#Reverse Engineering Services in India

Text

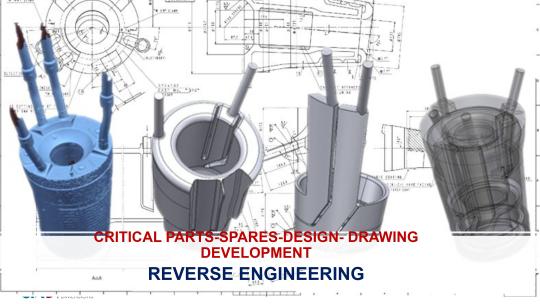

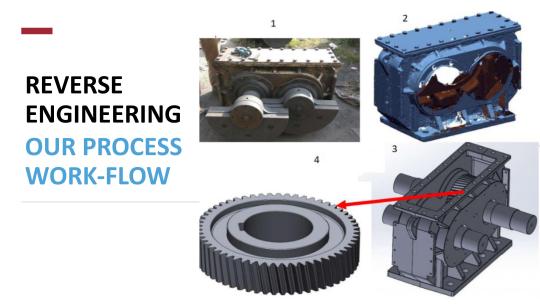

Reverse Engineering Services in India

With our reverse engineering services accelerate your product development process and streamline your processes at an affordable price by partnering with SixD India.

https://sixdindia.com/reverse-engineering/

#Reverse Engineering#Laser Scanners solutions in India#Laser Scanners solutions in noida#Reverse Engineering Services#reverse engineering services in Gurgaon#Reverse Engineering Services in Delhi#reverse engineering services in Noida Sector 62#reverse engineering services in Noida#reverse engineering services in india

0 notes

Text

The result is that industrialization, development, and massive income growth in East Asia has statistically “compensated” for stagnation almost everywhere else—with East Asian industrialization partly responsible for the loss of other countries’ manufacturing bases. This has been the case even as incomes have risen in most of the poor world, mainly on account of the 2000–15 commodity supercycle driven in part by the explosive growth in demand from the Chinese market—which, ironically, helped lock emerging markets into low-tech, undiversified export profiles. Asian success, in short, has obscured a bleaker picture in the rest of the world.

Most emerging markets have not found an engine of durable growth comparable to manufacturing—most have indeed grown over the last few decades, but dependence on services and commodities exports has not made them rich. Thus most “developing” countries—we are skeptical of that euphemistic label—are in a worse structural position than they were a few decades ago: less economically complex and more socially unstable, with their developmental coalitions, if they ever existed, badly frayed. For all the intermittent hype around “rising India” or “rising Africa,” systemic dynamics—deindustrialization, ecological disruption, demographic headwinds—will pose severe challenges to economic development over the coming decades. New waves of industrialization and meaningful development are unlikely in these parts of the world. From the perspective of poverty statistics, Africa will assume particular importance: by far the continent with the worst economic performance over the last several decades, it is there that the most significant population growth will occur over the next century. The result, pending dramatic change, is a world in which the progress made against poverty over the last forty years will slow, stagnate, or even reverse.

15 notes

·

View notes

Photo

What is design automation?

We are an automation company with highly skilled staff members, representing a range of expertise, we provide excellent service no matter the complexity or size of your project. Each member of our team is continuously trained to use state-of-the-art technology as well as up-to-date workstations and software.

What services do we provide?

Design and Automation Services provides a full range of CAD services, including Cad Conversion, 2D drafting, 3D modelling, 3D scanning, rendering, reverse engineering and Design & automation services provider in India since 2010. Our goal is to ensure each and every client obtains the highest possible level of quality and services, at a rate well lower than what they would pay for in-house or domestic services.

#designautomations#design#automation#automationcompany#designcompany#automationservices#designservices#cadcam#cad#2ddrafting#drafting#modelling#scanning#rendering#3d#3dmodelling#reverseengineering

1 note

·

View note

Text

Radox Engineering Pvt Ltd, an ISO 9001-2015 Certified Company, is at the forefront of the MEE Plant Supplier in Jaipur and exporting sector. Reverse osmosis (RO) plant, ultra filtration plant, sewage treatment plant, water softening plant, iron remover plant, and wastewater treatment plant. We provide our services to public, commercial, and municipal sectors as well as all types of industries. We are the top provider of water treatment plants in the UAE, Sri Lanka, South Africa, and India. Our business was founded in 2012 with a concept for a raw water and wastewater treatment facility. Under the motto "best production & supply," we expertly offer our clients the best option. We have now served over a thousand satisfied customers, and we still do.

1 note

·

View note

Text

Commercial RO Plant Services In Ravet

Saanvi Aquatech leads the way with its unrivaled Commercial RO Plant Services In Ravet. With a steadfast commitment to excellence and customer satisfaction, Saanvi Aquatech ensures that industries In Ravet have access to top-notch services for their commercial RO plants, empowering them to thrive in their operations.

https://www.saanviaquatech.com/wp-content/uploads/2024/04/commercial-ro-plant-services-in-ravet.jpg

Understanding the Importance of Commercial RO Plant Services

The Role of RO Plants in Industries

Commercial RO (Reverse Osmosis) plants are instrumental in ensuring the availability of clean and purified water for various industrial processes. These plants utilize advanced filtration technology to remove impurities, contaminants, and dissolved solids from water, producing high-quality water that meets industry standards.

Significance of Professional Services

While commercial RO plants are designed for robustness and reliability, regular maintenance and professional servicing are essential to ensure optimal performance and longevity. Professional services provide industries with access to skilled technicians who can diagnose issues, perform repairs, and optimize the efficiency of RO plants.

Commercial RO Plant Services In Ravet

Overview of Ravet

Wakad is a thriving industrial zone located in the Pune district of Maharashtra, India. With its strategic location, well-developed infrastructure, and diverse industrial base, Ravet is home to numerous manufacturing units across sectors such as automotive, engineering, pharmaceuticals, and more.

Need for RO Plant Services

In the competitive environment of Ravet, where operational efficiency is paramount, industries rely on uninterrupted access to purified water for their processes. RO plant services cater to this need by providing industries with reliable maintenance, repair, and optimization solutions for their RO plants, ensuring continuous operation and adherence to quality standards.

Benefits of Saanvi Aquatech’s Commercial RO Plant Services

Comprehensive Maintenance Solutions

Saanvi Aquatech offers comprehensive maintenance solutions tailored to the specific requirements of commercial RO plants. From routine inspections to membrane cleaning and system optimization, the company ensures that RO plants operate at peak efficiency, delivering high-quality purified water consistently.

Expert Technicians

The company’s team of expert technicians possesses extensive experience and expertise in servicing commercial RO plants. With their in-depth knowledge and skills, they can diagnose issues accurately and implement effective solutions to maximize the performance and lifespan of RO plants.

Quality Assurance

Saanvi Aquatech uses only genuine replacement parts sourced from trusted manufacturers to ensure the reliability and longevity of commercial RO plants. Industries can trust the authenticity and quality of the parts supplied, minimizing the risk of unexpected failures and costly downtime.

Saanvi Aquatech appears as the preferred choice for commercial RO plant services In Ravet, offering tailored solutions to meet the unique needs of industries. With its focus on excellence, reliability, and customer satisfaction, Saanvi Aquatech ensures that industries have access to purified water of the highest quality, enabling them to thrive in their operations.

0 notes

Text

A Deep Dive into India's Water Treatment Sector: Key Players and Innovations

Water is a precious resource, and in a country as populous as India, ensuring access to clean and safe water is paramount. The water treatment sector in India plays a crucial role in this endeavor, with key players and innovative technologies driving progress in the field.

Understanding India's Water Treatment Sector

India's water treatment sector encompasses a wide range of companies, from large-scale municipal treatment plants to small-scale community initiatives. These companies are tasked with treating water from various sources, including rivers, lakes, and groundwater, to make it safe for consumption and other uses.

Key Players in the Industry

Several key players dominate the water treatment sector in India, each contributing to the advancement of technology and practices in the field. Some of the prominent companies include:

Tata Projects: Known for its expertise in infrastructure development, Tata Projects has a significant presence in the water treatment sector. The company specializes in designing and constructing water treatment plants, with a focus on sustainability and efficiency.

Eureka Forbes: A household name in India, Eureka Forbes is renowned for its water purifiers and filtration systems. The company offers a range of products for both residential and commercial use, providing affordable solutions for clean drinking water.

Ion Exchange: With decades of experience in water treatment, Ion Exchange is a leading player in the industry. The company offers a comprehensive suite of services, including water treatment chemicals, equipment, and consultancy services.

VA Tech Wabag: VA Tech Wabag is a global leader in water and waste water treatment solutions. The company specializes in engineering and executing turnkey projects for water treatment plants, with a focus on innovation and sustainability.

Innovations in Water Treatment Technology

The water treatment sector in India is characterized by continuous innovation, driven by the need for more efficient and sustainable solutions. Some of the notable innovations in water treatment technology include:

Membrane Filtration: Membrane filtration technologies, such as reverse osmosis and ultra-filtration, are widely used in water treatment plants to remove contaminants and impurities from water. These membranes offer high efficiency and reliability in purifying water for various applications.

Advanced Oxidation Processes: Advanced oxidation processes (AOPs) involve the generation of highly reactive oxygen species to oxidize and degrade organic pollutants in water. AOPs are effective in treating waste water and industrial effluents, making them an important technology in the water treatment sector.

Smart Monitoring Systems: With the advent of Internet of Things (IoT) technology, smart monitoring systems are becoming increasingly prevalent in water treatment plants. These systems use sensors and data analytics to monitor water quality in real-time, allowing for proactive management and optimization of treatment processes.

Decentralized Treatment Systems: Decentralized treatment systems, such as modular treatment units and portable filtration units, are gaining popularity in rural and remote areas of India. These systems provide cost-effective solutions for small communities and industries that may not have access to centralized water treatment infrastructure.

Conclusion

India's water treatment sector is at the forefront of efforts to ensure access to clean and safe water for all. With key players driving innovation and advancements in technology, the sector continues to evolve and adapt to the challenges of an increasingly water-stressed world. By embracing sustainability and leveraging cutting-edge solutions, India's water treatment sector is making significant strides towards a future where clean water is accessible to everyone.

If You Want to Read More About Water Treatment Companies in India then Visit the Site: Jasmino

#technology#watertreatment#water treatment technology#watermanagement#safe drinking water#clean water#water filtration#filtration system#industry#water companies

0 notes

Text

Commercial Reverse Osmosis (RO) Plant Manufacturer In India

Commercial RO Plant is used for the physical separation of dissolved solids and bad equities in water.

Reverse Osmosis (RO) may be a process of physical separation of dissolved solids and minerals present in water. This technology uses the principle of reverse osmosis, in which the mineral concentration of raw water is reduced by applying high through a semi-permeable membrane.

Netsol Water offers a good range of Commercial and Industrial water treatment equipment that purifies water by deploying advanced RO technology that meets the challenging environment of industries. one among the simplest commercial RO plant manufacturers in India.

In the process of Reverse Osmosis, a high pump is employed to extend pressure on the salt side of RO and force water across the semi-permeable RO membrane that leaves around 95% to 99% of dissolved salts. the quantity of pressure required depends upon the concentration of salt within the feed water. Commercial RO Plant is the best commercial ro plant manufacturer in India at best price and quality.

Why choose us as Commercial RO Plant Manufacturers

Strength:

The organization’s main strength is its devoted staff of engineers. The company’s driving power is a tuned team of engineers in various areas and an active group of marketing and customer service executives under the direction of imaginative top management.

The everyday management of works, marketing, coordination, sales, and services within the factories and across the sales and agency network across the nation is controlled by a full-fledged administrative and marketing block located on the premises itself.

Quality:

Netsol create a product that may maximise customers’ production by upholding the highest standards and going through rigorous stage-by-stage quality inspections. Products that meet ISO criteria are of a high calibre.

Services:

A group of skilled and experienced experts are on call around-the-clock to assist clients with any technical needs. This guarantees complete client satisfaction, leading to their unwavering confidence in Netsol.

Commercial RO Plant Manufacturers Services:

For water testing, we provide a highly accurate and latest digital Pen type TDS meter.

Netsol RO System contains the latest and world-class technology like- Commercial RO Membrane and membrane housing, Dosing pump, Anti-scalant, Media( carbon, sand), and High-pressure pumps.

We are a globally recognized manufacturer, supplier, and exporter of Commercial RO Plants in India as well as the Delhi / NCR region. Our best quality RO plants to our clients are now completed over two decades. The journey of being a leading manufacturer and supplier start in 2000 with Netsol Group. Netsol Water Solutions Pvt. Ltd., which is a globally recognized and leading waste and wastewater treatment plant manufacturer in India & Globally.

#industrial ro plant manufacturers#commercial ro plant manufacturer#commercial ro plant manufacturers#industrial ro plant manufacturer#commercial ro plant manufacture#industrial ro plant manufacture#commercialroplant#commercial ro plant#industrial ro plant#netsolwater

0 notes

Text

Industrial RO Plant Manufacturer

The evolution of Industrial RO Plant, a non-chemical method widely preferred for water treatment and purification is employed by large private commercial units and municipal bodies. To contribute to sustainability and scarcity of water within the future, several industries are trying to find water recycling and reuse strategies.

Netsol Water is known together of the premier Reverse Osmosis plant manufacturers and suppliers in India. we provide services like installation, maintenance. Our state-of-the-art technology and brilliantly crafted planning are liable for providing never imagined RO plant solutions. we’ve with us a number of the simplest engineers, who aren’t only experts but also are experienced enough to supply the simplest and quickest solutions. Water Treatment Plants is the best industrial ro plant manufacturer in india at best affordable price.

Some of the exclusive features of our services are world-class designs, durability, excellent performance, and undisturbed operations. The RO plants installed by us are quite cost-effective as very little maintenance is required by them. We ensure greater longevity of the membranes, lesser fouling of the membranes, and also better recuperation of permeate. We ensure greater satisfaction to the purchasers as our RO systems are capable of recuperating obviate the contaminations.

WHAT IS THE REVERSE OSMOSIS PLANT?

Reverse Osmosis may be a technology-supported membrane that’s utilized in the water treatment industry. it’s the foremost preferred technology that’s capable of removing most dissolved salts and ions from water. This technology is additionally capable of removing all present pesticides, viruses, bacteria, and cysts. When it’s put to use serial with other multiple units, it’s referred to as a Reverse Osmosis plant and may be used for recycling and reusing water.

RO PLANT Working Rule

Where osmosis may be a phenomenon, the RO may be a technical process of passing the contaminated fluid through semi-permeable membranes. Extra pressure is applied to the side of the fluid with a high solute concentration. The membranes filter the water and make it usable by rejecting unwanted chemicals and soluble. After the separation, freshwater is prepared to consume for household or commercial use.

WHY CHOOSE US REVERSE OSMOSIS PLANT MANUFACTURERS?

The reverse osmosis system is that the hottest method of purifying water. People prefer this method of purification to other methods due to the number of impurities it can dissolve. Keeping this in mind, we shall become the foremost selected RO Plant manufacturers. We always keep ourselves updated with the newest technologies and implement them with the utmost perfection. The RO industry is undergoing an enormous change in terms of technologies adopted and that we are always the pioneers to adopt them. Our clients get to understand more about this once we provide them with our water treatment and advanced mineral services.

Features Of Our Industrial RO Plants

We provide perfectly carved RO plants which are easy to work. We never compromise on or performance.

Our Industrial RO plants are known for uninterrupted service. Durability isn’t a problem with our plants.

Cost effectiveness is guaranteed. Or RO systems are known for max dissolution of the contaminants.

The RO plants also consume less power and are easy to put in.

When you are going to buy or thinking about buying Industrial Water Treatment Plants, the very first question came into your mind is where and how to best wastewater treatment plant, Who is the best Manufacturer of Industrial RO Plant. For this problem, we suggest Netsol Water Solutions, one of the best companies in India with having its corporate office in Greater Noida the leading Industrial RO Plant Manufacturers in Delhi, Noida, India. Water Treatment Plants is the best industrial ro plant manufacturer in India at best affordable price.

#netsolwater#effluent treatment plant#commercial ro plant#industrial ro plant#industrialroplant#watertreatmentplants

0 notes

Text

The Ultimate Guide to Different Types of Valves for Instruments |Arcellor controls

Presenting the final compendium on instrument valves, courtesy of Arcellor Controls India – your esteemed companion in precision engineering answers. As the most reliable producer, dealer, and exporter of instrumentation valves, we concentrate on offering a wide variety of valves instruments tailored to suit the needs of numerous industries and programs. Whether you're on the lookout for instrument valves, instrumentation valves, valves instruments, valve instruments, or valves and instruments, look no similarly than our comprehensive services.

Understanding Instrumentation Valves:

Instrumentation valves play a vital position in controlling the waft of beverages and gases inside commercial processes. They are designed to face up to excessive strain, extreme temperatures, and corrosive environments, making them indispensable additives across a huge range of industries consisting of oil and fuel, petrochemical, prescription drugs, and more.

Types of Instrumentation Valves we offer:

Needle Valves:

Needle valves are precision-engineered valves with a slender, tapered needle-like stem that permits for particular manage of flow costs.

Ideal for packages requiring quality modifications and throttling, needle valves are normally used in instrumentation systems and manner manage packages.

Ball Valves:

Ball valves characteristic a spherical disc (the "ball") with a hole thru the center that may be circled to control the glide of fluid.

Known for his or her reliability, sturdiness, and brief quarter-flip operation, ball valves are appropriate for both on/off and throttling programs.

Gate Valves:

Gate valves utilize a sliding gate or wedge mechanism to alter flow. When completely open, the gate creates a instantly-thru passage for maximum waft.

These valves are properly-desirable for packages requiring minimal restriction and low strain drop, along with in pipelines and isolation offerings.

Globe Valves:

Globe valves feature a disc that moves perpendicular to the drift to modify fluid control. The design offers precise throttling capabilities and first rate close-off characteristics.

Commonly used in applications requiring precise manage and mild pressure drops, inclusive of in steam structures and water remedy flora.

Manifold Valves:

Manifold valves combine multiple valves into a unmarried compact unit, making an allowance for the simultaneous manipulate of multiple procedure lines.

These valves streamline installation, lessen potential leak factors, and enhance gadget performance, making them perfect for device isolation and calibration packages.

Check Valves:

Check valves, also known as non-return valves, permit fluid to waft in a single path whilst preventing reverse glide.

Essential for preventing backflow and protecting gadget, take a look at valves find packages in pumps, compressors, and piping structures.

Monoflange Valves:

Monoflange valves integrate isolation and venting capabilities into a unmarried compact unit, disposing of the need for separate valves and fittings.

These valves reduce capability leak factors, keep space, and simplify set up and maintenance, making them best for instrument mounting and gauge isolation.

Choosing the Right Valve inside the Instrument

Selecting the right instrumentation valve to your challenge requires cautious attention of numerous elements, along with:

Operating situations (stress, temperature, media)

Flow necessities

Material compatibility

Size and connection specs

Environmental and protection rules

At Arcellor Controls India, we provide a comprehensive range of instrumentation valves designed to meet the highest industry standards and specs. Our valves are to be had in numerous sizes, materials, and configurations to match diverse utility requirements. Whether you want precision control with needle valves, dependable close-off with ball valves, or flexible overall performance with manifold valves, we've got the solution for you.

Final Words!

Comprehending the diverse categories of instrumentation valves and their respective applications is paramount to ensuring top overall performance and dependability in commercial operations. With our tremendous collection of pinnacle-tier instrument valves and profound proficiency in precision engineering, Arcellor Controls India emerges as your pass-to ally for all your valve instruments necessities. Reach out to us nowadays to explore how our complete variety of valves and instruments can empower you to gain extraordinary overall performance and performance for your endeavors.

#instrument valve#instrumentation valves#valves instruments#valve instruments#valves and instruments

0 notes

Text

Supplier of Concrete Mixer in Haryana

Akshar Precast Industries Overview:

Akshar Precast Industries is a leading Manufacturer, Exporter, and Supplier of Concrete Mixer in Haryana, India.

Established in 2018, specializes in the manufacturing of construction machinery.

We are offering Semi semi-automatic fly Ash Brick Machine, Manual Bricks bricks-making machine, Block block-making machine, Paver Block Vibrating Table, Cement Brick brick-making machine, etc.

Concrete mixers efficiently blend ingredients required for concrete, ensuring uniform and consistent mixing.

Typically consists of a rotating drum or barrel and a motor or engine to power the rotation.

Available in various sizes, from portable units for DIY projects to large industrial mixers for construction sites.

Used in construction projects such as building foundations, roads, sidewalks, bridges, and more.

Types of Concrete Mixers:

Drum Mixers: Common type with a rotating drum; can be tilted for pouring.

Twin Shaft Mixers: Features two horizontal shafts with blades rotating in opposite directions.

Planetary Mixers: Utilize a rotating mixing arm around a central axis for even mixing.

Reversing Drum Mixers: Allows the drum to rotate in both directions for a more uniform mix.

Service Area:

Akshar Precast Industries Provides Supplier of Concrete Mixer in Haryana, covering cities like Ambala, Bhiwani, Chandigarh, Faridabad, Firozpur Jhirka, Gurugram, Hansi, Hisar, Jind, Kaithal, Karnal, Kurukshetra, Panipat, Pehowa, Rewari, Rohtak, Sirsa, and Sonipat.

For detailed information and inquiries, please feel free to contact us.

Read the full article

#ConcreteMixer#Exporter#ExporterofConcreteMixer#Haryana#India#Manufacturer#ManufacturerofConcreteMixerinHaryana#Supplier#SupplierofConcreteMixerinHaryana#SupplierofConcreteMixerinIndia

0 notes

Text

Reverse Engineering Services-SixD

Reverse engineering Service and many fields are very much adventurous when compared to the other fields as we know that engineering companies are in demand for technologies and engineering products. They want to implement new technology in all kinds of products to make their work efficient and straightforward. Our reverse engineering services utilize the latest 3D scanning software and metrology equipment for many commercial design and engineering applications.

#Reverse Engineering#Reverse Engineering Services#reverse engineering services in Delhi#reverse engineering services in Gurgaon#reverse engineering services in Noida Sector 62#reverse engineering services in Noida#reverse engineering services in india#3D Scanning Services in India#Dimensional Control#3D Scanning Services#3D Laser Scanning Services#laser scanning services#Laser Scanning Companies#3d scanning reverse engineering

0 notes

Text

Beverage Formulation | Guires Food research lab

Guires CDMO offers Beverage and Drink Product Formulation & Reverse engineering services for start-ups, global brands, and major retailers.

More Info >> https://www.foodresearchlab.com/what-we-do/new-product-development-service/beverage-formulation/

For Enquiry

United Kingdom: +44 – 161 818 4656

India: +91 9566299022

#Carbonated Soft Drink#Fermented Drinks#Functional Herb Drinks Product#Fruit Juice Industry#beverage drink

0 notes

Text

Sysargus is a leader in PCB (Printed Circuit Board) Reverse Engineering, offering specialized services in deciphering and recreating electronic circuits. With advanced technology and a skilled team, Sysargus excels in analyzing existing PCBs to unveil their designs and functionalities. This process enables the company to provide clients with accurate schematics, layouts, and documentation for replication or improvement. Sysargus's expertise in PCB Reverse Engineering supports industries in product enhancement, troubleshooting, and overcoming obsolescence challenges. By delivering comprehensive solutions, Sysargus plays a crucial role in advancing innovation and maintaining the longevity of electronic systems through meticulous PCB Reverse Engineering processes.

0 notes

Text

ETP STP WTP WWTP Manufacturer, Supplier, Design Consultants, India

ETP STP WTP WWTP Manufacturer, Supplier, Design, Engineering, Process Consultancy, Installation, Commissioning Services, Consultants, Pune, Maharashtra, India.

Effluent Treatment Plants, ETP, Waste Water Treatment Plants, WWTP, Water Treatment Plants, WTP, Sewage Treatment Plants, STP, Demineralization Plants, Demineralization Plants, DM Plants, Water Ultrafiltration Plants, Water Recycling Plants, Water Treatment Plants Operation & Maintenance, Water Treatment Plants Operation & Process Maintenance, Water Treatment Plants O&M, Waste Water Treatment Plants Operation & Maintenance, Waste Water Treatment Plants Operation & Process Maintenance, Waste Water Treatment Plants O&M, Industrial Water Softeners, Reverse Osmosis Plants, Industrial Reverse Osmosis Plants, RO Plants, Industrial RO Plants, Water Filtration Plants, Industrial Water Filtration Plants, Environmental Legal Services, Bioculture, WTP Design Services, WTP Engineering And Process Consultancy Services, WTP Consultants, WTP Consultancy Services, WTP Engineering Consultants, WTP Process Consultants, Water Treatment Components, Water Treatment Chemicals, Analytical Laboratory Services, Environmental Audits, Safety Engineering Consultancy, Environmental Safety Audits, ETP Training Programs, STP Training Programs, EMS Consultancy Services, OSHAS Consultancy Services, Manufacturer, Supplier, Exporter, Installation Services, Commissioning Services, Consultants, Consultancy Services, Pune, Maharashtra, India, Sri Lanka, Bangladesh, Asia, Africa, Middle East, UAE United Arab Emirates, Gulf, South America, North America, Europe, Kasarani, Roysambu, Nairobi, Kenya, Qatar.

0 notes

Text

Effluent Treatment Plant

Hydroflux Engineering Pvt Ltd, based in Delhi, India, stands as a distinguished manufacturer specializing in Effluent Treatment Plants (ETP), Sewage Treatment Plants (STP), Demineralization Plants (DM), and Reverse Osmosis (RO) Plants. With a robust reputation, we have successfully catered to diverse industries and applications globally, showcasing our commitment to excellence.

Our approach is characterized by continuous innovation, allowing us to broaden our range of offerings and meet the evolving needs of our clients. From initial requirement assessment to solution designing, on-site/off-site installations, and post-installation support, including break fixes and Annual Maintenance Contracts (AMCs), we provide comprehensive end-to-end solutions.

At Hydroflux Engineering, we understand the critical role of efficient effluent treatment in preserving the environment and promoting sustainable practices. Our team of experts is dedicated to delivering high-quality, customized solutions that align with the unique requirements of each client. Whether you are seeking reliable ETPs, STPs, DM, or RO Plants, Hydroflux Engineering ensures a seamless and dependable experience.

For inquiries and further information, please feel free to contact us at +91 8851066212, visit our website at www.hydroflux.co.in, or reach out via email at [email protected]. We look forward to contributing to your environmental sustainability goals with our cutting-edge solutions and unparalleled service.

#effluent treatment plant#wastewater treatment#wastewater treatment plant#etp plant#etp plant manufacturers in delhi#etp plant manufacturers in mumbai#etp stp plant manufacturers in delhi#etp plant manufacturers in delhi ncr#etp manufacturers in delhi#etp plant in delhi#etp stp plant manufacturers in mumbai#wastewater treatment system#wastewater treatment companies#mobile wastewater treatment plant#wastewater treatment companies near me#industrial wastewater treatment systems#modular wastewater treatment plant#wastewater treatment facility#industrial wastewater treatment plant#small wastewater treatment plant#effluent treatment#etp water treatment#domestic wastewater treatment plant#common effluent treatment plant

1 note

·

View note

Text

RVCR – a new dimension in ‘zero carbon’ technologies.

The route to Zero Carbon reality

The global Transport and power industry are focusing on Electrification of light vehicles, Green-Fuel, and Renewable energy, as mainstay strategies for adapting to environmental market drivers. Though these solutions have been pursued for long now, yet they are not widely implemented due to inherent technology limitations. We have developed RVCR technology, based on globally patented concept in ‘Mechanisms of Energy Conversion’, that bridges this gap. RVCR is a seed concept that outputs new breed of green Primemovers (wind, Hydro motors/ Green-fuel Engines/ Electric motors) for across sector applications to enable rapid implementation of newer long-term Climate Regulation compliance strategies. We provide the technological and business operations support services to clients in designing, developing, and commercializing newer products powered by RVCR technology based green Primemovers.

About RVCR

RVCR is based on a novel concept invention in ‘Mechanisms of Energy-Conversion’ used in Primemovers (Machines which converts energy in Wind, Hydro, green fuels etc. into Drive force). Current Primemovers (I.C.Engines, Electric Motors, Turbines etc.) are based on either ‘Slider-Crank’ or ‘Rotary’ mechanism. These machines are saturated at peak ceiling efficiency from incremental refinement since they were invented about a century ago and unable to cope-up with demands for ever stricter climate regulations. RVCR Mechanism simplifies the energy conversion process seeding new breed of Primemovers, with lower carbon-footprint, whilst delivering leap in Efficiency . It enables new adaptive features to deal with environmental challenges by combining the performance advantage of rotary motors and positive displacement mechanism We have developed the base know-how and have initiated individual dedicated projects for developing RVCR Technology for specific industry applications.

Why RVCR now?

Forceful societal pressures towards sustainable and lower carbon goals are leading to trillions in investments for large-scale diversification into Green/Renewable energy sources. We see massive investments made in European Super Grid to converge power from renewable energy generated across vast expanse of time zones, for streamlining power demand and supply and reducing reverse spinning margin. Similarly, Green energy source count is increasing, however the critical constraining points in the energy jugulars that registers losses are the node points of energy conversion. Fractional improvement here has a great impact in the cumulative systemic efficiency. RVCR technological innovation is the key to this energy-to-power-to-work exchange and stands as a unified solution applicable to the entire transport and Energy ecosystem. RVCR stands as an enabler technology based on superior Physics in energy conversion at a crucial juncture in time when conventional mechanism has exhausted all means of any substantial efficiency improvement and are saturating at their theoretical ceiling limits. RVCR’s success now will see the timely maturation of new solutions, clearing the road for next-gen Primemover, to add the missing component for achieving ‘Net Zero Carbon Emission 2050’ goals ‘with ease’.

Read More at

0 notes