#Round Bars Manufacturer in India

Text

Superior-Quality Aluminium Bronze Round Bar Manufacturer in India-Rajkrupa Metal Industries

Rajkrupa Metal Industries is one of the High Quality Aluminium Bronze Round Bar Manufacturer In India. We have emerged as the market leader in Aluminium Bronze Round Bar. Because of its superior corporate and technical people skills, Rajkrupa Metal Industries has purposefully positioned itself as a top-tier manufacturer and retailer in the global market for aluminium bronze round bars.

Our company, which manufactures with ISO 9001:2015 certification. Aluminium Bronze Round Bar Manufacturer that adheres to International Quality Standard (IQS) is one of the leading manufacturers of aluminum bronze round bars.

Aluminium Bronze Round Bar Suppliers are well-known for their excellent strength, corrosion resistance, thermal and electrical conductivity, and other properties. We are also the leading Round bars manufacturer in India.

Product Source : Aluminium Bronze Round Bar Manufacturers in India

Website: rajkrupametal.com

#Aluminium Bronze Round Bar#Aluminium Bronze Round Bar Manufacturer#Aluminium Bronze Round Bar Manufacturer in India#Aluminium Bronze Round Bar Suppliers#Round bars manufacturer in India

0 notes

Text

ASTM A453 Grade 660 Class A Round Bar: Fueling the Automotive Industry

The automotive industry is constantly evolving, driven by innovations in materials and technologies. Among the key components shaping this evolution is ASTM A453 Grade 660 Class A Round Bar. Neptune Alloys provides alloy steel bars that plays a pivotal role in fueling the automotive industry's growth and advancement. We also offer Alloy A286 Round Bar.

Properties of ASTM A453 Grade 660 Class A Round Bar

ASTM A453 Grade 660 Class A Round Bar boasts remarkable properties that make it indispensable in automotive engineering. With high tensile strength, superior durability, and resistance to corrosion, this material ensures optimal performance and longevity in automotive applications. Additionally, its temperature stability enables it to withstand the demanding conditions within vehicle systems.

Applications in Automotive Engineering

In the realm of automotive engineering, ASTM A453 Grade 660 Class A Round Bar finds widespread usage across various components. From engine parts to suspension systems and drive shafts, this versatile material contributes to the structural integrity and functionality of vehicles. Its robustness enhances the performance and reliability of automotive systems, ensuring smooth operation and longevity. We are also a Monel 400 Round Bar Supplier.

The adoption of ASTM A453 Grade 660 Class A round bar supplier in India offers numerous advantages to automotive manufacturers. By incorporating this high-quality material into their designs, manufacturers can achieve improved performance, enhanced safety, and cost-effectiveness in production. The superior properties of ASTM A453 Grade 660 Class A Round Bar translate into vehicles that are not only more durable but also more efficient and safer on the road.

Challenges and Solutions

While ASTM A453 Grade 660 Class A Round Bar Supplier offers unparalleled benefits, its adoption in the automotive industry is not without challenges. Cost considerations and supply chain management issues may pose hurdles for manufacturers. However, innovative approaches to material sourcing and production can help mitigate these challenges, ensuring a seamless integration of ASTM A453 Grade 660 Class A Round Bar into automotive manufacturing processes.

Looking ahead, the future of ASTM A453 Grade 660 Class A Round Bar Manufacturer in the automotive industry is promising. Continued advancements in material science will unlock new possibilities for enhancing its properties and expanding its applications. Moreover, the integration of new technologies, such as additive manufacturing and smart materials, will further elevate the role of ASTM A453 Grade 660 Class A Round Bar in shaping the future of automotive engineering.

Affordable ASTM A453 Grade 660 Class A Round Bar Solutions.

Consider the ASTM A453 Grade 660 Class A round bar supplier in India. Neptune alloys These round bars, known for their high tensile strength and corrosion resistance, provide durability at a reasonable price. With vendors offering a wide selection of sizes and requirements, enterprises can discover the ideal solution for their needs without breaking the bank. Invest in ASTM A453 Grade 660 Class A Round Bar options that will provide long-term value and performance while remaining within your budget.

When it comes to industrial requirements, cost and quality are essential. ASTM A453 Grade 660 Class A Round Bar Supplier provides durability at a low price. Businesses may rely on these round bars for important applications since their suppliers are committed to client satisfaction and consistency in quality.

Also visit Round Bar Weight Chart in mm kg Ft and Inconel 625 Round Bar Supplier in India.

In conclusion, ASTM A453 Grade 660 Class A Round Bar serves as a cornerstone in the automotive industry, offering unmatched strength, durability, and performance. Its widespread adoption across automotive engineering and manufacturing underscores its pivotal role in driving innovation and progress. As the automotive industry continues to evolve, ASTM A453 Grade 660 Class A Round Bar remains at the forefront, fueling advancements and shaping the vehicles of tomorrow.

0 notes

Text

A286 Round Bars: Meeting Demanding Engineering Requirements

When it comes to high-temperature applications, finding the right material that can withstand extreme conditions can be a challenge. This is where A286 Round Bars come into play. These bars are known for their exceptional strength, durability, and corrosion resistance, making them an ideal choice for applications that require reliable performance under harsh conditions.

In this article, we'll explore the benefits of A286 Round Bars and why they're an excellent choice for demanding engineering requirements. We'll also answer some frequently asked questions about these bars to help you make an informed decision for your next project.

What Are A286 Round Bars?

A286 Round Bars are a type of stainless steel alloy that is known for its excellent high-temperature properties. This alloy contains nickel, chromium, and molybdenum, which provides it with superior strength and resistance to oxidation and corrosion.

The A286 Round Bars are typically used in applications that require high strength and toughness, such as jet engine components, gas turbines, and other high-temperature applications. They are also used in the manufacturing of fasteners, bolts, and screws.

Benefits of A286 Round Bars

High-Temperature Resistance: One of the primary benefits of A286 Round Bars is their ability to withstand high temperatures. They can operate at temperatures up to 1300°F (704°C) without losing their mechanical properties, making them ideal for applications that require high strength and toughness.

Corrosion Resistance: A286 Round Bars have excellent corrosion resistance properties, which makes them suitable for use in harsh environments. They are highly resistant to corrosion from acids, alkalis, and saltwater.

Strength and Durability: A286 Round Bars are known for their exceptional strength and durability. They have high tensile strength and are resistant to deformation and breakage, even under high loads.

Easy to Machine: Despite their excellent strength and toughness, A286 Round Bars are relatively easy to machine. They can be machined using conventional methods, including drilling, turning, and milling.

Weldability: A286 Round Bars can be welded using conventional methods, making them ideal for applications that require welding.

Applications of A286 Round Bars

A286 Round Bars are used in a wide range of applications, including:

Aerospace components

Jet engine components

Gas turbines

Fasteners, bolts, and screws

Chemical and petrochemical processing equipment

Power generation equipment

These bars offer exceptional mechanical properties, making them ideal for use in aerospace, power generation, and chemical processing equipment. If you're looking for a reliable material that can withstand harsh environments, A286 Round Bars are definitely worth considering.

In addition to their high-temperature resistance, A286 Round Bars also offer excellent corrosion resistance. This is due to their high nickel and chromium content, which forms a passive oxide layer on the surface of the bars that protects against corrosion. This makes A286 Round Bars an ideal choice for use in harsh environments where other materials might fail.

Furthermore, Alloy A286 Round Bars are known for their strength and durability. They have a high tensile strength and are resistant to deformation and breakage, even under high loads. This makes them an ideal choice for use in critical applications where reliability is a top priority.

Despite their exceptional strength and toughness, A286 Round Bars are relatively easy to machine using conventional methods. This makes them an ideal choice for use in manufacturing fasteners, bolts, and screws. Additionally, A286 Round Bars can be welded using conventional methods, which makes them suitable for applications that require welding.

In conclusion, A286 Round Bars are a reliable and versatile material that can withstand harsh environments and demanding engineering requirements. They offer exceptional high-temperature resistance, corrosion resistance, strength, and durability, making them an ideal choice for a wide range of applications. If you're looking for a material that can improve the performance of your machinery and increase its lifespan, A286 Round Bars are definitely worth considering.

Frequently Asked Questions

Q: What makes A286 Round Bars ideal for high-temperature applications?

A: A286 Round Bars are made from a stainless steel alloy that contains nickel, chromium, and molybdenum, which provides them with exceptional high-temperature resistance, strength, and durability.

Q: What is the maximum temperature that A286 Round Bars can withstand?

A: A286 Round Bars can operate at temperatures up to 1300°F (704°C) without losing their mechanical properties.

Q: Are A286 Round Bars easy to a machine?

A: Despite their exceptional strength and toughness, A286 Round Bars are relatively easy to machine using conventional methods.

#alloy#alloy steel#alloy bars#metal industrial#stainless steel#architecture#construction#buildings#steel bars#round bars#round bar supplier#round bar manufacturer#round bars manufacturer in india#Steel Bars Price#A286 Hex Bars#A286 Flat Bar#A286 hallow bars#a286 square bar#Stainless Steel 1.4980 Bars#AISI A286 Round Bars#Industrial Steel Round Bars#ASTM B473 Round Bars

1 note

·

View note

Text

High Quality Round Bars Manufacturer in India

in India

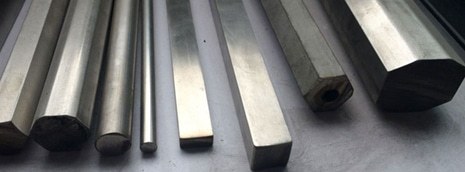

Timex Metals is known as one of the biggest Round Bars Manufacturer in India. We offer one of the finest qualities Stainless Steel Round Bars to various industries around the globe. Our Round Bars range from 15 mm to 400 mm and are provided in different conditions like Hot Rolled Round Bars, Annealed Round Bars and Pickled Round Bars. Round Bars are also known as SS Round Bars, Monel Round Bars, Inconel Round Bar, Nitronic Round Bars manufacturer in India.

For more details;

Website: timexmetals.com

Source: Round Bars Manufacturer

Email: [email protected]

Call: +91 76668 59511

1 note

·

View note

Text

Crafting Precision: Exploring the World of Stainless Steel Round Bars

Introduction to Stainless Steel Round Bars

Among the numerous kinds of industrial materials currently in the market, stainless steel round bars are particularly outstanding due to their versatility and capacity for strength and corrosion. These characteristics make them important in a wide range of industries, including construction, automotive, medical, and maritime applications. An investigation of the characterstics of crafting process shall involve stainless steel bar. carfting is one the best method in which its work very smoothly. concreting process is commonly seen in construction works. This article mainly go to the detectable way and help to work in easy way and quick.

Uses of Stainless Steel Round Bars

Construction and Architecture

Because of its strength, beauty, and ability to withstand weathering, stainless steel round bars are widely utilised in the construction sector. By using Architecture methods it can be easy to analyze the product. Their contribution is vital, in constructing buildings, bridges and various infrastructure projects. The ability to withstand conditions ensures their strength and longevity.

Automotive Industry

It is a automated machinery instruments which work in machinery way. In the sector various parts, like axles, bolts and engine components are crafted from stainless steel bars. These materials excel in applications that demand reliability and top notch performance due, to their durability and resistance to wear.

Medical Devices

In the field of medicine surgical instruments orthopedic implants and various medical devices are crafted from stainless steel bars. These materials are well suited for critical healthcare uses because of their ability to be sterilized without losing their quality and their compatibility, with the body.

The Crafting Process:

1. Choice of Raw Materials:

In the stage of the process one should opt for quality stainless steel. The specific application will dictate the choice of steel alloy with popular options being 304, 316 and 410 grades. common grades include 304, 316, and 410. Specific qualities like stronger corrosion resistance, better machinability, or higher strength are offered by each grade.

2. Pouring and Pouring Melt:

In an electric arc furnace, the chosen raw materials are melted at extremely high temperatures. This method ensures that the alloy composition remains consistent. The process involves melting steel and shaping it into finished forms, like slabs, billets or blooms.

3. Hot Rolling: The cast steel is put through rolling mills and heated above its recrystallization temperature during the hot rolling process. In this process, the steel is shaped into a rough cylindrical shape and its thickness is decreased.

4.Heat Treatment Process; The rolled bars undergo annealing to enhance their flexibility and reduce their toughness. In this procedure the steel is heated to a temperature. Then slowly cooled down. Moreover annealing helps in relieving stresses in the material.

5. Precision Rolling: To obtain the required diameter and surface finish, the bars are subjected to precision rolling or drawing after annealing. By taking this process, the round bars are guaranteed to meet strict criteria for surface quality and dimensional tolerances.

6. Cutting and Finishing: Depending on the needs of the ultimate use, the lengthy steel rods are cut into predetermined lengths and go through a variety of finishing procedures, including grinding, polishing, or coating. The circular bars get their distinctive glossy, smooth look from this process.

Conclusion

Round stainless steel bars are proof of the strength of expert engineering and fine craftsmanship. From raw material to essential industrial component, they go through a number of carefully regulated procedures, each of which adds to their remarkable qualities. The use of stainless steel round bars in aerospace, automotive, medical, and construction applications is still essential to the advancement of contemporary industry. These extraordinary materials will become even more important and versatile as production methods and technology advance.

#copper sheet manufacturers in india#stainless steel round bar manufacturers in india#stainless steel sheet#ss round bar manufacturer in india

0 notes

Text

Stainless Steel S32750 Forged Round Bars Exporters In India

#Duplex Stainless Steel S32750 Forged Round Bars Manufacturers#Duplex Stainless Steel S32750 Forged Round Bars Suppliers#Duplex Stainless Steel S32750 Forged Round Bars Stockists#Duplex Stainless Steel S32750 Forged Round Bars Exporters#Duplex Stainless Steel S32750 Forged Round Bars Manufacturers In India#Duplex Stainless Steel S32750 Forged Round Bars Suppliers In India#Duplex Stainless Steel S32750 Forged Round Bars Stockists In India#Duplex Stainless Steel S32750 Forged Round Bars Exporters In India

0 notes

Text

How Do I Maintain a Round Bar for Longevity?

Shashwat Stainless Inc. is the largest Round Bars Manufacturers in India. One of our popular products in the Metal Market is Round Bars. Round bars, also known as rods or solid bars, are cylindrical metal rods usually composed of stainless steel, aluminum, or brass. When it comes to extending the life of round bars, proper care is essential. Round bars, which are often used in many sectors for structural support, machining, and fabrication, require special care to retain their quality and durability over time. In this detailed article, we'll look at the most important strategies for keeping round bars looking good for a long time.

Understanding Round Bars

Round bars are cylindrical metal bars having a circular cross-section. They are often referred to as round steel bars or rods. They are used in many different sectors, including aerospace, automotive, manufacturing, and construction. They are often composed of carbon steel, stainless steel, or alloy steel.

Proper Handling and Storage

Proper handling and storage of round bars is one of the most important aspects impacting their lifetime. To avoid damage and corrosion, round bars must be handled carefully during shipping and storage. Here are some important considerations:

Handling:

Make sure round bars are securely fastened when being transported to avoid rolling or moving.

To properly handle big bars, use the proper lifting equipment, such as cranes or forklifts.

Steer clear of falling or hitting the bars as this may result in surface deformation or damage.

Storage:

To reduce the danger of corrosion, store round bars in a clean, dry environment.

To avoid moisture absorption, keep the bars elevated using pallets or racks.

Protect the bars against harsh factors including high temperatures, humidity, and corrosive chemicals.

Regular Inspection and Maintenance

Routine inspection and maintenance are essential for identifying any signs of damage or deterioration early on and addressing them promptly. Here's what you should include in your maintenance routine:

Visual Inspection:

Regularly inspect round bars for signs of surface damage, such as scratches, dents, or rust.

Check for any cracks, fractures, or other structural issues that may compromise the integrity of the bars.

Pay attention to any changes in appearance or dimensions that could indicate wear or corrosion.

Cleaning and Lubrication:

Clean round bars regularly using a mild detergent and water to remove dirt, debris, and surface contaminants.

Dry the bars thoroughly after cleaning to prevent moisture buildup.

Apply a thin layer of lubricant, such as oil or grease, to protect the surface and reduce friction during machining or fabrication processes.

Corrosion Protection:

Implement corrosion protection measures, such as applying rust inhibitors or coatings, to safeguard round bars from environmental corrosion.

Monitor the effectiveness of corrosion protection methods and reapply as necessary to maintain optimal protection.

Proper Machining and Fabrication Practices

It's critical to adhere to standard practices while machining or fabrication round bars in order to reduce stress and avoid damage. Here are some pointers to think about:

Cutting and Drilling:

Use proper cutting tools and procedures to reduce heat generation and prevent the material from overheating.

Use suitable coolant systems to disperse heat and lubricate cutting surfaces during drilling or milling operations.

Choose modest and steady cutting rates to avoid excessive friction and vibration, which can cause surface damage.

Welding and Joining:

Adhere to the specified welding processes and guidelines to guarantee correct fusion and reduce the possibility of weld imperfections.

To lessen thermal loads and avoid cracking during welding, preheat the round bars as needed.

Without sacrificing the integrity of the bars, create strong and long-lasting weld connections by using suitable filler metals and welding procedures.

Conclusion

Maintaining round bars for longevity requires a proactive approach that includes proper handling, storage, inspection, and maintenance practices. By following the tips outlined in this guide, you can ensure that your round bars remain in optimal condition, providing reliable performance for your applications.

Follow For More Detail

Website: shashwatstainless.com

Product Source: Round Bar Supplier in India

Other Product Source: Nickel Alloy Seamless Pipe Manufacturer in India.

0 notes

Text

Sankalp Alloys Overseas figured as unmistakable provider, exporter and producer of Incoloy 825 Round Bars among our supporters. These Incoloy 825 Bars (UNS N08825) are much of the time utilized in Substance Handling, Contamination control, Oil and gas well channeling, atomic fuel going back over, and that's just the beginning. Amalgam 825 Round Bars are additionally utilized in phosphoric corrosive evaporators; pickling-tank warmer, pickling snares and hardware; substance process gear; tank trucks; propeller screws, and spent atomic fuel component recuperation.

#Incoloy 825 Round Bars Manufacturers#Incoloy 825 Round Bars Suppliers#Incoloy 825 Round Bars Stockists#Incoloy 825 Round Bars Exporters#Incoloy 825 Round Bars Manufacturers in India

0 notes

Text

Top Quality Round Bar Manufacturer in India - United Stainless LLP

United Stainless LLP is a reputable Round Bar Manufacturer in India. Round bars are long, thick, cylindrical bars with circular bases. Round bars are available in various sizes, ranging from 1/4 inch to 2 inches in diameter. The bar size depends on the specific use, with larger bars used for heavier applications or when more strength is needed. The standard lengths for round bars are 36 inches, 48 inches, and 60 inches. However, custom sizes can also be ordered upon request. We are also a well known Round Bar Supplier in India.

We have created a name for ourselves as a trustworthy Round Bar Manufacturers. They are pre-finished metal products that find diverse uses in industries and businesses. Furthermore, their low maintenance and long-term durability make them a popular choice. We supply a comprehensive selection of Round Bars in various sizes and grades to meet national and international quality standards.

Product: Round Bar Suppliers

Website: unitedstainlessllp.com

0 notes

Text

Premium-Quality Round Bars Manufacturer in India-Rajkrupa Metal Industries

Rajkrupa Metal Industries is a leading Round Bars Manufacturers in India. We have established ourselves as one of India's Top names in the Round Bars sector. With significant commercial and technical personnel skills, Rajkrupa Metal Industries has strategically positioned itself as a top-tier manufacturer and supplier in the global Round Bars business.

We provide diverse sectors with a large volume and variety of Round Bars. We have been named one of India's top Round Bar manufacturer for our ability to handle the rising demand for Round Bars while also creating high-quality Round Bars products.

We are also one of the Top Quality Aluminium Bronze Round Bar Manufacturer In India. We have established ourselves as one of the leading names in the Aluminium Bronze Round Bar market. Aluminium Bronze Round Bar Suppliers are well-known for their high strength, resistance to corrosion, thermal and electrical conductivity, and other qualities.

Website: rajkrupametal.com

Source: Round Bars Manufacturer in India

#Round Bars Manufacturer in India#Round Bars Manufacturer#Round Bars#Aluminium Bronze Round Bar Manufacturer In India#Aluminium Bronze Round Bar#Aluminium Bronze Round Bar Suppliers

0 notes

Text

Top 4 Round Bar Manufacturers in India

Round Bars are versatile Cylindrical Metal Bars that are known for their Strength, Durability, and Wide Range of Applications across Industries. This Guide will provide you an insight into the world of Round Bars, Exploring their Uses, and Features, and Explore the Top Round Bars Manufacturers in India for Quality Products and Solutions. Find Trusted Manufacturers for Quality Round Bars for Diverse Industries who are known for their Quality Products and Services. Whether you’re in Construction, Manufacturing, or Engineering, choosing the Right Round Bar Manufacturer is crucial for ensuring the success of your Projects. Join us, as we Navigate through the Top Manufacturers like Sahyog Steels in the Industry and Uncover the Key Factors to Consider when Selecting Round Bar Suppliers.

What are Round Bars and their Uses?

Round Bars which are also known as Round Rods or Solid Bars, are Cylindrical Metal Bars which are characterized by their Circular Cross-Section. They are usually made from Materials like Stainless Steel, Alloy Steel, Carbon Steel, and Various Specialty Metals. Round Bars are widely utilized across Industries due to their Versatility, Strength, and Excellent Machinability.

Key Uses of Round Bars:

Construction

In the Construction Industry, Round Bars are used extensively for Structural Support, Reinforcement, and Fabrication of Frameworks, Columns, and Beams. Their Robustness and Ability to withstand Heavy Loads make them essential in Building Infrastructure.

Manufacturing

In the Manufacturing Sector, Round Bars serve Diverse Applications which include Machinery Components, Tooling, Shafts, Axles, and Fasteners. Their Uniform Shape and Consistent Mechanical Properties make them Ideal for Machining, Forging, and Welding Processes.

Engineering

In the Engineering Industry, Round Bars play a crucial role in various Engineering Applications, such as Automotive Parts, Aerospace Components, and Precision Instruments. Round Bars provide the essential Structural Integrity, Durability, and Dimensional Accuracy which is required for Critical Engineering Systems.

Industrial Equipment

Round Bars are widely used in Various Industrial Equipment which include Conveyors, Rollers, Gears, and Hydraulic Systems. Round Bar’s Reliability and Versatility make them suitable for withstanding Harsh Operating Conditions and ensure a smooth Operation of Machinery.

Decorative and Architectural Applications

Round Bars are also utilized in Decorative and Architectural Applications, such as Railing Systems, Ornamental Gates, and Furniture Designs. Their Aesthetic Appeal combined with their Strength and Durability, adds a Touch of Elegance to Architectural Structures.

Features of Round Bars

Round Bars boast several features which make them essential across various Industries. Understanding these Key Features is essential for Selecting the right Round Bars for specific Applications.

Strength and Durability

The Primary Characteristics of Round Bars are their Exceptional Strength and Durability. Round Bars are made from Materials like Stainless Steel, Alloy Steel, and Carbon Steel. Round Bars offer Robustness and Resilience which ensures Reliable Performance even in Demanding Environments.

Versatility

Round Bars are Incredibly Versatile which makes them suitable for a Wide Range of Applications in Construction, Manufacturing, Engineering, and many more. Their Cylindrical Shape and Uniform Cross-Section make them Adaptable to Diverse Requirements.

Machinability

Round bars are known for their excellent Machinability, making them easy to Cut, Drill, Mill, and Modify it into Desired Shapes and Sizes. This Feature makes it more suitable for Fabrication and Customization, according to Specific Project needs.

Corrosion Resistance

There are certain types of Round Bars like Stainless Steel Round Bars, they have a much higher Resistance to Corrosion, Rust, and Degradation, and they will survive even in Harsh Environmental Conditions. The Corrosion Resistance makes their Lifespan Larger and ensures Long-Term Performance.

Heat Treatment Compatibility

Round Bars are often Heat-Treated which allows them to enhance their Mechanical Properties, such as Hardness, Strength, and Toughness. This feature enables the Customization of Round Bars to meet Specific Performance Criteria for Different Applications.

Dimensional Accuracy

Round Bars are Manufactured with Precise Dimensional Tolerances which ensure Uniformity and Consistency in their Diameter, Length, and Straightness. This Dimensional Accuracy makes it easy to integrate Round Bars into various Systems and Minimizes Machining Requirements.

Cost-Effectiveness

Despite their High Performance and Durability, Round Bars offer Cost-Effective Solutions for a Wide Range of Applications. Features like Long Lifespan, Minimal Maintenance Requirements, and Recyclability contribute to their Overall Cost-Effectiveness.

Top 4 Round Bar Manufacturers in India

Sahyog Steels

Sahyog Steel India has rapidly emerged as one of India’s foremost Exporters of Stainless Steel. With the ISO 9001:2008 Certification, we were always Committed to Delivering Unparalleled Quality and Service to Clients Globally. We take pride in providing a Comprehensive Range of Stainless Steel, Aluminium, and many more Goods through which we cater to the diverse needs of our Global Clientele. We have a Clear and Unwavering mission to Become the Leader in our Market in offering High-Quality, Value-Added Goods, and Innovative Technologies, we maintain a firm Dedication to Ethical Business Practices and Core Values.

Fortran Steel

Fortran Steels have emerged as a Leading Manufacturer of Hot Rolled and Structural Steel Products they are driven by a commitment to Excellence and Customer Satisfaction. They Prioritize Customer-Centric Manufacturing Processes, Utilizing World-Class Raw Materials and Giving Global quality Standards Through their Production Procedures. They offer a wide range of Hot Rolled and Structural Steel Products which include Square Bars, Flat Bars, Round Bars, Hex Bars, and many more.Top of Form

Kisco Steels

Khanna Iron and Steel Corporation (KISCO) has emerged as a Leading Manufacturer for their Excellence in the Steel Industry. With a Strong Foundation, and their values of Integrity, Reliability, and Excellence, they have achieved a reputation for Delivering High-Quality Steel Products to their Customers across the Globe. With ISO Certifications for Quality Management, Environmental Management, and Occupational Health and Safety, KISCO continues to grow in the industry with its Cutting Edge Technology, Strict Production Processes, and Unwavering Dedication to Delivering Reliable Products with Trust and Commitment.Top of Form

Timex Metals

Timex Metals is one of the Premier Manufacturers and Suppliers of Round Bars, Wire Mesh, Fasteners, SS Column Pipe Adapters, Wire Rods, Shaft Sleeves Pumps, and SS Manhole Covers in India. Their mission always revolves around Nurturing Long-Term Relationships by Delivering Superior Workmanship, Efficient Manufacturing, and Unparalleled Customer Satisfaction.

FAQs

What are Round Bars used for?

Round Bars are Utilized in Various Industries such as Construction, Manufacturing, Engineering, and Architecture for Structural Support, Machinery Components, Architectural Aesthetics, and Many More.

What materials are Round Bars made from?

Round Bars are commonly made from materials like Stainless Steel, Alloy Steel, Carbon Steel, and Specialty Metals to meet Specific Application Requirements.

What are the Key Features of Round Bars?

The Key Features of Round Bars include Exceptional Strength and Durability, Versatility, Excellent Machinability, Corrosion Resistance, Heat Treatment Compatibility, Dimensional Accuracy, and Cost-Effectiveness.

Who are the Top Round Bar Manufacturers in India?

The List of Top Round Bar Manufacturers in India includes names like Sahyog Steels, Fortran Steel, Kisco Steels, and Timex Metals.

How do I Select the Right Round Bar Manufacturer?

Ans. When Selecting a Round Bar Manufacturer, consider the following factors which include the Company’s Reputation for Quality and Service, Regulations followed according to Industry Standards, the Range of Products Offered, Technological Capabilities, and Customer Reviews.

Conclusion

In Conclusion, Round Bars stand as Essential Components across Diverse Industries, Offering Strength, Durability, and Versatility for Various Applications. With a Large Numbers of Manufacturers in India, it’s Crucial to Partner with a Reputable Supplier like Sahyog Steels which is known for Delivering High-Quality Products and Exceptional Service. From Construction to Engineering, Selecting the Right Round Bar Manufacturer is crucial for ensuring Project Success and Longevity. By Understanding the Uses, Features, and Top Manufacturers which are highlighted in this Guide, the Users can make Informed Decisions to meet their Specific Requirements and they can achieve Excellence in their Projects.

#Round Bar Manufacturers in India#Top Round Bar Manufacturers in India#Best Round Bar Manufacturers in India

0 notes

Text

Leading Manufacturer and Supplier of Round Bars in India - Timex Metals

Timex Metals is known as one of the biggest Round Bars Manufacturer in India as well as Stainless Steel 316 Wires Rods Manufacturer in India. We offer one of the finest qualities Stainless Steel Round Bars to various industries around the globe.Our Round Bars are available in a variety of sizes ranging from 15 mm to 400 mm and in a variety of finishes including Hot Rolled Round Bars, Annealed Round Bars, and Pickled Round Bars. In India, Round Bars are also known as SS Round Bars, Monel Round Bars, Inconel Round Bars, and Nitronic Round Bars.

For more details;

Website: https://timexmetals.com

Source: Round Bars Manufacturer

Email: [email protected]

0 notes

Text

Applications and Uses of Stainless Steel in Automotive Industry

Did You Know?

45 to 50% of automotive exhaust systems are made of stainless steel.

Probably, we all are aware of establishing uses of stainless steel in different industries as per their required proportions but at Automotives behind the scenes are quite different, as you read the fact – the ratio of stainless steel is quite higher than other applicants of stainless steel.

So, is it bad/good that Automotives have adopted stainless steel? And if yes, what characteristics of stainless steel made the automotive industry to adapt this higher ratio? Let’s get on to answering step-by-step, when it comes to automotive there are several requirements that need to be fulfilled including a lightweight yet safer experience, environmental-friendly, and affordability.

Now steel can also deliver those segments so why stainless steel and not just steel for automotive, forgot!? “RUST” can easily eat away the whole engine compartment, can weaken exhaust system mounts, and be able to create air leaks.

Whereas stainless steel offers tremendous corrosion resistance, a wide yield strength range, and a lighter weight that apparently reduces vehicles’ weight and benefits in greater fuel efficiency and machinability rephrasing the whole thing into a reduced amount of CO2 emissions.

Thus, after these long checkmarks of benefits, stainless steel offers an environmentally-friendly approach too. Things are turning informative, then why not dig into some more of it? Come let’s do it together.

Role of Stainless Steel Used in Automotive Industry

Since the 1930s, the average count of 15 to 22 kilos of stainless steel gets used in a single car which was mainly found in the exhaust system and sundry small parts.

In today’s date uses of stainless steel in automotive are also extended to other automotive applications such as fasteners, springs, and tubing, as well as brackets, flanges, substructures, and panels.

At younger ages, the cost of wielding was more expensive than now as the years passed by – stainless steel types such as austenitic, martensitic, ferritic, and many other stainless steels were discovered.

From all these stainless steel categories austenitic stainless steel became ideal to use for the automotive industry due to its easy welding and long durability.

{Additional Information on Exhaust Systems: Where we saw the central importance of stainless steel in exhaust systems, we might forget the role of its valves that perform opening and closing operation that controls the gas flow and optimize the engine-back pressure enabling exhaust systems to provide improved performance and auditory control.

These exhaust valves get manufactured from bright bars – in different shapes such as square, round, or hex and with particular grades as per the requirement.}

To Read Full Blog : Applications and Uses of Stainless Steel

#stainless steel#stainless steel bars#stainless steel bright bars#stainless steel grades#stainless steel wire#steel bar manufacturer#bright round bar#stainless steel manufacturers in india#bright bar manufacturers

0 notes

Text

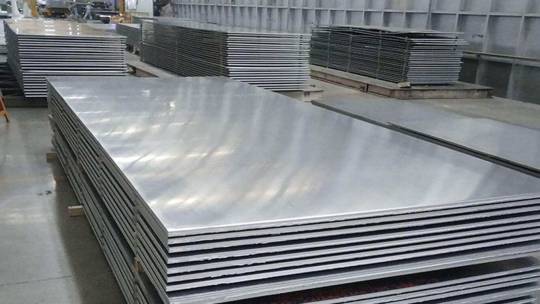

The Role of Stainless Steel Plates in the Automotive Industry

Applications in the automotive industry are to construct cars with the use of stainless steel plates as raw materials because of strength and beauty. From the exhaust systems to panels of the vehicle body, stainless steel is established as a key component in today’s vehicle manufacture. Now, it is high time to find out what cars are fitted with stainless steel plates and why these products are so valuable..Hans Metal India is an enormous Stainless Steel Round Bar Manufacturer in India and Stainless Steel Plate Manufacturer in India

Why Stainless Steel?

It is also common to use in various industries more so this one because it does not rust, it is strong enough and was aesthetically pleasing. It also makes sense that in cars, in particular, these qualities can be crucial. undefined a top supplier Stainless Steel Sheet Manufacturer in India and Round Bar Suppliers in UAE.

Corrosion Resistance: It is noted that the utilization of stainless steel has an advantage over other materials since it does not rust especially when used in areas that are a bit exposed to the hard environment.

Strength: It provides just enough added integrity to the several components without a huge increase in weight.

Aesthetic Appeal: The shine of the stainless steel, especially when used in cars, enhances the beauty of the car and thus using this product increases the viability of the car.Products: SS Round Bar Manufacturer in India and Copper Sheet Manufacturers in India

Recyclability: This makes the use of stainless steel having a high demand since it is fully recyclable which is an advantage to nature.

Key Uses of Stainless Steel Plates in Cars

1. Exhaust Systems

Corrosion being a major aspect of most constructions, materials that have high resistance to it are highly recommended for use in constructions thus making Stainless Steel a great product for construction due to its ability to withstand corrosion.

2. Body Panels and Structural Components

Durability and Weight Reduction

One very important feature of using stainless steel as exhaust system material is that it can handle high temperatures resulting from the exhaust gases and is also resistant to corrosion from such things as road salts. For this reason, the exhaust system ends up being more durable and high performing than when fabricated from traditional materials.

3. Fuel Tanks

Long-Lasting and Safe

The stainless steel fuel tank itself ages better than other types of tank material, as it will not rust from both fuel and the environment.

4. Trim and Decorative Parts

Aesthetic and Low Maintenance

This gives your vehicle a metallic shiny look that is why it is widely used in trim and other decorative parts like grille and emblems. However, Swarovski crystal remains shiny and fresh without much effort to preserve the look of the ornament.

5. Engine Components

Heat and Wear Resistance

In the engine, components manufactured from stainless steel are utilized so that they can withstand high temperatures and pressure, thereby diminishing worn out of such parts.

Common Stainless Steel Grades Employed in Automobile Sector

304 Stainless Steel: It is mostly used for trim and decorative purposes mainly because of its good corrosion resistance and workability.

409 Stainless Steel: Often found in exhaust systems intended to be cheaper, more resistant to corrosion and heat.

430 Stainless Steel: Available in those applications that demand moderate resistance to corrosion and some degree of formability as in the case of trim and paneling.

316 Stainless Steel: It is commonly employed for those parts of the equipment which need higher degree of protection against the corrosion and pitting particularly in marine environment.

Future Trends

Stainless steel has worked just as well and is likely to be integrated into automobiles as demand increases in the future. Advanced classes and standard packages are being introduced in the lavs that increase the reliability, safety, and efficiency of cars. With manufacturers doing all they can to design and produce automobiles that are fuel efficient and emit low levels of pollution, stainless steel is set to remain a defining feature for automobiles.

Conclusion

Stainless steel plates form the basis of automotive industries benefiting the product through aspects such as durability, safety, and outlook. Regardless of the specific use, such as the frame of the car or around the engine, stainless steel is an important material that contributes towards enhanced and stylish vehicle performance. It is for this reason that the readers can agree with me that rating of stainless steel usage on the future cars will improve as we advance in technology.

#Stainless Steel Round Bar Manufacturer in India#Stainless Steel Sheet Manufacturer in India#Round Bar Suppliers in UAE#SS Round Bar Manufacturer in India#Copper Sheet Manufacturers in India#Round Bar Manufacturer in Mumbai#Round Bar suppliers in Saudi Arabia

0 notes

Text

#SMO 254 Round Bars Manufacturers#SMO 254 Round Bars Suppliers#SMO 254 Round Bars Stockists#SMO 254 Round Bars Exporters#SMO 254 Round Bars Manufacturers In India#SMO 254 Round Bars Suppliers In India#SMO 254 Round Bars Stockists In India#SMO 254 Round Bars Exporters In India

0 notes

Text

The Top Round Bar Manufacturers in India

Shashwat Stainless is the top Round Bar Manufacturer in India. One such critical component is the round bar, a versatile cylindrical piece that has a wide range of applications. In India, the market for round bars is growing, with various manufacturers contending for attention. In this context, choosing a reliable and reputable manufacturer is vital to ensuring the quality and lifespan of your products. This post will go extensively into the world of Indian round bar manufacturers, highlighting the top rivals in the market and going over the key factors to take into account.

Round bars are used as core pieces in many projects, and they provide several benefits. These cylindrical marvels are essential in a variety of applications, providing structural support as well as aesthetic appeal.

We showcase well-known round bar manufacturers in India and draw attention to their commitment to quality, innovation, and customer satisfaction in an attempt to always improve. These businesses, which include both established titans and rising stars, set the standard for conventions in the field.

We are the best Round Bar Manufacturer in India, In Round Bar Varieties, We are leading Duplex Steel F53 Round Bars Manufacturers and Duplex Steel 2205 Round Bars Manufacturers.

For more details:

Website: shashwatstainless.com

Visit: Round Bar Suppliers in India.

0 notes