#Stainless Steel Forged Fittings Supplier in India

Text

5 Things about Stainless Steel 316H Forged Fittings manufacturer you will never know!

Stainless steel 316H forged fittings are widely used in a variety of industrial applications due to their exceptional strength, durability, and corrosion resistance properties. These fittings are made by a specialized manufacturer who uses advanced technology and techniques to produce high-quality components.

In this article, we will explore 5 things about stainless steel 316H forged fittings manufacturers that you may never have known before.

Expertise and Experience

SS 316H forged fittings manufacturer has extensive knowledge and experience in the field of metallurgy, engineering, and manufacturing processes. They have the expertise to produce customized fittings that meet specific customer requirements, such as dimensions, shapes, and materials. These manufacturers also have a deep understanding of the properties and characteristics of stainless steel 316H, which enables them to optimize the forging process and produce high-quality components.

High-Quality Standards

This manufacturer follows strict quality control measures to ensure that their products meet the highest industry standards. They use advanced testing and inspection techniques to verify the properties and characteristics of the components, such as hardness, tensile strength, and corrosion resistance. These manufacturers also use high-quality materials and production techniques to ensure that their products are durable and reliable.

Customization Capabilities

They also have the ability to produce customized components based on specific customer requirements. They can create fittings in a variety of shapes and sizes, including elbows, tees, couplings, and reducers. These manufacturers can also produce fittings with specific threads, such as NPT, BSP, or BSPT, and can create specialized components for unique applications.

Advanced Technology and Techniques

They also use advanced technology and techniques to produce high-quality components. They use computer-aided design (CAD) software to create 3D models of the fittings and simulate the forging process to optimize the production process. These manufacturers also use advanced forging equipment, such as hydraulic presses and hammers, to produce high-quality components with precise dimensions and properties.

Compliance with Industry Standards

Stainless steel 316H forged fittings manufacturers comply with various industry standards, such as ASTM, ASME, and ANSI. These manufacturers also adhere to various international standards, such as ISO and EN. Compliance with these standards ensures that the components produced by these manufacturers are safe, reliable, and meet the required specifications.

In conclusion, stainless steel 316H forged fittings manufacturers are experts in the field of metallurgy, engineering, and manufacturing processes. They use advanced technology and techniques to produce high-quality components that meet specific customer requirements. These manufacturers follow strict quality control measures and comply with various industry standards to ensure that their products are safe, reliable, and of high quality.

#Stainless Steel Pipe Fittings#Stainless Steel Forged Fittings#construction#buildings#alloy#steel products#plumbing#Water control system#engineering#civilengineering#SS 316H Pipe Fittings#SS Pipe Fittings#Stainless Steel Pipe Fitting Manufacturer in Mumbai#Stainless Steel Forged Fittings Supplier in India#Stainless Steel Pipe Fittings Price

5 notes

·

View notes

Text

Stainless Steel 316Ti Forged Fittings Manufacturers in India

Technolloy Inc. is the maker and stockiest of the wide degrees of the SS 316/316L/316Ti Forged Fittings. We are similarly the provider of the normal thought of the shaped fittings open from one side of the world to the other. The created fittings are also open in various nuances like surface zenith, end finish, viewpoints, shapes, sizes, and length.

The manufactured fittings are open in various sorts which are utilized in present day applications. In any case, a piece of the shaped fittings which are open are elbows, couplings, equivalent, and others. the manufactured fittings are the kind of line fittings which are made with following the making system.

SS 316 is the best grade of the austenitic mix which is having the presence of chromium and nickel content. In any case, this is the way that the blend coordinates molybdenum and different other alloying contents. The compound is having the uncommon use obstruction limit with which they are working in the raised temperatures.

SS 316L is the low carbon mix grade of the 316 blends tempered steel which is besides containing the things in chromium and nickel. Notwithstanding, this is the explanation that the compound is having phenomenal use block limit with the presence of carbon and the increases of molybdenum.

Nearby this, the SS 316Ti is the titanium changed hardened steel grade which is likewise having the extensions of carbon. The treated steel is having the things in chromium and nickel which are utilized in the cryogenic temperatures of the high level application. This is the way the compound steel is utilized in the conveyed fittings.

The SS 316/316L/316Ti Forged Fittings is having different attributes with the presence of the alloying parts. A piece of the properties which are there in the manufactured fittings are sensational adaptability, strength, steady quality in the raised temperature, extraordinary solidness, high flexibility, and fantastic weldability. This is the explanation that made fittings are utilized in two or three undertakings. A piece of the associations which are utilizing such planned fittings are drugs, petrochemical, oil and gas, pound and paper, rail lines and several others.

#Stainless Steel 316/316L/316Ti Forged Fittings Manufacturers in India#Stainless Steel 316/316L/316Ti Forged Fittings Suppliers in India

0 notes

Text

Forged Fittings - Grades, Types, Range, Form| Stainless and Carbon Steel

Metal Forge India is one of the leading manufacturers of high quality forged fittings in all major grades including ASTM A182, A105, A105N, A350 LF2, A182 F5. We produce forged pipe fittings for end-users and stockists all over the world. We can also offer forged pipe fittings in Low Temp ASTM/ASME SA350 LF2 and Stainless Steel ASTM/ASME SA182 F304/L & F316/L. We manufacture and supply ANSI forged pipe fittings in all materials and pressures.

#Forged Fittings Manufacturer in India#Forged Fittings Supplier in India#Forged Fittings Supplier#Stainless and Carbon Steel Manufacturer in India#Stainless and Carbon Steel Supplier in India

0 notes

Text

Types Of Flange & Flange Manufacturer in India

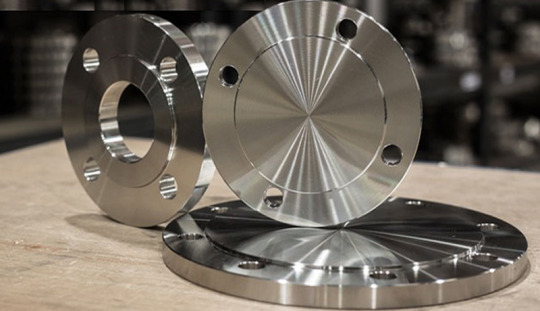

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

8 notes

·

View notes

Text

Stainless Steel 317/317L Boiler Tubes Manufacturers In Mumbai

Introduction:

Mumbai, the bustling metropolis on the western coast of India, is not just the financial capital but also a hub of industrial excellence. Among the many industries thriving in this vibrant city, the manufacturing of Stainless Steel 317/317L Boiler Tubes stands out as a testament to Mumbai's engineering prowess.Stainless Steel 317/317L stands out for its exceptional properties, particularly in the realm of boiler tubes. Metinoxoverseas, a leading supplier in India, Stainless Steel 317/317L Boiler Tubes. SS 317 Boiler Tubes (also known as UNS S31700 and WNR 1.4449) find typical applications in various industries, including boat fittings, structural members, architectural components in marine, polluted or industrial environments, food and beverage processing equipment, hot water systems, and plants for chemical, petrochemical, mineral processing, photographic, and other industries.

Description : Stainless Steel 317/317L Boiler Tubes manufactured in Mumbai embody the city's commitment to precision engineering and quality craftsmanship. These tubes are forged from premium-grade stainless steel alloys, meticulously selected for their superior corrosion resistance and high-temperature strength. The addition of molybdenum enhances the alloy's resistance to pitting and crevice corrosion, making it an ideal choice for boiler applications in industries such as chemical processing, petrochemicals, and power generation.

Product Overview: Metinoxoverseas offers an extensive range of Stainless Steel 317/317L boiler tubes meticulously designed to meet the stringent requirements of boiler applications. With a commitment to quality and customer satisfaction, Metinoxoverseas ensures that each tube undergoes thorough quality checks to guarantee superior performance and reliability. Their tubes are trusted by industries worldwide for their durability, corrosion resistance, and impeccable quality.

Stainless Steel 317/317L Boiler Tubing Specification :

Specifications : ASTM A / ASME SA213 A312

Range : 6.35 mm OD upto 152.4 mm OD in 0.6 TO 10 mm thickness.

Form : Round, Square, Rectangular, Coil, U Tube, Pan Cake.

Wall Thickness : 0.50 mm TO 6.0 mm

End : Plain End, Bevelled End

Length : Single Random, Double Random & Required Length

Types : Seamless / ERW / Welded

Conclusion: Stainless Steel 317/317L boiler tubes from Metinoxoverseas are the epitome of durability, performance, and reliability in demanding boiler applications. With their exceptional corrosion resistance, high temperature strength, and versatility, these tubes provide an ideal solution for various industrial sectors.

Contact : Metinoxoverseas today via email at [email protected] () or by phone at +91-98199 80997 / +91-70212 61928 to experience unparalleled quality and service in stainless steel boiler tubes.

0 notes

Text

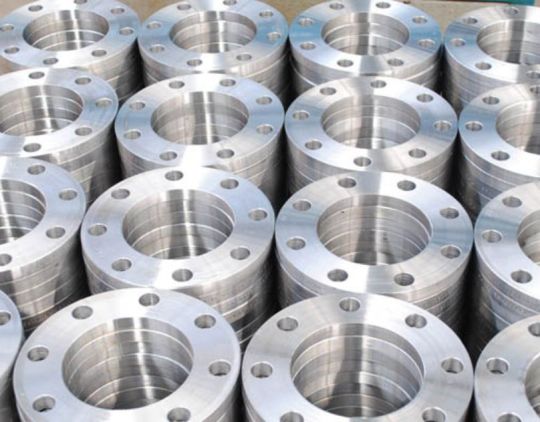

Unveiling the Secret: How to Select the Best Flange for Your Project

Metalica Forging Inc. is a leading Flanges Manufacturer in India. A flange is a projecting rim or edge that is commonly utilized for strength, alignment, or connection in engineering and building applications. Flanges are widely utilised in pipeline systems to help with the assembly and disassembly of pipes, valves, and other components.

Flange Supplier in India may seem like simple components in the grand scheme of engineering projects, but their importance cannot be overstated. They serve as crucial connectors, joining pipes, valves, and other equipment in a wide array of industries, from oil and gas to manufacturing and construction. However, choosing the right Flange Suppliers for your project is not always a straightforward task. With numerous types, materials, and specifications available, the selection process can be daunting. But fear not, for in this blog post, we will unveil the secrets to selecting the perfect flange for your specific needs.

Understanding Flanges:

Before diving into the selection process, it's essential to have a basic understanding of what flanges are and how they function. Essentially, a flange is a protruding rim or edge that is used to connect two objects, often by bolting them together. In the context of piping systems, flanges are used to join pipes, valves, fittings, and other components, allowing for easy assembly, disassembly, and maintenance.

Types of Flanges:

Flanges come in various types, each designed for specific applications and requirements. Some common types of flanges include:

Plate Flanges: are flat, circular flanges with bolt holes drilled directly into the flat surface, commonly used in low-pressure applications for connecting pipes, valves, and fittings. They offer a simple and cost-effective solution for joining components in systems where high pressure and temperature are not critical factors.

Slip-On Flanges: These flanges slide over the pipe and are then welded in place. They are relatively easy to install and are suitable for low-pressure applications.

Blind Flanges: As the name suggests, blind flanges are used to seal the end of a pipe or vessel. They are commonly used for pressure testing or when the end of the pipe needs to be closed off.

Socket Weld Flanges: Similar to slip-on flanges, socket weld flanges are welded to the pipe. However, they feature a recessed area (socket) into which the pipe fits, providing additional strength and stability.

Threaded Flanges: These flanges have threaded holes, allowing them to be screwed onto the pipe without the need for welding. They are commonly used in low-pressure, non-critical applications.

Hub Flanges: Hub Flanges can be customised to meet specific customer requirements and come in an assortment of sizes, dimensions, and forms. Being a top manufacturer of hub flanges, we supply them to a broad range of industries, including transportation, paper & pulp, plumbing, food processing and others. We are renowned for the outstanding quality, dependability, and durability of our goods. There are several different kinds of hub flanges that we offer, such as carbon steel, copper nickel, stainless steel, monel, inconel, and more. The International Quality Standards (IQS) are followed in the design and development of hub flanges. In accordance with the needs of the customer, we also provide customised Hub Flanges.

Factors to Consider:

When choosing the perfect flange for your project, several factors should be taken into consideration:

Pressure and Temperature: One of the most critical factors is the pressure and temperature conditions the flange will be subjected to. Different flange materials and designs have varying pressure and temperature ratings, so it's essential to select a flange that can withstand the operating conditions of your system.

Material Compatibility: Flanges are available in a wide range of materials, including carbon steel, stainless steel, and various alloys. The material chosen should be compatible with the fluid being transported and resistant to corrosion, erosion, and other forms of degradation.

Flange Facing and Gasket Material: The flange facing and gasket material play a crucial role in ensuring a reliable seal between flange joints. Factors such as the type of fluid, operating temperature, and pressure should be considered when selecting the appropriate facing and gasket material.

Size and Dimensions: Flanges come in various sizes and dimensions to accommodate different pipe sizes and pressure ratings. It's essential to select a flange that matches the size and specifications of your piping system to ensure proper alignment and functionality.

Consultation and Expertise:

While understanding the basics of flanges is essential, choosing the perfect flange for your project may require consultation with experts in the field. Engineers, manufacturers, and suppliers with experience in flange selection can provide valuable insights and recommendations based on your specific requirements and constraints.

We produce flanges in several Indian cities.

Flanges Manufacturer In Rajkot

Flanges Manufacturer In Ahmedabad

Flange Manufacturer In Surat

Flange Manufacturer In Bhavnagar

Flange Manufacturer In Pune

For More Detail

Website: metalicaforginginc.com

Other Product: JIS Flanges Manufacturer in India.

0 notes

Text

Supplier of Stainless Steel Bars in Chhattisgarh

Company Profile:

Rahul Steel India is a Manufacturer, Exporter, and Supplier of Stainless Steel Bars in Chhattisgarh, India.

Renowned for its top-quality SS Bars, Rahul Steel India operates from Ahmedabad, Gujarat, India.

Rahul Steel India Offers a comprehensive range of industrial raw materials, including stainless steel pipes, tubes, fittings, flanges, valves, patta, dairy valves, fasteners, sheets, plates, coils, bars, wires, and rods.

Produces bars from ferritic, austenitic, and martensitic stainless steel, meeting AISI standards such as 303, 304, 304L, 310, 316, 316L, 316Ti, 321, 403, 409, 410, 416, 420, 430, 430F, 430LBN, 431, and 630, as well as 2205, to fulfill various requirements.

Technical Specifications:

Dimensions: ASTM, ASME, API

Thickness: 5 mm To 500 mm

Size: from 2.00mm to 6.35mm (0.078″ to 0.25″)

Finish: Bright, Black, Polish

Form: SS Bars, SS Wires, SS Rods

Condition: Cold Drawn & Polished Cold Drawn, Centre-less Ground & Polished

Other Services: Machining (CNC), Centre-less Grinding (CG), Heat Treatment, Anne-ling, Pickling, Polish, Rolling, Forging, Cutting, Bending, Minor Fabrication

Key Features of Stainless Steel Bars:

Corrosion Resistant

High Tensile Strength

Very Durable

Temperature Resistant

Environmentally Friendly

Low-maintenance (long-lasting)

Attractive appearance

Long Durability

High Strength

Bend Fittings

Geographical Coverage in Chhattisgarh:

Rahul Steel India Supplier of Stainless Steel Bars in Chhattisgarh, including cities such as Raipur, Bhilai, Bilaspur, Korba, Durg, Rajnandgaon, Raigarh, Jagdalpur, Ambikapur, Kawardha, Mahasamund, Bhatapara, Dhamtari, Baloda Bazar, Balod, Mungeli, Pandariya, Takhatpur, Bhilai Charoda, Kumhari, Bemetara, Basna, Chirmiri, Dongargarh, Khairagarh, and Pithora.

For detailed information or inquiries, interested parties are encouraged to contact Rahul Steel India directly.

Read the full article

#Ambikapur#Balod#BalodaBazar#Basna#Bemetara#Bhatapara#Bhilai#BhilaiCharoda#Bilaspur#Chhattisgarh#Chirmiri#Dhamtari#Dongargarh#Durg#Exporter#ExporterSupplierofStainlessSteelBars#India#Jagdalpur#Kawardha#Khairagarh#Korba#Kumhari#Mahasamund#Manufacturer#Mungeli#Pandariya#Raigarh#Raipur#Rajnandgaon#StainlessSteelBars

0 notes

Text

Stainless Steel Angle in Vadodara

Luvana Metal Corporation is a Manufacturer, Exporter, and Supplier of Stainless Steel Angle in Vadodara, Gujarat.

Luvana Metal Corporation provides a wide range of stainless steel products, including coils, sheets, plates, bars, rods, wires, valves, pipes,

fittings, channels, angles,

butt weld fittings, flanges, and fasteners.

These SS Angles are available in different sizes, lengths, dimensions, thicknesses, types, standards, and other specifications as per clients' requirements.

We offer Stainless Steel Angles that are available in different sizes and dimensions by international market standards.

We offer Stainless Steel Angles according to the requirements of the clients.

These SS Angles Bars are available in various standards like ASTM, ASME, AISI, DIN, BS, EN IS, JIS & other international standards.

Specification:

Dimensions: ASTM, ASME, API.

Length: 1 meter – 7 meters ( 4 feet to 24 feet

Size: 24×1 mm to 150×50 mm

Finish: 2B, HR, Matt PVC, No. 8 PVC

Form: SS Angles, SS Channels, SS Flats

Condition: Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished

Other Services: Machining (CNC), Centreless Grinding (CG), Heat Treatment, Annealing, Pickling, Polish, Rolling, Forging, Cutting, Bending, Minor Fabrication

Stainless Steel: AISI 202, 301, 302, 303, 304, 304L, 310, 316, 316L, 317, 321, 347, 410, 416, 420, 430, 431, F51, F53, F55, F44, UNS S21800, Alloy 20, 904L, PH13-8Mo,

17-4ph, 15-5ph, 17-7ph, Ph15-7 Mo, 254Smo, Al-6Xn, 654SMO, duplex 2205, duplex 2507, nitronic terrarium 255

We supply these stainless steel angles to various industries & applications like oil & gas, petrochemicals, power generation, pharmaceuticals industries,

heat exchangers, condensers, pulp and paper industry, etc.

Luvana Metal Corporation is a Manufacturer, Exporter, and Supplier of Stainless Steel Angle in Vadodara, Gujarat, India and various locations like Sankheda,

Pavi-Jetpur, Dabhoi, Rangoli, Limbada, Nandesari, Makarpura, Vaghodia, Savli.

For further details, please feel free to contact us.

Read the full article

0 notes

Text

Best Quality Forged Fittings Manufacturer in India - Nitech Stainless Inc

Nitech Stainless Inc is the leading Forged Fittings Manufacturer in India.Forged fittings are composed of high-quality materials and are available in a range of sizes to fulfill the customer's requirements.Nitech Stainless Inc is well-known globally for its extensive and high-quality line of Buttwelded Pipe Fittings. At Nitech Stainless Inc., we have our own research center to help us gain the essential information about contemporary technologies and continue to enhance the quality of our goods with each new study in our lab.

We provide a wide range of Forged Fittings, including elbows, tees, crosses, bends, couplings, bushings, plugs, reducers, and end connections, in various grades. Nitech Stainless Inc manufactures pipe fittings and forged fittings in all classes, using high-quality materials to create the most robust and long-lasting Forged fittings. we are Also supplier of SS Flanges

The use of forged fittings demonstrates a dedication to quality and safety in fluid handling systems. Their strong structure and remarkable material qualities make them an excellent choice for harsh situations. We are also a Leading Pipes and Tubes Manufacturer and Sheets Manufacturers in India.

For More Details:

Website: nitechstainless.com

Also Visit: Stainless Steel Flanges Supplier In India

0 notes

Text

Industrial Fittings Supplier in Tamil Nadu

Simplex Steels is a Manufacturer, Exporter, and Industrial Fittings Supplier in Tamil Nadu.

We are ISO 9001:2015 certified, Ahmedabad, Gujarat, India.

Simplex Steels offers stainless steel products like sheets, plates, coils, pipes, tubes, bars, wires, rods, channels, flats, industrial flanges, and more.

We offer top-notch industrial fittings to various industries at competitive market rates, available in standard and flare types.

Our tube fittings are low-maintenance, boast extended service life, and resist rust, ensuring reliability and durability.

They provide leak-free connections and swift connections in high-vibration systems, manufactured using cutting-edge technologies to meet customer specifications.

Available in various sizes, our products have seen increased demand across industries for their quality and performance.

To order these high-quality tube fittings, visit our website and get excellent products at affordable rates.

Specializing in durable and high-performance products, our company ensures customer satisfaction with every purchase.

Explore our extensive array of industrial fittings, encompassing butt weld fittings, forged fittings, pipe fittings, socket weld fittings, and more.

Features:

Resistant to corrosion

Strong tensile strength

Temperature resistant

Low-maintenance

Appealing appearance

Simplex Steel is Industrial Fittings Supplier in Tamil Nadu and locations such as Chennai, Chidambaram, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kanchipuram, Kanniyakumari, Kodaikanal, Kumbakonam, Madurai, Mamallapuram, Nagappattinam, Nagercoil, Palayamkottai, Pudukkottai, Rajapalayam, Ramanathapuram, Salem, Thanjavur, Tiruchchirappalli, Tirunelveli, Tiruppur, Thoothukudi.

For more information, please feel free to contact us.

Read the full article

0 notes

Text

MS Flange Manufacturer in Mumbai

SK Steel Corporation is the Best MS Flange Manufacturers and Suppliers in Mumbai | MS Flange Manufacturer in Mumbai

SK Steel Corporation is the most trusted name in Best Quality Industrial Mild Steel Flange Manufacturer in Mumbai, India. We are one of all type of industrial MS Flange Manufacturers and Suppliers in Mumbai with Wide Range of Product which is highly precision forging pipe flanges, Forge fitting, Metal rings customized machining parts and forging part with consistent quality. Our product are widely used for different Industrial such as Plastic Molding, Packaging Machine, Pharmaceuticals etc. We are known for our Premium Quality Mild Steel Flanges with Excellent Durability and Performance as well as simple Installation.

This complete guide looks into the MS flange production and supply industry in Mumbai, showing major companies, their products, and useful data to help you make decisions.

The Importance of MS Flange: MS Flange Manufacturers and Suppliers in Mumbai

MS flanges are widely used in a variety of sectors because they combine the following:

Strength and durability: These flanges, which are made of premium mild steel, provide excellent durability to pressure and wear, guaranteeing long-lasting performance.

Versatility: Available in various sizes, shapes, and pressure ratings, MS flanges readily adapt to diverse application requirements.

Cost-effectiveness: Compared to other flange materials like stainless steel or alloy steel, MS flanges offer a more economical option, making them ideal for cost-sensitive projects.

Easy fabrication and installation: MS flanges are readily weldable and can be easily installed using standard tools and equipment.

Types of MS Flanges

MS flange come in various types, each suited for specific applications. Here are some commonly used types:

Weld Neck: Ideal for high-pressure and high-temperature applications due to their superior strength and rigidity.

Slip-On: Offers a cost-effective solution for low-pressure and low-temperature applications.

Lap Joint: Provides a flexible connection for piping with misalignment or thermal expansion concerns.

Blind: Used to close off the end of a pipe or create a pressure barrier.

Socket Weld: Designed for small-diameter pipes and offers ease of installation.

Threaded: Employs threads for connection, eliminating the need for welding.

Best MS Flange Suppliers and Manufacturers in Mumbai

Mumbai is home to numerous MS flange manufacturers and suppliers, each offering unique strengths and expertise. Here are a few prominent players to consider:

SK Steel Corporation: With years of experience and a commitment to quality, SK Steel Corporation has established itself as a Best MS Flange Manufacturer in Mumbai. They offer a comprehensive range of flanges, including weld neck, slip-on, lap joint, and blind flanges, in various sizes and pressure ratings. SK Steel Corporation also provides custom flange solutions to meet specific project requirements.

M.S. Flange Manufacturing Co.: Renowned for their high-quality flanges and prompt service, M.S. Flange Manufacturing Co. is a leading manufacturer in Mumbai. They offer a wide variety of flanges, catering to various industrial applications.

Flanges Manufacturer India M.K.Industries: This company specializes in the manufacture and supply of custom-made MS flanges. They work closely with clients to understand their specific needs and provide tailored solutions.

Jagdish Metals & Alloys: This leading supplier offers a comprehensive selection of MS flanges, along with other metal products and services. They cater to a wide range of industries and are known for their customer-centric approach.

1 note

·

View note

Text

Stainless Steel Forged End Caps Manufacturers in India

Stainless Steel Forged End Caps Manufacturers in India. Leading suppliers dealers in Mumbai Chennai Bangalore Ludhiana Delhi Coimbatore Pune Rajkot Ahmedabad Kolkata Hyderabad Gujarat and many more places. Sachiya Steel International manufacturing and exporting high quality Stainless Steel Forged End Caps worldwide. We are India's largest Stainless steel forged fittingss Exporter, exporting to more than 85 countries. We are known as Stainless Steel Forged End Caps Manufacturers and Exporters due to exporting and manufacturing on a large scale.

Types of Stainless Steel Forged End Caps-

Sachiya Steel International manufacture a wide variety of Stainless Steel Forged End Caps. There is a different types of Stainless Steel Forged End Caps used for different needs. Stainless steel forged fittingss are used with Nuts. Our Stainless Steel Forged End Caps are available in different sizes, grades and shapes. Sachiya Steel International manufactures and exports high-quality industrial Stainless Steel Forged End Caps. We are Exporters of the following Stainless steel forged fittings -Stainless Steel Forged Elbow, Stainless steel forged Cross, Stainless steel Forged Tee, Stainless steel forged Reducer, Stainless steel forged Coupling, Stainless steel Forged End Caps, stainless steel forged Bushing, Stainless steel forged Plug, Stainless steel forged End Connection and more.

About Stainless Steel Forged End Caps -

Sachiya Steel International india's largest Stainless Steel Forged End Caps Manufacturers. We provide forged fittings in different shapes and sizes and with different specifications as per the customer's requirement. These caps are available with a threadlike fitting inside them. These caps are a kind of precautionary measures and used to ensure the safety of the ends of the pipe. These caps are highly beneficiary to waterproof the connections to avoid leakage or adulteration. These caps are utilized under high pressure and temperature situation for better results. These caps are manufactured by different materials like heavy metals, alloys, plastic etc. We known as Stainless Steel Forged End Caps Manufacturers in India.

For More Info Visit our Website: https://sachiyasteel.com/stainless-steel-forged-end-caps-manufacturers-in-india.php

Email Us: [email protected]

Contact Us: 097690 56007a

0 notes

Text

Top Stainless Steel Sheet Supplier in Mumbai

Krystal Steels is one of the leading Manufacturer, Exporter, and Top Stainless Steel Sheet Supplier in Mumbai , Maharashtra, India.

Krystal Steels specializes in Stainless Steel Sheets, Plates, Coils, Fasteners, Pipes, Tubes, Bars, Wires, Rods, Strip Coils, Flanges, Fittings, Angles,

Channels, Flats, and Industrial Valves.

We adhere to international standards such as ASTM, ASME, AISI, DIN, BS, EN IS, and JIS for our SS Sheet production.

Specializing in stainless steel sheets, we offer grades 201, 304, 304L, 316L, 409, and 430 in various finishes.

These sheets, composed of iron, chromium, and other elements like nickel or molybdenum, are manufactured using advanced machining technology

and expertise.

Our dedicated team ensures the highest quality standards are maintained throughout production to meet customer demands.

Our sheets, designed to withstand high temperatures and pressures, ensure optimal performance and durability with machined and stamped finishing.

Technical Specifications:

Dimensions: ASTM, ASME, API.

Thickness: 0.4mm to 150mm

Width: as per requirement

Size: 1000 mm x 2000mm, 1220mm x 2440mm, 4? x 8?, 1250mm x 2500mm, 1500mm x 3000mm to 6000mm, 2000mm x 4000mm to 6000mm

Finish: Polished

Form: Shim Sheet, Perforated Sheet, B. Q. Profile.

Condition: Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished

Other Services: Machining (CNC), Centreless Grinding (CG), Heat Treatment, Annealing, Pickling, Polish, Rolling, Forging, Cutting, Bending, Minor Fabrication

Various sectors, including textiles, construction, transportation, and the maritime industry, widely use our SS sheets.

Krystal Steels is one of the leading Manufacturer, Exporter, and Top Stainless Steel Sheet Supplier in Mumbai,

Maharashtra and various locations like Panvel, Mira, Charkop, Ghatkopar, Badlapur, Kalyan, Ambernath, Ulhasnagar, Bhiwandi, Kharghar, Taloja.

Please get in touch with us with any questions or for additional information

Read the full article

0 notes

Text

Supplier of Stainless Steel Rods in Tamil Nadu

Meghmani Metal Industries:

Meghmani Metal Industries Leading Manufacturer and Supplier of Stainless Steel Rods in Tamil Nadu, India.

The company holds ISO 9001:2015 certification and specializes in providing high-quality stainless steel products.

Meghmani Metal manufactures and supplies an extensive range of stainless steel products, including sheets, plates, angles, channels, flats, rounds, patta, patti, rods, industrial fittings, and SS fasteners.

SS Rods adhere to Indian and International standards, such as ASME, ASTM, ANSI, AISI, ensuring meticulous craftsmanship.

Technical Specifications:

Dimensions: ASTM, ASME, API.

Thickness: 5 mm To 500 mm

Size: from 2.00mm to 6.35mm (0.078″ to 0.25″) dia.

Finish: Bright, Black, Polish

Form: SS Bars, SS Wires, S Rods

Condition: Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished

Other Services: Machining (CNC), Centreless Grinding (CG), Heat Treatment, Annealing, Pickling, Polish, Rolling, Forging, Cutting, Bending, Minor Fabrication

Stainless Steel Grades:

AISI 202, 301, 302, 303, 304, 304L, 310, 316, 316L, 317, 321, 347, 410, 416, 420, 430, 431, F51, F53, F55, F44, UNS S21800, Alloy 20, 904L, PH13-8Mo, 17-4ph, 15-5ph, 17-7ph, Ph15-7 Mo, 254Smo, Al-6Xn, 654SMO, duplex 2205, duplex 2507, nitronic ferralium 255.

Service Coverage:

Meghmani Metal Industries Provide Supplier of Stainless Steel Rods in Tamil Nadu, Including Chidambaram, Arcot, Ariyalur, Chengalpattu, Chennai, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kallakurichi, Kanchipuram, Kanniyakumari, Karur, Krishnagiri, Madurai, Mayiladuthurai, Nagapattinam, Namakkal, Nilgiris, Perambalur, Pudukkottai, Rajapalayam, Ramanathapuram, Ranipet, Salem, Sivagangai, Tenkasi, Thanjavur, Theni, Thoothukudi, Tiruchirappalli, Tirunelveli, Tirupathur, Tiruppur, Tiruvallur, Tiruvannamalai, Tiruvarur, Vellore, Viluppuram, Virudhunagar, Salem, Udhagamandalam.

For comprehensive details on our product catalog, feel free to reach out through the provided contact information.

Read the full article

#Arcot#Ariyalur#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Erode#Exporter#India#Kallakurichi#Kanchipuram#Kanniyakumari#Karur#Krishnagiri#Madurai#Manufacturer#ManufacturerofStainlessSteelRods#Mayiladuthurai#Nagapattinam#Namakkal#Nilgiris#Perambalur#Pudukkottai#Rajapalayam#Ramanathapuram#Ranipet#Salem

0 notes

Text

Forged Threaded Fittings Exporters in India

Forged Threaded Fittings, Forged Threaded Fittings Manufacturers, Forged Threaded Fittings Suppliers, Forged Threaded Fittings Exporters, Forged Threaded Fittings Stockists.

Forged Threaded Fittings in Mumbai, Forged Threaded Fittings Manufacturers in Mumbai, Forged Threaded Fittings Suppliers in Mumbai, Forged Threaded Fittings Exporters in Mumbai, Forged Threaded Fittings Stockists in Mumbai.

Forged Threaded Fittings in India, Forged Threaded Fittings Manufacturers in India, Forged Threaded Fittings Suppliers in India, Forged Threaded Fittings Exporters in India, Forged Threaded Fittings Stockists in India.

https://www.chhajedpipefittings.com/img/forged-threaded-fittings-manufacturers-suppliers-exporters-stockists.jpg

FORGED THREADED FITTINGS

We supply and fare manufactured strung fittings that display predominant working. These strung channel fittings are composed and created to meet different working conditions. These strung fittings give lasting welded associations with basic applications.DNNominal Pipe SizeCenter-to

-End

Elbows,

Tees,

Crosses, ACenter-to-

End 45

deg Elbow, COutside

Diameter

of Band, HMin.

Wall

Thickness, GMin

Length

of

Thread [Note (1)]200030006000200030006000200030006000200030006000BL261/82121251717192222253.183.186.356.46.781/42125281719222225333.183.306.608.110.2103/82528331922252533383.183.516.989.110.4151/22833382225283338463.184.098.1510.913.6203/43338442528333846563.184.328.5312.713.92513844512833354656623.684.989.9314.717.3321 1/44451603335435662753.895.2810.5917.018.0401 1/25160643543446275844.015.5611.0717.818.450260648343445275841024.277.1412.0919.019.2652 1/2768395525264921021215.617.6515.2923.628.980386951066464791091211465.998.8416.6425.930.510041061141147979791461521526.5511.1818.6727.733.0

SPECIFICATION

Grades :

Nickel Alloy:

ASTM / ASME SB 564 UNS 2200 ( NICKEL 200 ), UNS 4400 (MONEL 400 ), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) ASTM / ASME SB 160 UNS 2201 (NICKEL 201 ) ASTM / ASME SB 472 UNS 8020 ( ALLOY 20 / 20 CB 3 )

Copper Alloy:

ASTM / ASME SB 61 UNS NO. C 92200 & ASTM / ASME SB 62 UNS NO. C 83600. ASTM / ASME SB 151 UNS NO. 70600, 71500, C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30), ASTM / ASME SB 152 UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200.

Stainless Steel :

ASTM / ASME SA 182 F 304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel :

ASTM / ASME SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61.

Carbon Steel:

ASTM / ASME A 105. ASTM / ASME A 350 LF 2.

Alloy Steel:

ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91.

0 notes

Text

Stainless Steel Pipes Manufacturers in Mumbai,India

Yash Impex is API 5l Gr X 65 pipes, API 5l Gr X 52 pipes, API 5l Gr X 60, API 5l Gr X 70 pipes, ASTM A 53 Grade B seamless pipes a Carbon Steel Seamless Pipes suppliers and manufacturer in Mumbai, India 40, 80, 160, XS, XXS Carbon Steel Pipe suppliers, NACE TM0177, NACE MR0175, NACE TM0284, SSC TEST, HIC TEST, H2 SERVICE, IBR, etc.W section beams, gland packing material exporters, Pipe with puddle flanges exporters, carbon steel forged pipe fittings, stainless steel seamless pipes, Stainless Steel Tubes and casing pipes fabricated in various grades of steel and alloy steel.

0 notes