#Silicone Textile Chemicals Market industry

Text

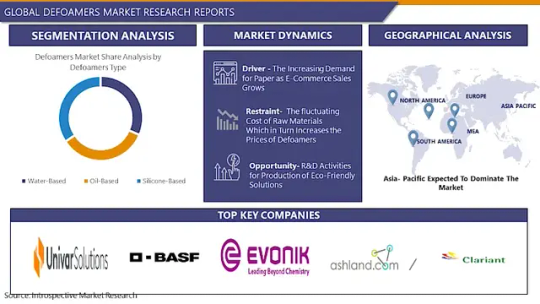

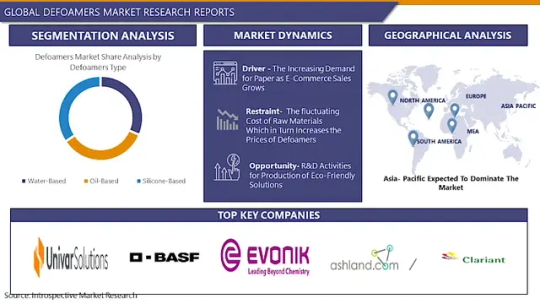

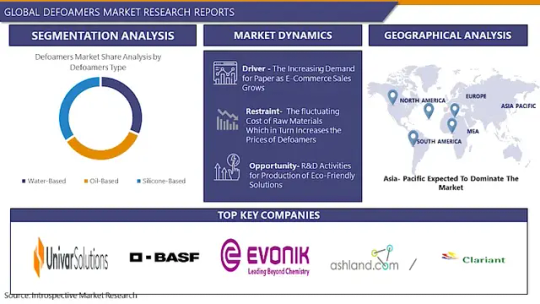

Defoamers Market: Global Industry Analysis and Forecast 2023 – 2030

Defoamers Market Size Was Valued at USD 3.91 Billion in 2022, and is Projected to Reach USD 6.09 Billion by 2030, Growing at a CAGR of 5.7% From 2023-2030.

Foam is a coarse dispersion of a gas in a liquid in which the volume percentage of gas is larger than the volume fraction of liquid. Foams are a major issue in industrial processes. They cause damage to the surface coatings.

They obstruct efficient container filling. Defoamers are chemical additives that minimize or prevent foam formation in industrial process liquids such as paints, inks, adhesives, and even construction materials. Although the phrases antifoam agent and defoamer are frequently used interchangeably, antifoam agents refer to compounds that prevent the creation and development of bubbles.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/16222

The latest research on the Defoamers market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Defoamers industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Defoamers market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

Leading players involved in the Defoamers Market include:

Air Products and Chemicals Inc.(USA), Momentive Performance Materials Inc. (USA), Lubrizol Corporation (USA), Wilflex Corporation (USA), Alzo International Inc. (USA), Dow Corning Corporation (USA), Chemours Company (USA), Ashland Inc. (USA), Dow Chemical Company (USA), Solvay SA (Belgium), Evonik Industries AG (Germany), Clariant AG (Switzerland), Wacker Chemie AG (Germany), Arkema SA (France), Lanxess AG (Germany), BASF SE (Germany), Kemira Oyj (Finland), Elements Plc (UK), Croda International Plc (UK), Shin-Etsu Chemical Co. Ltd. (Japan)

If You Have Any Query Defoamers Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/16222

Segmentation of Defoamers Market:

By Defoamer Type

Water-Based

Oil-Based

Silicone-Based

By Application

Pulp & Paper

Paintings & Coatings

Water Treatment

Food & Beverages

Textile

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Defoamers market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Defoamers market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Defoamers market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Defoamers market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Defoamers Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=16222

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1049

Email: [email protected]

#Defoamers#Defoamers Market#Defoamers Market Size#Defoamers Market Share#Defoamers Market Growth#Defoamers Market Trend#Defoamers Market segment#Defoamers Market Opportunity#Defoamers Market Analysis 2023

0 notes

Text

Defoamers Market: Global Industry Analysis and Forecast 2023 – 2030

Defoamers Market Size Was Valued at USD 3.91 Billion in 2022, and is Projected to Reach USD 6.09 Billion by 2030, Growing at a CAGR of 5.7% From 2023-2030.

Foam is a coarse dispersion of a gas in a liquid in which the volume percentage of gas is larger than the volume fraction of liquid. Foams are a major issue in industrial processes. They cause damage to the surface coatings.

They obstruct efficient container filling. Defoamers are chemical additives that minimize or prevent foam formation in industrial process liquids such as paints, inks, adhesives, and even construction materials. Although the phrases antifoam agent and defoamer are frequently used interchangeably, antifoam agents refer to compounds that prevent the creation and development of bubbles.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/16222

The latest research on the Defoamers market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Defoamers industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Defoamers market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

Leading players involved in the Defoamers Market include:

Air Products and Chemicals Inc.(USA), Momentive Performance Materials Inc. (USA), Lubrizol Corporation (USA), Wilflex Corporation (USA), Alzo International Inc. (USA), Dow Corning Corporation (USA), Chemours Company (USA), Ashland Inc. (USA), Dow Chemical Company (USA), Solvay SA (Belgium), Evonik Industries AG (Germany), Clariant AG (Switzerland), Wacker Chemie AG (Germany), Arkema SA (France), Lanxess AG (Germany), BASF SE (Germany), Kemira Oyj (Finland), Elements Plc (UK), Croda International Plc (UK), Shin-Etsu Chemical Co. Ltd. (Japan)

If You Have Any Query Defoamers Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/16222

Segmentation of Defoamers Market:

By Defoamer Type

Water-Based

Oil-Based

Silicone-Based

By Application

Pulp & Paper

Paintings & Coatings

Water Treatment

Food & Beverages

Textile

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Defoamers market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Defoamers market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Defoamers market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Defoamers market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Defoamers Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=16222

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1049

Email: [email protected]

#Defoamers#Defoamers Market#Defoamers Market Size#Defoamers Market Share#Defoamers Market Growth#Defoamers Market Trend#Defoamers Market segment#Defoamers Market Opportunity#Defoamers Market Analysis 2023

0 notes

Text

Garment Printing Inks | T-Shirt Printing Ink Price

Garment Printing Inks

Is it true or not that you are searching for premium quality piece of clothing printing ink providers?

We as a whole realize that there is enormous rivalry in the piece of clothing fragment in view of a conspicuous number of new players making debuts in this market. They concoct groundbreaking thoughts and recent fads. To put it plainly, we can say that the patterns of the article of clothing industry continue to change and refreshing each and every day. Because of this explanation, the meaning of Article of clothing Printing Inks becomes unmistakable. Since the nature of any readymade material straightforwardly relies upon the nature of ink utilized. T-Shirt Printing Ink Price

On the off chance that you are not utilizing premium quality ink then the texture will lose variety continuously and it will affect the standing of your image in the market because of this reason you ought to constantly go with presumed piece of clothing printing ink providers for example synthetic Siblings. Other than giving the best Shirt Printing Ink Cost in the market we offer other fundamental synthetics expected for the material business at profoundly reasonable rates. Our contributions incorporate

Material Colors

Helpers

Fluid Silicone

Speciality Synthetic substances

Pretreatment Helpers

Stain Removers

Fire Retardants

Why pick us?

When you would rather not think twice about the quality part of the item and simultaneously needed to take ideal benefits of reasonableness then who might be preferable over the synthetic siblings? It is a one-stop objective to get every one of the exceptional quality modern synthetics that are expected for various types of material ventures. Alongside the material business, we satisfy the prerequisites of the Pharma areas as well as the excellence care section. At the point when you are searching for master compound providers; so you don't need to think twice about the quality as well as amount of parts of your articles of clothing then you ought to just collaborate with us to get the most reasonable Shirt Printing Ink Cost as opposed to simply self-spreading sites.

What is our job in the public arena?

We as a whole are intimately acquainted with the job of synthetic compounds in our everyday life. Without synthetic compounds, we can't live briefly. We are utilizing restorative shampoos, we are wearing beautiful garments; that is all conceivable due to synthetics. So in short we can say that synthetic compounds have turned into the life saver of the ongoing scene so in this substance world the job of the compound siblings is unmistakable.

When you are searching for premium providers of shading associates, shading helpers or printing colors then who might be preferable over synthetic siblings to get top notch quality items and an on-time conveyance generally? The cutting edge article of clothing industry is advancing quickly. Because of this explanation, the compound siblings are awesome. We are the main suppliers of all such items that are appropriate for various types of textures. Being one of the most believed providers of Piece of clothing Printing Inks; we can gladly say that substance siblings are quite possibly of the most dependable name in the article of clothing fragment and we have been partaking in this heritage for over 10 years so you can aimlessly trust our foundation for getting quality synthetics.

0 notes

Text

A Look at Sodium Silicate and its Suppliers in India

Sodium silicate, often dubbed "water glass" for its transparent, glass-like appearance, is a versatile inorganic compound with surprising strength and resilience. It binds, cleans, strengthens, and protects diverse materials, making it a crucial player in numerous industries across India.

From crafting paper and soap to casting intricate metal parts and preserving ancient art, sodium silicate's applications are as varied as they are valuable. But where does this workhorse chemical come from? Let's delve into the world of Sodium Silicate supplier in India, exploring what sets them apart and how they contribute to the nation's industrial landscape.

The Alchemy of Silicate:

Manufacturing sodium silicate is a fascinating dance of sand and soda ash. Essentially, molten sand (silicon dioxide) and sodium carbonate are fused together at high temperatures, creating a liquid sodium silicate solution. The magic lies in the varying ratios of these ingredients, which determine the final product's viscosity, density, and other key properties. This allows for customized solutions to cater to specific industrial needs.

A Spectrum of Silicate Suppliers:

India boasts a thriving sodium silicate industry, with numerous suppliers dotting the map. Sudarshan Group offers a range of silicate solutions, from readily available liquid forms to specialized powdered variants. They cater to diverse sectors, including

Paper production: Sodium silicate acts as a binding agent, strengthening paper and improving its printing surface.

Construction: It's used as a deflocculant in cement, enhancing fluidity and workability. Additionally, it serves as a fire retardant and can strengthen concrete structures.

Foundry: Sodium silicate binds sand molds used in metal casting, ensuring precise shapes and smooth finishes.

Textile: It strengthens and softens fabrics, improves dyeability, and even acts as a flame retardant in certain applications.

Detergent manufacturing: Sodium silicate functions as a builder in soaps and detergents, boosting cleaning power and softening water.

Supplier Spotlight:

While exploring the landscape of sodium silicate suppliers in India, one name consistently emerges Renowned for its commitment to quality, innovation, and sustainable practices, Sudarshan Group has established itself as a leader in the field.

Sudarshan Group's dedication to excellence shines through in several aspects:

Stringent quality control: We adhere to rigorous international standards, ensuring consistent product quality and performance.

Diverse product portfolio: We offer a wide range of sodium silicate solutions to cater to varied industrial needs and specifications.

Technical expertise: Our team of experienced professionals provides valuable technical support and guidance to customers.

Commitment to sustainability: Sudarshan Group prioritizes environmentally responsible practices, minimizing waste and ensuring responsible resource management.

The Future of Silicate:

With India's rapid industrial growth, the demand for sodium silicate is projected to rise significantly. Sudarshan Group is well-positioned to meet this demand and continue playing a crucial role in the nation's industrial development. Additionally, research into new applications for sodium silicate holds immense potential, opening doors for further growth and innovation.

Conclusion:

In India's competitive landscape of sodium silicate suppliers, Sudarshan Group shines as a reliable, innovative, and customer-focused player. With a rich legacy, a commitment to quality, advanced manufacturing facilities, and a diverse product range, Sudarshan Group plays a pivotal role in supporting the growth and development of industries that rely on sodium silicate. As businesses seek dependable partners for their chemical needs, Sudarshan Group stands out as a beacon of excellence in the sodium silicate market.

0 notes

Text

A Retrospect of the ITCPE 2023 in Guangzhou

In May 20–22, organized by Hong Kong Allallinfo Media Group, Guangzhou Allallinfo Co., Ltd., and the magazine, Textile Printing, the 2023 Guangzhou (18th) International Textile Clothing and Printing Industry Expo (ITCPE) was successfully held in Guangzhou Poly World Trade Center.

Renowned enterprises and experts are gathered at ITCPE 2023, focusing on the business opportunities of the garment and textile printing industries. In the spot, all kinds of products are dazzling: not only automatic screen printing machines, industrial digital transfer printing, and DTG equipment, but also customization solutions, digital printing consumables, and supplies, all kinds of apparel accessories, DTF solutions, embroidery and sewing machines and consumables, and so on.

Visiting Groups from Hubei Province, Anyang City of Henan Province, and Citys of Northeastern China.

The scale of the 2023 ITCPE is much bigger than the previous year. This year's event featured more than 500 quality enterprises and covered more than 3 million square feet. We successfully created a platform for industry communication and exhibition, and business negotiations between exhibitors, experts, and spectators are a common sight.

We could perceive that more than 500+ enterprises such as KINZEL Printing, Epson, Brother,ORIC, Grando, KEUNDO, PENGDA, PO-TRY, FLORA, CNDING, Zhenfeng, Success Automation, Fourstar, Machine Elements, YiliJet, Pros-view, RATEX, POMAKER, DAHAO, SINSIM, CBL, Bihong, Yuanyin Digital, MAYA, CH-JIA, YUEMEI, RICOMA, Yuchen, MyColor, BOYAN, ZHOUSURNAME, Dongguan BEST, LNXWO, XINFYING, Zhongwang, Pinyin, Aomya, Chuanghui, ZHAOSHAN, M100, HDHT, kornit-print, TIANWEI XINCAI, Xinghao, INKBANK, KUYIN, JIUH LIH, Jiangchuan, Siheda, Nuowei, HY, YIXING TIANLI, KEDO SILICON, print-pretty, Chaolun, Chuangke, Shenzhen Boyan K3, Kalos, XMAYPRINT, JYIE, Color Spring, Junao, Caiyintong, Jiechuang, Lamborink, SAN GONG, HONGSAM, XING QI LASER, SEENSUN, Dongguan Gaoshang Machinery, COLORMADE, HOOSUN, SNS, KASULASER, 91TUKU, Yuqiaofu, Duotian, Golden XT, KAIOU, Hongzhongmachinery, Fanghua Digital, INKTEC, Tianli, Sunflower, Ruiyi New Maaterials, Dayuan, Jinhui, Wuxi Luoshe twon Yang City Chengming Textile Machinery Factory., Xiuzhiyuan, Xinshanlian, Wuzhou, Fujian Jiansheng, Dongguan Zhongtian, New Image Printing, Yeren Digital, Feiyue Textile Printing Equipment Factory, Junye, ZHENYING, Xiuzhiyuan, MSO, Quanzhou Yaxin, Foshan Xinbin, Dongguan Dingjun, ALSAFETY, Jinyan, Hummberg, Rong xuan creative factory, Shuangfei, Huacai, Tianma, Shishi Jianan Hot Melt Adhesive, Jinbao, Tianying, TaicangYangfan, Senhua, Junhao, COLOR WING, Chengna Chemical, Eurolite Optical, Jianyao, WUHAN SHANGGU INDUSTRIAL DESIGN, Shengshun Machinery, Yituna, Hongdashengchang, etc in the fields of textile printing, digital printing, embroridery, apparel fabrics & accessories have participated in the ITCPE 2023.

Compared to the previous year, ITCPE 2023 has more attention and a higher conversion rate. With the termination of the pandemic, many overseas spectators came here, which instilled confidence in our textile market.

The scorching and fickle temperature did not dampen spectators’ steps. There is an endless flow of people through the exhibition even after the closing ceremony, which reflects its soaring popularity.

Throughout the exhibition site, each booth is full of popularity, and each enterprise has taken out their skills with new technology and new products to seize business opportunities. Exhibitors patiently and professionally introduced their new products to the spectators, who watched the operation of the machines, touched the texture of embroidery, and appreciated the charm of textile art.

You Can Browser the Recap of the Exhibition by Clicking:A Retrospect of ITCPE 2023_ITCPE Guangzhou_Allallinfo Media Hong Kong Group

High Contract Rates

This exhibition is fairly successful since many exhibitors received new orders on the first day, and the incessant orders were witnessed in the follow-up two days. The overall satisfaction of the exhibitor is rather high, and even large booths were preordered.

Many exhibitors told us that the ITCPE is an expert stage and they harvest fruitful contracts. They praised that it is an established exhibition; hence, they get lots of new orders, and they will continue to be the attending companies.

So far, the three-day ITCPE 2023 has come to a successful conclusion here! We'll see you at 2024, 20, March!

0 notes

Text

Top Market Key Players in Silicone Masterbatch Market Unveiling the Leaders Driving Industry Growth

Introduction:

The Silicone Masterbatch market has witnessed significant growth in recent years, fueled by its diverse applications in various industries such as plastics, rubber, and textiles. This surge in demand can be attributed to the contributions of key players who have established themselves as industry leaders. In this blog, we will explore the history, growth rate, market size, and other relevant information about the prominent companies shaping the Silicone Masterbatch market. Let's delve into the world of these influential players and their impact on the industry.

1. Dow:

Dow, a global chemical company based in the United States, has been a pioneer in the Silicone Masterbatch market. With a rich history spanning over a century, Dow has a solid foundation in research and development, leading to innovative silicone-based solutions. The company's commitment to sustainability and product quality has been pivotal in driving its growth. Dow's market sales revenue is estimated to be around USD 20 million in 2022, with an expected CAGR of 5.8% during the forecast period.

2. Wacker:

Wacker, headquartered in Germany, is another major player in the Silicone Masterbatch market. The company has a long-standing reputation for delivering high-quality silicone products. Wacker's diverse portfolio of silicone masterbatches caters to various industries, including automotive, construction, and healthcare. The market sales revenue for Wacker is estimated to be around USD 18 million in 2022, with an expected CAGR of 5.7% during the forecast period.

3. Momentive:

Momentive, a global specialty chemical company, has made significant contributions to the Silicone Masterbatch market. With a history dating back to the 1940s, Momentive has a rich legacy of innovations in silicones. The company's focus on technical expertise and customer-centric solutions has contributed to its growth in the market. Momentive's market sales revenue is estimated to be around USD 16 million in 2022, with an expected CAGR of 5.6% during the forecast period.

4. Chengdu Silike:

Chengdu Silike, based in China, is a prominent player in the Silicone Masterbatch industry. The company's strong manufacturing capabilities and continuous investments in research and development have solidified its position in the market. Chengdu Silike's market sales revenue is estimated to be around USD 14 million in 2022, with an expected CAGR of 5.5% during the forecast period.

5. Javachem:

Javachem, headquartered in China, has been a significant contributor to the Silicone Masterbatch market's growth. The company's commitment to product innovation and customer satisfaction has allowed it to gain a strong foothold in the industry. Javachem's market sales revenue is estimated to be around USD 12 million in 2022, with an expected CAGR of 5.4% during the forecast period.

6. Matrix Polytech:

Matrix Polytech, based in India, is a key player in the Silicone Masterbatch market. The company's wide range of silicone-based products caters to various industries, including textiles, automotive, and electronics. Matrix Polytech's market sales revenue is estimated to be around USD 10 million in 2022, with an expected CAGR of 5.3% during the forecast period.

7. Prisma Color:

Prisma Color, based in Italy, is a renowned manufacturer of Silicone Masterbatch solutions. With a strong focus on sustainable practices and technical expertise, the company has gained recognition in the market. Prisma Color's market sales revenue is estimated to be around USD 9 million in 2022, with an expected CAGR of 5.2% during the forecast period.

8. Plastika Kritis:

Plastika Kritis, headquartered in Greece, has been a major contributor to the Silicone Masterbatch market. The company's extensive product portfolio includes silicone-based additives and masterbatches for a wide range of applications. Plastika Kritis' market sales revenue is estimated to be around USD 8 million in 2022, with an expected CAGR of 5.1% during the forecast period.

9. Plastiblends:

Plastiblends, based in India, is a prominent player in the Silicone Masterbatch industry. The company's commitment to innovation and technical excellence has been instrumental in its growth. Plastiblends' market sales revenue is estimated to be around USD 7 million in 2022, with an expected CAGR of 5.0% during the forecast period.

10. Kaijie:

Kaijie, headquartered in China, has been a significant player in the Silicone Masterbatch market. The company's advanced manufacturing processes and strong distribution network have enabled it to cater to a global customer base. Kaijie's market sales revenue is estimated to be around USD 6 million in 2022, with an expected CAGR of 4.9% during the forecast period.

Conclusion:

The Silicone Masterbatch market is witnessing impressive growth, and these key players are at the forefront of driving this expansion. Their commitment to product innovation, sustainability, and customer satisfaction has allowed them to carve a niche for themselves in the competitive landscape. As the industry continues to evolve and demand for silicone-based additives and masterbatches increases, these market leaders are poised to play a vital role in shaping the future of the Silicone Masterbatch market.

0 notes

Text

Silicone Fluid Market worth 9.6% CAGR by 2028 - A Press Release by IHR Insights

Bengaluru, July - Silicones, also known as polydiorganosiloxanes by chemists, are firm and resistant to extreme heat, electromagnetic radiation, and various influences. Silicone fluids are odorless, colorless liquids that can resist severe environments. Moreover, silicone fluids are more reliable than organic rubbers or polymers when exposed to ultraviolet and electromagnetic radiation.

Silicone fluids are widely used in electrical insulation, electronic cooling, and as damping fluids in electrical components. The expanding electronics industry, particularly in consumer electronics and telecommunications, fuels the demand for silicone fluids. Further, the industrial growth in emerging economies, coupled with rising disposable incomes, leads to increased demand for silicone fluids in diverse applications, including construction and consumer goods.

The rollout of 5G networks requires efficient thermal management solutions in base stations and data centers. Silicone fluids offer excellent thermal stability and electrical insulating properties, making them suitable for cooling electronic components in 5G infrastructures. Moreover, the rapid growth of the electric vehicle market presents significant opportunities for silicone fluids. As EV manufacturers focus on improving battery performance and thermal management, the demand for silicone fluids with excellent heat dissipation properties is expected to rise.

The Silicone Fluid Market research report titled “Silicon Fluid Market on the based on Product Type, End-User Industry and Geography – Global Forecast up to 2028”

Top-notch companies included in the Silicone Fluid Market are Shin-Etsu Chemical Co., Ltd, KCC Basildon, ACC Silicones, Gelest Inc., and BRB International.

The constantly increasing population in the region and surging interest of owning a vehicle among buyers encouraging huge fabrication of the automotive in the region coupled with the rising concern of individuals to spend more on their health and hygiene are the key factor responsible for the growth of the silicone fluid market in Asia Pacific region.

The report consists of ---- Tables 91 and charts 51 depicting the in-depth market study and the impact analysis of COVID-19 by Vendor name and detailed TOC.

Silicone Fluid Market on the basis of Product Type:

• Straight Silicone Fluid

• Dimethyl Silicone Fluid

• Methylphenyl silicone Fluid

• Methylhydrogen Silicone Fluid

• Modified Silicone Fluid

• Reactive Silicone Fluid

• Non-Reactive Silicone Fluid

Silicone Fluid Market on the basis of End-User Industry:

• Agriculture

• Energy

• Home Care

• Personal Care

• Textile

• Pharmaceutical

• Others

Silicone Fluid Market on the basis of Geography:

• North America

• Europe

• Asia Pacific

• Rest of the World

About IHR Insights:

We are Market Research and Consulting firm, Offers Market Intelligence, Custom Market Research, Consulting, Go-To-Market and Content Development Services. Consulting Services Includes Market Entry Strategy, Opportunity Assessment, Competition Tracking, Technology Mapping, Sentiment Analysis, Brand Reputation Management. We work on full time engagement model with clients supporting their market intelligence needs across various departments at global level. We work as a partner and provide continues support to the organizations from basic secondary research to strategic inputs in business planning and expansion.

For further inquiries or media contact:

Marketing & Communications

IHR Insights

[email protected]

0 notes

Text

Electronic Grade Hydrogen Peroxide Market Global Demand Analysis & Opportunity Outlook 2035

research analysis on “Electronic Grade Hydrogen Peroxide Market: Global Demand Analysis & Opportunity Outlook 2035” delivers a detailed competitor’s analysis and a detailed overview of the global electronic grade hydrogen peroxide market in terms of market segmentation by primary function, application, concentration and by region.

Economies of Gauge in Electric Creation to Promote Global Market Share of Electronic Grade Hydrogen Peroxide

In the fiercely competitive electronics market, manufacturers are searching for innovative ways to grow their market share and presence by providing cutting-edge products at lower prices through shorter lead times, with better product quality and more performance. A rising need for inexpensive electronic component removal from printed circuit boards is another factor driving the industry.

Due to the higher requirement for efficient and high-speed processing with smaller size, there have been more process stages added to the chemical mechanical planarization process in order to provide a crystalline silicon water surface. Hydrogen peroxide has been chosen by semiconductor manufacturers as one of their disinfection agents due to its strong disinfectant capabilities. This element is supporting the market.

Some of the major growth factors and challenges that are associated with the growth of the global electronic grade hydrogen peroxide market are:

Growth Drivers:

Increasing Demand for Etch ICs

Increased Use of Electronic Grade Hydrogen Peroxide in Paper and Pulp Industry

Challenges:

The biggest disadvantage of employing hydrogen peroxide products is that they can be extremely hazardous to handle if they contain more hydrogen peroxide than 3%. This substance may be harmful to the skin, eyes, and respiratory system due to its potent oxidative properties. A prolonged exposure may cause eye discomfort and hair bleaching.

Access our detailed report at:

By primary function, the global electronic grade hydrogen peroxide market is divided into four parts i.e., etchant, oxidizing, bleaching and cleaning agent. Out of these four categories, bleaching is expected to hold the largest share in the market. The substance is used in numerous industries, including textiles and medicine. Additionally, it is widely used as a whitening agent in the field of dentistry. In addition to being used as a mouthwash to maintain oral hygiene, it is used to bleach hair. A bigger percentage are used in the textile industry, where it is used to clean textiles and remove stains.

Asia pacific is expected to hold the largest market share. In 2021 the region, consisting of fast-growing economies such as India, China, South Korea and Indonesia, accounted for a 46.1 % global market share in industrial hydrogen. This growth has been facilitated by quick industrialization and increased demand from the end-use industries. Most of the major players in this market have their eyes on developing nations in the Asia-Pacific region, and they are steadily growing their manufacturing and research & development footprints. In Asia Pacific, the market is expanding as a result of rapid economic expansion.

Due to the long-term prevalence of water-borne illnesses in the region, North America is seen as being at the forefront of the wastewater treatment sector. Every day, the U.S. purifies more than 34 billion gallons of contaminated water to make it safe for locals to drink. One of the main requirements in the nation is the removal of phosphorus and nitrogen from water sources, along with the oxidation of wastewater. This has ultimately resulted in a significant use of hydrogen peroxide throughout the nation's industries.

This report also provides the existing competitive scenario of some of the key players of the global electronic grade hydrogen peroxide market which includes company profiling of Arkema Inc., Evonik Industries AG, PeroxyChem LLC, Chang Chun Companies, Aditya Birla Chemicals, Mitsubishi Gas Chemical Company, Akzo Nobel N.V., Kemira Oyj, OCI Company Ltd. and others.

Request Report Sample@

0 notes

Text

Ceramic Membrane Market Dynamics: Challenges and Opportunities in Water Treatment

The ceramic membrane market is a dynamic and evolving sector within the broader field of membrane technology. Ceramic membranes are advanced materials that find applications across various industries due to their unique properties and capabilities. These membranes are typically composed of inorganic materials such as alumina, zirconia, and silicon carbide, which impart excellent chemical and thermal stability, making them suitable for a wide range of processes.

The ceramic membranes market overview reveals a growing demand for these materials, driven by their increasing use in water treatment, pharmaceuticals, food and beverage, and other sectors. As industries focus on sustainability and efficiency, ceramic membranes have gained popularity due to their durability, resistance to fouling, and long lifespan. This has led to a steady market growth trajectory in recent years.

In terms of market industry, the ceramic membrane market spans several sectors, including water and wastewater treatment, pharmaceuticals, biotechnology, and chemical processing. In water treatment, ceramic membranes are employed for microfiltration and ultrafiltration applications, providing high-quality water purification solutions. In the pharmaceutical and biotechnology industries, these membranes are used for sterile filtration and separation processes. Additionally, the chemical industry utilizes ceramic membranes for solvent recovery and product purification.

Trends in the ceramic membrane market are indicative of the growing importance of sustainability and environmental protection. As regulatory requirements become more stringent, industries are turning to ceramic membranes to reduce waste, improve resource utilization, and lower energy consumption. The adoption of these membranes is also driven by the increasing need for water recycling and reuse in both industrial and municipal settings.

Furthermore, research and development efforts in the ceramic membrane market industry are focused on enhancing membrane performance, reducing production costs, and expanding their application areas. Innovations such as membrane modifications, novel materials, and improved manufacturing techniques are expected to further drive market growth in the coming years.

In conclusion, the ceramic membrane market is a thriving sector with a promising future. Its definition revolves around advanced inorganic membranes, its market overview reveals sustained growth, and its industry spans various sectors. The dominant trends in the ceramic membrane market emphasize sustainability and innovation, making it an exciting field for technological advancements and applications.

For More Reports:

Textile Flooring Market

Polymer Concrete Market

Conductive Carbon Black Market

Magnesium Metal Market

0 notes

Text

The Report Covers Global Surfactants Market by Application and is Segmented by Type (Anionic Surfactants, Cationic Surfactants, Non-ionic Surfactants, Amphoteric Surfactants, Silicone Surfactants, and Other Types), Application (Household Soaps and Detergents, Personal Care, Lubricants and Fuel Additives, Industry and Institutional Cleaning, Food Processing, Oilfield Chemicals, Agricultural Chemicals, Textile Processing, Emulsion Polymerization, and Other Applications), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Download Free Sample Report - Surfactants Market

0 notes

Text

Evaluating the Current & Future Scope of the Textile Coatings Market (2021-2031)

The global textile coatings market is projected to reach a market value of USD 14.2 billion by 2031, growing at a CAGR of 5.2% during the forecast period (2021–2031). The major drivers of the market include increasing demand from the automotive and transportation sector, growing demand for textile coatings from the apparel and footwear industry, and the growing consumer preference for apparel with superior properties.

Textile coatings are materials applied as a thin layer over the surface of a fabric or textile to improve its properties. These coatings can be applied to fabrics to impart water resistance, flame retardant, UV protection, and other properties. The major application sectors for textile coatings are automotive and transportation, apparel and footwear, and home furnishing.

Download Sample Copy of This Report:

The automotive and transportation sector is the largest consumer of textile coatings. This is mainly due to the growing demand for automotive interiors with superior properties. Textile coatings are used to provide automotive interiors with flame retardant, water resistance, and UV protection properties.

In terms of region, Asia-Pacific is the largest consumer of textile coatings due to the increasing demand from the automotive and transportation sector in countries such as India and China. The growing consumer preference for apparel and footwear with superior properties is also driving the demand for textile coatings in the region.

The major players operating in the textile coatings market are –

BASF SE

Clariant AG

Covestro AG

Du Pont

Huntsman International LLC

Omnova Solutions Inc.

Solvay SA

Sumitomo Chemical Co. Ltd.

Tanatex Chemicals B.V.

The Lubrizol Corporation

Competitive Landscape –

AkzoNobel N.V. is a leading supplier of textile coatings. The company offers a wide range of products including acrylics, polyurethanes, epoxies, and vinyls. The company also provides tailor-made products for specific requirements.

BASF SE is a leading supplier of textile coatings. The company offers a wide range of products including acrylics, polyurethanes, epoxies, and vinyls. The company also provides tailor-made products for specific requirements.

The Dow Chemical Company is a leading supplier of textile coatings. The company offers a wide range of products including acrylics, polyurethanes, epoxies, and vinyls. The company also provides tailor-made products for specific requirements.

Huntsman Corporation is a leading supplier of textile coatings. The company offers a wide range of products including acrylics, polyurethanes, epoxies, and vinyls. The company also provides tailor-made products for specific requirements.

Key Segments Covered

By Technology

Dot Textile Coating Technology

Full Surface Textile Coating Technology

By Raw Material

Thermoplastic Textile Coatings

Polyvinyl Chloride (PVC) Textile Coatings

Polyurethane (PU) Textile Coatings

Acrylic Textile Coatings

Other Thermoplastic Textile Coatings

Polyolefins

Nylon

Thermoset Textile Coatings

Styrene Butadiene Rubber (SBR) Textile Coatings

Natural Rubber Textile Coatings

Other Thermoset Textile Coatings

Nitrile Rubber

Butyl Rubber

Other Textile Coatings

Silicone

Fluoropolymers

By End Use

Geotextiles

Upholstery Fabric

Industrial Clothing

Sports & Leisure

Medical Hygiene Products

Other End Uses

By Region

North America

Europe

East Asia

South Asia

Oceania

Latin America

Middle East & Africa

Contact:

US Sales Office : 11140 Rockville Pike

Suite 400 Rockville, MD 20852 United States

Tel: +1 (628) 251-1583

E-Mail: [email protected]

0 notes

Text

Defoamers Market: Global Industry Analysis and Forecast 2023 – 2030

Defoamers Market Size Was Valued at USD 3.91 Billion in 2022, and is Projected to Reach USD 6.09 Billion by 2030, Growing at a CAGR of 5.7% From 2023-2030.

Foam is a coarse dispersion of a gas in a liquid in which the volume percentage of gas is larger than the volume fraction of liquid. Foams are a major issue in industrial processes. They cause damage to the surface coatings.

They obstruct efficient container filling. Defoamers are chemical additives that minimize or prevent foam formation in industrial process liquids such as paints, inks, adhesives, and even construction materials. Although the phrases antifoam agent and defoamer are frequently used interchangeably, antifoam agents refer to compounds that prevent the creation and development of bubbles.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/16222

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Leading players involved in the Defoamers Market include:

Air Products and Chemicals Inc.(USA), Momentive Performance Materials Inc. (USA), Lubrizol Corporation (USA), Wilflex Corporation (USA), Alzo International Inc. (USA), Dow Corning Corporation (USA), Chemours Company (USA), Ashland Inc. (USA), Dow Chemical Company (USA), Solvay SA (Belgium), Evonik Industries AG (Germany), Clariant AG (Switzerland), Wacker Chemie AG (Germany), Arkema SA (France), Lanxess AG (Germany), BASF SE (Germany), Kemira Oyj (Finland), Elements Plc (UK), Croda International Plc (UK), Shin-Etsu Chemical Co. Ltd. (Japan)

If You Have Any Query Defoamers Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/16222

Segmentation of Defoamers Market:

By Defoamer Type

Water-Based

Oil-Based

Silicone-Based

By Application

Pulp & Paper

Paintings & Coatings

Water Treatment

Food & Beverages

Textile

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Defoamers market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Defoamers market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Defoamers market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Defoamers market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Defoamers Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=16222

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1049

Email: [email protected]

#Defoamers#Defoamers Market#Defoamers Market Size#Defoamers Market Share#Defoamers Market Growth#Defoamers Market Trend#Defoamers Market segment#Defoamers Market Opportunity#Defoamers Market Analysis 2023

0 notes

Text

Defoamers Market: Global Industry Analysis and Forecast 2023 – 2030

Defoamers Market Size Was Valued at USD 3.91 Billion in 2022, and is Projected to Reach USD 6.09 Billion by 2030, Growing at a CAGR of 5.7% From 2023-2030.

Foam is a coarse dispersion of a gas in a liquid in which the volume percentage of gas is larger than the volume fraction of liquid. Foams are a major issue in industrial processes. They cause damage to the surface coatings.

They obstruct efficient container filling. Defoamers are chemical additives that minimize or prevent foam formation in industrial process liquids such as paints, inks, adhesives, and even construction materials. Although the phrases antifoam agent and defoamer are frequently used interchangeably, antifoam agents refer to compounds that prevent the creation and development of bubbles.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/16222

The latest research on the Defoamers market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Defoamers industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Defoamers market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

Leading players involved in the Defoamers Market include:

Air Products and Chemicals Inc.(USA), Momentive Performance Materials Inc. (USA), Lubrizol Corporation (USA), Wilflex Corporation (USA), Alzo International Inc. (USA), Dow Corning Corporation (USA), Chemours Company (USA), Ashland Inc. (USA), Dow Chemical Company (USA), Solvay SA (Belgium), Evonik Industries AG (Germany), Clariant AG (Switzerland), Wacker Chemie AG (Germany), Arkema SA (France), Lanxess AG (Germany), BASF SE (Germany), Kemira Oyj (Finland), Elements Plc (UK), Croda International Plc (UK), Shin-Etsu Chemical Co. Ltd. (Japan)

If You Have Any Query Defoamers Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/16222

Segmentation of Defoamers Market:

By Defoamer Type

Water-Based

Oil-Based

Silicone-Based

By Application

Pulp & Paper

Paintings & Coatings

Water Treatment

Food & Beverages

Textile

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Defoamers market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Defoamers market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Defoamers market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Defoamers market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Defoamers Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=16222

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1047

Email: [email protected]

#Defoamers#Defoamers Market#Defoamers Market Size#Defoamers Market Share#Defoamers Market Growth#Defoamers Market Trend#Defoamers Market segment#Defoamers Market Opportunity#Defoamers Market Analysis 2023

0 notes

Text

Silica aerogels play a role in the preparation of thermally insulating coated fabrics

Thermal insulation coated fabric is a coating with thermal insulation effect on the surface of the fabric, by blocking, reflecting or radiating solar energy, to achieve the purpose of reducing the internal temperature of the fabric covering and reducing energy consumption, it has a wide range of applications in the textile industry prospect.

According to the thermal insulation mechanism, fabric thermal insulation coatings can be divided into three types: barrier type, reflective type and radiation type. Barrier thermal insulation coating is a passive cooling coating that achieves thermal insulation through the resistance of heat transfer. In order to obtain good thermal insulation effect, it usually has the characteristics of relatively low bulk density, low thermal conductivity, and low dielectric constant. Reflective thermal insulation coating isolates sunlight energy through reflection. Commonly used reflective materials include ceramic micropowder, aluminum powder, titanium dioxide and ATO (antimony-doped tin dioxide) powder.

Common barrier fabric thermal insulation coating agents are divided into chemical structures, mainly including polyvinyl chloride (PVC), polyacrylate (PA), polyurethane (PU), silicone, rubber emulsion and PTFE Ethylene, etc., among which PA and PU are widely used; according to the medium used, they can be divided into two types: solvent type and water dispersion type.

As an amorphous nanoporous material, SiO2 aerogel has a controllable structure and a continuous three-dimensional network structure. And its density is adjustable between 3-500mg/cm3, it is a solid material with the lowest density in the world, the porosity can reach 80%-99.8%, the pore size is between 1-100nm, and the specific surface area can be as high as 1000m2/ g. Due to the unique nanoporous structure, its thermal conductivity is extremely low, and the thermal conductivity is as low as 0.017W/(m·K) under normal temperature and pressure, which is the lowest thermal conductivity of solid materials known so far. Since the structural units constituting the aerogel skeleton are smaller than the wavelength of visible light, it also has better light transmission properties. At the same time, it is an inorganic material with non-combustible or flame-retardant effect, and has wide application prospects in the field of thermal insulation.

According to statistics, in recent years, the compound annual growth rate of the global aerogel market size is 36.4%, while the compound annual growth rate of the domestic aerogel market is as high as 61.1%. Its application in thermal insulation fabrics can not only reduce the weight of thermal protective clothing, make it lighter and thinner, but also greatly reduce work loss during use.

For example, SiO2 aerogel can be added to PA or PU adhesives according to a certain proportion to obtain a thermal insulation coating agent, and the cotton fabric can be directly coated, and then the process of drying and baking can be carried out. Preparation of SiO2 Aerogel Thermal Insulation Coated Fabrics. Compared with the original fabric, the thermal insulation performance of the coated fabric with SiO2 aerogel is significantly improved, and when the amount of aerogel added in the coating agent is less than 10%, the thermal insulation effect of the fabric increases with the amount of SiO2 aerogel added. increases and gradually improves.

In addition, glass fiber SiO2 aerogel felt can also be selected as the material of the fabric insulation layer. Its thermal protection performance is greater than 60, and it can withstand high temperature flame combustion at 450 ° C for 50s, which significantly improves the thermal protection performance of the fabric, and can resist firefighting. instantaneous high temperature.

SiO2 aerogel has the characteristics of high porosity and low thermal conductivity, making it a new type of super insulating material. However, the flexibility and integrity of SiO2 aerogels are poor, and the thermal conductivity of aerogels prepared by drying at room temperature increases rapidly at high temperatures, which greatly limits the application of SiO2 aerogels. In recent years, SiO2 aerogel composite thermal insulation materials prepared by in-situ sol-gel method and molding method have improved their toughness, integrity and high-temperature thermal insulation performance to a certain extent, making SiO2 aerogels. It is possible as a single block insulation material.

https://www.wh-heat-insulation.com/thermally-insulating-coated-fabrics.html

0 notes

Text

Silicone Surfactants Market Size, Share, Demand, Growth & Trends by 2033

The global silicone surfactant market is currently valued at US$2.08 Billion in 2023 and is anticipated to expand at a CAGR of 4.66%. Owing to the increasing cosmetic care industry the market is likely to propel to US$ 3.28Billion by 2033.

Demand for silicone surfactants has been rising owing to their utility in the cosmetics industry. Personal care and grooming have become an important part of people’s lifestyles. This is driving the demand for cosmetic products.

Silicone surfactants are used in a wide range of personal care products such as shampoos, hair conditioners, body washes, and soaps, along with other skincare products, among others. Silicone surfactant is used as an ingredient in a variety of products, such as foaming agents, dispersants, emulsifiers, solubilizing agents, cleansers, and conditioners, among others, in the personal care industry.

Request a sample @ https://www.futuremarketinsights.com/reports/sample/rep-gb-15972

The major factor driving the market is a growing demand from the personal care industry. The personal care industry is expected to account for the largest share of the silicone surfactant market over the forecast period.

The silicone surfactants market is currently growing due to the rising application scope in manufacturing paints, coatings, and inks. Silicone surfactants are primarily organic compounds derived from petrochemical raw materials such as benzene and ethylene, or oleo chemical raw materials such as palm oil or coconut oil.

Key Takeaways from the Market Study

By application, the emulsifier segment accounted for the largest share of 31.5% and is expected to continue this trend over the forecast period.

“Increasing penetration of silicone surfactants in the personal care, paints and coatings, textile, and construction industries are expected to radically transform the silicone surfactants market in the coming years,” comments an analyst at FMI.

Competitive Landscape

DOW Inc., Innospec, Momentive, Elkem Silicones, Shin-Etsu Chemical Co., Ltd., Evonik Industries AG, Andisil, Supreme Silicones, Siltech Corporation, Silibase Silicone are some of the key players in the silicone surfactants industry.

The manufacturers are involved in the production of silicon surfactants in a larger capacity. The global silicone surfactants market is consolidated with the presence of major international players. However, the presence of small- and medium-sized domestic players makes the market highly competitive

In July 2022 – Shin-Etsu Chemical has developed a high-strength inorganic thin-film coating liquid with excellent antibacterial and antiviral properties suitable for surface functionalization of building materials.

In December 2020- Elkem has completed and opened a new production workshop in Shanghai, China, dedicated to the development and manufacturing of specialised silicones for hybrid and electric vehicles. This move further strengthens Elkem’s position as the largest silicones producer in China.

In July 2022 – The Momentive Performance Materials group, announced that it is has signed a purchase agreement which will keep the company’s headquarters in the Capital Region by relocating its global Corporate Headquarters from Waterford, N.Y., to the former SI Group location on Balltown Road in Niskayuna, N.Y.

In January 2021 – Momentive Performance Materials, Inc. announced it has reached a definitive agreement to acquire KCC Corporation’s (“KCC”) Silicones business – in Korea and the UK as well as its sales operations in China – further enhancing Momentive’s global capabilities in advanced silicones and specialized applications.

More Valuable Insights Available

FMI, in its new offering, presents an unbiased analysis of the silicone surfactants market, presenting historical demand data (2018-2022) and forecast statistics for the period of 2023-2033.

The study divulges essential insights on the Silicone Surfactants Market by Application (Emulsifiers, Foaming Agents, Defoaming Agents, Wetting Agents, Dispersants, Others) By Type (Water Soluble, Oil Soluble) by End-User (Personal Care, Construction, Textile, Paints & Coatings, Agriculture, Others) By Region – Global Forecast 2023-2033.

Browse Full Report: https://www.futuremarketinsights.com/reports/silicone-surfactants-market

0 notes

Text

What are the key features of food grade hose manufacturers?

Flexotech is a leading manufacturer and supplier of food-grade hoses in India. The company has provided top-quality hoses to various industries for over 20 years. Flexotech is committed to providing customers with innovative, reliable, high-performance products that meet their needs and exceed their expectations.

In this blog, we will discuss why Flexotech is the best food grade hose manufacturers, the manufacturing process, and the Key features of using these hoses in the food and beverage industry.

Key Features of Flexotech Food-Grade Hoses

Flexotech food-grade hoses are designed to meet the highest hygiene, safety, and performance standards. These hoses are made from top-quality materials such as FDA-approved silicone, EPDM, and NBR rubber. The key features of Flexotech food-grade hoses include the following:

Non-toxic and odourless: Flexotech food-grade hoses are made from materials free from harmful chemicals, toxins, and odours. These hoses are safe for use in food and beverage applications where hygiene and safety are critical.

High-temperature resistance: Flexotech food-grade hoses can withstand high temperatures up to 200°C. These hoses are suitable for high-temperature applications such as steam cleaning, hot water washdowns, and sterilization.

Chemical resistance: Flexotech food-grade hoses resist various chemicals and acids, including alcohol, oils, fats, and cleaning agents. These hoses are ideal for use in the food and beverage industry, where harsh chemicals are often used.

Easy to clean: Flexotech food-grade hoses are easy to clean and sanitize. These hoses have a smooth surface that prevents the buildup of bacteria and other contaminants.

Manufacturing Process of Flexotech Food-Grade Hoses

Flexotech food-grade hoses are manufactured using a state-of-the-art production process that ensures consistent quality and performance. Following are the steps involved in manufacturing:

Material selection: The first step in the manufacturing process is to select the appropriate material for the hose based on the application requirements. Flexotech uses FDA-approved silicone, EPDM, and NBR rubber for its food-grade hoses.

Extrusion: The selected material is then extruded into the desired shape and size using a specialized extrusion process. This process involves forcing the material through a die to create a uniform shape and size.

Reinforcement: The extruded hose is then reinforced with a high-strength textile layer or wire braid to enhance its durability and resistance to pressure.

Covering: The reinforced hose is then covered with a smooth or corrugated surface to protect it from external damage and enhance its flexibility.

Testing: The final step in the manufacturing process is to test the hose for quality, performance, and compliance with the relevant industry standards. Flexotech food-grade hoses undergo rigorous testing to ensure that they meet the highest quality and performance standards.

These features and manufacturing process makes Flexotech the best food grade hose manufacturers giving the best usage for various applications.

Description- Flexotech is a leading food-grade hose manufacturer in India, providing top-quality, reliable, and high-performance hoses for the food and beverage industry.

Why choose Flexotech stainless steel hoses?

Flexotech is a leading manufacturer of stainless steel hoses known for their durability and flexibility. With over 20 years of experience in the industry, Flexotech has established itself as a trusted name in the market, as a stainless steel hose manufacturers to clients across a wide range of industries.

In this blog, we will take a closer look at Flexotech and explore the many benefits of using stainless steel hoses.

What are stainless steel hoses?

Stainless steel hoses are flexible metallic tubes made from stainless steel and other alloys. They are designed to withstand high temperatures, pressure, and corrosive environments, making them an ideal choice for a wide range of industrial applications.

Stainless steel hoses are commonly used in oil and gas, chemical, pharmaceutical, and food processing industries. They have been used to transport liquids, gases, and other substances safely and efficiently.

Flexotech stainless steel hoses has-

Flexibility

One of the key benefits of using stainless steel hoses from Flexotech is their flexibility. These hoses are designed to bend and flex easily, allowing them to be installed in tight spaces and around corners. This flexibility also makes them less prone to kinking and cracking, reducing the risk of leaks and other issues.

Durability

Stainless steel hoses from Flexotech are built to last. They are resistant to corrosion, abrasion, and wear, which means they can withstand harsh environments and heavy use without deteriorating or breaking down.

High-pressure rating

Another advantage of Flexotech stainless steel hoses is their high-pressure rating. These hoses can handle up to 10,000 psi, making them suitable for high-pressure applications such as hydraulic systems and pressure testing.

Temperature resistance

Stainless steel hoses from Flexotech are also designed to withstand extreme temperatures. They can operate at temperatures ranging from -200°C to 600°C, making them suitable for use in hot and cold environments.

Versatility

Flexotech stainless steel hoses are available in a wide range of sizes and configurations, making them suitable for various applications. They can be customized to meet specific requirements and are compatible with various fittings, adapters, and connectors.

Quality assurance

At Flexotech, quality is a top priority. All our stainless steel hoses undergo rigorous testing and inspection to ensure they meet the highest quality and performance standards. We use only the best materials and manufacturing processes to produce our hoses, and we are committed to providing our customers with the highest level of service and support.

In conclusion, Flexotech is a leading stainless steel hose manufacturers that are durable, flexible, and versatile. With over 20 years of experience in the industry, we have established ourselves as a trusted name in the market, providing high-quality hoses to clients across a wide range of industries.

If you are looking for a reliable supplier of stainless steel hoses, Flexotech is a perfect choice. With our commitment to quality, customer service, and innovation, we are dedicated to helping our customers achieve their goals and succeed in their industries.

Description- Flexotech is a leading manufacturer of stainless steel hoses, offering flexibility, high-quality and durable products for a wide range of applications.

0 notes