#Pvc Membrane Foil

Text

Lamination Paper Print | Laminate Door Skin| Door Skin Paper - Wonder Sign

Wonder Sign Become Prominent As The Best Dealer And Manufacturer Of Digital Door Paper Print And Lamination Door Print, Sunmica Paper, Lamination Door Print In Ahmedabad, Gujarat.

Laminate Door Skin Is A Type Of Decorative Print Used On Doors That Involves The Application Of A Thin Layer Of Plastic Film Or Laminate Onto The Surface Of The Door. The Laminate Film Can Feature A Variety Of…

View On WordPress

#3D Digital Door Skin#3D Door Paper Print#Decorative Door Paper Print#Door Skin Paper#Laminate Door Skin#Lamination Door Print#Lamination Paper Print#Pvc Membrane Foil

0 notes

Text

Choose The Right Kitchen Cabinet Shutters | VMS Trade Link

How would you like to work in a modular kitchen? They give your space a nice appearance besides being functional. Everything is organised because each item has its place.

The modular kitchen is composed of individual cabinets. These cabinets are produced in the factory and installed at the site. If needed, they can quickly be taken apart and reassembled at another site. Just as you want to choose the cabinet for your kitchen, you would also like to select the kitchen shutter, as these will define the looks of your kitchen.

You can see below some of the most popular cabinet shutters that are available in the market:

1. Solid Wood Shutters

Solid wood shutters have unmatched beauty and charm, although, at present, they cannot be considered a sustainable option. This kitchen shutter price is high because wood is difficult to source due to the diminishing reserves of natural forests. The entire shutter is made of wood, and the exposed surface has a protective layer of waterproof resin, further improving the wood’s richness.

2. Membrane Shutters

PVC membranes are moulded on plywood or Medium Density Fiberboards (MDF). These kitchen profile membrane shutters have a smooth and seamless finish. It also has water resistance properties, and the PVC membrane seals the edges, so edge-banding to reinforce the thin foils is unnecessary. They have a modern look, are durable, and are very stylish, although they are more pricey than laminated shutters.

3. Veneer Shutters

Veneers are natural wood sliced very thinly and pressed onto the MDF or plywood. They look like real wood; besides, they can also be finished and polished to make them appear to have the qualities and features of solid wood. Another good news is that this kitchen shutter price is very cost-friendly. You can choose from the natural wood veneers of walnut, oak, and teak in various shades and patterns.

4. High Gloss PU Painted Shutters

These shutters are painted with auto-coat paints, with a clear PU (polyurethane) coating on ply boards or MDF. These waterproof shutters are readily available in glossy and vibrant colours and shades. They are also durable so that they can last for long periods. These shutters need regular maintenance, as fingerprints can show up easily.

5. Painted Glass Shutters

Kitchen glass shutters offer a unique and stylish appearance to your kitchen. You can have the glass painted or printed with any design you prefer. For lower cabinets, use toughened glass for durability.

6. Aluminum Shutter

Aluminum shutter for kitchen is made of stable metal. When used as kitchen shutters, particularly roller shutters, these can be the best for durability and quality. They are lightweight and do not rust, so they are the most commonly used shutters for the kitchen.

7. Laminated Shutters

Laminated shutters are the most popular type of kitchen shutters. Laminates come in various colours and natural finishes that resemble stone, wood, brick, or metal. Being moisture-resistant makes laminates the perfect choice for the kitchen cabinet shutter door; they can also withstand high temperatures. They are easy to maintain, too.

If you need more information and help to choose the right kitchen cabinet shutter door, please connect with VMS Tradelink and get the advice and support you need.

#kitchen shutters#aluminum shutter for kitchens#kitchen shutter price#kitchen profile#kitchen glass shutter#kitchen cabinet shutter door

0 notes

Text

Discover the Magic of Membrane Kitchens: Durable, Moisture-Resistant, and Stylish!

Experience the wonders of membrane finish, a Polyvinyl chloride (PVC) foil that transforms kitchens into modern marvels. With matte, glossy, and wooden finishes, it's the top choice for modular kitchens. Moisture-resistant, easy to maintain, and child-friendly, membrane is the ultimate solution for versatile interiors. Say hello to a kitchen that stands the test of time! Call us for more +91 8377044077

https://www.comaron.com/blog/membrane-kitchen

#modular kitchen#modern kitchen#kitchen design#kitchen cabinets#quartz countertops#garbage disposal#granite countertops

0 notes

Text

TM2480A PVC Foil Vacuum Membrane Press Machine

https://www.bikudo.com/product/922073.html

#vacuum #membrane #press #machine #negative #pressure

0 notes

Text

Pvc Membrane Foil

Pvc Membrane Foil

Kunlin Adhesive Vinyl Rolls Suppliers 6000+ designs and 30000+ colors, as operating characteristics, to small profits but quick turnover as the core of the popular selling in the consumer market, wholesale our decorative films to Egypt, Pakistan, Turkey, India, Indonesia, Malaysia, Vietnam, Russia, Brazil, South Korea, and etc. Our decor film designs can meet the demands of many countries, including decoration film, Pvc Membrane Foil, car film, advertising lettering stickers, PVC wallpaper, glass paste and other products, besides our existing decorative films designs, we also accept customized design production.

1 note

·

View note

Text

Pvc Membrane Foil

Pvc Membrane Foil

Kunlin Adhesive Vinyl Rolls Suppliers 6000+ designs and 30000+ colors, as operating characteristics, to small profits but quick turnover as the core of the popular selling in the consumer market, wholesale our decorative films to Egypt, Pakistan, Turkey, India, Indonesia, Malaysia, Vietnam, Russia, Brazil, South Korea, and etc. Our decor film designs can meet the demands of many countries, including decoration film, Pvc Membrane Foil, car film, advertising lettering stickers, PVC wallpaper, glass paste and other products, besides our existing decorative films designs, we also accept customized design production.

1 note

·

View note

Text

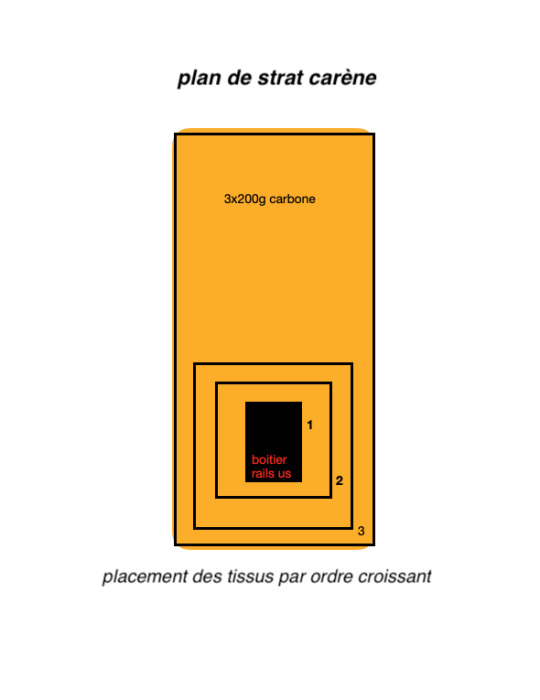

Planche wingfoil fabrication

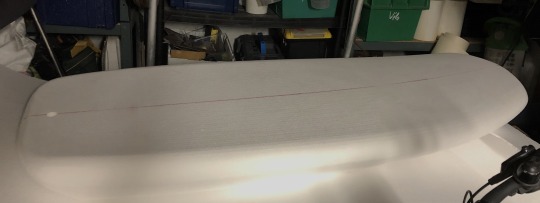

Réception du bloc polystyrène pré shapé

Pour les raisons de commodité, je commande à la société atuacores le pain de polystyrène pré shapé qui peut réaliser aussi le dessin de votre futur planche en fonction de vos envies; quelques mails suffisent pour finaliser la forme générale.

Travaux à effectuer à la réception du shape:

marquer les axes longitudinaux pont et carène

poncer au shaping block les traces du passage de la fraise de la machine

travailler les bi concaves de la carène si vous le souhaitez

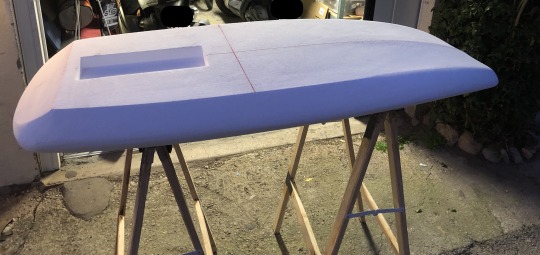

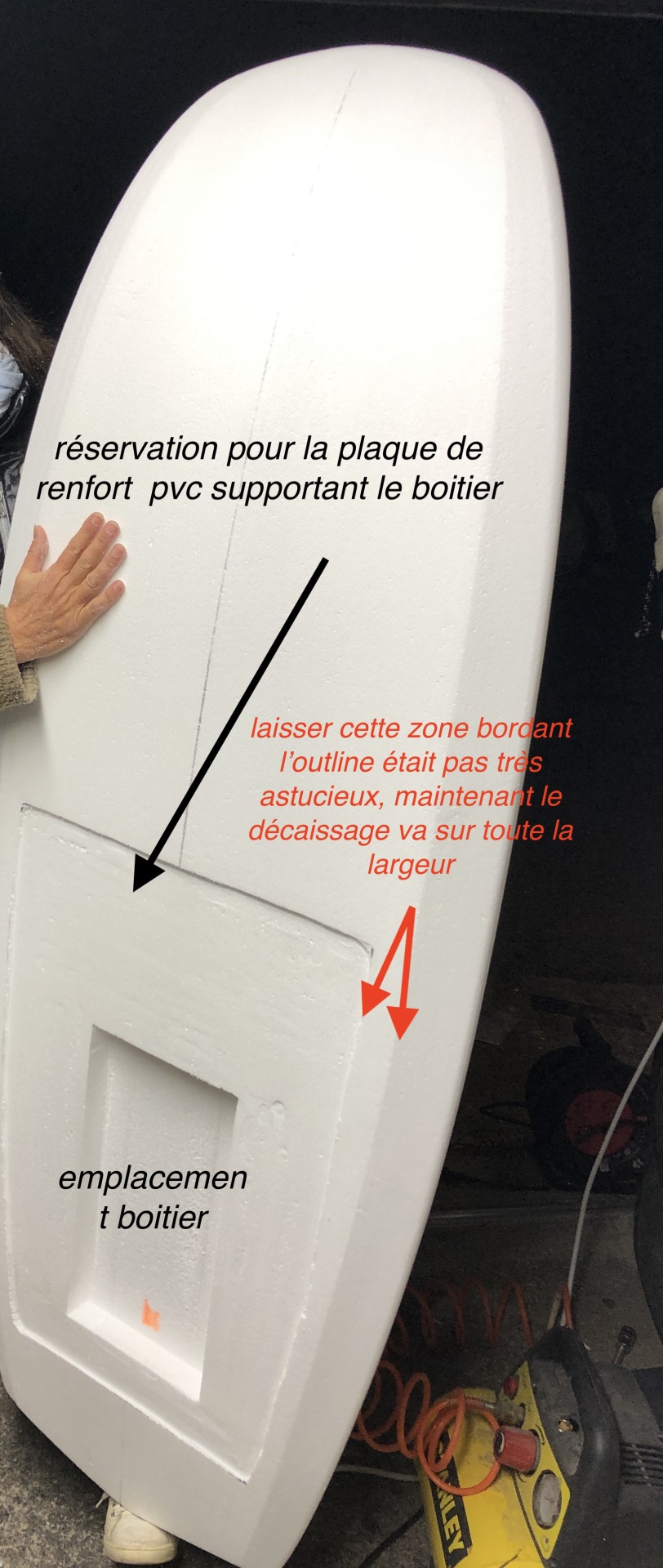

tracer les futurs zones à décaisser pour l’emplacement les plaques PVC de renfort pont et carène (construction en sandwich partiel)

l’emplacement du boitier et du plug de leash a été effectués à la commande.

décaisser les zones sur le pain qui supporteront les plaques de pvc de renforts à la défonceuse; terminé le travail de la zone avec un petit rabot trouvé ici par exemple .

Astuce:

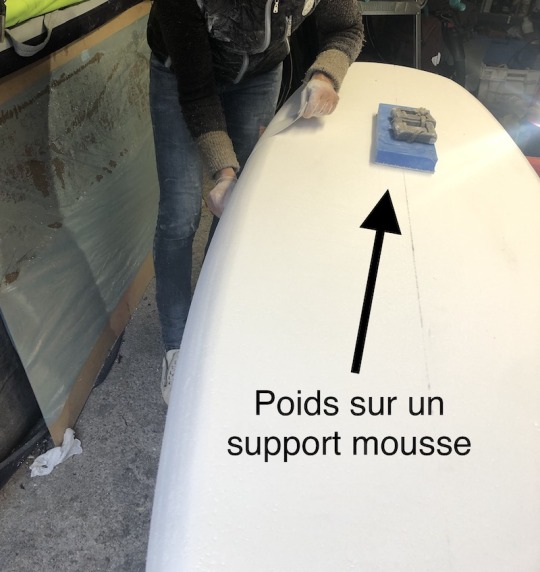

prévoyez un poids (1/1,5 kg) car vous travaillez sur un objet certes volumineux mais léger ; donc pour faciliter votre travail de ponçage il faut le stabiliser.

Pour les saignées, procéder en espaçant vos A/R avec la machine; de la sorte elle aura toujours en appui stable ( espace 1 cm environ) puis même chose à la perpendiculaire .

Important: travaillé avec des mains non graisses et manipuler le bloc à mains pleines même en 20kg/m” il peut marquer vos empreintes, votre signature digital.. Enfin prévoir un petit compresseur pour bien dépoussiérer le shape après le travail sur le polystyrène.

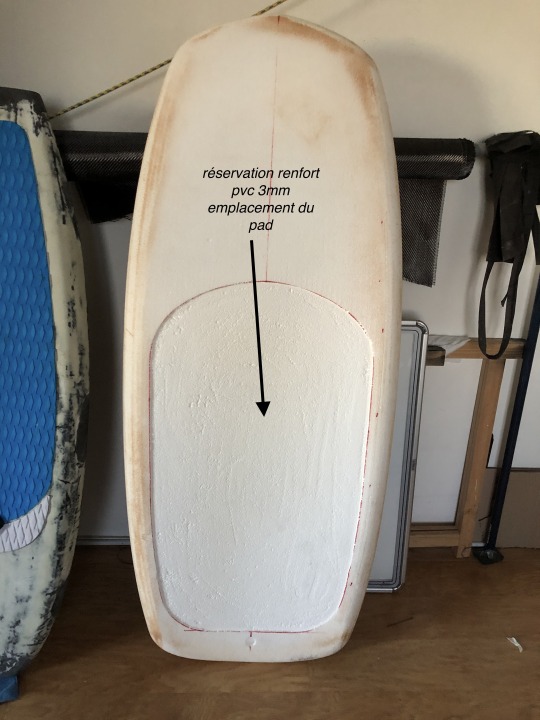

Préparation des plaques de PVC

Afin de renforcer le bloc de polystyrène de 20 kg/m3, il convient de placer à la fois sur la carène et sur le pont, un support plus dense ( environ 80kg/m3) sur les zones à fortes contraintes.

Sur la pont, dans la zone ou évolueront les placement de pied du rider

Sur la carène, au niveau du positionnement du boitier supportant le foil

Les plaques en 3 et 5 mm s’achètent sur ce site

L’ajustement entre les plaques de pvc découpées et la réservation effectuée sur le pain de polystyrène doit etre le plus précis possible; en effet si des irrégularités de contact sont présentes, elles devront être comblées par de l’enduit donc du poids bêtement pris..

Coté pont ( pvc de 3mm)

Coté carène (pvc de 5mm)

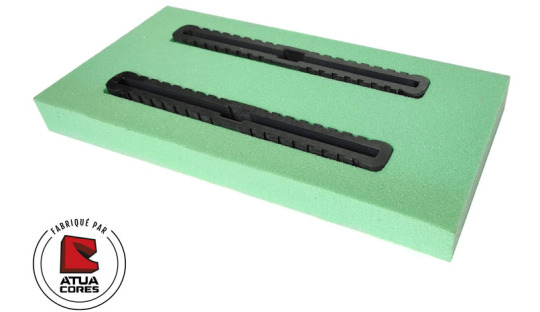

Coté carène, un élément va venir s’incruster sur la plaque de 5mm, il s’agit du boitier supportant des rails us; elle sera ajourée afin de laisser la placer à cet emboîtement. La réalisation de la stratification du boitier sera développée au chapitre suivant. Même principe d’ajustement, au plus près.

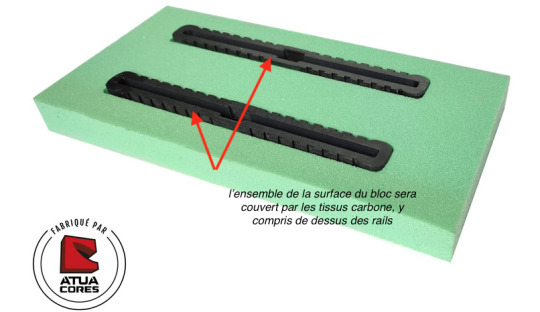

Première stratification: le bloc mousse du boitier

le bloc mousse adapté avec ses rails us trouvé ici

Il y a plusieurs manières de procéder , j’aime bien la mienne car je contrôle parfaitement le processus (étant fait hors planche) avec une strat sous vide très homogène et des retours propres sur le pvc de carène permettant un assemblage avec un minimun d’enduit. cette opération se terminera par une mise sous vide.

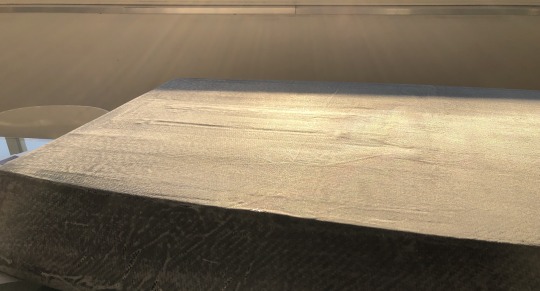

Le sous vide

Concernant la pompe à vide encore une fois nombreuses de solutions; celles faites “maison” celles à bain d’huile, à membrane et celle à pistons. Après avoir enfumé copieusement les pièces avec celles à bain d’huile je me suis dirigé vers une petite pompe à membrane ; cette dernière doit être assister obligatoirement au début avec un aspirateur de maison, sinon vous laissez passer plusieurs repas... Faible aspiration 6l/mn

Je l’ai achetée ici

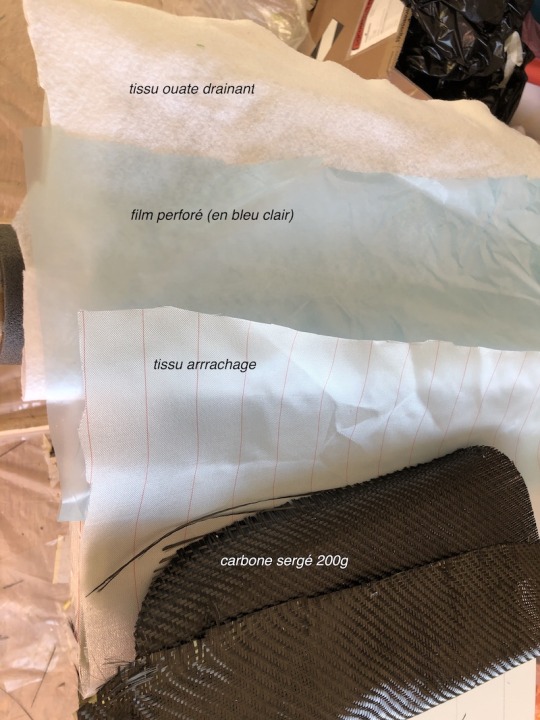

Matériaux nécessaire

tissu carbone

tisu arrachage ( à l’enlèvement laisse une surface plate et mate)

film perforé (éviter les remontées de résine trop importante)

tissu drainant (faire que l’air puise l’évacuer plus facilement)

matic de fermeture ou scotch

Le tout enveloppé dans une bache plastique tube trouvée avec les autres éléments cités ici

Mise en place

Sur un mélaminé à la largeur, on place dans l’ordre

un plastique de protection

un tissu d’arrachage

le bloc mousse retourné sans ses rails

Stratification

placé 2x200g de tissu sergé carbone avec des retours à plat sur le support d’environ 50mm de largeur; vous n’avez normalement pas besoin de couper le tissu pour le passage des angles, il épousera le volume en le mettant en forme doucement. Cette manip se fait à sec sans résine pour la première couche puis la deuxième viendra se positionneur une zone humide donc visualiser son placement global avant d’appuyer pour faire pénétrer la résine. Puis la gamme des couches présentée au dessus. Puis après séchage on retourne et on fait propre le pourtour . (photo)

Important:

même si cette opération se terminera par une mise sous vide, je termine mes strats en débullant mes tissus en soignant les angles, avec ces outils trouvés en France et.. ici

Mise en garde pour le sous vide

Le sous vide est une aide appréciable pour la stratification ou un collage mais encore faut il respecter certaines règles d’usage:

veuillez au départ d’avoir un bon ratio mélange ( résine durcisseur) et tissu ; pour cela vous pouvez peser votre tissu un fois découpé et avant stratification pour évaluer la quantité de résine nécessaire, même poids de mélange.

Ne négliger pas une bonne imprégnation dans les règles de l’art avec un placement méticuleux du tissu d’arrachage, si pli dans ce tissu il y aura marquage sur la strat. Le sous vide ne fait pas tout !

Ne pas dépasser -0,2 b avec votre pompe au risque d’assécher vos tissus et modifier la ratio idéal.

Le vide

Dépression 0,3 bar

2 écoles pour la préparation du pain:

Imprégnation préalable du polystyrène

La “non” imprégnation

1- Cette opération consiste à réaliser à la surface du bloc, une couche imperméable évitant ainsi que la résine ne pénètre trop dans la polystyrène; j’ai choisi de procéder privilégiant la légèreté; certains professionnels considèrent que de laisser un peu de résine rentrer dans le support favorise l’accroche et limite le délaminage de la strat... Si vous choisissez cette solution il vous faut passer cette étape.

Mise en place

résine

microballon ici ( créer du volume)

une teinte époxy ( permet de visualiser son passage)

le mélange doit être d’une consistance d’une pâte à crêpe et sera étalé à la spatule (carrossier pour ma part) en tirant afin de ne pas laisser de sur épaisseur.

Important veillez à ne laisser aucune aspérité sur l’enduit une fois forci; passez un coup de papier à poncer sur l’ensemble si cas contraire . Le tissu s’il s’accrocherait et se déformerait en créant des trous.

2- Aucun travail préalable sur le pain; cette façon de procéder considère qu’en semblant les biles du pain vierge de toute imprégnation, la résine de la stratification pourra venir combler les interstices, assurant ainsi une bonne accroche des tissus limitant ainsi les risques de délaminage; c’est maintenant cette façon de faire que j’ai adopté (maj 08/22)

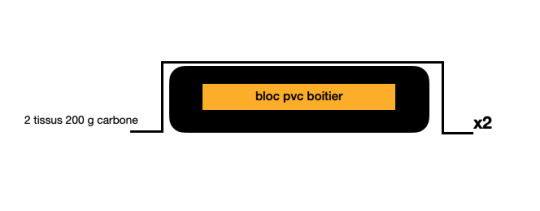

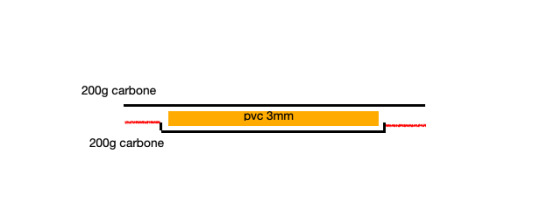

Stratification de la plaque PVC de pont

Ce qui défini la structure sandwich d’une construction, c’est une âme (plaque de 3 et 5mm pour notre exemple) et 2 peaux stratifiées de part et d’autre. cette plaque de pont sera donc foncée entre une peaux carbone 200g coté pain et une peau carbone 200g lors de la strat générale de ce coté.

Ce qui défini la structure sandwich d’une construction, c’est une âme (plaque de 3 et 5mm pour notre exemple) et 2 peaux stratifiées de part et d’autre. cette plaque de pont sera donc foncée entre une peaux carbone 200g coté pain et une peau carbone 200g lors de la strat générale de ce coté.

Mise en place

On place le tissu dans le décaissement en lui faisant bien prendre le contour; puis directement avec une lame de cutter neuve, on va découper le carbone.

Globalement j’essaie de manipuler le moins possible les tissus en faisant les découpes in situ.

Puis on imprègne le tissu bien humide et l’on place la mousse pvc; la mise en place en vide se déroule de la même façon que pour le boitier.

Remarque

une variante serait de faire déborder le tissu plus sur le pont pour réaliser une bonne accroche avec la strat extérieure un peu comme un petit oméga.

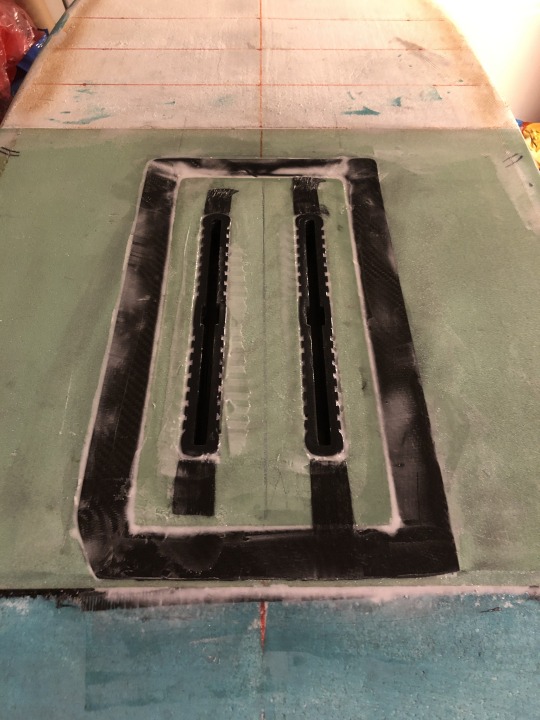

Stratification de la plaque PVC de carène

Coté carène en plus de la stratification du tissu de ce qui constituera la peau intérieure, il faudra coller le boiter dans son logement.

important tout ce qui pourra être fait (réservation sur les supports) pour limiter l’apport d’enduit sera bénéfique en fin de construction sur la balance..

On allons procéder à une deuxième réservation mais cette fois ci dans la plaque de 5mm; cette réservation permettra ne compenser l’épaisseur du retour de la strat du boitier.

la stratification (idem que celle de la carène)

Collage boitier

résine

silice ( 2/3 de l’apport)

microballon ( un petit 1/3)

le collage se fera sur toutes les faces et surfaces.

important contrôler toujours vos axes avant de mettre sous vide

Puis mise sous vide classique de l’ensemble.

Au déballage après le sous vide

vue d’ensemble où les différents éléments se sont plutôt pas mal imbriquer

plaque pvc dans le blocpolystyrène

boitier rails dans la plaque de renfort

collage des 2 rails us

Au préalable comme souvent en collage, il faut:

poncer ou rayer la pièce pour une meilleur accroche ( ce sont des pièces moulées de chez Chinook qui sont très dures vous pouvez utilisé une disqueuse)

comblé la fente pour préparer les futurs strats qui viendront se coller sur le dessus

Dans l’exemple de construction exposé dans ce blog, j’ai mis un tissu UD au fond du boitier avec des retours sur le plat en plus du collage; à voir...

Collage rails

résine

silice (2/3 )

microballon (1/3)

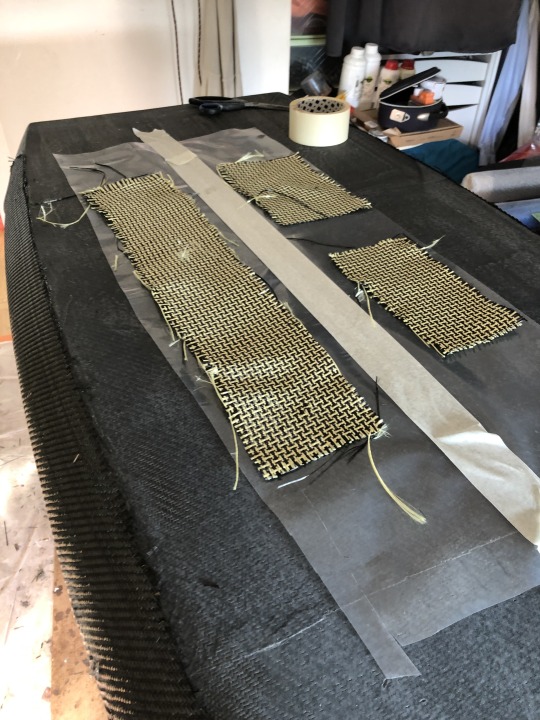

tissu carbone UD de 25 mm

on pré imprègne les 2 bandes de tissus grassement et l’on prépare notre mélange pour le collage; le tissu est appliqué au fond avec le retour et les rails sont garnis du mélange (résine , silice microballon)

mise en place en maintenant une pression au fond des rails .

Comblement des rails

on va combler les fentes des rails pour éviter qu’elles ne se remplissent de résine lors de la stratification des tissus de carène.

On commence par bourrer de sopalin au maximum puis on finit par combler avec de la pâte à modeler pour vraiment arrivé au raz de la surface.

Bien dégraisser toujours les surfaces avant stratifications.

Stratification de la peau extérieure de carène

couche 1

couche 2

couche 3 générale

Faute !

tissus d’arrachage ayant fait un pli entraine marquage de la surface de la strat

A prendre un peu de temps à assembler les différents éléments un peu près correctement on est gagnant sur la fin avec peu de géométrie à faire donc peu d’enduit entrainant une prise de poids contenu.

youtube

Coté face

Araser le retour de strat coté pont avec une Dremel ou sera monté un disque spécial stratification (ref en dessous)

scotch pose préalablement à la stratification

même scotch posé en fin de strat pour visualiser la découpe

Outil

J’ai trouvé un mini disque et d’autre accessoires (mines) à stratification pour araser; montage sur Dremel ici

Pose des inserts de straps et vis de décompression

Stratification de la peau extérieure de pont

Cette fois ci, j’ai procède d’une façon un peu différente en utilisant une colle de mise en place pour tissu.

Intérêt :

permettre une découpe à sec du pourtour du tissu

pouvoir imprégner face à soi une partie qui normalement se trouve être en dessous

Acheté ici

Alors voilà comment j'ai procédé :

Une fois le tissu en place bien plaqué et un peu découpé aux extrémités, je replie dans la longueur une moitié, je pulvérise et je viens plaquer; même opération de l'autre coté (le tissu est collé sur tout le plat donc sauf aux extrémités) ensuite je pulvérise sur le rails et je plaque en commençant bien par le centre vers les extrémités avec un mouvement toujours dirigé par le bas; idem l'autre coté; ensuite je retourne la planche pour procéder à la découpe des tissus. Pour les extrémités dans ce cas je voulais placer du carbone / kevlar donc j'ai fait cela in situ; mais vraiment le top ! je pulvérise sur le pain. Si j'avais su plus tôt GAFFE quand même vous n'avez pas de seconde chance ! Une fois plaqué....

Préparation des renforts carbone/kevalr pour le nose et le tail; l’imprégnation se faisant sur un polyane.

Finition

Je fais une finition simple à base d’enduit teinté puisé dans un catalogue de couleur RAL ( plus usé pur faire une réparation)

Composition:

résine époxy

pâte époxy colorée (trouvée ici )

microballon

La pâte doit etre de la consistance d’une pâte à crêpes; versé quasi l’intégralité du mélange et étalé à la squeegee.

Attention:

Respecté toujours scrupuleusement le même pourcentage d’ajout de colorant dans vos mélanges; au risque d’avoir un effet de tache; sauf si c’est l’effet recherché...

Nombreuses tailles et matériaux ici

Pose du pad

Je vous conseille de faire des découpes sur votre pad, cela permet d”alléger “ visuellement le support en évitant l’effet de masse; il y a une petite astuce pour ne pas galèrer à la pose des différents morceaux. A venir...

Egalement, vous pouvez biseauter les pourtours de votre pad afin de lui donner un rendu plus fini; avec cet outil, un cutteur à angle 45 °.

Trouvé ici

9 notes

·

View notes

Photo

Jeffrey Shaw, Theo Botschuijver, Sean Wellesley-Miller: Waterwalk tube, 1970. This site-specific installation was an inflatable tube made from transparent PVC foil that was floated across the Maschsee Lake in Hannover, connecting its opposite banks. The tube was approximately 250 meters long and 3 meters in diameter. This air-filled bridge had revolving doors at each end that functioned as airlocks, and its pliable floor was in direct contact with the water surface. Visitors were able to enter this almost-immaterial structure and cross from one side of the lake to the other, with the inflated membrane of the tube supporting them as they ‘walked on water’. https://www.instagram.com/p/CEUz3pNA_2e/?igshid=10ha161bqamd0

219 notes

·

View notes

Text

How It’s Made Index(S01~S10)

How It’s Made是由 Discovery Channel 制作一款王牌节目,又被翻译为制造的原理或造物小百科, 本片从2001年推出至今,涵盖了几乎所有的制造技术 ,非常适合机械专业和对此感兴趣的同学。希望大家享受这趟制造的艺术之旅!

第一季推出时间为2001-01-06至2001-03-31

S01E01 Aluminum foil, Snow Boards, Contact lenses, Bread. 铝箔,雪橇板,隐形眼镜,面包

本集看点:铝锭是如何一步步用轧制工艺压制成像纸一样薄的铝箔的;

S01E02 Compact Discs; Mozzarella Cheese; Pantyhose; Fluorescent Tubes. 光碟,奶酪,女式连袜裤,荧光灯管

本集看点:CD光盘是怎么从模具注塑出来的;玻璃管的热弯,以及荧光灯复杂的自动化制程;

S01E03 Toothpicks; Acrylic Bathtubs; Helicopters; Beer. 牙签,玻璃纤维增强塑料浴缸 ,直升机,啤酒

本集看点:牙签的制作,是类似于螺钉,是先用木材做成木板再切割而成;塑料的吸塑制程,玻璃纤维+树脂强化制程;碳纤维制作的飞机支架;

S01E04 Hearing Aids; 3-D Puzzles; Rubber Mats; Toilets 助听器,三维拼图,胶垫,抽水马桶

本集看点:用模具制作陶瓷的加工制程;

S01E05 Copy Paper; Jeans; Computers; Plate Glass 复印纸,牛仔裤,电脑,平板玻璃

本集看点: 浮法平板玻璃的制作过程;

S01E06 Nails and Staples; Safety Glasses; Fabrics; Bicycles 钉子,护目镜,布匹,自行车

本集看点:一卷钢丝的艺术之旅;透明塑胶模具的高亮抛光;线全自动编制成布;自行车架的焊接与喷涂工艺;

S01E07 Kayaks; Safety Boots; Electronic Signs; Cereals 皮划艇,安全靴,电子招牌,麦片粥

本集看点: 热塑性塑料的成型方法加工,不需要压力,只需要加热和摇晃即可;LED制成的大型广告或体育比赛显示屏

S01E08 Trucks; Adhesive Bandages; Computer Circuit Boards; Liquors 卡车,创口贴,计算机电路(PCB),酿酒(威士忌)

本集看点:SMT和波峰焊制程(单面器件),目前手机等产品已经主要使用回流焊制程;

S01E09 Steel; Apple Juice; Aircraft Landing Gear; Cosmetics 钢铁,苹果汁,起落架,化妆品

本集看点:钢铁是怎样练成的;车削和铣削加工,喷砂工艺,外观电镀处理;

S01E10 Holograms; Package Printing; Skin Culture; Canned Corn 全息摄影,包装盒,皮肤培植,罐装玉米

本集看点:还是不懂的全息摄影和底片冲洗;

S01E11 Plastic Bags; Solar Panels; Plastic Gasoline Containers; Hockey Sticks 塑料袋,太阳能电池板,塑料汽油桶,曲棍球棍

本集看点:塑料袋通过聚乙烯吹膜制程制作;吹塑制作塑料桶;

S01E12 Aluminum Screw Caps; Chocolate; Pills; Pasta 铝瓶盖,巧克力,药丸,面食

本集看点:铝合金的拉伸制程;

S01E13 Bicycle Helmets; Aluminum; Car Brakes; Lithium Batteries 自行车头盔,铝,汽车刹车,锂电池

本集看点:聚苯乙烯发泡注塑;电解铝制程,制作成铝锭;电池是怎么卷出来的;

本季资源链接:

magnet:?xt=urn:btih:e1ec692441019f65979f29e09bc9f84b3bdf563e&dn

第二季推出时间为2002-09-07至2002-12-07

S02E01 Eyeglass Lenses; Granite; Potato Chips; Microprocessors 眼睛镜片,花岗石板,薯片,微处理器

本集看点:塑胶镜片的抛光和AR镀膜;芯片的封装制程;

S02E02 Honey; Fiber-Optics; Bricks; Pipe Organs 蜂蜜,光纤,砖块,管风琴

本集看点:玻璃管拉丝成为光纤;

S02E03 Personal Watercraft; Wine; Office Furniture; Ice Skates 水上摩托,葡萄酒,办公家具,溜冰鞋

S02E04 Winter Jackets; Animation; Mushrooms; Gold Rings 冬季夹克衫,动画片,蘑菇,金戒指

本集看点:用 熔模铸造工艺制作魔戒;

S02E05 Hydroponic Lettuce; Construction Wood; Recycling; Fishing Flies 水培莴苣,建筑木材,垃圾回收,假蝇饵

本集看点:完全工业化种菜;

S02E06 Diamond Cuttings; Wood Doors; Paintballs; Newspapers 切割钻石,木门,彩色球,报纸

S02E07 Carpets; Drinking Water; Laser Eye Surgery; Acoustic Guitars 地毯,饮用水,激光眼科手术,吉他

S02E08 Fiberglass Boats; Clothes Dryers; Bubble Gum; Fireworks 玻璃纤维艇,干衣机,泡泡糖,焰火

本集看点:玻璃纤维+树脂制作的船体上盖;钢板制作圆筒;

S02E09 Steel Safes; False Teeth; Airplanes; Maple Syrup 保险箱,假牙,轻型飞机,枫糖浆

本集看点:来了,玻璃纤维+树脂制作的飞机机身;

S02E10 Gummies; Aluminum Cans; Fish Farming; Bronze Sculptures 花色软糖,易拉罐,养鱼,青铜雕塑

本集看点:可口可乐,来一罐!

S02E11 Aluminum Pots and Pans; Artificial Limbs; Peanut Butter; High Intensity Light Bulbs 旋压铝制品,假肢,花生酱,高光灯泡

本集看点:用旋压而非拉伸制作的铝合金罐子和盖子,两种方式各有优势;

S02E12 Cars; Grocery Carts; Rapid Tooling and Prototyping; Collectible Coins 小汽车,购物车,快速模具成型,纪念币

本集看点:钣金的加工制程,电阻焊;3D打印树脂零件,浇铸工艺及其模具制作;银币复杂的图案转移过程;

S02E13 Ball Bearings; Electrical Wires; Lost Wax Process Casting; Automated Machines 轴承,电线,熔模铸造,自动化机器

本集看点:钢球的制造过程(冲压+研磨); 熔模铸造的金属铸造件, 熔模本身也是通过模具制造的;极其舒适的全自动化制造过程合集;

本季资源链接:

magnet:?xt=urn:btih:543050ad51e44c744d235680efec5db2693724f7&dn

第三季推出时间为2003-10-01至2003-12-30

S03E01 Pre-inked Stamps; Cranberries; Cotton Yarn; Road Signs 原子章,酸果,棉纱,交通标志

本集看点:丝印网板的制作过程;

S03E02 Combination Locks; Pottery; Recreational Vehicles; Erasers 字码锁,陶器,休闲拖车,橡皮擦

本集看点:如何用模具制作陶罐;

S03E03 Wheel Loaders; Vegetable Oil; Hand Tools; Cotton Swabs 轮式装运机,植物油,手动工具,棉签

S03E04 Temporary Metal Fences; Asphalt Shingles; Polystyrene Products; Hard Candies 金属栅栏,沥青屋面板,泡沫板,花式硬糖

本集看点:泡沫发泡制程;

S03E05 Horse-drawn Carriages; Artificial Eyes; Dog and Cat Food; Mirrors 老式马车,假眼,猫粮和狗粮,镜子

S03E06 Yogurt; Candles; Neon Signs; Bookbindings 酸奶,蜡烛,霓虹灯,装订

S03E07 Prepared Mustard; Violins; Nuts and Bolts; Toilet Paper 芥末,小提琴,螺母螺帽,卫生纸

本集看点:螺杆的滚丝螺纹制程,螺母是钢丝在高温下压制而成的,螺母的螺纹后加工CNC制成;

S03E08 Fresh Cut Flowers; Adhesive Tape; Tofu; Lottery Tickets 鲜花,胶带,豆腐,彩票

S03E09 Inflatable Watercraft; Couscous; Modelling Dough; Wicker Products 充气筏,蒸粗麦粉,玩具胶泥,柳条编织

S03E10 Wind Generators; PVC Gloves; Thermo-Formed Glass; Fire Trucks 风力发电机,塑胶手套,热塑玻璃,消防车

本集看点:手工让平板玻璃热成型成精美盘子;

S03E11 Radiators; Hatchery Chicks; Filo Pastry; Cross-Country Skis 汽车散热器,孵蛋机,薄生面片,滑雪撬

S03E12 Electric Baseboard Heaters; Moulded Pulp Containers; Chicken; Video Games 电加热器,纸浆(鸡蛋)托盘,鸡肉,电脑游戏

本集看点:钣金连续冲压过程;

S03E13 Fire Fighter Boots; Garden Tools; Automated Machines; Gypsum Board 防火靴,园艺工具,自动化机械,石膏板

本集看点:新一期极其舒适的自动化流水线;

本季资源链接:

magnet:?xt=urn:btih:724f7b0bbf3278e4eec84db6c0373551017fb874&dn

第四季推出时间为2005-01-04至2005-03-29

S04E01 Plastic Bottles & Jars; Mail; Eggs; Handcrafted Wooden Pens 塑料瓶,邮件分拣,鸡蛋,木柄定制钢笔

本集看点:塑料瓶的吹塑制程(舒适);鸡蛋是怎么生产的;

S04E02 Plastic Injection Moulds; Automotive Oil Filters; Filing Cabinets; Blown Glass 塑料注塑模具,汽车滤油器,档案柜,吹塑玻璃

本集看点:塑料注塑模具的加工制程:CNC加工、EDM电极加工,以及双色注塑过程;钣金柜子的加工制程;美女是如何吹玻璃的;

S04E03 High-Precision Cutting Tools; Stained Glass; Semi-Trailers; Recorders 钻头,拼花玻璃,拖车,木直笛

本集看点: 涡流加热,通过热处理后软化或硬化金属;

S04E04 Conga Drums; Metal Plating; Buttons; 康茄鼓,金属电镀,纽扣

本集看点: 金属电镀制程;

S04E05 Grinding Wheels; Compost; Window Blinds; Milk 砂轮,堆肥,百叶窗,牛奶

S04E06 Brushes & Push Brooms; Blackboards; Smoked Salmon; Zippers 木刷子,黑板,熏鲑鱼片,拉链

本集看点: 毛刷组装时的金属U型倒扣固定住刷毛;

S04E07 3D Commercial Signs; Hardwood Floors; Corrugated Polyethylene Pipe; Mattresses 立体标牌,硬木地板,聚乙烯管,床垫

本集看点: 大型塑胶型材的成型过程;弹簧的制作过程;

S04E08 Ceramic Tiles; Nuts; Steel Forgings; Skateboards 瓷砖,果仁,炼钢,滑板

本集看点: 炼钢和轧钢;

S04E09 Car Engines; Flour; Recliners; Envelopes 轿车引擎,面粉,活动躺椅,信封

S04E10 Plastic Cups & Cutlery; Special Effects Makeup; Gold; Harps 塑料杯和餐具,特技化妆,黄金,竖琴

本集看点: 热成型一次性塑料杯;简单一些的塑料管型材制作过程;金锭的制作过程;

S04E11 Countertop Laminate; Frozen Treats; Children's Building Blocks; Detergents 表面压片,雪糕,儿童积木,清洁剂

S04E12 Architectural Moldings; Pulleys; Industrial Rubber Hose; Sheet Vinyl Flooring 装饰嵌条,滑轮,橡皮管,树脂地板

S04E13 Putty Knives; Garage Doors; Electric Motors; Wool 油灰刀,车库活动门,电动机,毛料衣物

本季资源链接:

magnet:?xt=urn:btih:0e69c6104b7c64173fa6ef64df6d7a801dd95f6f&dn

第五季推出时间为2005-09-07至2005-11-29

S05E01 Paving Asphalt; Marshmallow Cookies; Loudspeakers; Electronic Door Locks 沥青石料,葵糖饼干,高音喇叭,电子门锁

S05E02 Wood Burning Stoves; Orthoses; Ballet Slippers; Buses 木炭火炉,矫正鞋具,芭蕾舞鞋,公共汽车

S05E03 Robotic Arms; Tattoos; Sanitary Napkins; Concrete Pipes 机械手,纹身,卫生巾,水泥管

S05E04 Hockey Gloves; Snack Cakes; Remoulded Tires; Wastewater Treatment 曲棍球手套,点心蛋糕,轮胎翻新,污水处理

S05E05 Ambulances; Dining Room Tables; Diatonic Accordians; Acrylic Awards 救护车,餐桌,手风琴,有机玻璃工艺品

S05E06 Alkaline Batteries; Wheelchairs; Flutes; Cowboy Boots 碱性电池,轮椅,长笛,牛仔靴

本集看点: 学习一下最常见类型电池的制作原理;

S05E07 Golf Balls; Furniture Handles; Parking Meters; Room Dividers 高尔夫球,门扣,停车计时器,房间屏风

S05E08 Suits of Armour; Street Light Poles; Bent Hardwood; Membrane Switches 铁盔甲,电灯杆,弯曲硬木,薄膜开关

本集看点: 可以看到锅仔片的结构原理;

S05E09 Sulkies; Bagpipes; Yule Logs; Fishing Lures 单座两轮马车,风笛,圣诞节原木形大蛋糕,假鱼饵

S05E10 Goalie Pads; Lapel Pins; Cardboard Boxes; Crystal Wine Glasses 守门员护具,衣襟徽章,纸盒,水晶杯

S05E11 Cement; Caskets; Soft Drinks; Glider Rockers 水泥,棺材,饮料,摆动式摇椅

S05E12 Kitchen Knives; Mannequins; Socks; Hypodermic Needles 厨刀,人体模型,纱袜,针头

S05E13 Electrical Panels; Kites; Eyeglass Frames; Toothbrushes 配电板,风筝,眼镜架,牙刷

本季资源链接:

magnet:?xt=urn:btih:997cae2b195f96293de6b35858cc50fdc73431f3&dn

第六季推出时间为2006-01-04至2006-03-29

S06E01 Three-Wheeled Vehicles; Baseball Bats; Artificial Bonsais; Trombones 三轮摩托,棒球棍,盆景,长号

S06E02 Springs; Pavers; Pianos; 弹簧,路砖,钢琴

本集看点: 各种弹簧的全自动制作过程;

S06E03 Ropes; Billiard Tables; Sailboards; Cymbals 绳索,台球桌,帆板,铙钹

S06E04 Seatbelts; Windows; Wax Figurines; Hot Air Balloons 安全带,塑钢窗,小蜡像,热气球

S06E05 Air Filters; Billiard Cues; Ice Sculptures; Suits 空气过滤器,台球杆,冰雕,西服

S06E06 Escalator Handrails; Highlighters; Guitar Strings; Wigs 自动扶梯扶手,荧光记号笔,吉他弦,假发

S06E07 Traditional Bows; Coffee Machines; Mascots; Hammocks 传统的弓,咖啡机,吉祥物,吊床

S06E08 Fiberglass Insulation; Wooden Ducks; Gumball Machines; Exhaust Systems 玻璃纤维隔层,木鸭子,口香糖球售卖机,排气管

S06E09 Chains; Bagels; Vinyl Records; 链条,硬面包圈,唱片

S06E10 Windshields; English Saddles; Butter; Post Clocks 挡风玻璃,英式马鞍,黄油,柱钟

本集看点: 夹层玻璃的制作过程;

S06E11 Individual Transporters; Canoes; Electric Guitars 双轮代步车,雪松独木舟,电吉它

S06E12 Residential Water Heaters; Air Bags; Jelly Beans; Ice Resurfacers 宅用热水器,气囊,胶质软糖,冰面修整器

S06E13 Amphibious Vehicles; Putters; Model Ships; Drumheads 水陆两用车,高尔夫球杆,轮船模型,鼓面

本季资源链接:

magnet:?xt=urn:btih:2575f1794b6554ba85b38125e673a95ecb7bb668&dn

第七季推出时间为2006-09-05至2007-03-30

S07E01 Footballs; Electric Guitar Amplifiers; Marbles; Airplane Propellers 橄榄球,吉它扩音器,玻璃球,飞机螺旋桨

本集看点: 精美的艺术品玻璃球;先锻造再CNC成型的结构件;

S07E02 Engine Blocks; Jawbreakers; Drum Shells; Drums 引擎铸模,硬球糖,爵士鼓

本集看点: 引擎的模具制造和浇铸过程;

S07E03 Lighters; Fossils; Hockey Pucks; High-Pressure Cylinders 打火机,化石,冰球,高压钢瓶

本集看点: 铝合金的多次拉伸成型过程;

S07E04 Balloons; Wallpaper; Frozen French Fries; Incandescent Light Bulbs 气球,墙纸,炸薯条,白炽灯泡

S07E05 Matches; Carousel Horses; Fine Porcelain; Fuel Tanks 火柴,旋转木马,细瓷,汽油箱

S07E06 Glass Cookware; Soap Bars; Steel Drums; Firefighter Uniforms 玻璃炊具,肥皂,铁皮鼓,防火服

S07E07 Crayons; Wooden Kayaks; Lawnmowers; Gold Chains 蜡笔,木伐子,割草机,金项链

S07E08 Inflatable Safety Devices; Braille Typewriters; Carbon-Fibre Cellos 安全气囊,盲人打字机,碳纤维大提琴

S07E09 Carbon-Fibre Masts; Fortune Cookies; IMAX Projectors; Roller Chains 碳纤维桅杆,好运饼干,IMAX 放映机,滚子链

S07E10 Firefighter Helmets; Nautical Compasses; Packaging Tubes; Hand Saws 消防员头盔,罗盘,包装软管,手锯

S07E11 Halogen Bulbs; Cellulose Insulation; Aluminum Ladders; Bamboo Fly Rods 卤素灯,纤维绝缘层,铝梯,竹制飞蝇钓竿

S07E12 Drill Bits; Photo Booths; Stamps 钻头,照相亭,邮票

S07E13 Yacht Wheels; Braided Rugs; Automobile Thermostats; Chisels 游艇方向盘,编织毯,汽车调温器,凿子

本季资源链接:

magnet:?xt=urn:btih:06d33183a0f6ea98b8a64257d73ae0ce870082c6&dn

第八季推出时间为2007-01-02至2007-04-03

S08E01 Motorcycles; Clay Pipes; Drumsticks; Whistles 摩托车,水泥管,鼓槌,哨子

S08E02 Glass Bottles; Hacksaws; Goalie Masks 玻璃瓶,钢锯,守门员面具

本集看点: 极其舒适的玻璃瓶模具制造和吹制成型制程;

S08E03 Lacrosse Sticks; Frozen Fish Products; Flashlights; Paintbrushes 长柄曲棍球杆,油炸冻鱼肉,手电筒,油漆刷

S08E04 Deep Cycle Batteries; Tins; Optical Lenses 蓄电池,白铁罐,光学镜头

本集看点: 镜头的打磨抛光制程,以及多层镜片结构;

S08E05 Pistons; Paint Rollers; Parachutes; Chimneys 活塞,油漆滚筒,降落伞,烟筒

本集看点: 先锻压成型再CNC的典型结构件;由钢板卷成圆筒的典型制程,提前制作倒钩结构进行预固定,自动化制程不需要;

S08E06 Fishing Reels; Miniature Houses; Kitchen Mixers 渔线轮,迷你房屋,厨房搅拌器

S08E07 Photographs; Fur Tanning; Welding Electrodes; Electric Violins 照片,毛皮制革,电焊条,电子小提琴

S08E08 Horseshoes; Dishwashers; Graphite Fly Rods; Pizza 马蹄铁,洗碗机,石墨飞蝇钓竿,比萨饼

S08E09 CO2 Cartridges; Pretzels; Scissor Lifts; Skating Rinks 二氧化碳弹药筒,椒盐卷饼,剪式提升机,滑冰场

S08E10 Pro Hockey Sticks; Bronzed Shoes; Treadmills; Computers 职业曲棍球棍,古铜色婴儿鞋,跑步机,掌上电脑

S08E11 Handcuffs; Caulking Compound; Propane Tanks; Forensics 手铐,堵缝剂,丙烷罐,法医学面部再造

本集看点: 上下焊接的冲压铝罐制程;

S08E12 Fur Coats; Hearses; Outdoor Lighting Fixtures; Golf Tees 毛皮大衣,灵车,室外照明器材,高尔夫球座

S08E13 Manhole Covers; Range Hoods; Artificial Logs; Snowmobiles 下水道井盖,抽油烟机,人造原木,雪地摩托

本集看点: 简单一些的金属铸造制程;

本季资源链接:

magnet:?xt=urn:btih:c04d9b7696663c9326761cf99038907f5db5f089&dn

第九季推出时间为2007-09-21至2008-04-06

S09E01 Solid Tires; Cheesecake; Canoe Paddles; Globes 实心轮胎,奶酪蛋糕,独木舟短桨,地球仪

S09E02 Boomerangs; Barbeques; Pinball Machines; Strobe Lights 回力镖 ,烧烤炉具,弹球机,闪光灯

S09E03 Wooden Bowls; Chainsaws; Stackable Potato Chips; Jet Compressor Blades 木圆盆,链锯,马铃薯片,喷气压缩机叶片

S09E04 Steel Wool; Ranges; Carved Candles; Slot Machines 钢丝棉,炊具系列,雕刻蜡烛,老虎机

S09E05 CCD Semiconductors; Airline Meals; Paper Cups; Trumpets CCD半导体,航空餐,纸杯,小号

本集看点: 先进制程之相机CCD感应芯片制作过程;

S09E06 Padlocks; Hair Clippers; Wooden Shoes; Synthetic Leather 挂锁,电推剪,木鞋,人造革

S09E07 Racing Shells; Stainless Steel Sinks; Leather; Pedal Steel Guitar 划艇,不锈钢水池,皮革,踏板钢铁吉他

S09E08 Swords; Pontoons; Grandfather Clocks; Fuses 剑,浮船, 落地大摆钟,保险丝

S09E09 Bumpers; Lighting Gels and Camera Filters; Steam-Powered Models; Candy Canes 保险杠,滤色片,蒸汽模型,苔杖糖

S09E10 Umbrellas; Outboard Motors; Silver Cutlery; Tape Measures 雨伞,舷外马达,银制餐具,卷尺

S09E11 Scalpels; Oil Paints; British Police Helmets; Ice Axes 手术刀,油画颜料,英国警察头盔,冰斧

S09E12 Bacon; Snowblowers; Luxury Cars 熏肉,扬雪车,豪华轿车

S09E13 Automatic Transmissions; Silver Miniatures; Hot Air Balloon Baskets; Darts 自动变速器,银制微型复制品,热气球吊篮,飞镖

本季资源链接:

magnet:?xt=urn:btih:a9aa449eda3eeaa8d9e9d91996dde5510940630f&dn

第十季推出时间为2008-06-11至2008-09-03

S10E01 Magnets; Cooked Ham; Silver Teapots; Crash Test Dummies 磁铁,火腿,银制茶壶,撞击测试人体模型

本集看点: 用线圈磁化的磁铁;对于收口的茶壶,内芯���置冲压模具应该是用可变形的橡胶;

S10E02 Curling Stones; Refrigerators; Aluminum Baseball Bats; Opalescent Glass 冰壶,冰箱,铝制棒球棍,乳白玻璃

S10E03 Levels; Hot Dogs; Abrasive Grains; Sandpaper 水平尺,热狗,抛光粉,砂纸

S10E04 Ice Cream Treats; Wooden Golf Clubs; Aircraft Wings; Car Battery 冰淇淋,木制高尔夫球杆头,飞机机翼,车用蓄电池回收

S10E05 Automotive Fuel Pumps; Cricket Bats; Change Machines; Ductile Iron Pipe 汽车燃油泵,板球,纸币找换机,球墨铸铁管

S10E06 Wooden Barrels; Fire Hydrants; Automotive Seats; Cathode Ray Tubes 木桶,消防栓,汽车座椅,阴极射线管

本集看点: 老式CRT电视是如何制作的;

S10E07 Stainless Steel; Football Helmets; Resin Figurines; Laboratory Glassware 不锈钢,橄榄球头盔,树脂小塑像,实验室玻璃器具

本集看点: 不锈钢轧制制程;玻璃管的热切割制程;

S10E08 Fire Extinguishers; Doughnuts; Shock Absorbers; Banjos 灭火器,甜甜圈,减震器,班卓琴

S10E09 Dress Forms; Boat Propellers; Duvets; Faucets 女装人体模型,小艇螺旋桨,羽绒被,水龙头

本集看点: 注塑的融模,再进行浇铸;

S10E10 Bronze Bells; Wooden Airplane Propellers; Charcoal Briquettes; Gas Log Fireplaces 铜钟, 木制螺旋桨, 木炭和煤气炉

S10E11 Ice Cream Cones; Tent Trailers; Shoe Polish; Pliers 折叠刀, 皂石, 变压器和传统雪鞋

S10E12 Steel Shipping Drums; Police Whistles; Miniature Train Wagons; Glass Blocks 油桶, 警笛, 微型车厢和玻璃垫块

S10E13 Pocket Knives; Soapstone Products; Electric Pole Transformers; Snowshoes 蛋筒, 篷式挂车, 鞋油和钳子

本季资源链接:

magnet:?xt=urn:btih:3e5cd2ae716c8363111416709f962ae68ec36a60&dn

7 notes

·

View notes

Text

Manufacturer Digital Paper Print | Laminate Door Skin | Door Paper - Wonder Sign

In The Modern Era Of Digitization, We At Wonder Sign Make Amazing And Fabulous Digital Door Paper Print Or Digital Door Print For You. Every Time We Strive To Make Unique Designs of Door Digital Paper Print. The Printing Process Used To Create The Door Paper Involves Applying High-Resolution Images Or Patterns To The Paper Using A Specialized Printing Press.

This Allows For A Wide Variety Of Designs And Colors To Be Used, Which Can Range From Natural Wood Grains To Abstract Designs And Vibrant Colors. We Are Known As The Best Manufacturer, Exporter, And Supplier Of All Kinds Of Laminate Door Skin.

People Have Already Started Interesting In Our Products And Adopted Them. Moreover, You Can Also Feel The Rest Of The Products That Are Sunmica Paper, Decorative Door Paper Print, Digital Door Skin Paper, Lamination Paper Print, Lamination Door Print And Many More.

Website: http://www.wondersign in/

Email: [email protected]

Contact Us: +91-99046 88588

Address: Survey No. 644 Trustee Shri Dayawan Trust Kathwada, Moje Gam, Daskroi Nikol- 382430, Ahmedabad, Gujarat.

More Products:

Pvc Membrane Foil

Digital Uv Paper Print

3d Door Skin

Instagram: https://www.instagram.com/wondersign.1/

Pintrest: https://in.pinterest.com/wondersignprint/_saved/

#digital paper print #laminate door skin #door skin paper #door paper #sunmica paper #decorative door paper print

0 notes

Text

Types of Waterproofing | Waterproofing Membrane

Waterproofing is a lifesaver for your buildings now, in the future and forever. Waterproofing will make a massive difference for people of all ages, right from toddlers to the elderly. Making your home impervious to the ingress is called waterproofing, and it might cost only 1% of the total construction cost. But avoiding it to save you this 1% might cause a loss of 90% as the years pass. So never think twice about waterproofing the walls, foundations, roofs, kitchen or even toilets and bathrooms as these places might be prone to water and vapour ingress.

There are different types of waterproofing, and as the years advance, the technologies are getting better and better. The techniques that were used for waterproofing before a decade or two have now become obsolete.

You may also like to read:

1. What to Consider Before Contacting a Construction Company in UAE

2. Everything You Need To Know About Cementitious Waterproofing

3. MEP Means

In this blog, we’re going to explain different types of waterproofing and the benefits of each. Read the advantages and disadvantages of each method and choose wisely.

1. Bituminous Waterproofing

The bituminous waterproofing method is used to protect your buildings, both commercial and residential, from water ingress. The technique is covering the areas prone to water ingress using Bitumen, which is an amalgamation of organic substances. It is a semi-solid form of petroleum and is highly viscous, sticky and possess superior waterproofing features as hydrocarbons repel water. Bitumen is basically Asphalt or Coal-tar. Bitumen is also used to construct roofs as roofing felts or rolls and is very effective in protecting the building from damages due to water ingress. There are two types of Bitumen waterproofing methods: The bituminous coating waterproofing method and the Bituminous membrane waterproofing method.

Bituminous Coating Waterproofing Method

In the Bituminous coating waterproofing method, bituminous paints which have bitumen as their foundation are used. By mixing Bitumen with solvents such as mineral spirit or naphtha, bituminous paints are made. In coating applications, an advanced form of bituminous paint is used for coating the surfaces which need to be waterproofed. It is cost-effective and protects your surfaces from UV rays. The flexible coating will give additional protection to the concrete surfaces and prevent water from seeping in and damage the structure. Bitumen is naturally insoluble in water, and this property makes it even more effective as a sealant or a waterproofing coat. It is vapour-proof, flexible and is also known as Asphalt coating. Also, as Bitumen paints are Alkaline resistant, it is also used for coating underwater structures as well.

However, Bitumen is made from crude oil and is not sustainable. The material is also combustible and is not compatible in areas where the temperatures rise to the extreme. If combined with the right solvents, Bitumen will perform well and act as the perfect waterproofing coating for your buildings.

Bituminous Membrane Waterproofing Method

The Bituminous waterproofing membrane is used on sloped surfaces to prevent water and vapour ingress and is also highly cost-effective. The membrane comes as rolls or sheets and is laid on a firm surface which will be protected UV and water damages. The Bituminous membrane is stuck to the surface using a strong tar-based adhesive and a blowtorch. This will provide proper and improved adhesion and performance. The sheets or membranes are overlapped by almost four inches, or in some cases, the sheet itself is melted to stick it to the adjacent one to provide better adhesion and waterproofing. The quality is consistent, and you should ensure that an expert in Waterproofing is chosen to deliver the services to prevent leakages.

2. Cementitious Waterproofing

Cementitious waterproofing coatings are breathable coatings that can provide positive-negative side waterproofing for concrete and carved surfaces. Conventional ceiling and waterproofing systems include bituminous materials, plastic waterproofing foils, and metal tapes for interior and exterior applications. In addition to these systems, products based on reactive resins, thoroughly dispersed, pasty products, and cementitious waterproofing membranes are now widely used to maintain the structural condition of buildings and seal and protect exterior surfaces against the action of water and moisture.

By mixing cement with acrylic products, we acquire the waterproofing characteristics, which provides an excellent cementitious bonding that lasts longer. The cementitious waterproofing has two steps, and in the first step, the primary coat is applied. A trowel, a brush or a spray tool can be used to apply the mixture and to ensure uniform thickness throughout the surface. Ensuring uniform thickness throughout the cementitious membrane is essential for optimum results.

Application of Cementitious waterproofing

Water is crucial but can also be the biggest nightmare when it comes to constructions. The groundwater, rain, and surface water can be a threat to construction materials. Engaging cementitious waterproofing can protect the wet surfaces from water and vapour ingress. The applications of cementitious waterproofing include sealing and waterproofing of wet floors. Also, cementitious membranes can be used to protect concrete walls from aggressive chemicals. Cementitious waterproofing offers excellent waterproofing even if exposed to water or vapour permanently. The exceptional resistance to long-term weathering, great load-bearing capacity, good scratch resistance, and superior water vapour permeability make cementitious waterproofing methods much accepted and chosen over other waterproofing methods.

3. Polyurethane Waterproofing

Polyurethane is an amalgamation of Polyol and Isocianide, and they act as base and reactor, respectively, in the waterproofing process. By combining these two elements in a specific ratio, Polyurethane, a liquid with excellent waterproofing qualities, is formed. Polyurethane is a widely accepted waterproofing method as it is easy to install, unlike the other sheet or membrane waterproofing methods. This type of waterproofing can be done post construction as well. The installation is relatively easy, demands minimal supervision and ensures perfection. The Polyurethane waterproofing will protect your buildings from harsh weather, chemical attacks, UV protection and long term wear.

The method is highly economical, and you can even apply it over already existing waterproofing coatings if you want to. One must be careful before choosing the Polyurethane waterproofing available in the market. Otherwise, the one you select might not possess the properties to live up to your expectations when it comes to waterproofing. The perfect Polyurethane waterproofing coating will have the following features:

Impermeable

Flexible

Breathable

Durable

Resistant

Humidity Barrier

A good Polyurethane waterproof coating will:

Have hardly any water swelling rate and high retention of tensile strength.

Elasticity even if exposed to harsh climates for a longer duration.

Consistent adhesion to the surface.

Overall superior performance even under adverse climatic conditions.

4. Thermoplastic Waterproofing

Another most preferred waterproofing method is thermoplastics. It might not be the cheapest, but it does what it is intended to do best. The material is so good that it has the potential to waterproof your construction for at least 50 years. Thermoplastic, when heated, changes from solid into a semi-solid form and ensures perfect adhesion and zero leakage. The polyester knit fabric coated with ethylene interpolymer compound renders in with superior waterproof features. Its impressive tensile and tear resistance, puncture resistance and stability make the method even more user friendly and durable. The thermoplastic membranes are available in two thicknesses, and they can be your lifesaver when it comes to bladder type situations. The material has the ability to keep liquid and vapour out, so it is the perfect choice when it comes to waterproofing your constructions.

5. Rubberised Asphalt Waterproofing

Rubberised asphalt Waterproofing membranes consist of asphalt and rubberised polymers with some mineral stabilisers. The monolithic membranes created by rubberised asphalt can cover large surfaces and protect them from water ingress effectively. If you want to waterproof extensive vegetative assemblies or intensive roofing assemblies, hot rubberised asphalt will come in handy. Primarily rubberised asphalt is used for protecting commercial constructions. The material is really tough and can guarantee your buildings with protection and minimal vapour permeability. The cost of the process depends on the area which is to be waterproofed.

6. PVC Waterproofing Membrane

Poly Vinyl Chloride waterproofing membrane is made by mixing PVC resin with plasticisers, UV absorbers and other additives to render superior waterproofing characteristics. The polyester reinforced membrane is a promising material and will offer extended durability. The unreinforced membrane is more flexible than the reinforced ones and is used for waterproofing swimming pools, underground structures, tunnels, etc. some of the features that make PVC waterproofing popular are:

Durability

A strong bond between the membranes

Greater tightness and elasticity

Chemical and harsh weather resistance

100% water resistance

Frostproof

Wind load resistance

Ability to withstand higher temperatures

Oxidation and UV resistance

PVC membranes can be applied on flat roofs and offer irreplaceable finishing. After installing the PVC membranes, the roofs can be used for recreation as the surface becomes smooth and better. With the durability so high, the membrane can last up to fifty years with a meagre maintenance cost.

7. EPDM Rubber

EPDM is a type of synthetic rubber that is used for waterproofing flat surfaces. EPDM stands for Ethylene Propylene Diene Monomer. It has extreme weather and water-resistant features and is also used in vehicles. The material is class M rugged and is made of ethylene and propylene. EPDM rubber is better performing than other waterproofing membranes such as Bitumen, both technically and commercially. The EPDM membranes do not require a flame, torch or gas to apply. But bonding adhesives are used for the application, unlike the other torch-on membranes. EPDM is a material with high elasticity and viscosity. The high tensile strength it possesses and the ease of application make EPDM a common and widely used waterproofing material in both commercial as well as residential buildings.

8. Liquid Waterproofing Membrane

Liquid waterproofing membranes can be applied like paint and possess high elasticity. The materials used for liquid waterproofing will be based on the surface you wish to waterproof. Material like PVC, cement, Silicone, rubberised asphalt, etc., can be used for the liquid waterproofing method. Choosing the material will mainly depend on the surface and the use of the surface. Understand the features of each material and what circumstances a material cannot or can withstand. The liquid waterproofing system is monolithic, i.e., without joints. It is a fully bonded and highly secure system and prevents infiltration efficiently. A large number of people are adapting the environment friendly and easily repairable model waterproofing for cost-effectiveness and ease of installation.

Since liquid waterproofing membranes offer excellent durability, exceptional elasticity and much easier to implement, it is popular among the waterproofing methods. Choosing the right material to waterproof your buildings to prevent vapour and water ingress is important to protect and safeguard them for a longer time.

Final Words!

Waterproofing your buildings is crucial as water has the ability to destroy the entire construction if seeped in. Your buildings won’t be able to withstand even the vapour ingress. Waterproofing is a mandatory process that will benefit everyone if appropriately implemented. The construction costs are already high, and the waterproofing might come up to a maximum of ten per cent of the total construction costs. Avoiding the process to save you some money might be the reason to lose a lot more in the future. Be wise and do proper research before choosing a waterproofing method to be implemented before jumping at the first option. There are many waterproofing methods available in the market these days, and each has very specific features and purposes.

1 note

·

View note

Photo

Jeffrey Shaw, Theo Botschuijver, Sean Wellesley-Miller, Waterwalk Tube, Hannover, Germany, 1970 “This site-specific installation was an inflatable tube made from transparent PVC foil that was floated across the Maschsee Lake in Hannover, connecting its opposite banks. The tube was approximately 250 meters long and 3 meters in diameter. This air-filled bridge had revolving doors at each end that functioned as airlocks, and its pliable floor was in direct contact with the water surface. Visitors were able to enter this almost-immaterial structure and cross from one side of the lake to the other, with the inflated membrane of the tube supporting them as they ‘walked on water’.” #waterwalktube #jeffereyshaw #hannover (at Hannover, Germany) https://www.instagram.com/p/B37iJ1HA_2o/?igshid=d113v1f6hp0d

1 note

·

View note

Text

What is PE Film and Gas Permeability of PE?

Preservative film is a kind of plastic packaging products, which is mainly used in heating microwave food, preserving refrigerator food, fresh and cooked food packaging and other occasions. According to the different materials, the preservative film can be divided into the following types, which are suitable for different occasions.

The first film is polyethylene (PE),which is usually a mixture of similar polymers of ethylene. As the most common plastic in use today, it is primarily used for food packaging (fruits, vegetables and semi-finished cooked food sold in supermarkets).

The second is PVC, which can also be used in food packaging, but it has certain harm to the health. It is also used in making bottles, non-food packaging, food-covering sheets, and cards (such as bank or membership cards)

The last one is polyvinylidene chloride (PVDC) - a homopolymer of vinylidene chloride, which is mainly used for the packaging of cooked food, ham and other products.

Among the three kinds of fresh-keeping films, PE and PVDC are health and can be used safely, while PVC is harmful to human body because it contains carcinogens. Therefore, PE is the first choice when choosing fresh-keeping film. In general, the more higher the barrier property of the material is, the better the preservation of fresh food is.

Gas Permeability Coefficient (P), also known as Gas Permeability, is the volume of gas passed through unit thickness and area of the sample in unit time under constant temperature and unit pressure. GPT-201B Gas Permeability Tester is based on the differential pressure method and is professionally applicable to the determination of gas transmission rate as well as solubility coefficient, diffusion coefficient and permeability coefficient of plastic films, composite films, high barrier materials, sheeting, metal foils, rubber, tires and permeable membranes.

0 notes

Text

PVC tarpaulin is a three-ply fabric consisting of a piece of scrim laminated between two sheets of polyvinyl film (PVC).

Scrim is loosely woven material which can be made out of cotton, fiberglass, nylon, polyester, or a combination. The polyester is measured by the weights of the thread (denier) and the density of the weave (threads per inch) or count. The heavier the weight the higher the denier. A 9×9 scrim has 9 threads per inch by 9 threads per inch. The first number is the number of threads in the machine direction (or warp) and the second number is the number of threads in the cross direction (or fill). The vinyl is measured by its thickness (1 mil is 1/1000 of an inch). Vinyl is treated to have certain properties such as flame retardant, antimicrobial, antistatic, and ultra violet protected. PVC tarpaulin has a weight which is measured in ounces per square yard. For example: one square yard of a 13 oz. material weighs 13 ounces. As the material is put through the laminator, it is also embossed. An embossing is the surface texture. Duletai’s most common embossings are matte, taffeta, and polish. Our banner products usually have a matte finish for smoothness. Our tent products often have a polish finish, and our hospital products, such as mattress ticking have a taffeta finish. The material is rolled onto a cardboard core. Our standard core size is 3” inside diameter, but occasionally we will use a 2” core. The polyvinyl chloride (PVC) films were complemented by polyurethane films and coatings, silicone coatings, acrylic coatings, and blended rubber coatings. All of these films and coatings are reinforced with nylon and polyester fabrics which are non-wovens, wovens, and knits. There are many other films, fabrics, and foil that can be coated and laminated for a variety of special applications. The width of PVC tarpaulin is from 1.02 m up to 5.10m . Color can be customized according to customers’ requirement. We can produce laminated and coated PVC tarpaulin, for its good flexibility, excellent tensile strength and tear strength and develop all kinds of durable PVC tarpaulin materials for different applications:http://www.duletai.com/

Gernarlly speaking, pvc tarpaulin can be split into 4 types according to the technology and machine used:

Calendering machine: This machine is used to make pvc film. It can stir the pvc raw material to the paste. Then use roller system to calender into different thickness pvc films. Calendared vinyl films are formed from an older process of taking a dough-like material consisting of PVC, pigments, plasticizer and stabilizer, mixing them in an extruder and then rolling it through polished heated rollers which stretches the material to the proper thickness. The film is then fused to a polyester backing. The process is completed when the material is given a gloss, matte or embossed finish.

Cold lamination machine: This machine is the first generation invented for this industry. It is still wildly used to laminate pvc films onto polyester base fabric. It’s short process, high speed and low running cost. The disadvantage is the drum temprature and pressure is limited so the product quality is for short life time material like flex banner and tarpaulin for low price market.

Hot laminateion machine: This is the PRO version of cold lamination machine, it is almost twice longer process. This machine can reach much higher temprature and pressure, it has much more complex embossing roller and surface treatment system to can make high quality, high gsm material that can be used for tents, covers, inflatables…etc and with it’s surface treatment it can add acrylic coating to make it self cleaning. Also this machine can add extra glue to the film or base fabric to make simi-coated pvc tarpaulin which is better adhensive performance to improve the technical data and life-span of the product.

Knife coating machine is not like lamination machine that need calendering machine supply pvc film in big rolls. It directly coat pvc resin on to the base fabric with a doctor blade. Then the material go through embossing roller to heatcase for drying. Knife coating machine is a kind of luxury option for vinyls, the coating quality have led to significant increases in lifespan over 10 years. And it can make heavy-duty material over 1500gsm for membrane structure or tents. PVC coated vinyl has excellent tensile strength. This fabric is useful for both permanent and temporary projects. The PVC coated vinyl can be used for things like luggage, bags, cases, and protective coverings. PVC coated vinyl roll widths from 1.0mts -5.1mts, weight From 240gsm -2700gsm, thickness from 0.19mm -2.0mm.

0 notes

Text

2020 Ordinary Asphalt Roof Installation Prices: Just How Much Does an Asphalt Roofing System Price? Free Quotes, price quotes and also costs

Also the best, most pricey membranes will certainly stop working, if a contractor does not know what he is doing. Many people try to conserve cash on setup as well as believe promises of basic professionals who are willing to bill less, just to get your service. Often it takes just 1-2 heavy rain storms for the damages to show.

Nonetheless, steel roof has the longest lifespan, lasting between 20 and also thirty years. Metal is an exceptionally sturdy product as well as is unsusceptible to splits that influence single-ply roof coverings. Nonetheless, steel roofing systems can be at risk to leakages around the seams as well as roofing system edges.

You should use your very own UV protection to the surface area if your SBS changed asphalt roofings does not come with foil or granule coating. With SBS roofing, the asphalt is customized to form a polymer network inside the asphalt. SBS represents styrene butadiene styrene as well as provides the asphalt a rubber-like quality.

Each roll measures 10 metres by 1 metre and covers an area of 8.7 m ². With proper workmanship, the APP membrane layer is a extremely efficient and also long lasting waterproofing product utilized in many building and constructions. It is a common waterproofing product made use of on concrete flat roofing systems (which are still roof coverings) or roofing systems with low pitch.

Properly mounted PVC as well as TPO roofing systems should not have leaks, unless something creates a tear in the membrane that lets water in. Accumulated roofings frequently have leakages that are really tough to discover and also for that reason repair service, which is why these roofs are installed less as well as much less.

youtube

What is the very best flat roof covering product?

Atactic polypropylene bitumen roof covering is a popular selection for brand-new business roof building. This uses a polycarbonate polymer that offers the asphalt a plastic-like top quality, allowing it to much better withstand water and UV light exposure. Styrene-butadiene-styrene is another sort of bitumen roofing as well as features a sticky support to the membrane.

This implies utilizing a 2 or 3-ply product and also having it covered against UV direct exposure.

PVC roof is roofing company midland Texas somewhat extra pricey than other single-ply business roof covering products, nonetheless it supplies a wide variety of benefits for the price.

We damage down one of the most prominent and also ideal commercial roof covering materials that you ought to take into consideration when replacing your company's roof covering.

Asphalt Roof Covering- Negative Aspects

Can you walk on torch down roofing?

youtube

EPDM is an extremely durable synthetic rubber roofing membrane (ethylene propylene diene terpolymer) widely used in low-slope buildings in the United States and worldwide. Its two primary ingredients, ethylene and propylene, are derived from oil and natural gas.

TPO is the second most regularly installed flat roofing on homes. This can be vague, yet if you have numerous infiltrations, curbs, roof-to-wall blinking, challenging drain, pick the Medium or even Complex setup. If your professional requires to work with authorities detail, or if your roof is 7 tales off the ground, the cost WILL go up. Surface area granules are the shingles initially layer of safeguarding versus the elements, and CertainTeed's Northgate SBS make-up supplies a much better layer of protection. Over time, exposure to the aspects can likewise create roof asphalt to reduce or split.

" The roofing company by which all others are measured."

Furthermore, once mounted, a PVC roofing system will certainly call for very little maintenance and almost no fixings (unless some significant accident takes place that will certainly tear the membrane layer). Over the last few years flat roofings have grown in popularity because of their definitely contemporary appearance, in addition to ease of installation and also repair service. When it pertains to set you back, a level roof is cheaper than most of sloped roof covering products, with the exception of composite roof shingles. The process of liquid roof covering offers a cost-efficient method of making a new or existing roof waterproof. It can deliver up to 25 years performance depending on the finish system employed.

0 notes