#aliphatic isocyanate market

Text

Aliphatic Isocyanates Market May See a Big Move

Advance Market Analytics published a new research publication on "Aliphatic Isocyanates Market Insights, to 2028" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Aliphatic Isocyanates market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample Copy of This Research @ https://www.advancemarketanalytics.com/sample-report/42679-global-aliphatic-isocyanates-market

The Aliphatic Isocyanates Market report covers extensive analysis of the key market players, along with their business overview, expansion plans, and strategies. The key players studied in the report include: Alipa (Belgium), Bayer (Germany), Evonik (Germany), Vencorex (France), BASF (Germany), Asahi Kasei (Japan), Wanhua Chemical (China), Covestro AG (Germany), Everchem Specialty Chemicals (United States), Huntsman Corporation (United States).

Definition: Aliphatic Isocyanates (ADI) are specialty intermediary chemicals which are used primarily to make polyurethane coatings, adhesives and sealants and elastomers. Isocyanates may be produced by several methods but the most common method used commercially to produce isocyanates is the phosgene based process. Free amines are responded with additional phosgene in an inert organic solvent at low temperature, the resulting slurry of carbamoyl chlorides and amine hydrochloride is then heated at elevated temperature in the presence of excess phosgene to give the desired isocyanates.

The following fragment talks about the Aliphatic Isocyanates market types, applications, End-Users, Deployment model etc. A thorough analysis of Aliphatic Isocyanates Market Segmentation: by Type (Hexamethylene Diisocyanate (HDI), Isophorone Diisocyanate (IPDI), Methylene Dicyclohexyl Diisocyanate (MDI) or Hydrogenated MDI, Others), Application (Coatings (Auto/Transportation, General Industrial, Materials (Non-Metallic) Coatings), Adhesives and Sealants, Elastomers, Others)

Aliphatic Isocyanates Market Drivers:

Increasing Demand from Manufacturing and Construction Industry

Aliphatic Isocyanates Market Trends:

Innovations in End Use Applications of Aliphatic Isocyanates

Aliphatic Isocyanates Market Growth Opportunities:

Rising Environmental Awareness about Aliphatic Isocyanates

As the Aliphatic Isocyanates market is becoming increasingly competitive, it has become imperative for businesses to keep a constant watch on their competitor strategies and other changing trends in the Aliphatic Isocyanates market. Scope of Aliphatic Isocyanates market intelligence has proliferated to include comprehensive analysis and analytics that can help revamp business models and projections to suit current business requirements.

We help our customers settle on more intelligent choices to accomplish quick business development. Our strength lies in the unbeaten diversity of our global market research teams, innovative research methodologies, and unique perspective that merge seamlessly to offer customized solutions for your every business requirement.

Have Any Questions Regarding Global Aliphatic Isocyanates Market Report, Ask Our Experts@ https://www.advancemarketanalytics.com/enquiry-before-buy/42679-global-aliphatic-isocyanates-market

Strategic Points Covered in Table of Content of Global Aliphatic Isocyanates Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the Aliphatic Isocyanates market

Chapter 2: Exclusive Summary and the basic information of the Aliphatic Isocyanates Market.

Chapter 3: Displaying the Market Dynamics- Drivers, Trends and Challenges & Opportunities of the Aliphatic Isocyanates

Chapter 4: Presenting the Aliphatic Isocyanates Market Factor Analysis, Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying the by Type, End User and Region/Country 2018-2022

Chapter 6: Evaluating the leading manufacturers of the Aliphatic Isocyanates market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by Manufacturers/Company with revenue share and sales by key countries in these various regions (2023-2028)

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source

Finally, Aliphatic Isocyanates Market is a valuable source of guidance for individuals and companies.

Read Detailed Index of full Research Study at @ https://www.advancemarketanalytics.com/reports/42679-global-aliphatic-isocyanates-market

What benefits does AMA research study is going to provide?

Latest industry influencing trends and development scenario

Open up New Markets

To Seize powerful market opportunities

Key decision in planning and to further expand market share

Identify Key Business Segments, Market proposition & Gap Analysis

Assisting in allocating marketing investments

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia.

Contact US :

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: +1 201 565 3262, +44 161 818 8166

[email protected]

#Global Aliphatic Isocyanates Market#Aliphatic Isocyanates Market Demand#Aliphatic Isocyanates Market Trends#Aliphatic Isocyanates Market Analysis#Aliphatic Isocyanates Market Growth#Aliphatic Isocyanates Market Share#Aliphatic Isocyanates Market Forecast#Aliphatic Isocyanates Market Challenges

0 notes

Text

Science Meets Innovation: How Rust Bullet is Transforming the Battle Against Corrosion

With the support of science and innovation, the Rust Bullet emerges as a revolutionary force in the ongoing battle against corrosion. Established in 2001 in Reno, Nevada, Rust Bullet, LLC has become a trailblazer in rust prevention, undergoing rigorous testing for two years before entering the market.

Unrivaled Quality and Environmental Responsibility

Rust Bullet takes pride in its commitment to quality. All products are crafted with the highest quality raw materials, adhering to stringent quality control standards. More than just a rust inhibitor, Rust Bullet is an environmentally conscious choice, containing no lead, no zinc, no chromates, and no heavy metals. It meets and exceeds EPA Standards for Potable Water and California VOC Standards, making it a responsible and eco-friendly solution.

Patented Excellence

Notably, Rust Bullet has received two patents from the United States Patent and Trademark Office (USPTO), a testament to the groundbreaking technologies embedded in its rust and corrosion control products.

Innovative Advancements: Introducing Rust Bullet DuraGrade

Building on its impressive lineup, Rust Bullet introduces DuraGrade, a game-changer with significantly reduced VOC content, including Ultra Low VOC. This innovation showcases Rust Bullet's dedication to providing consumers with effective, environmentally friendly solutions.

Aliphatic and Aromatic: The Winning Combination

Understanding the significance of coating stability, Rust Bullet uniquely combines aliphatic and aromatic properties. This dual approach ensures strength, flexibility, and UV resistance, setting Rust Bullet apart from the rest.

Moisture Cure Urethane: A Technological Marvel

Rust Bullet's moisture-cured urethane signifies a paradigm shift in the coating industry. No artificial heat source is required for curing, making it a safe and efficient choice. The inclusion of isocyanates, safely bound in the polymer chain, poses no health or environmental risks when applied following Rust Bullet guidelines.

Polyurethane Excellence: Beyond Elastomeric Coatings

With cross-linking density, Rust Bullet's polyurethane coatings exhibit superior chemical and moisture resistance. The competition with elastomeric coatings is evident in their exceptional abrasion resistance, impact resistance, and flexibility.

Versatility in Exposure: Atmospheric, Immersion, and Underground

Rust Bullet coatings provide optimum performance in various environments, from atmospheric exposure and immersion to underground conditions. The adaptability to weather, chemicals, and groundwater positions Rust Bullet as a comprehensive solution.

Sustainable Solids: A Greener Choice

Boasting 70% solids content, Rust Bullet is a more environmentally friendly and cost-effective coating. The reduced levels of solvents contribute to decreased flammability and health risks, ensuring safety without compromising quality.

Outperforming Competitors: Epoxy, Polyethylene, and More

Rust Bullet stands tall against epoxy coatings with its one-part process, rapid curing, and self-inspecting properties. It outshines polyethylene coatings in thermal stability and fire-retardant capabilities.

Superior Adhesion: From Chrome to Steel

Rust Bullet's adhesive qualities extend to various surfaces, including polished chrome, galvanized surfaces, stainless steel, and more.

Barrier, Inhibition, and Sacrificial Action

Threefold Protection:

Rust Bullet goes beyond ordinary coatings, providing a non-porous barrier, corrosion-inhibitive pigments, and sacrificial action through aluminum-rich formulas.

In conclusion, Rust Bullet isn't confined to rust prevention alone; it stands as a testament to scientific ingenuity, borne out of years dedicated to redefining the possibilities of protective coatings. Opting for Rust Bullet isn't just about shielding against rust; it signifies embracing a revolutionary era of surface protection—one characterized by a commitment to quality, innovation, and environmental responsibility. Make a choice that goes beyond the conventional; opt for Rust Bullet to usher in a future where surfaces remain immaculate and corrosion is relegated to history.

0 notes

Text

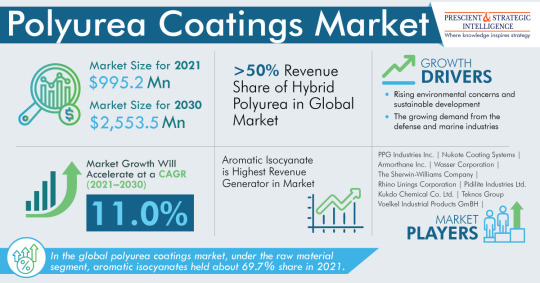

Seamless Protection: Exploring the Polyurea Coatings Market

The size of the polyurea coatings market was USD 995.2 million in the recent past, and it will power at a rate of 11% and reach a value of USD 2,553.5 million by 2030, according to P&S Intelligence.

The automotive and transportation sector had the second-largest share, of about 26%. Polyurea coatings are used on the exteriors of vehicles, such as two-wheelers and trucks. They are usually seen on the chassis, driveshafts, gearboxes, and engines, as they provide good resistance to the exterior thermal and physical pressure.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/polyurea-coatings-market/report-sample

Consequently, polyurea coatings are becoming popular among automakers. China, Germany and Japan are the top three passenger vehicle producers. Consequently, polyurea coatings’ applications have advanced greatly in these countries. Volkswagen, Mercedes, Audi, Porsche, Opel, and BMW are all part of Germany's extremely competitive automobile industry.

This industry generates about USD 468.5 billion, which accounts to about 20% of the total revenue of the German industry.

Aromatic isocyanates are formulated with the use of benzene and toluene as raw materials. Methylenediphenyl disocyanate and Toulenedisocyanate are two of the most-common aromatic isocyanates used in the construction industry.

The weather of Europe and North America is favorable for the use of aromatic polyurea coatings, which are less expensive than aliphatic substitutions. Aromatic isocyanates are used as a basecoat, meaning they are the first layer applied to any surface. Consequently, they are widely used in vehicles, that is the reason aromatic polyurea coatings market size will grow rapidly.

The requirement for polyurea coating will surge in the APAC with a rate of 11.9% in the years to come. The high-pace monetary growth and substantial investment by private and government companies in numerous sectors, such as maritime, manufacturing, automotive, and construction, are driving the regional demand for industrial coatings.

It is because of the increasing ecological concerns and requirement for sustainable expansion, polyurea coatings had a major place in the coatings sector, garnering high investment in R&D.

#Polyurea coatings#Protective coatings#Industrial applications#Corrosion resistance#Waterproofing solutions#Abrasion resistance#Coating technology#Surface protection#Infrastructure maintenance#Automotive coatings#Flooring solutions#Market trends#Seamless coatings#Chemical resistance#Environmental durability#Spray-on coatings#Application versatility#Market growth#Coating innovation#Future of polyurea coatings.

0 notes

Text

0 notes

Text

0 notes

Text

The Chemistry of Polyurea

Polyurea is a highly specialized coating that has an excellent range of performance characteristics. It can provide the flexibility and durability to solve tough problems like corrosive exposure, moisture control, abrasion resistance, and other factors.

Polyurea can also be used to create a lining for a dump truck or pickup bed that offers a permanent, watertight surface that protects the vehicle from damage. It also provides abrasion and impact protection for mine equipment, including conveyors that transport abrasive coal or metallic ores.

The chemistry behind polyurea is fairly simple, but the variety of properties it can offer makes it a versatile and durable choice for certain applications. This is why it's so popular for industrial and commercial projects.

This coating is made up of two chemical ingredients, known as "A" and "B." Aside from the basic chemical components, there are many different variations that can affect its gel and cure times, adhesion, flexibility, impact resistance, and tear strength among other special qualities.

It is the reaction of alternating monomer units (isocyanates) and amines that creates the linkage between them that makes polyurea unique. This linkage consists of a carbamic acid intermediate that quickly decomposes and liberates carbon dioxide, which leaves an amine that can react with another isocyanate group to form the polyurea linkage.

The type of isocyanate that forms the polyurea linkage can vary based on the product's origin. These include aliphatic diisocyanates, aromatic polyureas, and polyaspartics.

Generally speaking, the aliphatic polyureas are more difficult to process than the aromatic polyureas. They're typically lighter in color and can resist sunlight-induced color change, but they are much more expensive.

There are two types of aliphatic polyurea systems on the market: hot sprayed and cold applied. The hot sprayed systems require high pressure plural component pumps and an impingement type spray-gun to apply the coating.

In contrast, the cold applied systems don't need any type of spraying equipment and are manually processed using a rubber float, spatula or trowel. They take longer to dry than hot sprayed but are very effective for small jobs and repairs.

Polyurea is a very versatile material that can be used to waterproof, seal and protect concrete structures from water. It can be sprayed on roofs, foundations and walls as a liquid coating that dries quickly to create a long-lasting, permanent waterproof barrier.

It can also be sprayed on concrete floors and other surfaces to give them a strong, durable finish. It's ideal for coating retaining walls, walkways, and driveways, and it can be used to protect concrete pools and other water tanks.

When it comes to applying a concrete coating, it's important to choose a contractor that uses a pure polyurea coating system. This will ensure the best possible results for your project.

The right polyurea coating system will allow you to achieve the desired results without compromising the quality of your project. It will help you avoid costly mistakes, and will save you time and money in the long run.

1 note

·

View note

Text

Industry analysis provides a company with an understanding of its position relative to other companies in the industry. This can help them identify opportunities and potential threats, so they can prepare for the present and future. MRI Research helps organizations to figure out whats happening in a given industry, including demand and supply statistics, degree of competition, state of competition with other emerging industries, future prospects considering technological changes, and external factors on the industry.

0 notes

Link

Global Aliphatic Isocyanates Market is expected to grow at a CAGR of 8.6% during the forecast period and is expected to reach US$ 9.2 Bn by 2027.

0 notes

Link

0 notes

Link

#Aliphatic Isocyanates#Aliphatic Isocyanates market trend#Aliphatic Isocyanates market insights#Aliphatic Isocyanates market growth#Aliphatic Isocyanates market size#Aliphatic Isocyanates market research report#Aliphatic Isocyanates industry news

0 notes

Link

#aliphatic isocyanates#market research reports#market reports#market growth#industry analysis#industry news#industry insights#market news

0 notes

Text

High-Performance Coatings: Epoxies and Polyurethanes

High-Performance Coatings: Epoxies and Polyurethanes

When talking about coatings, paints seem to rule supreme. At some point, nearly everyone has used or come into contact with paint, whether it is on a canvass in art class or changing the color of their living room.

While conventional paints are relatively inexpensive and easy to use, they have their limitations. Especially in the commercial and industrial markets, where concrete and steel substrates are more common, there is a need for more versatile and durable coating products.

This is where high-performance coatings come into play. While there is a wide range of High-Performance Coatings, Epoxies and Polyurethanes are two of the most common. Each type has its own distinct advantages and disadvantages. Below we will discuss each of these coatings and how they may be able to take your next project to the next level.

Epoxies

What is epoxy?

An epoxy is a coating compound consisting of two separate elements: an epoxy resin and a curing agent (or hardener). When mixed, the resin and hardener go through a chemical reaction as it cures. When fully cured, the resulting product is a durable, rigid plastic coating with numerous desirable mechanical properties.

Advantages/Disadvantages of Epoxy:

Since the term “epoxy” can refer to such a wide range of epoxy coatings, it is hard to list specific benefits and drawbacks that apply to every product. Here are some of the advantages and disadvantages that apply to most epoxy coating systems.

Advantages:

• Strong adhesion to many substrates

• Provides excellent resistance to chemicals

• Provides superior resistance to corrosion

Disadvantages:

• Not ideal for cold weather as lower temperatures can slow cure time

• Does not hold color as well as other coating systems

• Gloss tends to fade with time

Polyurethanes

What is Polyurethane?

Polyurethane is a versatile coating designed so that its microscopic resin molecules will bond tightly with one another as it dries. As a result, polyurethanes provide a finish that is much more resistant to water, solvents, and abrasion as compared to traditional paint finishes. Due to their excellent color and gloss retention, polyurethane coatings are often used as a topcoat in combination with epoxies and zinc-rich primers. Polyurethanes typically come in two categories: Aliphatic and Aromatic. Aliphatic Polyurethanes perform very well in sunlight, making them ideal for exterior projects. Aromatic Polyurethanes, on the other hand, have a tendency to chalk in sunlight but hold up especially well in water. For this reason, aromatic polyurethanes are ideal for submerged environments.

Advantages/Disadvantages of Polyurethane:

Similar to epoxies, there is a wide range of polyurethane products on the market, each of which is designed to suit specific applications. As such, the advantages and disadvantages will vary from product to product. Listed below are a few advantages/disadvantages that, for the most part, apply to polyurethanes as a whole.

Advantages:

• Excellent gloss and color retention

• Very resistant to abrasion

• Available in low VOC formulas

• Aliphatic Polyurethanes hold up well against weather and sunlight

• Aromatic Polyurethanes hold up well when submerged

Disadvantages:

• Can be more expensive than epoxies/paint

• Is known to contain potentially harmful carcinogens (mainly isocyanate)

• Will likely require a multiple component system

About QC Commercial, LLC – Raleigh, NC Commercial Painting Contractor

QC Commercial, LLC is a commercial painting company and industrial painting contractor based in Raleigh, NC. We provide painting services in North Carolina and throughout the southeast region of the US. Our steady growth in the industrial painting and commercial painting industry is achieved by emphasizing safety, environmental awareness, attention to detail while in the field and in the office, continuous improvement in process and product knowledge, pre-project planning using our comprehensive submittal processes, and proactive approach to hazardous material programs. Our commitment to Total Quality Management (TQM) continues to drive our quality and reliability up while keeping our costs down.

Source: https://ift.tt/2IDnrMa

from QC Commercial LLC https://qccommercial.wordpress.com/2020/03/12/high-performance-coatings-epoxies-and-polyurethanes/

1 note

·

View note

Text

0 notes

Text

Polyurea Coatings Market is expected to witness rapid growth in the forecast period 2018-2026

Polyurea is produced through a process called step-growth polymerization. The reaction of amine resins with a pre-polymer forms polyurea coating. Polyurea coating is durable, exhibits high resistance from corrosion and is flexible in nature. With different methods of formation, the properties and applications of polyurea coatings vary. Polyurea coatings find wide application in construction, infrastructure, manufacturing, automobiles, and marine industries. Polyurea coatings experience significant demand from the oil & gas and chemical industries, owing to the high hydrocarbon and gas resistance properties. Moreover, due to the zero VOC content of polyurea coatings, demand for traditional coatings such as polychloroprene, epoxy, and polyurethane has decreased substantially.

Polyurea Coatings Market Taxonomy

On the basis of raw material, the global polyurea coatings market is classified as:

Aliphatic Isocyanate-Based

Aromatic Isocyanate-Based

On the basis of product type, the global polyurea coatings market is classified as:

Hybrid polyurea coating

Pure polyurea coating

On the basis of application, the global polyurea coatings market is classified as:

Construction industry

Transportation industry

Oil & gas industry

Request Copy Of This Business Report: https://www.coherentmarketinsights.com/market-insight/polyurea-coatings-market-857

Major Keyplayers: Specialty Products Inc., VersaFlex, PPG Industries, Rhino Linings Corporation, VIP GmbH, Sherwin-Williams Company, PPG Industries, and Kukdo Chemicals.

About Us:

Coherent Market Insights is a global market intelligence and consulting organization that provides syndicated research reports, customized research reports, and consulting services. We are known for our actionable insights and authentic reports in various domains including aerospace and defense, agriculture, food and beverages, automotive, chemicals and materials, and virtually all domains and an exhaustive list of sub-domains under the sun. We create value for clients through our highly reliable and accurate reports. We are also committed in playing a leading role in offering insights in various sectors post-COVID-19 and continue to deliver measurable, sustainable results for our clients.

Contact:

Coherent Market Insights

1001 4th Ave, #3200 Seattle, WA 98154, U.S.

Email: [email protected]

United States of America: +1-206-701-6702

United Kingdom: +44-020-8133-4027

Japan: +050-5539-1737

India: +91-848-285-0837

0 notes