#aluminium casting

Text

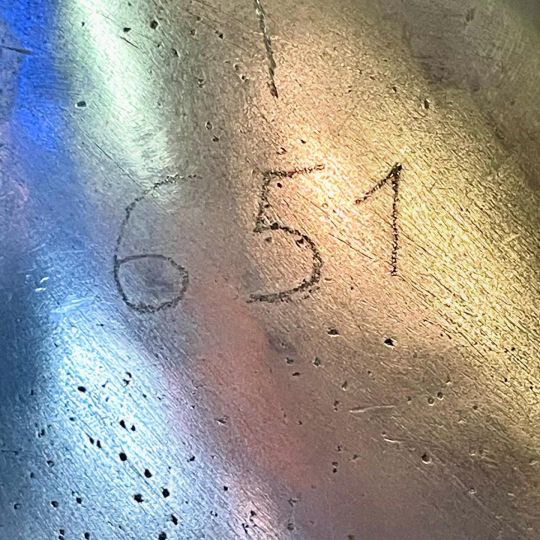

mother of bra

"The underwear manufacturer Triumph was one of the leading inventors of bras without a front fastening and with adjustable straps. These sculptural shapes made of cast aluminium were used in the production of bras, probably from the 1960s onwards."

cred: instagram.com/nichtsneues_wien

6 notes

·

View notes

Text

Aluminium Casting: Empowering The Automotive Industry

Lightweight auto parts

Aluminium is almost three times lighter than steel but offers almost the same strength and rigidity. Aluminium casting makes vehicles lightweight vehicles and fuel-efficient.

Shaped for better control and speed

Aluminium casting creates high-precision parts faster than any other process. The process is ideal for aerodynamic designs and intricate components of the engine.

Unquestionable durability

Aluminium is corrosion-resistant and possesses excellent thermal conductivity. It is suitable for any weather condition and dissipates heat faster than steel.

Suitable for EVs

Aluminum casting offers excellent solutions for EVs that need to be lightweight. Right from battery housing and enclosure to stator and rotor of the motor are designed with aluminum alloys.

Eco-friendly components

Lightweight vehicles consume less fuel reducing carbon emissions and making cars eco-friendly.

Aluminium is one of the best recyclable metals that can retain its core features even after repetitive recycling.

For more information visit https://www.rockman.com

0 notes

Text

Stylish and Durable Aluminium Windows in Mohali | Upgrade Your Home Today!

Transform your home with our range of premium aluminium windows in Mohali. With sleek designs and exceptional durability, these windows are the perfect addition to any modern or traditional home. Contact us now to upgrade your windows and enhance the aesthetics and functionality of your living space.

0 notes

Text

Aluminium Actuator Housing, Manufacturer, Supplier, Sangli, India

We are Manufacturer, Supplier, Exporter of Aluminium Actuator Housing, Aluminium Casting For Electrical Products from Sangli, Maharashtra, India.

Aluminium Actuator Housing, Aluminium Casting For Electrical Products, Aluminium Gravity Die Castings, Machined Components, Gravity Die Casting, Aluminium Gravity Die Casting, Aluminium Casting, Pressure Die Casting, Aluminium Pressure Die Casting, Manufacturer, Supplier, Exporter, Sangli, Asia, Mumbai, Thane, Navi Mumbai, Pune, Nashik, Aurangabad, Ratnagiri, Nagpur, Ahmednagar, Akola, Amravati, Chandrapur, Dhule, Jalgaon, Raigad, Satara, Belgaum, Kolhapur, Belgaon, Maharashtra, India.

#Aluminium Actuator Housing#Aluminium Casting For Electrical Products#Aluminium Gravity Die Castings#Machined Components#Gravity Die Casting#Aluminium Gravity Die Casting#Aluminium Casting#Pressure Die Casting

0 notes

Text

#supplier#manufacturer#company#stockholder#aluminiumalloy#aluminiumsheet#casting alloy#aluminium casting#bar

0 notes

Text

A device and method for online vacuum degassing of aluminum liquid

Background technique

The gas element in the aluminum liquid is mainly hydrogen, and its content is generally greater than 0.35ml/100g. During the solidification process of the aluminum liquid, it precipitates and forms bubbles. Once captured by the solidification front, pinholes, pores, looseness, etc. will be formed in the ingot. Casting defects lead to scrapped ingots or subsequent processing defects. According to reports, casting waste caused directly or indirectly by excessive hydrogen concentration in liquid aluminum accounts for more than 40% of the total waste. As the application scope of aluminum alloy products becomes wider and wider, the attention to the internal structure of aluminum alloy ingots has become more and more important.

Tightness requirements are also getting higher and higher. Reducing the hydrogen content in molten aluminum plays an important role in improving the quality of aluminum alloy ingots. In order to reduce the hydrogen content in the aluminum liquid, domestic aluminum processing enterprises currently use a degassing device that rotates and sprays inert gas. This type of traditional rotating spray degassing device places a graphite rotor in the aluminum liquid in the launder system and sprays the inert gas through it. The rotating graphite rotor breaks the bubbles and forms small bubbles, which increases the contact area between the inert gas and the aluminum liquid and the bubble floating time. Since the hydrogen partial pressure of the inert bubble is low, the hydrogen atoms in the aluminum liquid form hydrogen molecules and enter the inert bubble. Within, the bubbles float up and are removed to achieve the purpose of hydrogen removal. However, when domestic enterprises produce high-end aluminum alloys, they still need to mix a small amount of toxic gas chlorine into the inert gas to ensure high degassing efficiency. This poses great safety hazards and environmental pollution risks, and the hydrogen content of the aluminum liquid after degassing mainly depends on The hydrogen concentration of the incoming aluminum liquid before degassing is unstable, and the degassing efficiency of the aluminum liquid is unstable. Therefore, the incoming aluminum liquid must be pretreated before online degassing, which increases the process cost and production cycle.

This online vacuum degassing device for aluminum liquid includes a vacuum furnace, a double-chamber tank and a vacuum pump; there are two depressions at the bottom of the vacuum furnace, which are connected to the liquid riser pipe and Downcomer; two recessed parts are provided with breathable bricks along the peripheral sides of the riser pipe and downcomer; an aluminum liquid flow tank inlet and an aluminum liquid flow tank outlet are respectively provided on both sides of the double-chamber tank; the middle part of the double-chamber tank A partition is provided, which separates the double-chamber tank into a liquid inlet tank and a liquid outlet tank;

The aluminum liquid level on one side of the riser pipe in the double-chamber tank is higher than that on the side of the downcomer; the vacuum furnace is set up in the double-chamber tank. and can move in the vertical direction. The riser pipe and the downcomer pipe extend into the liquid inlet tank and the liquid outlet tank respectively; the vacuum pump is arranged on the top of the vacuum furnace. The present invention separates the vacuum furnace from the double-chamber tank, adjusts the relative height and vacuum degree of the vacuum furnace to adjust the depth of the aluminum molten pool in the vacuum chamber, and controls the flow of aluminum liquid and degassing by injecting inert gas into the breathable bricks. Stable and efficient.

An online vacuum degassing device for aluminum liquid, which is characterized by: including a vacuum furnace, a double-chamber tank and a vacuum pump; the bottom of the vacuum furnace is provided with two recessed portions; the two recessed portions are respectively connected to the riser where the aluminum liquid flows into the vacuum furnace The liquid pipe and the aluminum liquid flow out of the downcomer of the vacuum furnace;

The two recessed parts are provided with breathable bricks along the peripheral sides of the riser pipe and the downcomer, and the breathable bricks are used to provide inert gas; the double chamber Both sides of the tank are respectively provided with an aluminum liquid flow tank inlet and an aluminum liquid flow tank outlet; in the double-chamber tank

A partition is provided at the bottom, and the partition divides the double-chamber tank into a liquid inlet tank and a liquid outlet tank; the height of the aluminum liquid level on one side of the riser tube in the double-chamber tank is higher than that of the aluminum liquid on one side of the downcomer. Liquid level height; the vacuum furnace is set up on the double-chamber tank and can move away from or close to the double-chamber tank in the vertical direction. The lower ends of the riser tube and the downcomer tube extend into the liquid inlet tank and the outlet port respectively. In the liquid tank; the vacuum pump is installed on the top of the vacuum furnace.

content

The purpose of this invention is to solve the problems of "unstable degassing effect" and "toxic chlorine gas sprayed when producing high-end aluminum alloys" existing in the existing aluminum liquid degassing technology, and to provide a stable and efficient online vacuum for aluminum liquid The purpose of the degassing device and method is to reduce the hydrogen content in the aluminum liquid before casting, thereby improving the internal structural quality of the aluminum alloy ingot.

In order to solve the above problems, the present invention adopts the following technical solutions:

An online vacuum degassing device for aluminum liquid, including a vacuum furnace, a double-chamber tank and a vacuum pump; the bottom of the vacuum furnace is provided with two recessed portions; the two recessed portions are respectively connected to the riser tube and the aluminum liquid flowing into the vacuum furnace. The liquid flows out of the downcomer of the vacuum furnace; the two recessed parts are provided with breathable bricks along the peripheral sides of the riser pipe and the downcomer, and the breathable bricks are used to provide inert gas;

Both sides of the double-chamber tank An aluminum liquid flow tank inlet and an aluminum liquid flow tank outlet are respectively provided.

The middle part of the double-chamber tank is provided with an The partition board separates the double-chamber tank into a liquid inlet tank and a liquid outlet tank; the height of the aluminum liquid level on one side of the riser pipe in the double-chamber tank is higher than the height of the aluminum liquid level on one side of the downcomer pipe. ; The vacuum furnace is set up on a double-chamber tank and can move in the vertical direction away from or close to the double-chamber tank. The lower ends of the riser tube and the downcomer tube respectively extend into the liquid inlet tank and the liquid outlet tank. The vacuum pump is arranged on the top of the vacuum furnace.

1 note

·

View note

Text

Aluminum casting and forging

Aluminum casting and forging have a rich history that dates back centuries, showcasing the evolution of these manufacturing processes and their pivotal role in various industries. They form the backbone of various manufacturing operations, enabling the production of intricate components and structures that uphold the integrity and functionality of various products.

0 notes

Text

What is the Process of Aluminum Foundry and its advantages?

The process of aluminum foundry, also known as aluminum casting, is a manufacturing method used to produce a wide range of aluminum parts and products. It involves melting aluminum and pouring it into molds to create the desired shapes. Here's an overview of the process and its advantages:

Process of Aluminum Foundry:

Pattern Creation: The process starts with the creation of a pattern or mold that represents the final product. Patterns can be made from various materials, such as wood, metal, or plastic, and they are typically shaped to match the desired part.

Mold Making: A mold is created by packing sand or other refractory materials around the pattern. This mold is made in two halves, the cope (top) and the drag (bottom). The molds must be designed to allow the molten aluminum to flow into them.

Melting Aluminum: Aluminum is melted in a furnace at temperatures exceeding 1,000 degrees Celsius (1,832 degrees Fahrenheit). Various alloys can be used depending on the desired properties of the final product.

Pouring: Once the aluminum is molten, it is poured into the mold. The mold is typically placed in a flask to maintain its shape during the pouring process.

Cooling and Solidification: As the molten aluminum cools and solidifies in the mold, it takes on the shape of the pattern. This process can be aided by cooling water or other methods to control the cooling rate and prevent defects.

Shakeout: After the aluminum has cooled and solidified, the mold is broken, and the cast part is removed. Excess material, called the casting flash, is typically trimmed or removed in this step.

Finishing: The casting may undergo additional processing steps such as machining, sandblasting, heat treatment, or surface finishing to meet specific requirements and tolerances.

Advantages of Aluminum Foundry:

Lightweight: Aluminum is a lightweight material, making it ideal for its uses where weight is a significant factor. It's commonly used in the aerospace, automotive, and transportation industries.

High Strength-to-Weight Ratio: Aluminum alloys offer excellent strength-to-weight ratios, providing structural integrity while keeping weight low.

Corrosion Resistance: Aluminum has natural corrosion resistance, which can be enhanced through various surface treatments and coatings.

Complex Geometries: Aluminum foundry allows for the production of complex and intricate parts with precise detailing.

Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice. Recycling aluminum consumes significantly less energy compared to primary production.

Thermal Conductivity: Aluminum has good thermal conductivity, making it suitable for heat exchange applications.

Cost-Effective: Aluminum foundry processes can be cost-effective for high-volume production runs due to efficient production and relatively low material costs.

Design Flexibility: Aluminum casting allows for the creation of intricate and customized designs, offering flexibility in product development.

Ductility and Malleability: Aluminum is ductile and malleable, allowing for easy forming and shaping of parts.

Excellent Electrical Conductivity: Aluminum has good electrical conductivity, making it useful in electrical and electronic applications.

It's important to note that the specific foundry process, such as sand casting, die casting, or investment casting, can affect the final product's properties and cost. The choice of process depends on the desired part, production volume, and other requirements.

0 notes

Text

We are well-known manufacturers of an Aluminium casting manufacturers, Brass casting manufacturers, Garden bench manufacturers, Brass polish services, Brass Award Manufacturers and more.

1 note

·

View note

Text

Электросон

nicely casted aluminium sign for a sleep laboratory of a former hospital

1 note

·

View note

Text

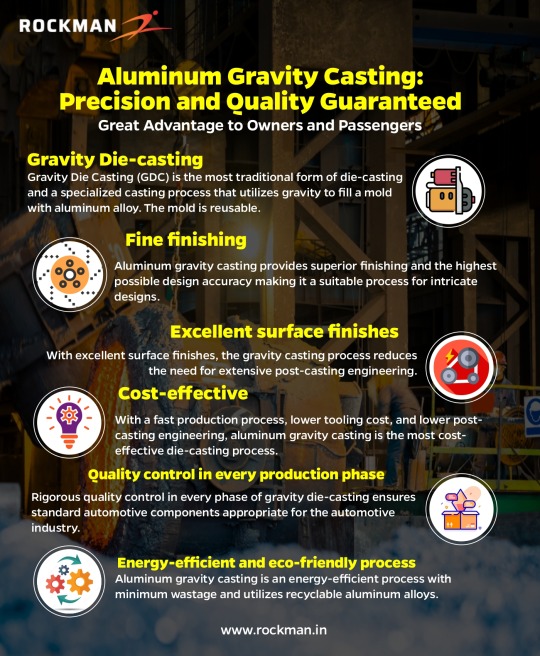

Aluminum Gravity Casting: Precision and Quality Guaranteed

Gravity Die-casting

Gravity Die Casting (GDC) is the most traditional form of die-casting and a specialized casting process that utilizes gravity to fill a mold with aluminum alloy. The mold is reusable.

Advantages of aluminum gravity casting

Fine finishing

Aluminum gravity casting provides superior finishing and the highest possible design accuracy making it a suitable process for intricate designs.

Excellent surface finishes

With excellent surface finishes, the gravity casting process reduces the need for extensive post-casting engineering.

Cost-effective

With a fast production process, lower tooling cost, and lower post-casting engineering, aluminum gravity casting is the most cost-effective die-casting process.

Quality control in every production phase

Rigorous quality control in every phase of gravity die-casting ensures standard automotive components appropriate for the automotive industry.

Energy-efficient and eco-friendly process

Aluminum gravity casting is an energy-efficient process with minimum wastage and utilizes recyclable aluminum alloys.

For more information on gravity casting and aluminum die-casting visit: https://www.rockman.in/

#Aluminum gravity casting#Alloy wheels for passenger cars#Aluminium die casting#die casting parts#High Pressure Die Casting suppliers in india#Aluminium casting#Aluminium Die cast#Aluminium die casting parts suppliers in india

0 notes

Text

"Leading UPVC Window and Aluminium Manufacturers in Mohali | High-Quality Products

Looking for top-notch UPVC windows and aluminium products in Mohali? Look no further than our reputable manufacturer. With years of experience and a commitment to quality, we offer a wide range of durable and stylish windows and doors for your home or business. Our team of experts uses the latest technology and materials to ensure superior products that are energy-efficient and long-lasting. Trust in our company's reputation for excellence and customer satisfaction. Contact us today to elevate the aesthetics and functionality of your property with our UPVC windows and aluminium products."

0 notes

Text

aluminium foundry in india

We are a reputed manufacturer of Aluminium Castings, we deal in low/medium/high volume, small/medium/large sized machined versions of the same. One stop foundry for Aluminum Bronze Castings, Aluminum Die Castings, Tin Castings, Zinc Castings, Copper Castings, Non-Ferrous Castings in India

0 notes

Link

Due to heat generated, it is not possible to repair cracks and damage to cylinder heads, cylinder liners, and components made of aluminium or cast iron using the welding procedure. Generally, metal locking and metal stitching surgery may fix any heavy components made of aluminium casting. For more information on aluminium crack repair, repair of aluminium cast pistons, and cast iron or steel casting components call +91 9810012383 and email [email protected].

#aluminium crack repair#metal locking and metal stitching#metal locking#metal stitching surgery#cylinder liners#aluminium or cast iron repair#Cast Iron Crack Repair#Aluminium Piston Crack Repair#aluminium crack repair by metal stitching#metal surgery process#Cracked Aluminium Cylinder Head Repair#aluminium casting#damage of cylinder head#manufactured of aluminium or cast iron#repair of damage aluminium casting#Metal Locking process#Fix cracked engine block#Turbine casing crack repair on site

0 notes

Text

Alcoa considers closing Norway's Lista aluminum smelter completely

According to foreign media reports, due to rising electricity prices, international aluminum giant Alcoa is considering closing its Lista aluminum smelter in southern Norway.

Alcoa Energy Director Ole Lofsnaes wrote in a letter to the Norwegian Ministry of Petroleum and Energy: "The Lista aluminum smelter is still struggling to make a profit, although it will reduce some capacity in 2022 due to high electricity prices. Struggles, 2024 is expected to be a more difficult year. For this reason, Alcoa is now considering all possible future scenarios for the Lista aluminum smelter, with complete closure of the aluminum smelter being one of the scenarios being considered. " Last August, when electricity prices reached record highs, Alcoa reduced some capacity at its Lista aluminum smelter. In February this year, the company announced that it would reduce the factory's production capacity by 30% throughout 2023. Alcoa Energy Director Lofsnaes said it was crucial for the company to sign a new power supply agreement as soon as possible to protect it from high spot prices in the future. The Norwegian government plans to cut carbon dioxide offsets for industrial companies starting in 2024, which will also compound the problems at the Lista aluminum smelter. It is understood that Alcoa's Lista Aluminum Smelter in Norway has an annual primary aluminum production capacity of 94,000 tons and a total of three electrolytic aluminum production lines. One of the production lines was closed last year. Alcoa also operates an aluminum smelter in Mosjoen, northern Norway, with an annual production capacity of 200,000 tons of primary aluminum. Spot electricity prices in southwestern Norway have averaged €78.79/MWh so far this year, well below the 2022 average price of €211.28/MWh but still higher than the average price in northern Norway of €26.91/MWh.

Adtech company strives to build a diligent and studious, meticulous work, sincere service, Wenmin hard work, scientific operation, to create high-quality products; be a person first, then do things; social benefits and corporate benefits grow simultaneously; customer satisfaction, employees are happy, and sustainable development Harmony type enterprise. The main products of adtech areporous ceramic filter,cff filter. ceramic foundry filter . porous ceramic plate . ceramic filter plate . deep bed filter. deep bed filter aluminium.

ceramic foam filter, online degasser, launder system .tap out cone, caster tip ,etc. To learn more, please follow website:http://www.adtechamm.com/ Contact: [email protected]

1 note

·

View note

Text

Aluminum Forging Supplier in India

Cast & Alloys is a leading provider of integrated solutions for Aluminum Forging and Aluminum Castings (GDC & HPDC) to the industry, backed by 30+ years of experience. Our capability to provide END to end-to-end solutions sets us apart from the competition.

0 notes