by Shanti Technology. These solutions provide comprehensive functionalities specifically designed for manufacturing processes, enabling organisations to enhance production efficiency, minimise expenses, and enhance overall profitability.

· ERP for Small Manufacturing Businesses:

Enterprise Resource Planning (ERP) systems are not exclusively designed for huge organisations but can also be beneficial for small manufacturing businesses. ERP systems can provide significant advantages to small manufacturing enterprises as well. Indeed, the implementation of an appropriate Enterprise Resource Planning (ERP) solution can effectively equalise the competitive landscape for small-scale firms, equipping them with the necessary resources to compete efficiently. Scalable choices, such as Shanti Technology's STERP, present themselves as suitable solutions for small enterprises seeking expansion opportunities.

Challenges in ERP Implementation for Manufacturing:

Although the potential benefits of Enterprise Resource Planning (ERP) are alluring, the process of deploying such systems might be perceived as a formidable endeavour accompanied by several obstacles. Manufacturers frequently encounter several challenges in their operations.

· Resistance to Change:

Resistance to change is a prominent obstacle encountered with the adoption of Enterprise Resource Planning (ERP) systems. There may exist a certain degree of resistance among employees who have become accustomed to utilising legacy systems over an extended period of time, hence exhibiting hesitancy towards embracing novel technological advancements. In order to surmount this problem, it is imperative to engage employees from the inception, effectively communicate the advantages of Enterprise Resource Planning (ERP), and offer thorough training and assistance.

· Data Migration:

The process of data migration is often characterised by its complexity and time-intensive nature. The process of migrating data from outdated legacy systems to a modern Enterprise Resource Planning (ERP) system has the potential to result in errors and compromise the integrity of the transferred data. The rigorous planning, validation of data accuracy, and implementation of a comprehensive data migration strategy are crucial.

· Integration Issues:

The effectiveness of ERP systems relies on their ability to smoothly integrate with other software and systems utilised inside the organisation. The integration process may encounter difficulties when preexisting systems lack compatibility with the newly implemented Enterprise Resource Planning (ERP) system. Conducting a comprehensive compatibility study and making necessary investments in middleware are critical measures to ensure seamless integration.

· Budget Overruns:

Budget overruns are a common occurrence in Enterprise Resource Planning (ERP) implementations, mostly attributed to unanticipated expenditures such as customisation, supplementary training, or prolonged project schedules. In order to address the issue of budget overruns, it is advisable to develop a comprehensive budget plan, including provisions for unforeseen circumstances, and maintain vigilant oversight of expenditures during the execution phase.

Overcoming ERP Implementation Challenges:

· Change Management:

In order to mitigate resistance towards change, it is imperative to involve employees at an early stage of the process. Organise seminars, facilitate training sessions and effectively articulate the advantages of the Enterprise Resource Planning (ERP) system. Promote the solicitation of feedback and implement necessary modifications in accordance with user input. Resistance to the implementation of the best ERP software for manufacturing company tends to decrease when employees perceive the system's usefulness and receive enough support during the transition process.

· Data Migration Strategy:

The effectiveness of data migration is contingent upon thorough planning and precise implementation. Establish a data migration team tasked with the responsibilities of data cleansing, validation, and mapping. It is advisable to conduct testing of data migration procedures inside a controlled setting prior to executing the implementation on a larger scale. It is imperative to consistently perform data backups in order to safeguard data integrity throughout the transfer process.

· Integration Expertise:

In order to address integration difficulties, it is advisable to engage in collaboration with ERP suppliers and IT professionals who possess specialised knowledge and skills in the field of integration. These individuals possess the ability to identify possible challenges related to integration and devise appropriate strategies to address them. It is advisable to explore the option of investing in middleware or connectors that can effectively facilitate the integration process between the Enterprise Resource Planning (ERP) system and the pre-existing systems.

· Budget Management:

In order to mitigate the occurrence of budget overruns, it is advisable to design a budget that is grounded in realism and includes a contingency fund. It is advisable to conduct periodic evaluations of expenditures and make necessary modifications to the budget accordingly. It is advisable to give precedence to fundamental customization and supplementary components while postponing non-essential functionalities to subsequent stages of the implementation process. The implementation of a staged approach can effectively manage expenses while also guaranteeing the establishment of essential functionality.

Leveraging STERP for Manufacturing Company:

In the context of addressing the obstacles encountered during ERP adoption, it is vital to underscore the potential value that Shanti Technology's STERP solution holds for manufacturers.

· STERP's Manufacturing Expertise:

The manufacturing expertise of STERP is highly regarded as it is an ERP solution that has been specifically tailored to meet the needs of the manufacturing industry. The software provides a variety of functionalities specifically designed for manufacturing operations, including but not limited to demand prediction, production scheduling, and quality management. The industry-specific experience of STERP facilitates the deployment process and guarantees a seamless alignment between your ERP system and your manufacturing requirements.

· Scalability for Small Manufacturers:

Scalability is a crucial aspect for small manufacturers, and it has been observed that the Small Manufacturer Enterprise Resource Planning (STERP) system offers a viable solution in this regard. As an enterprise expands, the Scalable Technology and Enterprise Resource Planning (STERP) system may effectively meet the increasing requirements, so serving as a favourable option for organisations seeking efficient scalability without the necessity of investing in a new Enterprise Resource Planning (ERP) system in the future.

· Comprehensive Training and Support:

STERP provides a comprehensive training and support programme aimed at facilitating a seamless changeover process. STERP offers a comprehensive range of services, including on-site training sessions and round-the-clock customer support, to ensure that your staff is adequately equipped to maximise the efficiency and effectiveness of the ERP system.

Final Thoughts:

The deployment of Enterprise Resource Planning (ERP) systems in the manufacturing business presents several difficulties. However, by employing appropriate techniques and utilising the best ERP software for manufacturing companies, developed by STERP (Shanti Technology), these issues can be effectively addressed. Manufacturers can optimise the utilisation of ERP systems by effectively handling resistance to change, methodically preparing data migration, managing integration processes efficiently, and maintaining strict adherence to budgetary considerations.

It is important to acknowledge that the adoption of Enterprise Resource Planning (ERP) systems should not be viewed as a singular occurrence, but rather as a continuous endeavour aimed at achieving optimal performance. It is imperative to consistently evaluate the performance of your Enterprise Resource Planning (ERP) system, solicit input from users, and remain abreast of prevailing industry standards in order to ascertain that your ERP system is capable of efficiently supporting your manufacturing activities.

The STERP system represents an optimal enterprise resource planning (ERP) solution specifically designed for the manufacturing sector. It provides customised functionalities, scalability, and comprehensive assistance to enable firms to excel in a highly competitive market. Manufacturers can achieve operational streamlining, enhanced efficiency, and long-term success in the ever-changing industrial landscape by making informed decisions on the selection of an appropriate Enterprise Resource Planning (ERP) solution according to established implementation best practices.

#ERP for manufacturing industry#Best ERP for manufacturing industry#ERP for small manufacturing business#Best ERP software for manufacturing#Manufacturing software for small business#Best ERP for small manufacturing business#ERP software for manufacturing industry#ERP for manufacturing company

7 notes

·

View notes

Text

10 Cutting-Edge Manufacturing ERP Tools Unveiled in 2024

In the ever-evolving landscape of manufacturing, complexity and sophistication have surged. The era of simplistic inventory management through barcode scanning or widget counting is a thing of the past. The contemporary demand is for an Enterprise Resource Planning (ERP) system for manufacturing that seamlessly integrates with all facets of an organization's business systems.

Instantaneous insights are the lifeblood of the sales team, requiring real-time data on shelf units. Finance departments lean on manufacturing ERP systems to project revenues and expenses in the months ahead. In an era of heightened interconnectivity in business processes, internal systems and technology must support this synergy. The paramount manufacturing ERP software will catapult your organization to new heights by optimizing the Order-to-Cash (O2C) process, providing predictive insights, leveraging AI for production decisions, and harmonizing with other business systems for optimal outcomes.

Behold, our compilation of the premier manufacturing ERP systems available in the market. Your ideal choice depends on the size of your organization, your production requirements, and your existing business platforms, as one may outshine the others.

Unveiling the Essence of Manufacturing ERP Software

At its core, manufacturing ERP software meticulously monitors all elements of the production process. It comprehends the raw materials on hand, Work-in-Progress (WIP) products, finished inventory levels, and customer demand. Leveraging revolutionary technology, these ERP systems disseminate this information across the business landscape, facilitating financial analysis, supply chain and logistics management, and more.

Imagine if your ERP for manufacturing seamlessly communicates with customer relationship management tools, human resources software, project management solutions, and automation enablers. This integration heralds a new era for your business, dismantling siloed functions and systems to enhance the efficiency and effectiveness of every individual within the organization.

Gone are the days of on-premise limitations; today's cloud-based ERP software for manufacturing transcends boundaries. Accessible from anywhere, boasting extensive data capabilities, and fortified security, these modern ERP solutions redefine the manufacturing landscape.

Pervasive Benefits of Manufacturing ERP Software

Selecting the right ERP for manufacturing is not just a choice; it's a strategic move with far-reaching consequences. Manufacturing, as the bedrock of any business producing goods, reaps multifaceted benefits from these ERP systems. Beyond inventory management, these top 5 advantages are indispensable:

Revolutionizing Warehouse Management and Operations: ERP systems for manufacturing bring about a paradigm shift in managing warehouses, elevating operational efficiency.

Enhancing Customer Experiences: Ensuring timely deliveries, maintaining product quality, and more contribute to an enriched customer journey.

Automation for Unparalleled Productivity: Reliable ERPs usher in automation, a pivotal productivity enhancer across industries, recognizing the criticality of every second in manufacturing.

Strategic Inventory and Supply Management: Effectively managing inventory and supplies is paramount for cash flow optimization, encompassing bulk purchases, waste prevention, and meeting demand.

Empowering Sales Teams: Equipping your sales team with real-time insights into inventory and production allows for a nuanced balance between production and sales.

The Elite 10 Manufacturing ERP Software of 2024

The right ERP manufacturing systems not only simplify invoice management and improve supply chains but also monitor purchase orders, highlight bulk orders, streamline vendor management, and alert leadership when anomalies arise. In the realm of manufacturing ERPs, investing wisely is as crucial as selecting the right accounting ERP. Here are the standout solutions of the year:

1. Acumatica

With tailor-made product solutions for organizations of all sizes, Acumatica's ERP for manufacturing seamlessly adapts to your business growth. The inclusion of industry-specific editions ensures a personalized approach, with features like built-in AI and ML capabilities, analytical dashboards, customization features, and automated reporting.

Pros: Acumatica's manufacturing ERP software is renowned for its adaptability, offering personalized solutions aligned with industry needs.

Cons: Users cite limitations in the mobile app associated with Acumatica's ERP systems, hindering on-the-go production management.

2. Syspro

Focused on smart manufacturing, SYSPRO's manufacturing ERP software is a boon for production companies aiming to elevate their capabilities. From simplified order management to meticulous tracking of production stages, this ERP accommodates various manufacturing methods. Assemble-to-order, batch manufacturing, discrete manufacturing, make-to-stock, and process manufacturing find reliable support in this system.

Pros: SYSPRO manufacturing ERP software is celebrated for its user-friendly interface and swift implementation. Its scalability and comprehensive features ensure longevity as your business evolves.

Cons: Lack of Human Resources (HR) functionality in the SYSPRO ERP suite poses integration challenges for this vital business function.

3. Oracle NetSuite

Boasting decades of market presence, Oracle NetSuite's ERP for manufacturing stands tall as an industry leader, ideal for large enterprises. Leveraging the Internet of Things (IoT) and real-time business intelligence updates, this ERP integrates machine learning into the production ecosystem.

Pros: Oracle NetSuite enjoys substantial financial backing, constantly evolving its manufacturing ERP systems for heightened efficiency.

Cons: Tailored for large enterprises, it may not be accessible for small or mid-market companies due to its high cost.

4. Microsoft Dynamics 365 ERP

Tailored for small businesses, Microsoft Dynamics 365 ERP leverages Azure for cloud support and harnesses the Internet of Things (IoT) to augment manufacturing operations. Highly rated in the Small and Medium-sized Business (SMB) space, it integrates seamlessly with Microsoft 365 products, offering features like integrated sensors, embedded AI capabilities, and modules for various functional insights.

Pros: Microsoft Dynamics 365 ERP provides an all-encompassing solution, simplifying business operations, assessing insights, and facilitating app development based on individual needs.

Cons: Users note a steep learning curve in the interface, posing challenges in intuitiveness, especially for those familiar with other Microsoft 365 products.

5. Epicor Manufacturing ERP

A stalwart in the manufacturing ERP systems arena, Epicor has evolved to offer a cloud-based ERP manufacturing software. Embracing the Industrial Internet of Things (IIoT) and featuring a push-notification system for leadership alerts, Epicor caters to medium-sized businesses worldwide.

Pros: Epicor's extensive knowledge base spans global supply chains, best practices in manufacturing, and a forward-looking approach.

Cons: Managing Epicor requires a tech-savvy team, potentially posing challenges for organizations lacking internal IT resources.

6. SAP

Deployed by major companies globally, SAP is a manufacturing ERP system capable of handling intricate business structures. Beyond manufacturing, it extends to finance and accounting functionalities, incorporating IoT, AI, ML, and Blockchain into its comprehensive solution.

Pros: SAP's widespread industry reach eases adoption, as many employees may be familiar with its functionalities.

Cons: The high price tag and size of the platform might limit adaptability to customer needs or tailored solutions.

7. Aptean

Revolutionizing the food and beverage industry and other niche sectors requiring precise manufacturing settings, Aptean stands out. Specialized in tracking products from inception to delivery, it ensures compliance with food safety regulations and FDA requirements.

Pros: Aptean's AI-driven suggestions support continuous improvement, focusing on specific industries.

Cons: Limited compatibility with every industry demands careful consideration of business fit before adoption.

8. MRPeasy

Originating as a Material Requirements Planning (MRP) system, MRPeasy has expanded into the realm of manufacturing ERP systems. Combining features of classic ERPs like Xero or QuickBooks, it excels in manufacturing management, inventory monitoring, and related activities.

Pros: One of the most cost-effective systems, MRPeasy offers extensive manufacturing capabilities.

Cons: Reliance on multiple software integrations may be necessary for non-manufacturing business functions.

9. SyteLine ERP (Infor CloudSuite Industrial)

Acquired by Infor and often known as Infor CloudSuite Industrial, SyteLine ERP caters to diverse manufacturing processes simultaneously. Tailored for medium and large businesses, it excels in supporting complex production lines.

Pros: SyteLine adapts easily to changing manufacturing needs, offering automation-enabled shop floor processes.

Cons: With a more manufacturing-focused approach, it provides less support for finance, sales, and marketing functions.

10. Genius ERP

Crafted for custom manufacturers, Genius ERP goes beyond traditional manufacturing software. With accounting and business process functionalities, it integrates specialized features with CAD and SOLIDWORKS.

Pros: Specialized integrations with CAD and SOLIDWORKS make Genius ERP an ideal choice for high-mix, low-volume manufacturers.

Cons: Due to its specialized use case, mastering Genius ERP may pose challenges, and customer support during implementation is noted to be limited.

Choosing the Optimal ERP for Manufacturing

The selection of ERP systems for manufacturing necessitates a thorough evaluation of various factors. Consider your budget, ensure reliable support mechanisms in times of need, ascertain the features align with your requirements, and choose a system that fits the scale of your organization. Today is the day to embrace manufacturing ERP systems, unlocking advanced capabilities for finance automation, accounting best practices, and comprehensive inventory management. Seize the opportunity to elevate your business with the transformative potential of ERP software.

#manufacturing software for small business#manufacturing erp software#erp for manufacturing industry#erp software for manufacturing industry#erp systems for manufacturing#best erp for manufacturing#erp for manufacturing#best erp for small manufacturing business#visual manufacturing#best erp software for manufacturing#cloud manufacturing erp#erp solutions for manufacturing

1 note

·

View note

Text

#erp benefits for manufacturing industry#erp for manufacturing industry#erp for small business manufacturing#best erp for small manufacturing business

0 notes

Text

SAP Business One for Chemical Industry

With all its benefits, global chemical manufacturing companies are incorporating SAP B1 at an increased rate for chemical production. Not only does it help in improving business efficiency and enhancing collaboration but it also aids in increasing customer satisfaction and increasing revenue by up to 10-30%. With the change in business dynamics and fluctuations in demand, robust ERP software can empower chemical businesses to take advantage of their competition while adhering to safety, quality, and compliance requirements. SAP b1 solutions are already used by nearly 6500 chemical industry businesses and more are soon to follow.

Managing costs effectively is an essential aspect of chemicals and any industry. In the chemical industry, SAP Business One provides intuitive planning and scheduling to manage time and resources efficiently and cut down on business costs to control every aspect. The cost of materials can also be estimated by analyzing the production data history and past purchases in a single click to simplify business processes. SAP chemical industry best practices optimize different processes, improve workflow efficiency, and reduce overtime costs by 48%.

#sap business one#SAP Business One Partner in India#SAP Business One partner#SAP Business One ERP Solution#SAP Business One for Manufacturers#SAP chemical industry#ERP Software#best erp software#best erp software in india#food beverage erp software#erp software for construction#erp#enterprise software#ERP Solution#SAP ERP#erp for small business#erp development company#erp consulting services#enterprise resource planning#erpsystem

2 notes

·

View notes

Text

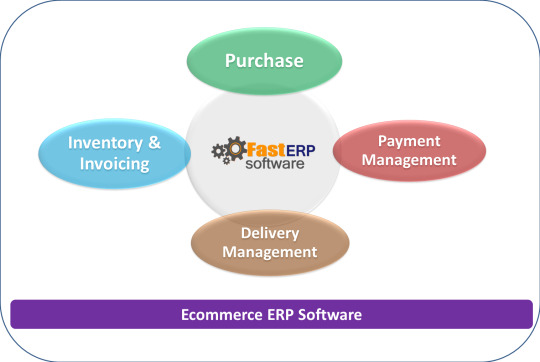

Future-Proofing Your Business: Fast ERP Software's Path to Success

We provide integrated ERP Software for Retail, Distribution and Manufacturing to thousands of customers to date, helping them to meet their business goals. ERP solutions developed by Fast ERP software are characterised by their flexibility and scalability to aid in the business growth of the customers in the time ahead. Cost-effective solutions are designed for specific needs and verticals, help mid-sized to large business ventures address issues, review business performances, and assist strategic decisions to fulfil the demands of the market.

ERP computer software stands for enterprise resource planning, but what does ERP mean? The simplest way to define ERP is to think about all the core business processes needed to run a company: finance, HR, manufacturing, supply chain, services, procurement, and others. At its most basic level, ERP helps in efficiently manage all processes in an integrated system. It is often referred to as the system of record of the organisation.

Importance of Enterprise Resource Planning (ERP) software- we provide The best web-based ERP solutions software in India, serve enterprise resource management and offer for managing core functions such as finance, human resources, supply chain, manufacturing, and customer relationship management. By consolidating data and processes into a centralised system, ERP enables organisations to break down silos, improve collaboration, and gain real-time insights into their operations.

Utilities- need to constantly review their capital assets, not only to meet the demand for future services but also for the replacement of ageing assets. Without ERP, the effort to prioritise these major asset investments would be difficult and error-prone. ERP also helps solve another critical utility company issue: forecasting of spare parts. Not having the right parts during an outage can create a significant customer service issue.

Wholesalers- importers, direct store delivery, and 3PL/4PL firms, on-time delivery. All organisations want to reduce distribution costs, increase inventory turns, and shorten order-to-cash time.

Manufacturers- ERP is manufacturing software for small businesses and supply chain systems to meet product quality goals, manage asset utilisation, control overtime costs and handle customer returns and money.

Service companies – including accounting, tax, engineering, IT, legal, and other professional services firms – require powerful, real-time mobile ERP computer software to balance service delivery commitments with financial health.

Enhancing Visibility and Control: increasing visibility and control over business operations. In real-time access to data and analytics, track project progress, and identify areas for improvement. It facilitates, monitoring cash flow, analysing sales trends, or forecasting demand, ERP computer software gives you details needed to make decisions and respond to changing market conditions. By installing security protocols and access controls, ERP safeguards confidential information.

Growth and Innovation: ERP enables businesses to innovate by providing a flexible platform for evolving market trends and customer demands. ERP supports strategic initiatives that yield growth and profitability. with cloud-based ERP solutions, businesses can access the latest features and able to grow in the dynamic business environment.

ERP software emerges as a strategic partner for your business growth. integrating core functions, streamlining operations, and providing actionable insights. ERP empowers organisations to optimise performance, mitigate risks, and seize new opportunities. small startup or a global enterprise, with ERP you will gain long-term benefits and propel your business towards success in the digital age.

#manufacturing erp software#best web based erp software in india#manufacturing software for small business

0 notes

Text

Top Cloud ERP Software for Manufacturing Industry in Ahmedabad

ZipERP is a renowned provider of Cloud ERP Software for Manufacturing Industry in Ahmedabad, India. We provide the best ERP software specially designed to fulfill the needs of the manufacturing industry while helping them reduce costs. For more information, contact us today.

#cloud erp software for manufacturing industry ahmedabad#cloud erp software for manufacturing business in india#best erp for small manufacturing business in india

0 notes

Text

Erp for Manufacturing: a Comprehensive Guide to Optimising Processes

In the era of digital transformation, the very fabric of the manufacturing industry has altered dramatically. As technology evolves, every facet of the manufacturing process, from designing and production to marketing and sales, has been influenced significantly. In this dynamic milieu, Enterprise Resource Planning (ERP) software for manufacturing emerges as a vital instrument that meets all contemporary business needs by unifying all aspects of the business. This comprehensive guide discusses ERP for manufacturing, elaborating on its importance, features, benefits and the top contenders in the marketplace.

The Importance of ERP in Modern Manufacturing

In the context of the manufacturing industry, ERP systems have become an indispensable backbone. These are comprehensive suites of applications that amalgamate data from various departments, thereby offering a consolidated, real-time snapshot of business operations. ERP systems facilitate better intra-departmental coordination, enhance operational efficiency and expedite decision-making. With robust manufacturing ERP solutions, businesses can align their diverse operations, including production, procurement, inventory, sales, finance and human resources under one canopy. This enables them to swiftly adapt to ever-changing market demands and maintain an edge over the competition.

Advantages Of ERP For Manufacturing Industries:

1. Operational Efficiency: ERP systems automate repetitive tasks and streamline complex processes. This reduces the scope for errors and improves overall efficiency.

2. Real-Time Insights: ERP software provides real-time, accurate information from across the organization. This helps in making informed and timely decisions.

3. Cost Reduction: By improving operational efficiency and reducing waste, ERP systems can significantly lower operational and administrative costs.

4. Enhanced Collaboration: ERP systems break down data silos and facilitate better communication and collaboration between departments.

5. Scalability: ERP solutions are scalable and adaptable, making them ideal for growing businesses. As a company expands, the system can be updated to accommodate new processes and functions.

6. Inventory Management: ERP systems offer sophisticated tools for managing inventory, forecasting demand and ensuring that production can keep pace with orders.

7. Improved Customer Service: With improved order accuracy and faster response times, ERP systems can greatly enhance a company’s customer service.

8. Regulatory Compliance: ERP software makes it easier for businesses to adhere to industry-specific regulations by providing built-in compliance tools and keeping a complete audit trail of all actions.

9. Risk Management: By providing a bird’s eye view of the business operations, ERP systems help identify potential issues before they become problems, aiding in risk management.

10. Forecasting: ERP systems provide tools that utilize the data they hold to forecast trends, allowing businesses to make proactive decisions and strategic plans.

For More information visit our site: Erp for Manufacturing

#erp consultant#erpsolutions#Erp Software for Manufacturing Industry#erp for small business#production planning and control#best erp solution providers#erp#youtube#erp software

0 notes

Text

Quality Assurance in the Digital Age: Leveraging ERP Solutions

In the digital age, quality assurance has become a critical aspect for businesses across industries. In particular, the metal alloys industry and extrusion processes require advanced solutions to ensure consistent quality and efficiency. This is where “Extrusion ERP” comes into play. By using Extrusion ERP for the metal alloys industry, businesses can effectively manage inventory levels, track production performance, and monitor quality control measures.

Key Benefits of Using Extrusion ERP for Quality Assurance:

In an industry where quality can make or break your reputation, Extrusion ERP is the key to ensuring consistent, high-quality products. By leveraging ERP solutions for quality assurance, businesses can unlock several key benefits, including:

Increased Efficiency and Productivity

Enhanced Product Quality

Better Supply Chain Collaboration

Data-Driven Decision Making

Take the Leap to Quality Excellence!

Ready to transform your quality assurance practices in the metal alloy industry? Extrusion ERP is your best partner on this journey.

Don't settle for mediocrity. Advance your quality standards, streamline your operations, and enhance your environmental sustainability with Extrusion ERP. It's time to empower your business for success in the digital age.

Contact us today for a personalized demonstration and discover how Extrusion ERP can unlock a new era of quality assurance in the metal alloy industry. Your quest for exceptional quality begins now.

#ERP Software for Aluminium Extrusion#ERP Software for Aluminium Extrusion Companies#ERP Solution for Aluminium Extrusion Industry#ERP Software for Metal Industry#ERP for Aluminium Extrusion Companies#ERP Software Development Services#ERP Development Company#ERP Software Development Companies#ERP Software for Aluminium Industry#ERP Software Development Company#ERP Software for Extrusion Companies#Ultimate Extrusion ERP Solution#Extrusion ERP Software Maintenance#Extrusion ERP Solutions in India#ERP Software For Metal Alloys Industry#Small Business Manufacturing Software#Best ERP for Aluminium Extrusion Industry#Tailored ERP for Aluminium Extrusion Industry#Extrusion ERP Software for Aluminium Extrusion Manufacturing#Extrusion ERP Excellence for Aluminium Extrusion Manufacturers#Aluminium Extrusion Management ERP#erp for aluminium extrusion industry

0 notes

Text

7 Best ERP Softwares For Manufacturing In 2023

What Are The Manufacturing Software Benefits?

Consider upgrading your manufacturing ERP system with new technology to handle manufacturing operations and business processes. As a result, your manufacturing company will experience cost savings, increased profitability, and improved business intelligence and decision-making, all of which will boost revenue and ROI.

Streamline Processes: The benefit we get from ERP systems or software is you can automate and streamline processes with ERP software and improve your entire department’s complete efficiency and productivity.

Cash Flow Management: ERP software allows constant and reliable cash flow which is important to most businesses. Integrated ERP software can help you manage your cash flow and hence minimize development risks. Once all transactions are logged, you have an in-depth log of what is received and what is sent.

Easy Production Management with Different Locations:

Process across various manufacturing plants from the duration the number of workforces that are involved, the budget spent, and raw material used the product lifespan, and the internal and external transferals consequently cloud-based software for manufacturing can help the manufacturing review process from any place on a mobile device.

Improved Decision-Making with Accurate Data: Manufacturing software facilitates manufacturers to gain estimation accuracy by supplying data on all aspects of their business operations. For instance: profit and loss, customers, sales performance, labor, inventory, and many more. All the generated data helps investors create more precise estimates and real forecasts, allowing management to act smarter and faster in business making decisions.

List of 7 ERP Software for the Manufacturing

ERP software can improve operational efficiencies by serving as a one-stop shop for all of your business processes. This is far more desirable and efficient than using disparate tools from disparate vendors that don’t work well together or requiring employees to log in to multiple accounts to complete simple tasks.

Here we have listed The 7 Best ERP Software for Your Business

1. ECI M1

The cloud-based business management software of ECIM1 minimizes workflow tussles and provides you visibility into your whole operation. They designed M1 for SMBs that focussed on make-to-stock, repetitive, discrete, project, and volume-based make-to-order manufacturing industry processes.

Benefits:

1. This ERP software is intended for small or medium-sized business manufacturers, containing mixed-mode, job shops, and custom and to-order manufacturers.

2. ECI M1 software provides complete integration and automation of jobs from estimating through invoicing.

2. PMTrackERP Software

PMTrack ERP is the popular ERP Software Company in Pune that delivers ERP software services to Manufacturing companies. The Company similarly provides ERP software services for the plastic and Rubber, sheet metal, and forging industries. The suite of applications includes modules for managing accounting, order processing, inventory management, production management, and supply chain operations.

Benefits:

PMTrackERP software offers numerous benefits to businesses. Here are some of the benefits of using PMTrack ERP software:

1. Improved Productivity: The software provides real-time data on employee workflow, which helps managers and stakeholders to identify areas of improvement and increase productivity.

2. Better Decision-Making: PMTrack ERP software provides accurate and up-to-date information on various business processes, which helps managers make informed decisions.

3. Enhanced Collaboration: The software allows for seamless collaboration among team members, which leads to better communication, increased efficiency, and better results.

4. Efficient resource management: The software helps businesses to manage resources such as inventory, finances, and human resources more efficiently, leading to cost savings and increased profitability.

5. Streamlined business processes: PMTrackERP software automates various business processes, reducing the need for manual intervention and minimizing errors. This leads to improved efficiency and helps in reduced operational costs.

PMTrack ERP is the Best ERP software for manufacturing and offers a wide range of benefits to businesses, including improved productivity, better decision-making, enhanced collaboration, efficient resource management, and streamlined business processes.

3. SAP Software

SAP is a leading enterprise software company that provides a wide range of Solutions to businesses of all sizes and industries. Its software suite includes enterprise resource planning (ERP), customer relationship management (CRM), supply chain management (SCM), and financial management software

Benefits:

1. SAP’s ERP software, SAP S/4HANA, uses in-memory computing to process large amounts of data and support advanced technologies such as artificial intelligence (AI) and machine learning (ML).

2. The company’s solutions are designed to help businesses run more efficiently and effectively by providing automation, integration, and intelligence across all day-to-day business operations

4. QT9

This ERP software is designed for life sciences companies and offers features such as quality management, document control, and inventory control. It is also a scalable solution that can be customized to meet the specific needs of the business.

Benefits

1. Easy Business Operations: The suite provides automation, integration, and intelligence across all day-to-day business operations and includes enterprise performance management software to help plan, budget, and forecast financial performance across the organization.

2. Customized application: The suite of applications is also highly customizable, allowing businesses to tailor the software to their specific needs and requirements

5. Infor CloudSuite Industrial

Infor CloudSuite Company is providing a dynamic and flexible Industrial solution during the COVID lockdown. Even though their staff had to work remotely, they were able to hold the business running and keep up with consumer orders.

Benefits:

1. Management Features: This ERP software is designed for manufacturers and offers features such as financial management, supply chain management, production management, and quality control.

Easily Accessible: It is also a cloud-based solution that can be accessed from anywhere.

6. Oracle ERP software:

Oracle ERP software is a suite of cloud-based enterprise resource planning (ERP) applications designed to help businesses manage their day-to-day operations, including accounting, procurement, project management, risk management and compliance, and supply chain operations

Benefits:

ERP software of Oracle, includes Cloud ERP, Oracle Fusion which is a comprehensive, up-to-date, cloud ERP suite that provides innovative capabilities such as analytics to react to market shifts and AI to automate manual processes in a short span.

1. Business Operations Facility: Oracle’s ERP software is designed to help businesses run more efficiently and effectively by providing automation, integration, and intelligence across all day-to-day business operations

2. Better Financial Operations: The suite also includes enterprise performance management software that helps plan, budget, and forecast financial performance across the organization.

3. Better Management and Operations: Oracle ERP software is a suite of cloud-based applications that helps businesses manage their operations, including accounting, procurement, project management, risk management and compliance, and supply chain operations.

7. NetSuite ERP

NetSuite ERP software is a cloud-based business management solution that helps administrations operate more efficiently by automating fundamental processes and providing real-time visibility into financial as well as operational performance.

Benefits:

1. Analytics Tool For Informed Decisions: NetSuite ERP offers advanced capabilities likewise analytics and AI to support businesses makes informed decisions and reacting to market shifts immediately.

2. Unified Business View: One of the key benefits of NetSuite ERP is its ability to provide a unified view of the business, enabling organizations to streamline processes, reduce costs, and improve efficiency

3. Software Access with Less Cost: Additionally, NetSuite ERP is a cloud-based solution, which means that businesses can access the software from anywhere with an internet connection and do not need to invest in expensive hardware or IT infrastructure

4. Provides Instant Visibility: We can say NetSuite ERP is cloud-based business management software that provides instant visibility into financial and operational performance. The suite of applications includes modules for managing accounting, order processing, inventory management, production management, and supply chain operations. NetSuite ERP is highly customizable, offers advanced capabilities such as AI and analytics, and is accessible from anywhere with an internet connection.

Conclusion:

Firms can reduce risk, increase collaboration, and drive growth by leveraging automation and interconnected data. ERP software has undoubtedly linked data via a fully integrated system, which typically saves companies money that would otherwise be spent on hundreds of unconnected apps.

Considering the top Best ERP software listed above can undoubtedly provide benefits to businesses. Oracle NetSuite and Microsoft Dynamics 365 are two of the best ERP systems available today. Depending on your requirements, PMTRACK ERP, SAP Business One, and Sage 300 are also excellent tools.

#best erp for manufacturing#ERP Solution#erp system#erp implementation#ERP for manufacturing industry#ERP for Manufacturing#erp for small business

0 notes

Text

Looking for the best cloud ERP software company in Malaysia? Look no further than Hypernix! As a leading ERP Software company in Malaysia, we understand the importance of cloud ERP software for modern businesses.

Cloud ERP software is an essential tool for managing all aspects of your business, from finances and inventory to supply chain management and customer relationships. With cloud technology, ERP software has become more accessible and affordable than ever before.

#Best Cloud ERP Software In Malaysia#Cloud ERP Software In Kuala Lumpur#cloud-based ERP system#Cloud-Based ERP Solution#Manufacturing Cloud ERP Malaysia#Cloud Based ERP For Small Business#Cloud Based ERP Software Company In Malaysia

0 notes

Text

#top ERP Solutions#clolud based erp#Cloud ERP#best ERP for food manufacturing#small business ERP software#best ERP system#best manufacturing software best ERP software#best ERP for small business

0 notes

Text

Streamline Your Operations with Manufacturing Software for Small Business | shantitechnology | STERP

Discover the best ERP for small manufacturing businesses at shantitechnology (STERP). Our ERP software for the manufacturing industry is designed to boost efficiency and productivity. Get the tools you need to excel in the manufacturing sector. Elevate your manufacturing company's performance and competitiveness.

Take your manufacturing company to new heights with shantitechnology (STERP).

#Manufacturing software for small business#Best ERP for small manufacturing business#ERP software for manufacturing industry#ERP for manufacturing company#shantitechnology#STERP

6 notes

·

View notes

Text

3 Questions to ask your ERP consultant pre-hire

ERP consultants are very pricey these days. Before you engage one for your ERP project, examine the following criteria to help you find the ideal one. These should be the ideal questions on whether you want to employ a consultant for selection, project management, or another ERP reason.

What ERP software is available?

With so many ERP options on the market, picking which one is best for your…

View On WordPress

#best erp software for manufacturing#best erp software for small business#best erp software in dubai#best erp software in uae#erp consulting companies#ERP Dubai#ERP for Manufacturing industry#ERP Software for Textile Companies#ERP Software for Trading Companies#erp software solutions#erp software solutions dubai#erp software uae#erp solution#erp solution dubai#erp solution providers#erp solution providers in uae#erp uae#Financial Management#Food Manufacturing ERP Solutions#retail erp software#retail erp software dubai#retail erp solutions#top 10 erp software#top erp companies#top erp software vendors

0 notes

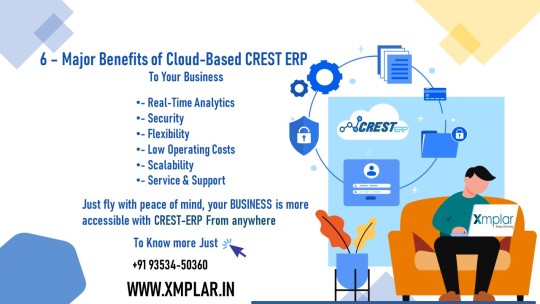

Photo

6-major Benefits of Cloud-Based CREST-erp

#erp#erp software#erp consultant#manufacturing software#erp for manufacturing#erp for small business#erp integration#best erp software

0 notes

Link

#erp#erp software#erp for small business#erp for manufacturing#erp system#erp solutions#erp implementation#erp modules#erp company#erp services#best erp software#erp provider

0 notes

Text

ERP in the Cloud: Advantages for Small Manufacturers

Fast ERP software is providing one of the best ERP for manufacturing industry or manufacturing software for small business that make things this helps them manage everything from making stuff to keeping track of what they have. This software is helpful because it's made just for small businesses, so it fits their needs perfectly. It's easy to use and helps them work faster and smarter. With this software, small businesses can compete better and grow bigger in the manufacturing world.

Small manufacturers face many challenges in running their businesses efficiently. They need to manage their resources, track inventory, and plan production schedules—all while trying to grow their businesses. These are the times when manufacturing ERP software in the cloud come in handy. Small manufacturers can get a lot out of these tools that can help them deal with problems and do well in today's tough market.

Small manufacturers can often save more money with cloud-based manufacturing ERP software than with traditional on-premise options. When you use cloud-based ERP, you don't have to buy expensive hardware or hire IT people to keep it running. Small makers don't pay a big fee up front; instead, they pay a monthly fee to access the software. This is often cheaper and more predictable.

Cloud-based ERP systems are very adaptable and scalable, which means they can easily change to meet the needs of small businesses as they grow.

One of the best things about ERP for manufacturing industry is that anyone with an internet link can use them. This means that small producers can run their businesses from home, the office, or while they're out and about. Team members can work together and get more done when they are flexible, even if they are not all in the same place.

Small manufacturers don't have to worry about installing updates or keeping the software up to date because cloud-based ERP systems are managed and updated by service provider of ERP for manufacturing industry.

This makes sure that they always have the newest features and security changes without having to do anything extra.

ERP systems that run in the cloud usually have stronger security than systems that are installed on-site. Both while data is being sent and while it is being stored, it is encrypted. To protect against cyber threats, we (Fast ERP software technology) providers usually have multiple layers of security, such as firewalls and breach detection systems. This gives small manufacturers peace of mind because they know their private business info is safe.

Cloud-based manufacturing erp software makes business processes more efficient by handling tasks that are done over and over again and showing key metrics in real-time. Small makers can then make better choices and react more quickly to changes in the market. Cloud-based ERP systems can also help boost general efficiency and productivity.

Integrating third-party apps and services, like financial software, e-commerce platforms, and CRM systems, is something that a lot of cloud-based ERP systems can do. Small producers can now run all of their businesses from one platform. Because they can connect to other tools and systems, cloud-based ERP software can help small makers improve how they work together and streamline their processes.

#manufacturing erp software#manufacturing software for small business#best erp for manufacturing industry

0 notes