#Silicone Textile Chemicals

Text

The Significance of Dye Fixing Agents in Textile Industry

Enhanced Color Fastness: By chemically attaching colors to the fabric fibers, dye fixing agents increase the color fastness of textiles that have been dyed. This keeps the colors bright and true for the duration of the garment by stopping the dyes from leaking or fading when washed, rubbed, or exposed to light.

Long-lasting Color Retention: Dye fixing chemicals help textiles retain their original color intensity and brilliance even after repeated launderings or exposure to environmental variables by successfully fixing dyes onto fabric fibers. This guarantees that clothing will maintain its visual impact and aesthetic appeal over time.

Diminished Environmental Impact: By decreasing dye waste and run-off, dye fixing agents help to lessen the environmental impact of textile dyeing operations. Water and energy resources are conserved during the dyeing process when these chemicals improve the attachment of dyes onto fibers, hence reducing the need for unnecessary rinsing and washing.

Better Wash Fastness: Dye fixing chemicals help dyed textiles wash more quickly, keeping the colors vibrant and preventing them from smearing onto other fabrics. This keeps the appearance of the garment intact and stops color migration or staining—especially in textiles with several colors or prints.

Textiles treated with dye fixing agents: Have better stain resistance against typical things including food, drinks, and household chemicals. This increases the general durability and endurance of the fabric and makes clothing easier to clean and maintain, thereby decreasing the possibility of unattractive stains.

Compatibility with a Variety of Fibers: Cotton, wool, polyester, nylon, and other natural and synthetic fibers are among the many fabrics that dye fixing agents work well with. Due to its adaptability, textile producers are able to guarantee uniform coloration and performance by achieving consistent and dependable dye fixing outcomes on a variety of fabric types.

Regulatory Compliance: Dye fixing agents assist textile producers in adhering to strict safety regulations and standards pertaining to textile performance and color fastness. These agents help to produce high-quality and compliant textile goods by making sure dyed textiles meet industry standards for color fastness, durability, and consumer safety.

Consumer happiness: In the end, dye fixing agents are essential for raising consumer happiness since they guarantee that colored textiles keep their color vibrancy, look, and functionality throughout time. Clothes that hold their color and don't fade or bleed are more likely to live up to client expectations and provide long-term value.

Visit site

#Dyeing Printing Auxiliaries Manufacturer#Dyeing Printing Auxiliaries Manufacturer in India#Textile Finishing Chemicals Manufacturers#Textile Finishing Chemicals Manufacturers in India#Textile Finishing Chemicals Suppliers#Dyes Manufacturers#Textile Dyes Manufacturers#dyes manufacturers in india#textile finishing chemicals#textile dyes manufacturers#dyeing auxiliaries#Finishing Chemical Manufacturers#Printing Dyes Suppliers#Textile Auxiliaries#Textile Auxiliary Manufacturer#Pretreatment Textile Manufacturer#Textile Pretreatment Chemicals#Printing Dyes Manufacturers#Silicone softeners Manufacturer#Silicone softener for textiles#Desize Enzymes Manufacturer#Optical Brightener#Optical Brightener Manufacturer#Turkey red oil manufacturer#Printing Dyes#Printing Dyes Manufacturer#optical brightening agent in textile#textile auxiliaries manufacturers in india#dye manufacturers in india#dyeing and printing

0 notes

Link

Cosmo Speciality Chemicals' Lyosil BHL 1E and Lyosil BHL 3I are non-toxic and Eco-friendly Hydrophilic Block Silicone Softner Emulsions that exhibit better softening properties and are suitable for a wide range of applications. Explore our products and services at

0 notes

Photo

Switch to eco-friendly cationic softeners to improve the characteristics of textiles. Cosmo Speciality Chemicals has introduced Silky SF – a cationic softener that enables an excellent softening effect on all kinds of textiles.

0 notes

Link

Data Bridge Market Research analyzes that the North America Silicone Textile Chemicals Market will record a CAGR of 3.65% for the forecast period 2021-2028. The increasing demand for silicone textile chemicals, especially in developed countries such as the United States, the increasing use of silicone -Textile Chemicals for various end-use applications such as apparel, home and office furniture, technical textiles and others, the strong influence of social media and industrial growth, especially in developing countries, is the main driver of market growth.

0 notes

Photo

If you menstruate and are on a path of zero-waste, avoiding plastics, avoiding toxic chemicals, minimizing your footprint, or all of the above, then you’ve likely been faced with a frustrating conundrum: Menstruating is a natural part of your life, but there doesn’t seem to be too many ‘clean’, safe options to deal with it.

First off, let me say that I have been off and away from mainstream menstrual care for over 14 years, including birth control (wrecked my hormones), and storebought sanitary products (full of harmful chemicals like bleach, perfume and hormone-disrupting PFAs!). I have used silicone cups, discs, and cloth pads, and have a lengthy and thorough review of how they are used and what brands I prefer up on my Patreon.

However, for today I want to focus on one tried and true item: The pad.

Pads have been around for centuries- longer if you include their earlier predecessor, The Rag. However, in this time we’ve come pretty far to create a more secure, clean and manageable item— though the creation of the chemically-treated, plastic lined disposable pad has been a regrettable pit stop.

Cloth pads are great because they come in a wide range of colors and patterns (making them more appropriate for more kinds of menstruating people, including men and children) and can be reused for years if cared for properly. Over the past decade, they’ve gone from being available solely from independent sellers on sites like Etsy to being sold alongside menstrual cups in the ‘alternative’ period care section of many stores. You can also specifically buy pads made from organic or natural materials and avoid petrol-based textiles.

However, a downside here is that purchasing pads can still be expensive even if you aren’t buying direct from an indie seller. Now, it’s not that they aren’t worth every penny; having made 3 sets myself I fully understand the time, skill and materials that go into making them. But the fact of the matter is that under late-stage capitalism, paying the higher up-front cost for a set of reusable pads can be daunting, even if you know it’s cheaper in the long run (and it is).

If you have access to fabric, a sewing machine, and sewing skills, you can half the price, and I’m going to show you how. The cost of fabric can even be lowered by recycling old towels and clothing and I’ll talk about what you need in the tutorial! As a set of good cloth pads can last from 4-6 years or more, this is a great, frugal and eco-friendly option!

Additionally, I’m going to tell you how to wash and care for your pads since working with reusable pads is way different than just wrapping them up and throwing them in the trash.

For the step by step directions, photos and care tutorial, click here to read for free on my Patreon. All of my content is Patron-supported and Patrons also receive private and early-release posts! If you appreciate my work, feel free to visit my membership page and choose the tier that works for you.

Free tutorial here.

Tips + Thank yous

Insta

447 notes

·

View notes

Text

i have once more Read a Book !

the book was jim morris' cancer factory: industrial chemicals, corporate deception, & the hidden deaths of american workers. this book! is very good! it is primarily about the bladder cancer outbreak associated with the goodyear plant in niagara falls, new york, & which was caused by a chemical called orthotoluedine. goodyear itself is shielded by new york's workers' comp law from any real liability for these exposures & occupational illnesses; instead, a lot of the information that morris relies on comes from suits against dupont, which manufactured the orthotoluedine that goodyear used, & despite clear internal awareness of its carcinogenicity, did not inform its clients, who then failed to protect their workers. fuck dupont! morris also points out that goodyear manufactured polyvinyl chloride (PVC) at that plant, and, along with other PVC manufacturers, colluded to hide the cancer-causing effects of vinyl chloride, a primary ingredient in PVC & the chemical spilled in east palestine, ohio in 2023. the book also discusses other chemical threats to american workers, including, and this was exciting for me personally, silica; it mentions the hawks nest tunnel disaster (widely forgotten now despite being influential in the 30s, and, by some measures, the deadliest industrial disaster in US history) & spends some time on the outbreak of severe silicosis among southern california countertop fabricators, associated with high-silica 'engineered stone' or 'quartz' countertops. i shrieked about that, the coverage is really good although the treatment of hawks nest was very brief & neglected the racial dynamic at play (the workers exposed to silica at hawks nest were primarily migrant black workers from the deep south).

cancer factory spends a lot of time on the regulatory apparatus in place to respond to chemical threats in the workplace, & thoroughly lays out how inadequate they are. OSHA is responsible for setting exposure standards for workplace chemicals, but they have standards for only a tiny fraction—less than one percent!—of chemicals used in american industry, and issue standards extremely slowly. the two major issues it faces, outside of its pathetically tiny budget, are 1) the standard for demonstrating harm for workers is higher than it is for the general public, a problem substantially worsened during the reagan administration but not created by it, and 2) OSHA is obliged to regulate each individual chemical separately, rather than by functional groups, which, if you know anything at all about organic chemistry, is nonsensical on its face. morris spends a good amount of time on the tenure of eula bingham as the head of OSHA during the carter administration; she was the first woman to head the organization & made a lot of reasonable reforms (a cotton dust standard for textile workers!), but could not get a general chemical standard, allowing OSHA to regulate chemicals in blocks instead of individually, through, & then of course much of her good work was undone by reagan appointees.

the part of the book that made me most uncomfortable was morris' attempt to include birth defects in his analysis. i don't especially love the term 'birth defect'—it feels cruel & seems to me to openly devalue disabled people's lives, no?—but i did appreciate attention to women's experiences in the workplace, and i think workplace chemical exposure is an underdiscussed part of reproductive justice. cancer factory mentions women lead workers who were forced to undergo tubal ligations to retain their employment, supposedly because lead is a teratogen. morris points at workers in silicon valley's electronics industry; workers, most of them women, who made those early transistors were exposed to horrifying amounts of lead, benzene, and dangerous solvents, often with disabling effects for their children.

morris points out again & again that we only know that there was an outbreak of bladder cancer & that it should be associated with o-toluedine because the goodyear plant workers were organized with the oil, chemical, & atomic workers (OCAW; now part of united steelworkers), and the union pursued NIOSH investigation and advocated for improved safety and monitoring for employees, present & former. even so, 78 workers got bladder cancer, 3 died of angiosarcoma, and goodyear workers' families experienced bladder cancer and miscarriage as a result of secondary exposure. i kept thinking about unorganized workers in the deep south, cancer alley in louisiana, miners & refinery workers; we don't have meaningful safety enforcement or monitoring for many of these workers. we simply do not know how many of them have been sickened & killed by their employers. there is no political will among people with power to count & prevent these deaths. labor protections for workers are better under the biden administration than the trump administration, but biden's last proposed budget leaves OSHA with a functional budget cut after inflation, and there is no federal heat safety standard for indoor workers. the best we get is marginal improvement, & workers die. i know you know! but it's too big to hold all the same.

anyway it's a good book, it's wide-ranging & interested in a lot of experiences of work in america, & morris presents an intimate (sometimes painfully so!) portrait of workers who were harmed by goodyear & dupont. would recommend

#if anyone knows about scholarship that addresses workplace chemical exposure#& children born with disabilities through a disability justice lens please recommend it to me!#booksbooksbooks#have reached the point in my Being Weird About Occupational Safety era where i cheered when familiar names came up#yay irving j. selikoff champion of workers exposed to asbestos! yay labor historians alan derickson & gerald markowitz!#morris points out the tension between workers - who want engineering controls of hazards (eg enclosed reactors)#& employers who want workers to wear cumbersome PPE#the PPE approach is cheaper & makes it even easier to lean on the old 'the worker was careless' canard when occupational disease occurs#i just cannot stop thinking about it in relation to covid. my florida library system declined to enforce masks for political reasons#& reassured us that PPE is much less important than safety improvements at the operational & engineering level#but they didn't do those things either! we opened no windows; upgraded no HVACs; we put plexi on the service desks & stickers on the floors#& just as we have seen covid dangers downplayed or misrepresented workers still do not receive useful information about chemical hazard#a bunch of those MSDS handouts leave out carcinogen status & workers had to fight like hell to even be told what they're handling#a bunch of them still do not know—consider agricultural workers & pesticide exposures. to choose an obvious & egregious example.

8 notes

·

View notes

Text

Maintenance and Longevity of Water and Oil Repellent Surfaces

Water and oil repellent technologies have revolutionized the way we protect various surfaces, from textiles to construction materials and automotive interiors. These coatings not only shield surfaces from stains and damage but also extend their lifespan. However, the effectiveness of water and oil repellent treatments is not indefinite. Proper maintenance is essential to ensure these surfaces retain their protective properties over time. This article explores practical strategies for maintaining and enhancing the longevity of water and oil repellent surfaces.

Understanding Water and Oil Repellent Technologies

Water and oil repellent coatings are designed to provide surfaces with a protective layer that repels liquid substances and prevents them from penetrating or adhering to the surface. These technologies typically involve the application of fluoropolymers or silicone-based compounds that create a microscopic barrier on the surface. This barrier reduces the surface tension, causing liquids to bead up and roll off instead of soaking in.

Regular Cleaning

Regular cleaning is crucial for maintaining the efficacy of water and oil repellent surfaces. Dirt, dust, and other particulates can accumulate on the coated surface, eventually embedding themselves in the microscopic structure of the repellent layer, thereby diminishing its effectiveness. To clean these surfaces properly:

Use a soft cloth or sponge to avoid scratching the protective coating.

Employ mild soap and water for routine cleaning, steering clear of abrasive detergents that can degrade the coating.

Gently pat the surface dry with a soft towel after cleaning, as rubbing can wear down the repellent finish.

Timely Reapplication

Even the best water and oil repellent treatments wear off over time, especially in high-traffic or frequently used areas. Manufacturers typically recommend a schedule for reapplication, which can vary from one product to another. Paying attention to the manufacturer’s guidelines can prevent the premature expiration of the surface’s repellent qualities. For instance:

Textile products might need a reapplication after a number of wash cycles.

Outdoor building materials exposed to harsh weather conditions may require more frequent re-treatments.

Avoiding Harsh Chemicals

The longevity of repellent surfaces can be significantly reduced by the use of harsh chemicals. Cleaning agents that contain strong solvents, acids, or alkalis can break down the chemical structure of the repellent layer. It’s advisable to:

Check the compatibility of cleaning agents with the specific type of repellent coating.

Opt for pH-neutral cleaners that are less likely to interfere with the integrity of the repellent properties.

Handling Scratches and Abrasions

Physical damage such as scratches or abrasions can compromise the integrity of water and oil repellent coatings. Such damage provides channels for moisture and oils to penetrate beneath the surface. To mitigate this risk:

Use protective coverings or pads on furniture and other heavy items that might scratch floor surfaces.

Avoid using sharp objects or abrasive tools near repellent-coated surfaces.

Professional Maintenance

Some water and oil repellent treatments, especially those used in industrial or commercial settings, may require professional maintenance to ensure optimal performance. Professional services can provide:

Advanced cleaning techniques that are safe for repellent coatings.

Expert reapplication of coatings to ensure uniform coverage and maximum protection.

Assessment and repair of any damage that could undermine the repellent properties.

Monitoring Performance

Regularly assess the performance of water and oil repellent surfaces to catch any deterioration in their repellent properties early. Simple tests, such as sprinkling water on the surface and observing whether it beads up, can provide quick indications of the coating's condition. Early detection allows for timely interventions, whether it's a simple cleaning or a full reapplication of the coating.

Conclusion

Maintaining water and oil repellent surfaces is key to ensuring their continued effectiveness and longevity. By adhering to proper cleaning protocols, avoiding harsh chemicals, managing physical wear, and following manufacturer guidelines for maintenance, these protective coatings can continue to safeguard various surfaces effectively. Regular upkeep not only preserves the functionality of these treatments but also extends the life of the materials they protect, ensuring they remain pristine and functional for years to come.

0 notes

Text

Auxiliaries for Textile Industry in Delhi | Textile Chemicals

Auxiliaries For Textile Industry In Delhi

Are you in search of high-quality auxiliaries for the textile industry? Look no further! Welcome to our premier service for textile auxiliaries in Delhi. The textile industry encompasses a wide array of materials, from yarns to various fabrics, fibers, and finished articles. Each requires specialized solutions for their chemical processing, and we are here to provide exactly that. Our range of products is diverse, catering to the unique needs of textile manufacturers. textile auxiliary producer Delhi

Why Choose Us?

As leading textile auxiliaries manufacturers in Delhi, we pride ourselves on several key points:

Diverse Product Range: We offer more than just a single product; our catalogue boasts a wide variety of auxiliaries for chemical processing.

Versatility: Our products cater to a range of fabrics and fibers, ensuring we are not limited to one specific type.

Quality: All our products are of exceptional quality, designed for optimal performance and excellent results.

Multi-Purpose: Whether it's dyeing, printing, or other fabric treatments, our auxiliaries are versatile and effective.

Comprehensive Solutions: Consider us your one-stop solution for all textile processing requirements.

These aspects set us apart as premier textile auxiliary producers.

Our Categories of Auxiliaries

Here's a glimpse into some of the textile industry auxiliaries we offer in Delhi:

Pretreatment Auxiliaries

Our pretreatment auxiliaries boast highly absorbent and low-foaming formulations, with impressive binding capabilities. They are eco-friendly, GOTS approved, and free of APEO/NPEO. Examples include Scowet TT Conc., Rikoclean – STR, and Trinitron. These auxiliaries include stain removers tailored for synthetic and natural fibers, such as Rikoclean – STR.

Dyeing Auxiliaries

Our dyeing auxiliaries feature excellent levelling properties, ensuring uniform distribution of dye. They offer high soaping and washing-off abilities, all while being GOTS approved. For instance, Milaniaks- R serves as a cationic retarder for controlled and uniform acrylic dyeing. Additionally, Trinitron – LTS is a low-temperature washing off agent suitable for various fibers, providing excellent soaping fastness and easy wash.

Finishing Agents

Our finishing agents consist of both silicone and non-silicone specialty softeners, crafted to meet the industry's specific needs. These auxiliaries are invaluable, offering versatile finishes tailored to the desired garment or fabric. From exhaustible to inexhaustible finishes, as well as hydrophobic and oleo phobic options, our range covers a spectrum of textile chemicals and auxiliaries in Delhi.

If you're in need of top-notch textile auxiliaries, don't hesitate to reach out to us today. We are your partners in achieving exceptional textile processing results.

#auxiliaries for textile industry in Delhi#textile auxiliaries manufacturers Delhi#textile auxiliary producer Delhi

0 notes

Text

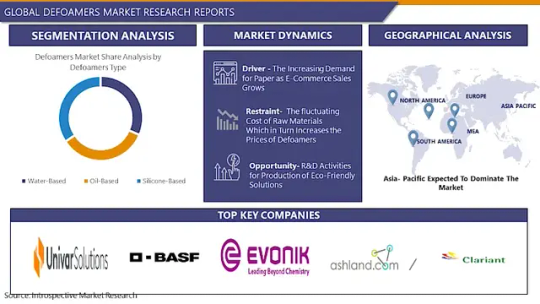

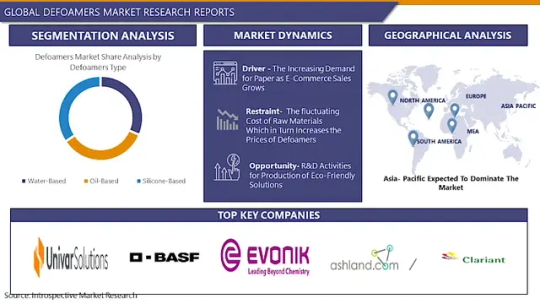

Defoamers Market: Global Industry Analysis and Forecast 2023 – 2030

Defoamers Market Size Was Valued at USD 3.91 Billion in 2022, and is Projected to Reach USD 6.09 Billion by 2030, Growing at a CAGR of 5.7% From 2023-2030.

Foam is a coarse dispersion of a gas in a liquid in which the volume percentage of gas is larger than the volume fraction of liquid. Foams are a major issue in industrial processes. They cause damage to the surface coatings.

They obstruct efficient container filling. Defoamers are chemical additives that minimize or prevent foam formation in industrial process liquids such as paints, inks, adhesives, and even construction materials. Although the phrases antifoam agent and defoamer are frequently used interchangeably, antifoam agents refer to compounds that prevent the creation and development of bubbles.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/16222

The latest research on the Defoamers market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Defoamers industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Defoamers market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

Leading players involved in the Defoamers Market include:

Air Products and Chemicals Inc.(USA), Momentive Performance Materials Inc. (USA), Lubrizol Corporation (USA), Wilflex Corporation (USA), Alzo International Inc. (USA), Dow Corning Corporation (USA), Chemours Company (USA), Ashland Inc. (USA), Dow Chemical Company (USA), Solvay SA (Belgium), Evonik Industries AG (Germany), Clariant AG (Switzerland), Wacker Chemie AG (Germany), Arkema SA (France), Lanxess AG (Germany), BASF SE (Germany), Kemira Oyj (Finland), Elements Plc (UK), Croda International Plc (UK), Shin-Etsu Chemical Co. Ltd. (Japan)

If You Have Any Query Defoamers Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/16222

Segmentation of Defoamers Market:

By Defoamer Type

Water-Based

Oil-Based

Silicone-Based

By Application

Pulp & Paper

Paintings & Coatings

Water Treatment

Food & Beverages

Textile

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Defoamers market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Defoamers market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Defoamers market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Defoamers market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Defoamers Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=16222

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1049

Email: [email protected]

#Defoamers#Defoamers Market#Defoamers Market Size#Defoamers Market Share#Defoamers Market Growth#Defoamers Market Trend#Defoamers Market segment#Defoamers Market Opportunity#Defoamers Market Analysis 2023

0 notes

Text

Defoamers Market: Global Industry Analysis and Forecast 2023 – 2030

Defoamers Market Size Was Valued at USD 3.91 Billion in 2022, and is Projected to Reach USD 6.09 Billion by 2030, Growing at a CAGR of 5.7% From 2023-2030.

Foam is a coarse dispersion of a gas in a liquid in which the volume percentage of gas is larger than the volume fraction of liquid. Foams are a major issue in industrial processes. They cause damage to the surface coatings.

They obstruct efficient container filling. Defoamers are chemical additives that minimize or prevent foam formation in industrial process liquids such as paints, inks, adhesives, and even construction materials. Although the phrases antifoam agent and defoamer are frequently used interchangeably, antifoam agents refer to compounds that prevent the creation and development of bubbles.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/16222

The latest research on the Defoamers market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Defoamers industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Defoamers market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

Leading players involved in the Defoamers Market include:

Air Products and Chemicals Inc.(USA), Momentive Performance Materials Inc. (USA), Lubrizol Corporation (USA), Wilflex Corporation (USA), Alzo International Inc. (USA), Dow Corning Corporation (USA), Chemours Company (USA), Ashland Inc. (USA), Dow Chemical Company (USA), Solvay SA (Belgium), Evonik Industries AG (Germany), Clariant AG (Switzerland), Wacker Chemie AG (Germany), Arkema SA (France), Lanxess AG (Germany), BASF SE (Germany), Kemira Oyj (Finland), Elements Plc (UK), Croda International Plc (UK), Shin-Etsu Chemical Co. Ltd. (Japan)

If You Have Any Query Defoamers Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/16222

Segmentation of Defoamers Market:

By Defoamer Type

Water-Based

Oil-Based

Silicone-Based

By Application

Pulp & Paper

Paintings & Coatings

Water Treatment

Food & Beverages

Textile

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Defoamers market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Defoamers market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Defoamers market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Defoamers market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Defoamers Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=16222

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1049

Email: [email protected]

#Defoamers#Defoamers Market#Defoamers Market Size#Defoamers Market Share#Defoamers Market Growth#Defoamers Market Trend#Defoamers Market segment#Defoamers Market Opportunity#Defoamers Market Analysis 2023

0 notes

Text

A Look at Sodium Silicate and its Suppliers in India

Sodium silicate, often dubbed "water glass" for its transparent, glass-like appearance, is a versatile inorganic compound with surprising strength and resilience. It binds, cleans, strengthens, and protects diverse materials, making it a crucial player in numerous industries across India.

From crafting paper and soap to casting intricate metal parts and preserving ancient art, sodium silicate's applications are as varied as they are valuable. But where does this workhorse chemical come from? Let's delve into the world of Sodium Silicate supplier in India, exploring what sets them apart and how they contribute to the nation's industrial landscape.

The Alchemy of Silicate:

Manufacturing sodium silicate is a fascinating dance of sand and soda ash. Essentially, molten sand (silicon dioxide) and sodium carbonate are fused together at high temperatures, creating a liquid sodium silicate solution. The magic lies in the varying ratios of these ingredients, which determine the final product's viscosity, density, and other key properties. This allows for customized solutions to cater to specific industrial needs.

A Spectrum of Silicate Suppliers:

India boasts a thriving sodium silicate industry, with numerous suppliers dotting the map. Sudarshan Group offers a range of silicate solutions, from readily available liquid forms to specialized powdered variants. They cater to diverse sectors, including

Paper production: Sodium silicate acts as a binding agent, strengthening paper and improving its printing surface.

Construction: It's used as a deflocculant in cement, enhancing fluidity and workability. Additionally, it serves as a fire retardant and can strengthen concrete structures.

Foundry: Sodium silicate binds sand molds used in metal casting, ensuring precise shapes and smooth finishes.

Textile: It strengthens and softens fabrics, improves dyeability, and even acts as a flame retardant in certain applications.

Detergent manufacturing: Sodium silicate functions as a builder in soaps and detergents, boosting cleaning power and softening water.

Supplier Spotlight:

While exploring the landscape of sodium silicate suppliers in India, one name consistently emerges Renowned for its commitment to quality, innovation, and sustainable practices, Sudarshan Group has established itself as a leader in the field.

Sudarshan Group's dedication to excellence shines through in several aspects:

Stringent quality control: We adhere to rigorous international standards, ensuring consistent product quality and performance.

Diverse product portfolio: We offer a wide range of sodium silicate solutions to cater to varied industrial needs and specifications.

Technical expertise: Our team of experienced professionals provides valuable technical support and guidance to customers.

Commitment to sustainability: Sudarshan Group prioritizes environmentally responsible practices, minimizing waste and ensuring responsible resource management.

The Future of Silicate:

With India's rapid industrial growth, the demand for sodium silicate is projected to rise significantly. Sudarshan Group is well-positioned to meet this demand and continue playing a crucial role in the nation's industrial development. Additionally, research into new applications for sodium silicate holds immense potential, opening doors for further growth and innovation.

Conclusion:

In India's competitive landscape of sodium silicate suppliers, Sudarshan Group shines as a reliable, innovative, and customer-focused player. With a rich legacy, a commitment to quality, advanced manufacturing facilities, and a diverse product range, Sudarshan Group plays a pivotal role in supporting the growth and development of industries that rely on sodium silicate. As businesses seek dependable partners for their chemical needs, Sudarshan Group stands out as a beacon of excellence in the sodium silicate market.

0 notes

Text

Which industries require the use of plastic-metal/plastic-plastic lubricant | Caravan Oil Supplier's Dow DuPont

Dow DuPont is the result of two of the largest chemical companies Dow and DuPont merging into a single entity. Amongst its vast portfolio of products are the Speciality Lubricants Line under the brand name Molykote and the Sealants Line from Dow SIL.

Molykote : Molykote is Dow Dupont’s brand in Speciality Industrial Lubricants. Molykote is a world leader in this field having invented and patented Silicone

Extreme temperature oils and greases :

These lubricants can withstand operational temperatures of up to 250° These have been successfully used in Oven and Kiln Conveyor chains in many Automotive/Auto Component Manufacturers, and in the Stenter Chains of Textile Industries. The high chemical resistance of these products ensures that the greases and oils do not stain the components, especially in overhead chain conveyors.

NSF H1 (food grade) lubricants :

These are most useful in Pharmaceutical and Food Processing Industries where the need for such lubricants is a must. All our food-grade lubricants have NSF H1 certification.

Anti-Friction Coatings :

These are most suitable for applications where either dry lubrication is the only solution available or preferred or where components need an extra layer of protection from the environment. Our range of AFCs has been used in many sectors such as Automotive, Textile, Aerospace, Machining, and Chemical.

Pastes :

Pastes are used in low-speed, high-temperature applications in temperatures exceeding 300°C. Mostly used in the Chemical and Petrochemical Industries, Textile Industries, and Aerospace Component Manufacturers.

Plastic-metal/plastic-plastic lubricants :

we have lubricants that do not react with plastic components. These are most useful in the Textile and Automotive Industries.

Automotive Speciality Lubricants:

We have a line of lubricants specifically designed for the Automotive Sector and can be used in powertrains, chassis, brake systems, vehicle exteriors, and interiors as well as HVAC Lubrication.

You can find out more from dow distributors.

Address: 106 Road number 4 2nd phase, Jigani Industrial Area Anekal Taluk Bangalore, Karnataka 562106

Phone Number: 9980005255

Email: [email protected]

0 notes

Text

stainless steel sheet dealers in Chennai

Stainless Steel Sheets, Versality, Composition and Application

Stainless steel sheets are strong and versatile and are used in a variety of applications. It is primarily selected for its corrosion resistance, durability, and formability. Stainless steel sheets/plates are mainly used in construction, transportation, shipping, chemical, textile, food service industries, etc.

Stainless steel is used in kitchen accessories, cutlery, and cookware. Less ductile steel types are used to make sharp knife blades. For items that require shaping - ductile grades of stainless steel are used.Highly ductile types of stainless steel are used in appliances such as stoves, grills, sinks, and pots.Are you in search of stainlesssteel sheet dealers in Chennai?

Stainless Steel Sheet Application Shape and Making

Stainless steel sheet is a type of sheet metal and is composed of an alloy of steel and chromium. A stainless-steel sheet varies in thickness but is generally thicker than a metal sheet or metal foil and thinner than a metal plate. Most metal sheets are easy to bend and can be bent by hand, but plates are not.Stainless steel sheets are used for both decorative and structural purposes due to their relatively attractive appearance. There are many different types of stainless-steel sheet construction, but most fall into one of three basic categories.

Type 306 is the most common as well as the least expensive type.

Type 316 is a more expensive version of a standard stainless-steel sheet, offering higher levels of strength and corrosion resistance.

Type 410 is the simplest type and is commonly used for making cutlery and kitchen utensils.

Stainless steel sheet or Stainless-steel plate is very versatile and used in various applications. Stainless steel sheet is chosen mainly because it has properties like corrosion resistance, longevity and formability. Typical applications for stainless steel sheet/plate can be found in construction, food service applications, transportation, chemical, marine and textiles. Choose the reputed stainless steel sheet dealers in Chennai!

Why is Stainless Steel used?

Stainless steel is a combination of metals and other elements that make it strong, flexible, and even light. Stainless steel is the term used to refer to a group of iron-based alloys that contain close to 10.5% chromium. Chromium is an important additive with anti-corrosion effects. Chromium forms an ultra-thin passive layer and plays an essential role in preventing rust.

If you are looking for a stainless-steel sheet to purchase, you will find alloys that contain carbon 1, 2 and other materials such as nickel, silicon, manganese, nitrogen, and niobium. This concludes that stainless steel is a combination of many metals and other elements that give it a wide variety of properties, comes in a variety of grades, and offers many advantages in terms of design and application.

Properties of Stainless-Steel Sheet Metal

Stainless steel has several attractive properties making it versatile for many purposes.

Shiny and sturdy - Stainless steel is partially corrosion and stain-proof. It entirely depends on its composition and chemicals.

Thickness up to 1/4th inch - Metal that is 1/4 inch thick is called a metal plate. This thickness is measured with a gauge. The sheet is thinner than metal.

Stainless steel sheet is available in different configurations, sizes, grades, finishes and types.

Metal & Alloy Industries is one of the best stainless steel sheet dealers in Chennai offering a premium range of stainless-steel sheets of varied sizes and dimensions.

0 notes

Text

Angel Chem India: Taming the Foam Monsters in Your Industry

Foaming – it can be a beautiful spectacle in a latte, but a nightmarish enemy in countless industrial processes and Defoamer Chemicals Manufacturers. Enter Angel Chem India, the company armed with a chemical arsenal to conquer those pesky bubbles and ensure smooth operations across diverse industries.

From Water Treatment to Food Processing, Angel Chem Has a Defoamer for You:

Angel Chem India’s defoamer portfolio is as diverse as the industries they cater to. Whether you’re battling foam in your paint production, struggling with frothing in your pharmaceutical fermentation tanks, or facing bubbling woes in your wastewater treatment plant, Angel Chem has the defoamer solution. Here’s a glimpse into their arsenal:

Silicone Defoamers: Reliable workhorses, these defoamers excel in a wide range of applications, from paint and coatings to textiles and paper production. Their long-lasting effectiveness and heat resistance make them ideal for high-temperature processes and Defoamer Chemicals.

Polyethylene Glycol Defoamers: Gentler on the environment, these water-soluble defoamers are perfect for food processing and pharmaceutical applications. They break down foam effectively without leaving any residue, ensuring product safety and quality.

Antifoaming Agents: For those facing persistent foaming challenges, Angel Chem offers specialized antifoaming agents. These potent formulations prevent air bubbles from forming in the first place, offering a proactive approach to foam control.

Innovation Underpins Performance:

Angel Chem India doesn't believe in resting on its laurels. Their Research & Development team is constantly churning out new and improved defoamers, tailored to meet the evolving needs of their clients. Here are some of their innovative approaches:

Customizing for Specific Needs: No two foaming problems are identical. Angel Chem technical experts work closely with clients to understand their unique challenges and formulate customized defoamers for optimal performance.

Developing Eco-Friendly Solutions: Sustainability is at the forefront of Angel Chem agenda. They prioritize the development of biodegradable and non-toxic defoamers, minimizing their environmental impact while ensuring excellent functionality.

Investing in Cutting-Edge Technology: Angel Chem utilizes state-of-the-art manufacturing facilities and stringent quality control processes. This commitment to quality translates to consistent, reliable defoamers that clients can trust.

Beyond the Lab: Building Trust and Partnerships:

For Angel Chem India, defoamers are just the beginning. They believe in building strong relationships with their clients, offering comprehensive support and expertise alongside their products. Here’s how they go the extra mile:

Technical Assistance: Angel Chem’s team of specialists provides invaluable technical guidance, helping clients identify the right defoamer for their application and optimize its use for maximum effectiveness.

On-Site Support: For complex foaming challenges, Angel Chem offers customized on-site assistance. Their experts work directly with clients to analyze the problem and implement the most effective defoaming solution.

Continuous Improvement: Angel Chem actively fosters a culture of learning and feedback. They regularly engage with clients to understand their experiences and incorporate their insights into product development and service improvement.

Partnering for Foam-Free Success:

Choosing Angel Chem India is not just choosing a defoamer; it’s choosing a partner in ensuring efficient and hassle-free operations. Their diverse defoamer portfolio, commitment to innovation, and unwavering focus on customer satisfaction make them the ideal choice for companies across industries. So, next time foam threatens to disrupt your workflow, remember Angel Chem India – the foam tamers who can help you achieve smoother, more profitable operations.

0 notes

Text

Beyond Pipes and Pumps Unveiling the Secrets of Bangalore's Water Treatment Revolution

In the heart of Bangalore, where technology and industry converge, the need for efficient industrial water treatment solutions is paramount. The burgeoning industrial landscape in this vibrant city demands sustainable and cutting-edge solutions to address the challenges posed by water management. In this article, we delve into the significance of an Industrial Water Treatment Plant in Bangalore and how it plays a pivotal role in promoting environmental sustainability and industrial growth.

Understanding the Need for Industrial Water Treatment

The Industrial Boom in Bangalore

As Bangalore continues to solidify its position as the Silicon Valley of India, the industrial landscape has witnessed an unprecedented boom. From high-tech manufacturing units to research and development facilities, industries in Bangalore contribute significantly to the nation's economic growth. However, this rapid industrialization brings along a surge in water consumption, necessitating robust water treatment strategies.

Environmental Imperatives

With the heightened focus on environmental sustainability, industries in Bangalore are under increasing pressure to adopt eco-friendly practices. Industrial processes often generate wastewater laden with pollutants and chemicals, posing a threat to the local ecosystem. Here, the role of an Industrial Water Treatment Plant becomes indispensable in mitigating the environmental impact of industrial activities.

The Significance of Industrial Water Treatment Plants

Ensuring Compliance with Regulatory Standards

Industrial units in Bangalore are subject to stringent environmental regulations. An efficient water treatment plant ensures that industries adhere to these standards, avoiding legal complications and fostering responsible corporate citizenship.

Preserving Natural Resources

Water, being a finite resource, requires prudent management. Industrial Water Treatment Plants play a crucial role in recycling and reusing water, reducing the strain on local water sources. This not only conserves precious natural resources but also contributes to the overall sustainability of the region.

Key Features of an Effective Industrial Water Treatment Plant

Advanced Filtration Technologies

To combat the diverse range of contaminants present in industrial wastewater, state-of-the-art filtration technologies are employed. Reverse osmosis, ultrafiltration, and electro-deionization are some of the cutting-edge techniques used to ensure the purity of treated water.

Tailored Solutions for Different Industries

Every industry in Bangalore has unique water treatment requirements. An effective Industrial Water Treatment Plant recognizes these variations and offers tailored solutions. Whether it's the semiconductor industry requiring ultra-pure water or the textile industry dealing with dye effluents, the plant's adaptability is paramount.

Energy-Efficient Operations

Sustainability is not just about water quality; it also involves energy efficiency. Leading Industrial Water Treatment Plants in Bangalore incorporate energy-efficient processes, utilizing technologies like solar-powered filtration systems to minimize their carbon footprint.

Choosing the Right Industrial Water Treatment Partner

Expertise and Experience

Selecting the right partner for water treatment is critical. Look for companies with a proven track record and extensive experience in designing and operating Industrial Water Treatment Plants. Certifications and client testimonials can provide insights into the reliability and efficiency of the service provider.

Compliance with Industry Standards

Ensure that the chosen water treatment partner complies with industry standards and regulations. This not only guarantees the quality of their services but also safeguards your business against potential legal ramifications.

As industries in Bangalore continue to thrive, the role of Industrial Water Treatment Plants cannot be overstated. From environmental compliance to resource conservation, these plants contribute significantly to the sustainable growth of the region. Choosing the right water treatment partner is not just a business decision; it's a commitment to the well-being of the environment and the community. Embrace the future of industrial water treatment and pave the way for a greener and more sustainable Bangalore.

0 notes

Text

A Retrospect of the ITCPE 2023 in Guangzhou

In May 20–22, organized by Hong Kong Allallinfo Media Group, Guangzhou Allallinfo Co., Ltd., and the magazine, Textile Printing, the 2023 Guangzhou (18th) International Textile Clothing and Printing Industry Expo (ITCPE) was successfully held in Guangzhou Poly World Trade Center.

Renowned enterprises and experts are gathered at ITCPE 2023, focusing on the business opportunities of the garment and textile printing industries. In the spot, all kinds of products are dazzling: not only automatic screen printing machines, industrial digital transfer printing, and DTG equipment, but also customization solutions, digital printing consumables, and supplies, all kinds of apparel accessories, DTF solutions, embroidery and sewing machines and consumables, and so on.

Visiting Groups from Hubei Province, Anyang City of Henan Province, and Citys of Northeastern China.

The scale of the 2023 ITCPE is much bigger than the previous year. This year's event featured more than 500 quality enterprises and covered more than 3 million square feet. We successfully created a platform for industry communication and exhibition, and business negotiations between exhibitors, experts, and spectators are a common sight.

We could perceive that more than 500+ enterprises such as KINZEL Printing, Epson, Brother,ORIC, Grando, KEUNDO, PENGDA, PO-TRY, FLORA, CNDING, Zhenfeng, Success Automation, Fourstar, Machine Elements, YiliJet, Pros-view, RATEX, POMAKER, DAHAO, SINSIM, CBL, Bihong, Yuanyin Digital, MAYA, CH-JIA, YUEMEI, RICOMA, Yuchen, MyColor, BOYAN, ZHOUSURNAME, Dongguan BEST, LNXWO, XINFYING, Zhongwang, Pinyin, Aomya, Chuanghui, ZHAOSHAN, M100, HDHT, kornit-print, TIANWEI XINCAI, Xinghao, INKBANK, KUYIN, JIUH LIH, Jiangchuan, Siheda, Nuowei, HY, YIXING TIANLI, KEDO SILICON, print-pretty, Chaolun, Chuangke, Shenzhen Boyan K3, Kalos, XMAYPRINT, JYIE, Color Spring, Junao, Caiyintong, Jiechuang, Lamborink, SAN GONG, HONGSAM, XING QI LASER, SEENSUN, Dongguan Gaoshang Machinery, COLORMADE, HOOSUN, SNS, KASULASER, 91TUKU, Yuqiaofu, Duotian, Golden XT, KAIOU, Hongzhongmachinery, Fanghua Digital, INKTEC, Tianli, Sunflower, Ruiyi New Maaterials, Dayuan, Jinhui, Wuxi Luoshe twon Yang City Chengming Textile Machinery Factory., Xiuzhiyuan, Xinshanlian, Wuzhou, Fujian Jiansheng, Dongguan Zhongtian, New Image Printing, Yeren Digital, Feiyue Textile Printing Equipment Factory, Junye, ZHENYING, Xiuzhiyuan, MSO, Quanzhou Yaxin, Foshan Xinbin, Dongguan Dingjun, ALSAFETY, Jinyan, Hummberg, Rong xuan creative factory, Shuangfei, Huacai, Tianma, Shishi Jianan Hot Melt Adhesive, Jinbao, Tianying, TaicangYangfan, Senhua, Junhao, COLOR WING, Chengna Chemical, Eurolite Optical, Jianyao, WUHAN SHANGGU INDUSTRIAL DESIGN, Shengshun Machinery, Yituna, Hongdashengchang, etc in the fields of textile printing, digital printing, embroridery, apparel fabrics & accessories have participated in the ITCPE 2023.

Compared to the previous year, ITCPE 2023 has more attention and a higher conversion rate. With the termination of the pandemic, many overseas spectators came here, which instilled confidence in our textile market.

The scorching and fickle temperature did not dampen spectators’ steps. There is an endless flow of people through the exhibition even after the closing ceremony, which reflects its soaring popularity.

Throughout the exhibition site, each booth is full of popularity, and each enterprise has taken out their skills with new technology and new products to seize business opportunities. Exhibitors patiently and professionally introduced their new products to the spectators, who watched the operation of the machines, touched the texture of embroidery, and appreciated the charm of textile art.

You Can Browser the Recap of the Exhibition by Clicking:A Retrospect of ITCPE 2023_ITCPE Guangzhou_Allallinfo Media Hong Kong Group

High Contract Rates

This exhibition is fairly successful since many exhibitors received new orders on the first day, and the incessant orders were witnessed in the follow-up two days. The overall satisfaction of the exhibitor is rather high, and even large booths were preordered.

Many exhibitors told us that the ITCPE is an expert stage and they harvest fruitful contracts. They praised that it is an established exhibition; hence, they get lots of new orders, and they will continue to be the attending companies.

So far, the three-day ITCPE 2023 has come to a successful conclusion here! We'll see you at 2024, 20, March!

0 notes