#alloy vacuum plating case

Text

Microwear W68+ Ultra Smart Watch

Today we’re looking into the Microwear W68+ Ultra Smart Watch, a feature-packed wearable companion with a staggeringly low price tag. Is this an affordable version of the Apple Watch? Let’s take a look…

Microwear

“Shenzhen Naijingyun Technology Co., Ltd is a modern high-tech enterprise that integrates design, research development, production, sales, branding, and service in the field of smart…

View On WordPress

#7-day weather forecast#affordable smart watch#affordable version#alloy vacuum plating case#alternative to apple smartwatch#Apple Watch#apps#battery life#Bluetooth functionality#built-in speaker#crazydiscostu#DIY video watch faces#Ergonomic design#feature-packed#fitness enthusiasts#geek#GPS tracking#health tracking#IP68 waterproof rating#IPS screen#Lightweight#long-lasting battery#low price#MActivePro app#Microphone#Microwear W68+ Ultra Smart Watch#Microwear website#Nerd#NFC connectivity#notifications

0 notes

Text

17 million years hence

17 million years hence the end of the anthropocene, mankind has changed. Most organs have atrophied to the point of vestigiality due to vast technological advances and the expansion of brain mass which requires vast amounts of nutrients to be redirected away from other organs. The liver, reduced to nothing more than a small fist-sized lump of stem cells; bone marrow, converted into porous storage for nutrient supplies; the heart, reduced to a bundle of convulsing knotted arteries, often connected to external blood-sacs and biomechanical vacuum-pump muscular aides in order to keeps the blood flowing. The blood has thinned, no longer requiring the costly lymph and immune cells, complex hemoglobin simply reduced to simple ferrous oxides, a byproduct of human genetic experimentation to reduce bodily demands for complex replacement proteins in old age that need to be produced in resource-intensive chemical vats after the extinction of ~95.7% of all species of life on Earth. The limbs are practically useless; legs only containing an extended femur knitted with cartilage to a rudimentary bowed leg bone, the patella completely obliterated, muscle tissue practically non-existent; the arms, still fairly similar to those of today, asides from their distension to an average length of 2 meters, fingers, too, distended and spindly to operate minute and complex machinery, nails turned to rigid hoof-like finger caps, thumbs used as secondary fingers in case of a needed transplant. The skin has mostly thinned to a thin sheet at most ~500 cells in thickness, nearly transparent in colour, having lost all pigmentation, exposing the fleshy red hues of muscle and blood and sinew. The skull has lost most its covering of the back of the brain to allow a grotesque state of macroencephaly, brain often making up 40-50% of total body mass. The face mainly remains unchanged asides from slightly enlargened eyes and a smaller jaw and mouth, increasing the neoteny of the modern human. Some are hooked into mechanical cradles, protected from the outside world by metallic alloys and plexiglass, their innerworlds connected to life-supporting machines that pump them full of drugs and filter toxins and waste, air conditioning and heating units keeping the innerworld a close climate-controlled 37 degrees centigrade, brains held in place by specially-constructed metallic braces and straps, needles placed into the skin everywhere, minds often hooked up to virtual escapist fantasies and mindfeeds of constant information and entertainment. Others go into biologically engineered protective suits, effectively separate organisms that do all of the biological work of the human for them, created long ago out of the now-extinct and forgotten common Earth Pig, Cattle, Sheep, Chimpanzee, and flesh-eating bacteria. This organic armour has tough, almost impenetrable leathery skin, bone plates, anywhere from 5-7 separate heart-like organs in case one fails, constant production of stem-cells to repair the body, sacs of organic sedatives, stimulants, and neurotransmitters to pump into the human if need be, 2 strong grasping claws to hold onto tree branches, hydrogen sacs to help keep afloat when the human employs telekenetic levitation to move, breast-ike teat structures for the human to suck on in case of food emergency, double-digestive systems to account for the human's athrophied digestion, phosphorescent lights to see in the dark, xylanth patches of photosynthetic tissue to generate sugars from sunlight, chemosynthetic microorganisms in appendix-like sacs to further break down and use waste products, and even a prehensile tail-like structure with neutoxins in its needles to kill prey and defend the human inside.

7 notes

·

View notes

Text

The Chhajed Steel & Alloy Pvt Ltd. are the very well known worldwide traders and exporters of SA 387 GR.91 CL.2 PLATE. We are devoted to our services and always provide our customers with the highest standards of services. We are the dealers in India and in many of the different countries. We are having a full stock of steel plates SA 387 of the grade GR.91 CL.2. We are manufacturing these steel plates with high-quality raw material and distribute and export them all across the globe. We are the stockholders and suppliers of high-quality steel plates for many decades. The SA 387 GR.91 CL.2 PLATE is considered as the best for the industrial purposes in case of making pressure vessel and many more machining products. These plates are very multipurpose in nature and they are having greater demand in many fields. The material alloy used in these plates is having very higher resistance to corrosion and thus accounts greater durability. They also have greater resistance to heat and high temperature and that is the reason they are having the use in pressure and gas industries. This is so as these plates comprise of chromium and molybdenum. They are having good fabrication ability and the material is also good for welding and machining.

ASME SA387 GR.91 CL 2 Plate Manufacturers, ASME SA387 GR.91 CL 2 Plate Suppliers, ASME SA387 GR.91 CL 2 Plate Stockists, ASME SA387 GR.91 CL 2 Plate Exporters

ASME SA387 GR.91 CL 2 Plate Manufacturers In India, ASME SA387 GR.91 CL 2 Plate Suppliers In India, ASME SA387 GR.91 CL 2 Plate Stockists In India, ASME SA387 GR.91 CL 2 Plate Exporters In India

The SA 387 plates are used by many of the top fabricators and industries leading in the construction and building business. The alloys thus correspond to higher elongation and compression properties and are having greater tensile strength. It is a highly usable and versatile steel alloy. This steel is having different levels of hardness and strength labeled as grade A, grade B, and grade C. we at Chhajed Steel & Alloy Pvt Ltd. provide the steel plates of all types of the three grades according to the need of the customer. We use the latest technology tools and machinery for the constructing and designing of these plates.

Testing-

The plates manufactured by the Chhajed Steel & Alloy Pvt Ltd. are having many tests and analysis done to examine them before and after the manufacturing. As the raw material is fetched by us the steel undergoes vacuum treatment, product analysis, additional tensile test, simulated post weld heat treatment, and impact test. After the steel is converted to steel plates they undergo the drop-weight test, hot tensile test, ultrasonic test, the practical examination through examination, and the vacuum carbon deoxidized steel.

0 notes

Video

youtube

Z52 Pro Smartwatch Bluetooth Call BD | AR TECH BD | Bangla Review | 2023

Z52 Pro Smartwatch 1.92 Big Display Calling Option Metal Body Wireless Charger

Model : Z52 Pro

Display 1.9 inch ips Display,240 x 285

watch faces download,

Main Features : Watch face download, Split display, BT call, Heart rate, BP,

Basic frequency: RAM:196KB; ROM:1MB+64MB

Size : 45*38*10.7MM

Weight: 50g

Case: Alloy Vacuum Plating

Strap: 45mm Silicone band

Charger Wireless charging

Color Black,

Touch panel : Multiple touch

Notifications Calls, Email, SMS, WhatsApp, WeChat etc.

Pedometer: Daily steps counting, calorie burn morning

Sleep Monitor : Objective and scientific quantification to record and analyze your sleep conditions,

BT : BT 5.0

Battery 280 MAH Lithium ion polymer battery, wireless charger, 150mins to full charge

Vibration :Support

What's The Box :

1 Z52 Pro Smartwatch

1 Wireless Charger

1 user Guide

Shop Name : AR TECH & IT ZONE

115/4 (1st Floor) Bijoy Sharoni Link Road,Old Airport Road,Tejgaon-1215

ফার্মগেট : বিজয় সরণী ব্যাংক এশিয়ার বিপরীত পাশে Walton শপ এর সাথে ## AR TECH & IT ZONE ##

Showroom Opening & Close Time 10:00 AM to 9:00 PM ( Friday Shop Off)

সরাসরি অর্ডার এর জন্য 01611-288488,01915-537928 অথবা 01742-230494

Visit Our Website : www.artechbd.com

Facebook Page Link -https://www.facebook.com/artechbd

1 note

·

View note

Text

Writing Your Affiliate Company Plan

Items that lack certain qualities could be ruined by attempts to engrave both of them. alquiler barcelona but are cast a good inexpensive alloy and plated finish. Stressed cases quality plating can survive some engraving processes but nearly than not the plating will peal or allow corrosion under the engraving causing severe problems down the path.

youtube

It one other available when you are departing a good international cruise (e.g. from Barcelona or Valencia). Alternative is called 'barco + tren' (Ship + train).

Quite in addition to the mystery of "who is Banksy?", another mystery remains, namely, "how has Banksy never been spotted?". It is generally understood that he has a very loyal team working for him which serves enable keep him secretly. It is quite feasible that Banksy's "works" are actually created a new team of folks working together, or on the other hand, different individuals at different attractions. The individual "Banksy" may not actually exist at all. Nobody really knows, but as just about all the "mysteries" specific truth would blow apart the myth and the hype would evaporate. Consumers are fascinated via the "unexplained" it is perhaps better it stays that alternative.

Reason #1 - Could earn Value. When you stick with something, you develop respect from other. When you flit from opportunity 1 you barco 6 metro possibly be viewed a few skepticism from others who'll wonder how much time you'll last with brand new business before changing yet again!

Clean the actual dust. Just as much as we humans hate dust, so do computers. Not in a visual sense but alternatively from an operating sense. Graphs dust cause heat build up, hence you fans need to spin faster in order to remove the heat, thus causing rather more noise and causing the fans to need replacing prematurely. To repair this, unscrew the side panel of the case and employ a can of compressed air and these can be bought from an electronic store to blow the actual unwanted allergens. Do not use a cleaner! A vacuum cleaner causes static that destroy the electronics inside your PC.

It is undisputed that Banksy originates from the Bristol area. In line with the Daily Mail, he is produced by a place called yate which is a small town just several miles north of Bristol. The housing boom within 80's and 90's and rapid growth of new housing developments in Bristol has effectively "merged" yate with regard to Bristol. The Daily Mail claimed that Banksy's actual name is Robin Mortgage brokers. That's a great name in itself and may potentially even be forgiven that "real" name is manufactured!

For the same reason you must have a teacher - to gets you familiar with new concepts and ways of thinking you will never have conceived of. For similar reason you must use a football coach - to teach you the rules of the. For the same reason you would like a mountain-climbing guide - to adopt you through treacherous terrain to a safer placement.

#alquilar#alquiler#alquilo#barco#barcos#yate#velero#boat house#houseboats#buy a home#water front#lake house#boats for sale#yachts for sale#sell a boat#buy a boat#houseboats for sale#buy a yacht#boat dealer#boat broker#yacht dealer#homes#real estate#water#travel#houseboat#yacht#self efficiency

1 note

·

View note

Text

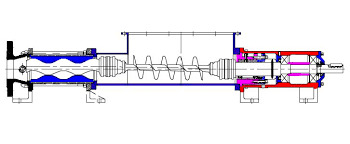

Introduction to Wide Throat Progressive Cavity Pump

Wide Throat Progressive Cavity Pump (WTPCP) is a centrifugal pump that has a progressive cavity along with a wide throat and low shear. It is designed to handle difficult fluids and slurries with high solids content. It is the most efficient way to move liquids and solids because it can handle high viscosities without clogging. With this pump, you can move more products faster with less effort. Wide Throat Progressive Cavity creates a strong suction force to draw in the liquid which makes this pump perfect for moving thick or sticky products like honey, molasses, peanut butter, and other viscous liquids. It can also handle grainy or fibrous materials like cornmeal and flour with ease without damaging them or the pump.

This pump has a wide throat that allows large chunks to pass through without getting stuck. The progressive cavity design ensures that the material is moved smoothly and efficiently from beginning to end. Then the wide throat allows for easy passage of the fluid, while the low shear prevents damage to the fluid.

The WTPCP is also great for pumping viscous liquids with high solids content. Because of the wide throat and progressive cavity, this pump can handle these types of liquids without any problems. Wide Throat Progressive Cavity Pump in India are available in both electric and hydraulic versions, so they can be used in a variety of applications.

Component configuration

Wide Throat Progressive Cavity Pump consist of the following components as follows,

Wettable Housing can be made of materials like cast iron, cast stainless steel, fabricated steel, etc.

Stator

Rotor, commonly used material are alloy steel, stainless steel or few other kinds of steel/ material depending upon the use.

Coupling Rod and the shaft is commonly made from alloy steel or stainless steel

Other Exotic Materials such as duplex, super duplex, alloy 20, haste alloy

Rotor Surface Coatings are manufacture of ceramic coating, tungsten carbide, hard chrome plating, etc.

Protective Coatings: rubber lining, epoxy coatings.

Working of WTPCP

Wide Throat Progressive Cavity Pump in India employs the latest technology that helps in pumping viscous and shear sensitive fluids, it has a wide throat or inlet to accommodate large size particles. The pump operates by using an expanding and contracting cone-shaped eccentric rotor that moves within a stationary casing to create a pumping action. This action creates pockets of air and liquid which are drawn into the pump and expelled out the discharge port to the desired container or place

Advantages and Characteristics

Wide Throat Progressive Cavity Pump in India has plenty of advantages some of them are mention in the given list,

It’s self-priming rate is high.

A variety of installation positions are available.

It is possible to reverse the direction of rotation and, therefore, reverse the flow of delivery.

It is possible to handle suspensions with a high solids percentage without clogging a non-clogging system.

Inherently self-priming, it can be used to eliminate Snore

It’s NPSH(R) is low, can withstand high vacuum conditions, and is effective at high suction lift.

Due to the low internal velocity, products that are shear sensitive and abrasive are handled gentle and do not experience excessive internal wear.

Easily interchangeable: by simply switching the rotation direction of the prime mover, the suction and delivery ends can be interchanged.

For more information on Submerged P.C Pumps Supplier in Uttar Pradesh & Barrel Pumps Manufacturer in Uttar Pradesh , please visit : Deepa Pumps.

1 note

·

View note

Text

What are the advantages of cast steel valves?

Cast steel is a type of carbon steel, usually with a carbon content of between 0.1-0.5percent. It is a commonly used alloy steel known for its good impact resistance. Cast steel is not prone to deformation, breakage, or bending in the face of frequent or sudden impacts.

Cast steel is known for its ability to withstand high stresses and strains. The combination of strength & ductility of steel makes it a staple material in mechanical and structural applications because of its ability to withstand heavy loads. That's why cast steel is one of the most commonly used metals in the world.

Now let's find out about cast steel ball valve by cast steel ball valve manufacturer China.

Cast steel ball value advantages

The opening & closing of the cast steel ball valve is driven by the stem & rotates around the axis of the stem. Cast steel ball valves are mainly used for cutting, connecting media in pipes & for fluid regulation control. Cast steel ball valves have a wide range of applications, ranging in diameter from a few millimetres to a few meters, and can range from high vacuum to high-pressure applications.

Small fluid resistance. When fully opened, the cross-sectional area of the ball channel, valve body channel, and a connecting tube are equal and connected. Straight line. The medium flows through the ball valve. This is the same as flowing through a straight pipe. The fluid resistance of the ball valve is the lowest of all types of valves.

High-speed opening and closing, convenient and high-speed

Simple structure, small size, lightweight: Its height is much lower than that of gate valves & globe valves. Tight and reliable ball valve sealing surfaces are now widely used in plastics and have excellent sealing properties.

Easy maintenance, the simple structure of the ball valve, the seal ring is generally movable, easy to disassemble and replace. Where s it’s hard to maintain in case of forged steel ball valve, explained by forged steel ball valve supplier in China.

W5. When fully opened or completely closed, the sealing surface of the ball and valve seat is isolated from the medium. Even if the medium passes through no corrosion of the valve seal surface occurs.

What are the advantages of cast steel gate valves?

The opening & closing parts of the cast steel gate valve are gate plates. The direction of movement of the gate plate is perpendicular to the direction of the fluid, and the gate valve can only be fully opened and fully closed and cannot be regulated and throttled. The gate has two sealing surfaces, the two sealing surfaces of the commonly used pattern gate valve form a wedge and wedge angle that varies with the valve parameters.

The cast steel gate valve Supplier in China said the major advantages of cast steel gate valves is small fluid resistance, sealing surface subject to medium brushing & erosion is small. Opening and closing are less laborious. The flow direction of the medium is unrestricted, with no spoilage, and no pressure reduction. The structure is simple, the structure length is short, the manufacturing process is good, the high-temperature resistance and high-pressure resistance are optional materials, and the scope of application is wide.

#cast steel ball valve manufacturer China#forged steel ball valve supplier in China#cast steel gate valve Supplier in China

0 notes

Text

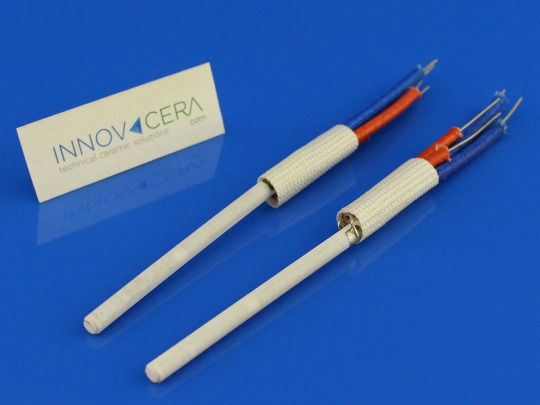

What can a soldering iron be used for?

Every craftsman is familiar with a soldering iron. It melts solder (a metal alloy with a low melting point), allowing the two materials to be heated and melted through a central point. It is especially convenient for merchants such as electronics technicians, jewelers, and metal workers.

It's also safer and more accurate than melting with other heating tools like torches, and there's almost no risk of igniting or burning the material you're using. To learn more about what soldering irons do, here are 10 ways to do it:

- Roofing welding business

Roofers often use solder to fuse the components of a copper roof. It is also used to make sparkling roofs. Since roofs do not need to be handled with the same precision as small parts, soldering irons commonly used for roofs have a wide tip that heats up quickly and is usually gas-assisted to retain their heat in windy conditions.

- Weld metal sinks

Domestic metal sinks are welded together. It's similar to what roofers use to make shiny roofs. Welding creates a permanent bond that makes the sink leak proof. Rainy days are definitely convenient!

- Weld stained glass and Mosaic

The beautiful patterns of different colors that you see in stained glass and mosaics are held together by solder. These usually require a stronger 100-watt soldering iron, as well as other tools such as a glass cutter or glass grinder.

- Welding of the plastic circuit board

As one of the most common uses for electric soldering irons, plastic circuit boards are used in electronics. The metal alloy of the solder establishes a continuation of the current when connecting two wires. This required precision often means using more precise tools, including temperature control of the soldering iron.

- Solder for electrician

Just like circuit boards, electricians use soldering irons to splice wires in residential or commercial wiring. They also use them to fuse wires in electrical terminals or control panels.

- Car maintenance solder

Although solder is not strong enough to repair engines, it is commonly used to fill irregular Spaces, smooth rough surfaces, or tighten joints. It can also be used to fill holes, fuse metal plates, and tin metal plate edges to do body repairs on your car.

- Household welding tools

Another common use for soldering irons is DIY home projects by home artisans. This broad theme means that there are a variety of soldering tools to choose from, such as soldering pencils or soldering guns, in addition to the typical soldering iron.

- Jewelry welding

This is another industry that requires very high precision, and jewelers often use soldering pens or irons with interchangeable soldering tips to improve accuracy. Solder also has a high silver content.

Because oxides form when metal is heated, jewelers often use borax flux to reduce oxidation and help maintain work quality.

- Welding vacuum tubes

For metal-ceramic connections, vacuum tubes can be welded into sealants and insulating parts. This is important in electronics because the near vacuum allows electricity to flow freely.

- Pipe welding

To be on the safe side, plumbers use lead-free solder when connecting water pipes. While large projects can often be done with a welding torch, in some cases they need to work in tight Spaces where soldering irons are safer and easier to handle.

That's right! Soldering irons not only have several different uses, but also several different types.INNOVACERA produces ceramic heating elements for soldering irons and has cooperated with a number of well-known electronic tools.

Our heating element is the PROCESS of MCH (Metal Ceramics Heater). It is the material of tungsten, molybdenum, molybdenum, manganese, and other high melting points Metal heating resistance paste is printed on 92 ~ 96% alumina flow ceramic green billet according to the requirements of heating circuit planning, with 4 ~ 8% sintering agent multi-layer superposition. At 1500 ~ 1600°C under high temperature burning into one body has the advantages of corrosion resistance, high temperature resistance, long life, high efficiency and energy saving, uniform temperature, good thermal conductivity, thermal compensation speed, and does not contain lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyl, polybrominated diphenyl ethers, and other harmful substances, in line with the European Union RoHS environmental protection requirements. It is another generation product after alloy heating wire and PTC heating element.

If you have relevant requirements, feel free to contact us. Customized is accepted.

Read the full article

0 notes

Text

This Flat Iron Costs What?!

Justifying buying a new fly rod is easy. Explaining to my husband why I bought a new laptop is a none issue. Trying to convince myself I need a $499 hair straightener from Dyson is not something I think I can do. I mean, I do not consider myself to be a person who spends much time in the way I present my hair but I also can’t help but still be attracted to the world of beauty and hair care. But, why would anyone spend that much money for a hair styling tool?!

I had many questions and researched as many sites as possible to figure out IF this product is worth purchasing, and I have to say… I’m more surprised with what I discovered about Dyson as a company rather than by this flat iron itself.

Growing up, I remember the contemporary and stylish Dyson commercials about their vacuums. In fact, I don’t recall any advertisements from Dyson about anything but vacuums. I was surprised to find that Dyson makes a variety of different household items, albeit not a huge variety of items but still rather impressive.

James Dyson, the owner and founder of Dyson, first started making vacuums in 1974. His main focus for all his innovations over the years is to make products that have a low carbon footprint and break the conventional mold of consumer expectations. After many years that turned into decades of prototypes and lawsuits, the current line of Dyson products include vacuums, blade-less fans, air purifiers, hair care products, and lighting equipment.

As mentioned previously, not a huge line of products but it’s clear that Dyson focuses on trying to perfect the products they choose to manufacture instead of creating a large amount of items that could collectively be considered mediocre among consumers.

Well before this new flat iron was released Dyson shook up the hair care world with a hair dryer called the Supersonic. It’s clear from the press release of this device that Dyson wanted to revolutionize small engines within electric hair products and in doing so created the first “supersonic” hair dryer that is the lightest and quietest hair dryer on the market. This hair dryer, much like the hair straightener, is sold at a whopping $400.

With the release of one of the most expensive hair dryers available, James Dyson explained that the reason the cost is so high is because the company spent 4 years and $71 million dollars to make it’s hair dryer. There were 600 prototypes, over 100 patents pending, all done by a group of 103 engineers. That is some serious time, money, and effort for the sake of a hair dryer.

Dyson also went the extra mile for their flat iron, the Corrale. This tool is for both consumers and professionals. It is the first hair straightener to utilize manganese copper alloy to create a “flexible” hot plate that allows for the tool to successfully hold hair evenly while distributing heat which results in less hair damage over time.

As far as what this type of technology is able to do, it’s obviously only used on hair. But the most surprising aspect of this product I found was the fact that it is a cordless tool that can adjust to use a chord if necessary with a magnetic cable. The battery is 4-cell lithium ion that charges rapidly and can detach in special cases where you may need to take the straightener with you, like on a flight.

Dyson is one of the leading companies trying to find a way to make batteries more efficient and safe for commercial use. The largest project Dyson had that involved improving batteries was outside the realm of vacuums and hair care products and in the world of electric vehicles.

Back in 2015, Dyson had spearheaded the EV Project which aimed to create a vehicle that only ran on electricity and dramatically reduce the carbon footprint of personal vehicles. The project lasted four years until last October when James Dyson decided to pull the plug on it, worried there was too much risk to complete it. The company could have potentially had a lot of success with the EV Project, but they are a privately owned company so they do not receive public funding the way a company like Tesla does. The last concern they had was that the battery they had designed may not have been suitable for commercial use.

After reading as much as I could about a flat iron and whether it was worth purchasing, I still can’t determine whether I would purchase it or not. I now think Dyson is the “Tesla” of household appliances and it’s interesting to see what they have decided to put their time, money, and effort into for the sake of innovation. Hats off to Dyson, but I think for now I will hold out on purchasing a Dyson product. Maybe I will purchase this flat iron when I’m no longer a broke college student.

2 notes

·

View notes

Photo

Qingdao Tianwei Casting (located in Qingdao,Shandong,China) is very specialized in investment casting,precision casting and sand casting to produce all types of engineering/metal parts. We can cast more than 100 kinds of alloys.

As for investment casting(lost-wax casting method),we have two production lines: silica-gel and water-glass so that we can meet the different demand of different customers.

Investment casting(lost-wax investment casting):stainless steel,carbon steel,alloy steel,duplex stainless steel,iron casting. ISO9001:2008 certificated.

Sand casting: stainless steel 304,316;duplex stainless steel 17-4ph,630;heat-resisting steel,high alloy steel,duplex stainless steel,supper alloy.

Part name: Auto parts,overflow valve parts, Pipe fitting,flange,pump body,pump cover,valve body ,valve cover,impeller(Primary,HP),bearing,gear,gearbox,bolt socket,bracket,tee coupling,fork,fuel pipe,knuckle,fuel filler,connection shaft,housing,mounting bracket,steel elbow,guide vane,golf putt head,vacuum pump parts,sewage pump case,axial flow pump impeller,draught fan case,tank cap,compressor case,double suction impeller,ring drive;union M/F,hexagon cap,hexagon plug,socket bended,coupling,hexagon nipple,square plug,reducing tee,hexagon bushing,cross pipe,reducing elbow,hose nipple.

Machining: lathing/turning,milling,drilling,grinding,

Tapping threads,5-axis CNC machining;CMM inspection; spectrometer for checking chemical compositions; mechanical properties testing; pressure-testing under water;anti-rust oil;salt spray test.

Heat treatment: solution annealing,normalization,quenching and tempering,

carburizing treatment ,case-hardening, nitriding treatment.

Surface treatment:

zinc-coating,nickel-plating,blackening,mirror-polishing,satin-polishing,E-polishing.Dacromet surface treatment.

Qingdao Tianwei Casting is the metal stock for your engineering solution.

We would like to become your Chinese production base!

Sincerely hope to cooperate with you!

Best regards

Maria Li

E-Mail: [email protected]

Web Site:www.tianweicasting.com www.chntianwei.com

��

1 note

·

View note

Text

SEMA is a hard show at which to properly appreciate cars. On one hand – it’s a show overflowing with some of the best builds you will see all year. On the other hand – it’s that same overflow that makes it almost impossible to keep your wits about you. It’s almost too much of a good thing. In a sea of thousands of cars, I feel like some inevitably get lost. The great thing is: The cars that are truly memorable, the cars you are talking about weeks and months after the show… are cars which rise above the temporary flash-in-the-pan Instagram fame. Some cars deserve to be immortalized. More than digital noise or passing fancy, they draw their inspiration from the timeless. The classic.

This 240Z certainly qualifies as one of these cars. While it has some innovations and forward thinking design elements, it also honors the tradition and legacy of Datsun’s Z car heritage. Car owner Dennis wanted a Z that could be as menacing on the street as it was on the track. In looking to manifest his dreams into reality, he was fortunate enough to meet aspiring builder Kyle Kuhnhausen. Kyle is a fresh out of business school automotive entrepreneur with a penchant for metal work. Ok, more than a penchant… he has a gift. From the paint scheme to the heavily gusseted cage, this car is well thought out & beautifully executed. How well executed? Well, when we talked he made sure I knew that the LS swap was a place holder engine until they built something truly epic for under the hood. WOW. Some place holder.

Let’s take a moment and revel in my three favorite aspects of this car.

First)

There is the paint scheme. Nimbus Grey (or battle ship grey in some parlance) has to be my personal favorite hue on show cars. It’s rich, it allows shadows to adopt a deep dark over tone, and light reflections to be silvery & pronounced. Every truly beautiful design looks amazing in this color. So… win number one? CHECK! The Peter Brock homage striping is as evocative and respectful of the Z’s motorsport heritage as it is a tasteful modern touch of racer bravado. I dig it. Those famous side stripes actually start on the hood at the vents and then cascade over the fender and down the side forming the Brock stripes we are all familiar with. A killer design cue that is at once forward thinking and period correct. Nicely done.

Second)

Let’s talk about that metal work. The Aero is mean, functional, and gives the car a seriously provocative stance. What’s more – it’s designed to just rip/break away cleanly in the case of a momentary lapse in driver skill (for example paying a visit to say, China Beach at the end of the straight at Mid Ohio). Well played Kyle, well played. However, as fantastic as that aero is, it is nothing compared to the beautifully executed roll cage. Meant to be a street car that can participate is serious track time… it had to be a car from which Dennis could easily get in and out. Kyle kept the safety high by fabricating one seriously artful, yet stout, fully gusseted integrated cage. Take a few moments and look at the cage in this car. I have severe race car envy. My race car has race car envy. Seriously. It is so good that it easily merits adjectives like superlative, excellent, exemplary. Bravo.

Third)

And this is one where so many cars sort of take a pass… the gauge cluster. When a car has track day toy duties, it’s easy to just pick up a digital display, mount it up, and just call it done. Not in this car. The cluster in this car is 13 individual pieces of aluminum lovingly hand shaped into what you see before you. It honestly called to mind some of the extreme and bespoke modern interpretations currently en vogue built around the Porsche 911. The Singer cars being the most notable, they take an air cooled 911 and massage every aspect of the car… and polish, preen, & refine it until it is absolutely jewel-like. The perfect 911. Well, that’s where this Z took me. It’s like a really nice 240Z… only polished to the highest possible degree. Everywhere you look there are tasteful touches. This instrument cluster exemplifies that. The angle at which it is canted toward the driver, the alignment of it inside the MOMO wheel. It’s absolutely glorious.

So yeah, this car is one of the highlights of last year’s SEMA show. It truly was. Bespoke modern takes on past classics are hot right now. Cars like the Singer 911s are fetching 500k and more per unit, so it makes builds like this kind of a serious proposition. Get it right and the value and classic status is legitimate. In the end, Dennis can drive this car on the road or the track, confident in the fact that he found the perfect enthusiast to execute his vision. And he can rest well in the fact that he’s now driving the Singer of Datsun 240Zs.

InZanity 240Z

CHASSIS

1972 Datsun 240z shell

10-point fully tig welded roll cage featuring flared hole body tie-in gussets

Lower jacking & towing points welded to bottom of main cage shelfs

Every unibody seam is fully stitch-welded inside & out, and seam sealed

All top strut mounts replaced with camber adjustable heavy duty plates

Pre-load adjustable tie-rod strut braces featured in engine bay

Tig welded fuel cell cradle with integrated rear center mount tow hook

Rear sub-mounted battery with remote charging points and kill switch

Custom tig welded engine & transmission mounts. Optimized center of gravity

50/50 weight distribution

Bolt-in aluminum transmission tunnel stiffeners / driveshaft hoops

Integrated scraping points for oil pan protection

BODY MODS

Trackspec Motorsports heat extracting louvers on hood & front fenders

Front fender-exit side exhaust with custom alloy diffusing louvers

Rear rockers clearanced for functional rear brake vents, and lowered 1.25”

Fender & rear emblems shaved

Antenna & side marker lamps shaved

CNC billet aluminum laser engraved KMC tail lamp insets

CNC billet aluminum quarter panel vent emblems featuring modernized “Z”

Rear bumper & mounts shaved

Symmetrical rear body pan recess, opposed to unsymmetrical stock recess

Front bumper shaved & swissed with dimple die punched holes

Reinforced rear hatch for functional spoiler mounts

Rear quarter panel turbulent air extraction holes with alloy bezels added

Wide “ZG” style flares, adding 6” of width to the rear fender wells

All body gaps cut, welded, and staked.

Shaved hood springs & streamlined hinges

Show grade bodywork

One-piece front & rear windscreen gaskets

POWER

GM 2004 LS1 engine with T56 6-speed manual transmission

Modified & ported 1.625” primary headers ceramic coated in gold

Bespoke 2.5” Fully pie-cut and tig welded exhaust with front X-pipe (167 weld joints)

Dual 8” sectioned Magnaflow Corvette style mufflers mounted in front wheel wells

Improved Racing 180 degree oil cooler thermostat with 400hp Setrab cooler

Holley Coil on Cover valve covers

Radium Engineering FCST fuel cell surge tank and full fuel system

Vibrant Performance –AN fuel lines

Modified stock throttle body with Lokar stainless throttle cable

Custom 4” aluminum air intake with K&N filter outside engine bay

Aluminum crossflow radiator with 16” Flex-A-Lite electric fan and custom shroud

Modified Hurst short shifter with KMC integrated transmission fluid top-fill

Centerforce single disc clutch

ACT Clutch Prolite lightweight flywheel

Custom one-piece driveshaft

Infinity Q45 R200 differential with VLSD limited slip unit and 3:54 final drive ratio

Nissan Armada CV axles

BRAKES

6-piston Wilwood front calipers & 4-piston Wilwood rear calipers

Fully functional ram-air 3” brake ducting to all 4 corners with custom caliper hats

ASD Motorsports hydraulic 16” e-brake system with braided -3an lines

Wilwood billet master cylinder with modified vacuum booster assembly

Optimized pedal box with reduced weight and improved pedal placement

3/16” Stainless hardlines and -3an braided flex lines

Wilwood proportioning valve with hidden custom mount

Remote Wilwood proportionating valve in-cabin adjustment knob custom retrofit

Custom aluminum master cylinder heat shield

SUSPENSION

Full Arizona Z-Car “Track Pack” billet aluminum adjustable suspension

Arizona Z-Car struts with coilover adjustable springs, modified for tire clearance

Apex Engineered bump steer adjustment kit and high steer knuckles.

Full polyurethane bushings

Modified front crossmember for improved roll center

ST Suspension front & rear sway bars with Energy Suspension polyurethane bushings

5 Lug converted hubs with front Wilwood spindles

ARP chromoly extended wheel studs

Stitch welded and reinforced front crossmember

AERO

Custom HDPE adjustable front air splitter with alloy radiator and brake dams

Custom HDPE adjustable rear diffuser with jacking point & air straighteners

Custom HDPE 6” side splitters with exhaust vent & rear brake vents integrated

Aluminum tunnel underbelly, mostly flat under entire car

Pitch adjustable 3-piece rear deck spoiler with Ringbrother’s micro hinges

ARP carbon fiber micro mirrors

Lexan headlamp aerodynamic fillers

4 Piece aluminum radiator ducting with cabin air ducts integrated

#gallery-0-33 { margin: auto; } #gallery-0-33 .gallery-item { float: left; margin-top: 10px; text-align: center; width: 33%; } #gallery-0-33 img { border: 2px solid #cfcfcf; } #gallery-0-33 .gallery-caption { margin-left: 0; } /* see gallery_shortcode() in wp-includes/media.php */

ELECTRONICS

Street and Performance engine wiring harness with reflashed stock ECU

Braille lightweight I25X lithium battery

Bowler Performance phantom key with Honda s2000 push button starter

Fully custom KMC chassis wiring harness

Fully integrated Passport 9500ci radar detector system

Alpine double-din 6” monitor with frenched backup camera, navigation, and satellite radio

Dakota Digital VHX-1100 competition dash with 16 digital readouts

Dakota Digital BIM 1 OBDII gauge interface

EPAS electronic power steering integrated into Woodward steering column with input potentiometer knob on dash

Custom carbon aircraft-style switch panel with u-shaped toggle protectors

Quick Latch removable main electronics panel featuring Marine resettable circuit breakers

WHEELS / TIRES

18” CCW 3-piece LM20 wheels with gloss black lips, satin black centers, and ARP bolts (18×10 front 18×11 rear)

BFGoodrich Rival S 200tw extreme performance tires (275/35zr18 front 315/30zr18 rear)

Gorilla extended race lug nuts

INTERIOR

MOMO Super Cup FIA homologated seats and alloy brackets

MOMO 350mm MOD. 07 suede steering wheel

MOMO 6pt. harnesses

MOMO quick release hub w/ bespoke manually machined adapter to race column

Highly modified pedal box

Longacre 17” wide rear view mirror

Bowler performance billet shift knob and lever

Aluminum bead-rolled hexagonal pattern fuel cell fire wall

Custom alloy center console, and 3-piece alloy bespoke quick removable dash

Smoothed transmission tunnel

Bespoke flared-hole heel plates

Flared-hole fabricated dead pedal and geometry optimized clutch and brake pedals

Custom heater with 4 vents hidden under removable dash

Hexagonally stitched suede door cards with carbon fiber aircraft riveted inserts

PAINT (All Axalta Refinishes Products)

Chromax Mosaic SBBC B9*01 – Color: Ford Stealth Grey

Imron 3.5 HG+ Polyurethane RH-3714 – Color: Gray 057

LF Epoxy DTM Primer Gray 2540S

Chroma Base “4 to 1” 2K Urethane Primer Filler Gray 7704S

Chroma Priemier Premium Appearance Clearcoat 72500S

Epoxy DTM Activator Medium Temp 2505S

Basemaker Medium Temperature 7175S

Activator-Reducer 60-70 Degree 7765S

Plas-Stick Flexible Additive 2350S

Chroma Premier Pro Normal Activator 14305S

#gallery-0-35 { margin: auto; } #gallery-0-35 .gallery-item { float: left; margin-top: 10px; text-align: center; width: 33%; } #gallery-0-35 img { border: 2px solid #cfcfcf; } #gallery-0-35 .gallery-caption { margin-left: 0; } /* see gallery_shortcode() in wp-includes/media.php */

OTHER

Rear sub-mounted SPA Technique fire suppression tank with 6 nozzles in cabin/engine

2-piece removable front chassis-mount tow hook

Proprietary differential snout oiling system with Tilton commercial pump and Setrab cooler

Functional side hood winglet to integrated tig welded alloy coolant expansion tank

Dual “II Much fabrication” differential and fuel system vents with custom bracketry and aluminum hard lines.

Extensive use of ARP 12 Pt. stainless fasteners

Text by Tim Neely Photos by Dominick Barbero

InZane in the Membrane: Datsun 240Z SEMA is a hard show at which to properly appreciate cars. On one hand - it’s a show overflowing with some of the best builds you will see all year.

1 note

·

View note

Text

How to make welding fixture and metal molds

https://www.hotformed.com

1. Fixture design

1.1 The definition of fixture

Generally speaking, fixture can be any auxiliary device which can make scientific molding process more quick, convenient and safer during the die manufacturing. Broadly speaking, fixtures include machine fixture, press fixture, heat treatment fixture, welding fixture, assembling fixture and so on. In a narrow sense, it is machine fixture. And it’s mainly used during the machine dies processing. At present, the general definition is that fixture is a device tool used for clamping die parts. And another definition is that he fixture or jig is a kit used for clamping the casting part and guiding the tool.

1.2 Types of dies fixture

There are two main types of die fixture, tooling fixture and testing fixture.

Metal casting manufacturers mainly use tooling fixture to satisfy their requirement of casting manufacturing process convenience and high level of precision. In a word, the tooling fixture should help to make die making process of metal punch machine work, welding and assembly be easy.

And die set manufacturers always use testing fixture for testing. Because there are many examples of die casting products which shapes are complex and dimensions are difficult to measure. In this case, we have to make the die design of special detection block. Or we design the testing fixture for particular metal casting products of detection use.

For example, punch press dies suppliers have some regular testing fixtures for metal dies, such as plug gauge, ring gauge and so on. However, there are also many irregular machine dies, for which punches and dies engineering people have to make special forming die design. What’s more, we press die manufacturer may use some machine metal casting methods to ensure the precision of the testing fixture. Such as wire cutting, spark-erosion machining, CNC machining center and so on.

2. Principles for fixture design

2.1 Fixture usage

In some special metal casting process scenes, we need to make fixtures to facilitate and serve our die production. There are these main using scenes.

2.1.1 Using fixtures to fix products and tools

Die set manufacturers always fix die casting products and tools with fixed vise and clamps. It can release a hand of operators with metal casting techniques, and then they can work with both of their two hands.

2.1.2 Using special tools

Tooling we use on the die production line should be best fit for this forming die and special tools for manual operation. And the aim of this operation is to increase the die production efficiency.

2.1.3 Merging the two different types of dies tools into one

As die casting parts manufacturers all know, this operation can reduce the trouble of changing metal casting tools and the labor hour consumption for transfer. Therefore, it can significantly increase the working efficiency of die casting parts manufacturers. One featured application is a pencil with an eraser on the top.

2.1.4 Improving die casting tooling design convenience

Firstly, punch press dies suppliers design the die casting tooling handle to make it easy to grasp. Secondly, the operating die casting tools are in harmony with human movements. Thirdly, punch dies suppliers should evaluate the fixture with IE method.

2.1.5 Operation process

Firstly, as large steel castings manufacturers all know, the operating position should be close and focused. Secondly, we should try to make the die making machine minimize or even disengage human’s monitoring and assistance. Thirdly, punch and die manufacturers need to take the switch position and the next process into account. The start switch position of the die press machine and the operation of the next mold casting process should be coherently coordinated in the action.

Fourthly, it’s about the auto uncaging of parts of die. We try our best to make the finished die cut parts automatically fall off by means of gravity or springing.Last but not least, we use self-checking automation system, and put safe first.

2.2 Design principles

There are different fixture design principles for different conditions.

2.2.1 Measuring and auxiliary positioning fixture design

A.Make the shape of fixture be simple and die making process be convenient.

B.It’s easy to pick and place die casting products.

C.Ensure the position of the fixture and metal casting products to be accurate.

D.Learn the measurement key point and measurement methods of metal molds.

E.In general, the material used in dies fixture measurement is aluminum alloy. And when the precision requirement is higher, press die manufacturer uses steel mold.

2.2.2 Position fixture design

As for assembly positioning fixture, die manufacturers should protect it by teflon tape. And reserving 0.2-0.3mm position on one side to avoid scratches of die casting products.

The metal die position should be accurate, and not be too loose. The standard is to make the pick and place of metal punch dies be easy.

Die casting manufacturers reserve about 0.1-0.2mm gap on one side when they put protective film and locate the fixture. If the dimension of press dies is small, we can consider to reduce the gap within 0.1mm.

With regard to gloss positioning fixture, die casting supplier reserves about 0.2mm. And the standard is also to make the pick and place of metal punch dies be easy. If it’s gloss machine fixture, the reservation gap should be about 0.1mm. Certainly, the aim is to avoid the drop of forming die in the wipe process because it is too loose.

With respect to printing and laser carving tools, metal stamping die manufacturers reserve 0.05-0.1mm gap. The support surface at the printing position and the positioning of the laser engraving fixture needs to be precise.

2.2.3 Coating fixture design

Punch and die manufacturer should know the spray printing range of mold die and the paint types.

It should be easy to pick and place of thermoformed products on the fixture.

When the precision requirement of mold coating products is pretty high, the die mould manufacturer need to adjust the tolerance on fixture design.

Die set manufacturers need to think about the lacquer flying area and painting accumulation problem. What’s more, there are die making process problems of gas pattern, solvent evaporation marks, sawtooth and so on.

Pay attention to the coating method during metal moulding process. For example, rotary machine, reciprocating machine, hand painting, water electroplating, vacuum plating and so on.

3. Common thermoforming material used for fixtures

3.1 Rolled Steel

There are many different types of hot rolled steel, and the applications of rolled steel products are diverse. According to the different shape of cross section, the steel can be divided into four main types. Steel rolled sections, hot rolled steel plate, hot rolled steel tube and rolled metal products. The rolled steel is made from ingots and billets by pressure casting. It can be different shapes, dimensions and casting properties.

3.1.1 45# steel

Chemical components of 45# steel includes these. The carbon content is 0.42-0.50%, the silicone content is 0.17-0.37% and the manganese content is 0.50-0.80%. What’s more, the chrome content is within 0.25%, the nickel content is within 0.30#, and the copper content is within 0.25%. Also, the density of hot rolled steel 45# is about 7.85g/cm3,, and its hardness is about 45-52HRC. In addition, according to the different shape, we divide the roll formed steel 45# into hot rolled steel sheet, rolled steel tube, and hot rolled steel bar.

3.1.2 SKD11

SKD11 is a kind of hot rolled alloy steel with high content of carbon and chrome. And it has a high hardness and good wear resistance. What’s more, this hot rolled steel properties include strong hardenability and good dimension stability. Therefore, it’s suitable for making cold steel die with high precision and long lifetime, and mold die of thermosetting plastic products.

Properties of hot rolled steel SKD11 are as follows. Firstly, it has good toughness and high temperature fatigue resistance. Secondly, this rolling steel can withstand temperature fusion, ands is suitable for long-term work at high temperatures. Thirdly, it has good cutting performance and polishing performance.

What’s more, the application of hot steel SKD11 is diverse. For example, cutting die, stamping die, thread rolling die, wear-resistant sliding block mould, thermosetting resin forming die, and so on. The hardness of them can be 56-58 HRC. What we commonly see are sheet metal die and metal bar mold.

3.1.3 D2

D2 rolling steel is a kind of high wear resistant cold rolled steel and tool steel with micro deformation. The carbon content is up to 1.5%, and the chrome content is up to 11.5%. After the hot finishing process, its hardness can be up to 60HRC. Its application includes metal stamping die, drawing die, stainless steel die, reeling die, metal parts production, machinery manufacturing and so on.

3.1.4 Other rolled steel

Besides for the above steel, the common hot steel we usually use to make fixture and compound die are CR12, tungsten steel, stainless steel, spring steels, SPCC、SUS、SK7、SK5 and so on.

3.2 PF

PF is the acronym of phenolic resin. In general, it has several colors including orange, black, yellow and brown. PF is an insulation switch and variable resistor for electronic products, a mold die for machinery, and a fixture on a production line. Because it has properties of insulation, static electricity, wear resistance and high temperature resistance. What’s more, the PF can be used in transformer oil. The common thickness of PF is 3-50mm, and its common shape is plate.

3.3 PE

PE plate is also known as high density polyethylene. It’s a kind of non-polar thermoplastic resin with high crystallinity. And the PE sheet is translucent to a certain degree in the thin section. As for properties, it has excellent resistance to most of the life and industrial chemicals. Firstly, the polymer is non-hygroscopic and has good vapor resistance. Therefore, it can be used for packaging applications. Secondly, it has good chemical stability, and can resist the erosion of most acids, alkalis, organic solutions and hot water. Thirdly, it also has good electrical insulation. Commonly, they are white or black, and their main shape are sheet and bar.

3.4 Acrylic

Acrylic is a kind of chemical material, which chemical name is PMMA and belongs to propylene alcohol. In the application industry, acrylic raw materials generally appear in the form of particles, plates, pipes, etc. Acrylic, also known as special treatment of organic glass, is a special generation of organic glass products. Its common colors are transparent and white, the thickness ranges from 1mm to 50mm, and its average hardness is 89 HRC. In addition to acrylic, common plastic materials we usually use to produce fixtures are ABS plastic, PS, PP plastic and so on.

4. Common fabricating machinery

Xu Zhuo Industrial Co., Ltd. is a professional fixture manufacturer. As early as 2010, it has a variety of fixture production equipment. Including ordinary lathes, numerical control lathes, milling machine, CNC, grinding machine, drilling machine, discharge machine, wire cutting machine and so on. We not only produce fixture and mould die for our plastic parts and silicone products, but also sale them to many famous clients. And we have advanced and practical model room. Therefore, our mould and fixture enjoy a high reputation in Dongguan, China.

1 note

·

View note

Text

How copper watering can is made

Let's start with the following terminology.copper plating treatment: copper watering can, an unstoppable metal, has been used for most of human existence. Maybe it was one of the first metals used by humans. Although copper was often used for religious purposes, it was found to have practical benefits. Since copper is an excellent conductor of electricity, electroplating copper is the best choice for metal surfaces. The copper plating process can be challenging because it requires high technology, precision and great patience. stainless steel 201: copper watering can 201 stainless steel is an alloy that contains half the nickel and more manganese and nitrogen than other popular steel. While it is less expensive than some other alloys (because of its low nickel content), it is not as easy to work or form. Type 201 is an austenitic metal because it is non-magnetic stainless steel that contains high levels of chromium and nickel and low levels of carbon.stainless steel 304: copper watering can 304 stainless steel is the most widely used stainless steel and contains 18-20% Cr and 8-10.5% Ni, also known as 18-8 stainless steel. Type 304 is non-magnetic under annealed conditions, but after cold working (e.g., stamping, drawing, bending, rolling), a portion of the austenitic structure may change to martensite and is therefore weakly magnetic. AISI 304 has good resistance to atmospheric corrosion and oxidation. The high NiCr alloy content gives it excellent corrosion resistance and it is widely used in the food industry as a standard food grade stainless steel. Approximate professional production process.

1. Shell processing process Outer tube receiving material - Cutting tube - Expanding - Segmenting - Expanding - Rolling the middle angle - Shrinking the bottom - Cutting the bottom - Punching - Flat upper mouth - Punching the bottom - Flat bottom mouth - Cleaning and drying - Inspection and hammering - Qualified casing

2. Inner Shell Processing Process Receiving material for inner pipe - Cutting pipe - Flat pipe - Expanding - Rolling top corner - Flat top opening - Flat bottom opening - Rolling threads - Cleaning and drying - Inspection and knocking pit - Butt welding - Water testing and leak testing - Drying - Qualified inner pipe

3. Shell and inner case assembly process Cups - welding mouth - pressure bottom - welding bottom - inspection welding mouth welding bottom - bottom spot welding aspirate - vacuum - temperature measurement - electrolysis - polishing - temperature measurement - inspection polishing - pressure bottom - spray paint - sampling temperature measurement - inspection spray paint - screen printing - packaging - finished product storage.

Heat can be transmitted in three ways: radiation, convection, and transfer. Let's start with the following terminology.

copper plating treatment: copper watering can, an unstoppable metal, has been used for most of human existence. Maybe it was one of the first metals used by humans. Although copper was often used for religious purposes, it was found to have practical benefits. Since copper is an excellent conductor of electricity, electroplating copper is the best choice for metal surfaces. The copper plating process can be challenging because it requires high technology, precision and great patience. stainless steel 201: Type 201 stainless steel is an alloy that contains half the nickel and more manganese and nitrogen than other popular steels. While it is less expensive than some other alloys (because of its low nickel content), it is not as easy to work or form. Type 201 is an austenitic metal because it is non-magnetic stainless steel that contains high levels of chromium and nickel and low levels of carbon. stainless steel 304: 304 stainless steel is the most widely used stainless steel and contains 18-20% Cr and 8-10.5% Ni, also known as 18-8 stainless steel. Type 304 is non-magnetic under annealed conditions, but after cold working (e.g., stamping, drawing, bending, rolling), a portion of the austenitic structure may change to martensite and is therefore weakly magnetic. AISI 304 has good resistance to atmospheric corrosion and oxidation. The high NiCr alloy content gives it excellent corrosion resistance and it is widely used in the food industry as a standard food grade stainless steel.

Read the full article

0 notes

Video

youtube

W97 Pro Plus Smartwatch BD | AR TECH BD | Bangla Review | 2023

W97 Pro Plus Smartwatch With Apple Logo Calling Watch

Model : W97 Pro Plus

Display 1.9 inch Display,

500+ watch faces download,

Dual Mode BT

Main Features : Watch face download, Split display, BT call, Heart rate, BP,

Basic frequency: RAM:196KB; ROM:1MB+64MB

Size : 45*38*10.7MM

Weight: 50g

Case: Alloy Vacuum Plating

Strap: Original 44/45mm Silicone band

Charger Wireless charging

Color Black,

Touch panel Multiple touch

Notifications Calls, Email, SMS, WhatsApp, WeChat etc.

Pedometer: Daily steps counting, calorie burn morning

Sleep Monitor : Objective and scientific quantification to record and analyze your sleep conditions,

BT : BT 5.0

Battery 280 MAH Lithium ion polymer battery, wireless charger, 150mins to full charge

Vibration :Support

What's The Box :

1 W97 Pro Plus Smartwatch

1 Wireless Charger

1 user Guide

0 notes

Text

Making everyday objects out of plastic is common, even habitual.

To do this, many companies offer various techniques, including plastic injection molding manufacturer. In Europe, we face competition from manufacturers who do not have the same ethics as we do. We have focused our production on relocating cheap injection moulds to France and Belgium.

But before presenting the manufacturing policy of our production unit, it is important, even essential, to specify what Plastic Injection Molding represents. What is this process that facilitates design? What can be achieved using this state-of-the-art plastic technology? What plastics are used in our designs? Let's take a look at Plastic Injection Molding at your fingertips.

1. What is plastic injection moulding?

In order to reproduce parts on a large scale, the technique of molding dates back to the dawn of humanity. Egyptian artefacts, for example, bear witness to the mastery of this technique with various metal alloys. Many civilisations have used this technology to produce coins bearing the effigy of monarchs, artillery components and many other everyday objects.

The lost-wax technique has also had many followers. Of course, the advent of plastics in the 20th century completely changed the casting industry. Whereas metals were heavy and alloys difficult to stabilise, plastic and consequently plastic molding became the material of choice for the production of various parts. The process is based on the injection of pre-melted plastics into moulds of different shapes and sizes. When the plastic cools, its appearance permanently takes on the shape given to the mould.

Plastic injection molding thus allows the large-scale production of plastic parts of various origins. However, there are tolerance limits for the different qualities of plastic which can prevent the production of particularly complex mouldings. For this reason, it is necessary to call on the services of a specialist in plastic injection moulding in order to obtain quality designs.

2. What plastics are used and what are their characteristics?

As our plastics industry is very rich, there are thousands of different types of plastics, which makes their characteristics and aesthetic specificities very diverse. However, there are two main groups that can be used to make a Plastic Injection Mould:

- Thermoset plastics: to make a plastic thermoset, it must undergo polymerisation, which makes its structure irreversible. It is therefore impossible to recycle them. They are used in liquid or paste form. On the other hand, their increased strength makes them very durable.

3. What are the main plastic injection moulding techniques?

Different plastic injection moulding techniques can be developed. Each has its own specificities depending on the quality of the material, its thickness and the quantity of parts to be produced.

- Low-pressure plastic injection moulding: this is a process that consists of filling the bottom of an open mould. The mould is connected to a pipe underneath so that the molten plastic rises. This type of moulding makes it possible to produce fairly large parts in small series. This is the case for the plastic injection of polycarbonate showers;

- Thermoforming moulding: this is a plastic processing technique adapted to parts with a simple geometry, particularly rounded parts. A plastic sheet is heated in an oven to make it malleable and placed over the mould. The mould, connected to a vacuum system, comes into hermetic contact with the plate, and all that remains is to suck out the air so that the plate adheres perfectly to the mould.

- Thermocompression moulding: its main advantage is that it is done in one go. The heated material is then distributed in single or multi-layers depending on the thickness of material required. It is then processed in a press to obtain the desired shape. This process, which superimposes several layers, improves the mechanical characteristics of the part;

- Overmoulding: this is a technique that allows plastic material to be added to a specific point on an existing product. The target location can be on the surface or inside depending on the need to reinforce the base part. It is a technique that allows the optimisation of an assembly in order to quickly commercialise small and medium series;

- Bi-injection moulding: thanks to this innovative technique, two different materials are injected through two pipes into the same mould. The result is a mixed product with combined specificities.

Our best injection molding company is constantly looking for performance in order to produce low-cost injection moulds by reducing its production costs. Limiting transport and controlling the production chain allows us to meet this objective. By calling on our professionalism to produce plastic injection moulds quickly, you are assured of a reliable service that meets your expectations. Whether it is for a plastic injection molding France or any other request concerning our plastic production units, we are at your disposal.

0 notes

Photo

Amorphous alloy dry type transformer SCBH15-10KV

High voltage coil adopts segmented cylindrical coil , Thin insulation seal vacuum pouring.

There is the axial airway in the large capacity winding. The coil with the high voltage resistance level . low local discharge , good waterproof and dustproof effect .

Low voltage coil adopts foil coil , there is the DMD between layers , resolve the problem of imbalance of low voltage , large current coiling . Meanwhile , there is no axial winding of the spiral angle in the foil coiling . The axial force is greatly reduced in the case of short circuit . good artist , low loss , high ability of short circuit resistance .

The transformer can equip the general steel plate , aluminium alloy or stainless steel sheel according the client’s requirements , There are the IP20 , IP23 for choice , also can customized the line in out connection port of high , low voltage busbar .

Senhengli Electric Co.,Ltd

Website: http://www.senhengli.cc

Email : [email protected]

wechat : uedluck

TEL : +86-577-57107960

FAX: +86-577-51709994

0 notes