#PET blowing machine supplier

Text

PET is a clear, strong, and lightweight plastic that is widely used for packaging foods and beverages, especially convenience-sized soft drinks, juices and water. PET is approved as safe for contact with foods and beverages by the FDA and health-safety agencies throughout the world. Seppasolutions is a leading manufacturer of fully & semi automatic PET bottle blowing machine in Chennai, serving clients across the globe. PET blowing machine's capacity ranges from 2 cavities to 8 cavities that can be blows from 200 to 12000 BPH. Order your own Pet blowing machine. Call us now at or just log on to www.seppasolutions.com

#PET blowing machine#PET blowing machine manufacturer#PET blowing machine supplier#PET bottle making machine#PET bottle blowing machine#PET blow moulding machine

0 notes

Photo

The PET bottle-blowing machine manufacturing industry is expected to grow significantly in the near future. Several factors are driving this growth, including the increasing demand for environmentally friendly products and the increasing popularity of recreational activities. Invest in your own pet blowing machine. To learn more about Seppa Solutions, please call us at or go to our website at www.seppasolutions.com.

#PET blowing machine#PET blowing machine manufacturer#PET blowing machine supplier#PET bottle making machine#PET bottle blowing machine#PET blow moulding machine

0 notes

Text

#PET Blowing Machine in Delhi#PET Blow Moulding Machine in Delhi#PET Blowing Machine Manufacturers in Delhi#PET Blow Moulding Machine Manufacturers in Delhi#PET Blowing Machine Suppliers in Delhi#PET Blow Moulding Machine Suppliers in Delhi#PET Blowing Machine Exporters in Delhi#PET Blow Moulding Machine Exporters in Delhi

0 notes

Text

China Sanshun is offering SHE120 Fixed Pump Injection Moulding Machine, the perfect solution for creating high-quality plastic products. Our machine boasts a range of features and advantages, including linear transducer control for precision in clamping, injection, and ejection.

The nitride hardened screw and barrel ensure durability, while the high torque hydraulic motor and modular design offer versatility and efficiency.

Contact us now for more information.

#plastic auxiliary machine#Injection Blow molding machine#Injection Blow molding machine leading suppliers#Injection Molding Machine for Basins#Injection Molding Machines for Pharmaceutical packaging items#Variable Energy Saving Injection Moulding Machine leading suppliers#LED Bulb Cover Making Injection Blow Machine#PET Preform Injection Molding Machine OEM manufacturers

0 notes

Text

Pet Stretch Blow Moulding Machine, SP Pristine Series | Shyam Plastic

SP Pristine Series-II is a Fully Automatic Electric Pet Stretch Blow Moulding Machine by Shaym Plastic with 9000-18000 BHP & 7-12000 bottles per hour.

0 notes

Text

There are minimum scrap losses

Plastic injection molding is a process of injecting small particles of the thermoplastic material, in order to produce plastic mold.. The molten thermoplastic pet preform mold manufacturers solidifies rapidly under a plastic mold, which can further be removed from it. The cast is then clamped under pressure within a fixed temperature keeping in mind the melting point of the thermoplastic. The entire system helps in manufacturing various materials & machines from commodity to engineering base. Running cost varies. Advantages of plastic injection molding: Injection molding produces various daily use products such as plastic glasses, dust bins, bottle caps and other materials. There are several factories which are providing high-end injection molding procedures.

The plastic is first melted and then injected into a mold with some plunger arrangement. As plastic is dangerous for the environment if thrown in the landfill, this process of plastic injection molding reduces the environmental risk. There are minimum scrap losses. Straight pulls The ejection within the machine The CNC milling process Creating a perfect plastic mold: The procedure of creating a perfect plastic mold from the injection casting method is highly tech savvy. A mechanical expert who knows what exactly a plastic mold is? Or knows the entire procedure of plastic injection molding can better judge and decide the inflow of right raw materials for the entire procedure. Part draft angles and radii must be checked twice. Disadvantages of injection molding: It is expensive to buy injection molding machine, but again one time investment produces high benefits.

These manufacturing organizations allow rapid and fine molding of molten material. Of course it saves the cost, which goes with the waste. Whether it is a car or a large production machine, thermoplastic injection molding produces wide range of things. But when it comes to getting on with the work mechanical experts are the best for allocation. Choosing right plastic molding material: Choosing the right material for shaping within the synthetic casts is a daunting task. In this molding procedure the material is required to be in the granulated form, which is then transferred from a feed hopper to heated barrel.

Using plastic molds reduced waste production and allows recycling of left out parts. Even defected materials can be reused by recycling. The production of the thermoplastic molds depends on the material, which should be bought only from the trusted sources. The material is melted in this procedure and then processed under different stages in the plastic injection molding equipment. This procedure is used to make bigger things out of small object particles such as cars and vehicles

0 notes

Text

Crafting Quality: Awanti Polymoulds’ Precision moulds for PET

Plastic bottles and containers serve a diverse range of purposes across industries such as beverages, food processing, pharmaceuticals, liquor, and home care products. They are utilized for packaging water, soda, juice, oil, jams, medicines, liquor, as well as personal and home care items, with sizes varying from small volumes to several litres.

At Awanti, we specialize in manufacturing blow moulds for PET bottles, employing advanced designing, high precision manufacturing and accelerated testing. Established in 1990, Awanti Polymoulds has been at the forefront of designing, manufacturing, and testing PET blow moulds to meet international standards. Precision and accuracy are paramount in our manufacturing process to ensure consistent, high-quality bottles that meet our customers’ expectations.

Our commitment to customer satisfaction extends both domestically and internationally, driving our continuous efforts to excel. Our moulds are engineered for durability, precision, and longevity. Properly matched with moulding machines, they have the capacity to endure for years and produce millions of bottles. We prioritize precision, customization, and attention to detail throughout the bottle designing, mould manufacturing, and testing phases.

With a longstanding presence in the beverage industry and tooling industry, Awanti Polymoulds has been a trusted supplier of blow moulds for brands like Coca-Cola, Unilever, Parle Agro, Bisleri, Pepsi, AJE and many more. Whether it’s fruit juices, carbonated beverages, natural mineral water, packaged drinking water, personal care products, or edible oils, Awanti has consistently delivered, always aiming for customer satisfaction.

1 note

·

View note

Text

The Various Uses of Seppasolutions Pet Blowing Machine: Revolutionizing Your Business

Running a successful business in today's competitive market requires innovation, efficiency, and reliability. One such innovation that has been transforming the manufacturing industry, particularly in the realm of packaging, is the Seppasolutions pet bottle blowing machine. But what exactly is this machine, and how can it benefit your business? In this article, we delve into the various applications and advantages of Seppasolutions pet blowing machines, exploring how they can elevate your business operations to new heights.

Understanding Seppasolutions Pet Blowing Machine

What is a Seppasolutions Pet Blowing Machine?

Seppasolutions pet blowing machines are state-of-the-art equipment designed for the production of PET (Polyethylene Terephthalate) containers, such as bottles, jars, and other packaging materials. These machines utilize advanced technology to heat and stretch PET preforms, transforming them into high-quality finished products.

How does it work?

The operation of a Seppasolutions pet blowing machine involves several precise steps. First, PET preforms are loaded into the machine's mold. Then, using a combination of heat and pressure, the preforms are stretched and blown into the desired shape within the mold. The result is a seamless, uniform container ready for filling and distribution.

Seppasolutions Pet Blowing Machine Applications:

Beverage sector

One of the most common applications for Seppasolutions pet blowing machines is the beverage sector. These machines are used to manufacture a wide variety of PET bottles for carbonated drinks, water, juices, and other liquids. Manufacturers can develop unique packaging that sticks out on the shelves, drawing customers and increasing brand recognition by customizing bottle forms, sizes, and designs.

Food Packaging

In addition to beverages, Seppasolutions pet bottle blowing machine play a crucial role in the food packaging sector. From condiments and sauces to edible oils and dressings, PET containers produced by these machines offer a lightweight, durable, and hygienic solution for storing and transporting various food products. Moreover, the transparency of PET allows consumers to see the contents clearly, instilling confidence in the quality and freshness of the packaged items.

Household and personal care items

The adaptability of Seppasolutions pet blowing machines extends beyond the food and beverage industries to include personal care and household items. These machines may produce PET containers for the packaging of various products, such as shampoos, lotions, detergents, and cleaning chemicals. PET is a great material for these kinds of products because of its strength and aesthetic appeal, which increase the products' marketability and consumer appeal.

Advantages of Seppasolutions Pet Blowing Machine

Cost-Efficiency

Investing in a Seppasolutions pet blow machine offers significant cost savings for manufacturers in the long run. By producing PET containers in-house, companies can eliminate the need for outsourcing production, thereby reducing transportation costs, lead times, and reliance on third-party suppliers. Moreover, the efficiency and automation of these machines minimize material waste, further optimizing operational expenses.

Personalization

The versatility of Seppasolutions automatic pet bottle blowing machine to tailor packaging to meet specific needs is one of its best characteristics. Manufacturers can customize their packaging to match consumer preferences and branding plans by changing the forms, sizes, colors, and embossing logos and designs on the bottles. This level of customization not only boosts brand awareness, but it also encourages consumer loyalty and involvement.

Sustainability

The fully automatic pet blowing machine from Seppasolutions offers a strong advantage in a time when environmental sustainability is becoming more and more important. Compared to more conventional packaging materials like glass and metal, PET containers are more environmentally friendly because they are totally recyclable. Businesses may show their dedication to environmental stewardship, win over ecologically sensitive customers, and improve their brand by investing in PET blowing equipment.

In conclusion, pet blowing is a cutting-edge technology with a broad range of applications across a variety of industries. These devices offer unrivaled flexibility, productivity, and customization for applications ranging from food and beverage packaging to personal hygiene and household goods. Businesses can enhance product quality and appeal, reduce costs, and streamline their manufacturing processes with the help of Seppasolutions pet blowing technologies. In today’s highly competitive industry, innovation is key for businesses to remain ahead of the competition. Pet blowing machines provide businesses with the perfect platform to grow and succeed.

#automatic pet bottle blowing machine#pet blowing machine#pet bottle blowing machine#bottle blowing machine#pet bottle making machine#pet making machine#pet blowing machine manufacturer in india#automatic pet blowing machine#bottle blower machine#bottle blow machine#pet bottle blow machine#fully automatic pet blowing machine#bottle making machine

0 notes

Text

IntraPac India 2024: A Glimpse into the Future of Plastic Packaging

Get ready to be amazed by the latest innovations in the world of plastic packaging! IntraPac India 2024, the premier trade fair dedicated to the plastics industry, is just around the corner, and it promises to be an event unlike any other. From cutting-edge technologies to sustainable solutions, Intra Pac India will showcase everything you need to know about the future of plastic packaging.

What is Intra Pac India?

Intra Pac India is a four-day event organized by the Indian Printing, Packaging & Allied Machinery Manufacturers' Association (IPAMA). It is the largest and most comprehensive plastics exhibition in India, bringing together leading manufacturers, suppliers, and distributors from around the world. This year's event will be held at the India Expo Centre in Greater Noida, NCR Delhi, from March 14th to 17th, 2024.

Why should you attend IntraPac India 2024?

Whether you are a manufacturer, a designer, a brand owner, or simply someone interested in the latest trends in packaging, Intra Pac India has something for you. Here are just a few reasons why you should attend:

Discover the latest innovations: See the latest technologies and trends in plastic packaging, from biodegradable materials to smart packaging solutions.

Network with industry leaders: Meet and connect with key decision-makers from across the plastics industry.

Find new suppliers and partners: Source new materials, equipment, and services to help your business grow.

Learn from the experts: Attend informative seminars and workshops on a variety of topics related to plastic packaging.

Get inspired: Be inspired by the creativity and ingenuity on display at the exhibition.

What to expect at Intra Pac India 2024

The exhibition floor at IntraPac India will be buzzing with activity. You can expect to see a wide range of exhibits, including:

Packaging materials: From traditional plastics like PET and HDPE to innovative new materials like bioplastics and compostable plastics.

Packaging machinery: From blow molding machines to printing and labeling equipment.

Packaging design: From creative and eye-catching designs to functional and sustainable packaging solutions.

Recycling and waste management: Learn about the latest technologies and initiatives for recycling and reducing plastic waste.

Sustainability in focus

One of the key themes of IntraPac India 2024 will be sustainability. The plastics industry is facing increasing pressure to reduce its environmental impact, and IntraPac India will showcase a variety of sustainable solutions. This includes:

Biodegradable and compostable plastics: These materials are made from renewable resources and break down naturally, reducing landfill waste.

Recycled plastic content: Many manufacturers are now using recycled plastic content in their packaging, which helps to conserve resources and reduce pollution.

Design for recycling: Packaging that is designed to be easily recycled is essential for reducing plastic waste.

Intra Pac India 2024 is a must-attend event for anyone interested in the future of plastic packaging. It is an opportunity to learn about the latest trends, network with industry leaders, and discover innovative solutions that can help your business grow. So, mark your calendars and don't miss out on this exciting event!

I hope this blog has given you a glimpse into what you can expect at Intra Pac India 2024. I encourage you to visit the official website for more information and to register to attend.

Additional tips for attending Intra Pac India 2024:

Plan your visit: The exhibition floor is large, so it is important to plan your visit in advance. Make a list of the exhibitors you want to see and create a schedule.

Wear comfortable shoes: You will be doing a lot of walking, so wear comfortable shoes.

Bring business cards: You will have the opportunity to meet a lot of potential business partners, so bring plenty of business cards.

Follow Intra Pac India on social media: Stay up-to-date on the latest news and events by following Intra Pac India on social media.

I hope you have a great time at Intra Pac India 2024!

Intra Pac India 2024: A Glimpse into the Future of Plastic Packaging

Get ready to be amazed by the latest innovations in the world of plastic packaging! Intra Pac India 2024, the premier trade fair dedicated to the plastics industry, is just around the corner, and it promises to be an event unlike any other. From cutting-edge technologies to sustainable solutions, Intra Pac India will showcase everything you need to know about the future of plastic packaging.

What is Intra Pac India?

Intra Pac India is a four-day event organized by the Indian Printing, Packaging & Allied Machinery Manufacturers' Association (IPAMA). It is the largest and most comprehensive plastics exhibition in India, bringing together leading manufacturers, suppliers, and distributors from around the world. This year's event will be held at the India Expo Centre in Greater Noida, NCR Delhi, from March 14th to 17th, 2024.

Why should you attend IntraPac India 2024?

Whether you are a manufacturer, a designer, a brand owner, or simply someone interested in the latest trends in packaging, IntraPac India has something for you. Here are just a few reasons why you should attend:

Discover the latest innovations: See the latest technologies and trends in plastic packaging, from biodegradable materials to smart packaging solutions.

Network with industry leaders: Meet and connect with key decision-makers from across the plastics industry.

Find new suppliers and partners: Source new materials, equipment, and services to help your business grow.

Learn from the experts: Attend informative seminars and workshops on a variety of topics related to plastic packaging.

Get inspired: Be inspired by the creativity and ingenuity on display at the exhibition.

What to expect at IntraPac India 2024

The exhibition floor at IntraPac India will be buzzing with activity. You can expect to see a wide range of exhibits, including:

Packaging materials: From traditional plastics like PET and HDPE to innovative new materials like bioplastics and compostable plastics.

Packaging machinery: From blow molding machines to printing and labeling equipment.

Packaging design: From creative and eye-catching designs to functional and sustainable packaging solutions.

Recycling and waste management: Learn about the latest technologies and initiatives for recycling and reducing plastic waste.

Sustainability in focus

One of the key themes of IntraPac India 2024 will be sustainability. The plastics industry is facing increasing pressure to reduce its environmental impact, and IntraPac India will showcase a variety of sustainable solutions. This includes:

Biodegradable and compostable plastics: These materials are made from renewable resources and break down naturally, reducing landfill waste.

Recycled plastic content: Many manufacturers are now using recycled plastic content in their packaging, which helps to conserve resources and reduce pollution.

Design for recycling: Packaging that is designed to be easily recycled is essential for reducing plastic waste.

IntraPac India 2024 is a must-attend event for anyone interested in the future of plastic packaging. It is an opportunity to learn about the latest trends, network with industry leaders, and discover innovative solutions that can help your business grow. So, mark your calendars and don't miss out on this exciting event!

I hope this blog has given you a glimpse into what you can expect at IntraPac India 2024. I encourage you to visit the official website for more information and to register to attend.

Additional tips for attending IntraPac India 2024:

Plan your visit: The exhibition floor is large, so it is important to plan your visit in advance. Make a list of the exhibitors you want to see and create a schedule.

Wear comfortable shoes: You will be doing a lot of walking, so wear comfortable shoes.

Bring business cards: You will have the opportunity to meet a lot of potential business partners, so bring plenty of business cards.

Follow IntraPac India on social media: Stay up-to-date on the latest news and events by following IntraPac India on social media.

I hope you have a great time at IntraPac India 2024!

#IntraPacIndia#Plastic exhibition.#plastics industry#plastic fair#bioplastic exhibition#plastic trade fair#international plastic exhibition#7PlastFocus#PlastFocus plastic exhibition

0 notes

Text

What are The Main Machines in the Animal Feed Making Plant

Crusher part of animal feed pellet machines:

Crushing is one of the important processes in animal feed pellet processing. It is the main factor affecting the quality, yield, and cost of compound feed. The significance of crushing is to improve feed digestibility, enhance the feeding effect, and improve feed quality.

Now widely used is the drop-shaped pulverizer. The hammer mill has a simple structure, strong versatility, convenient use and maintenance, and high production efficiency.

The working process of the pellet feed crusher machine:

When the pellet feed crusher machine is working, after the material enters the crushing chamber, it is crushed by the impact of the high-speed rotating hammer. The flies to the toothed plate at a high speed, and collide with the toothed plate for further crushing. It was such a blow that the material shattered into small particles.

Mixing part of the animal feed pellet machines:

The main purpose of feed mixing is to mix all kinds of raw materials evenly according to the formula. This allows animals to eat a balanced feed that meets the requirements of the formula.

The horizontal ribbon mixer generally has two layers of ribbons inside and outside, and the two layers of ribbons are left and right spirals respectively. When one spiral belt sends the material from one end of the mixer to the other end, the other spiral belt conveys the material in the reverse direction. The inner helical belt is wider than the outer layer, which produces strong convection and shear mixing inside the machine.

The double-shaft paddle mixer is acted by two rotors that rotate in opposite directions. The material is driven by the paddle to rotate counterclockwise around the casing, and at the same time, the material is turned up and down, forming a weightless area where the two rotors overlap. The material forms an all-around continuous cycle flipping in the body, and shears staggered with each other, to achieve the effect of fast, gentle, and uniform mixing.

The two asymmetrical helical shafts of the conical planetary mixer rotate and make planetary motions along the cylinder wall at the same time. The short helix moves close to the center, which improves the mixing in the center and achieves a fast and uniform mixing effect.

Feed pelleting part of animal feed pellet machines:

It should also be mentioned that general poultry, livestock, etc. use ordinary feed pellets. And fish, pets, etc., eat more puffed particles.

According to the classification of feed physical properties, the feed can be divided into powder feed and pellet feed. Powdered feed is made by grinding a variety of feed raw materials into powder shape, and mixing them with additive premixed feed according to the requirements of feeding standards. The advantage is that the production and processing technology is simple, and the cost is relatively low.

The disadvantage is that the dust is large during production and the loss is large. During storage and transportation, nutrients are easily inactivated by external interference, and waste is caused by animals being picky eaters and scattered. In addition, the particle size of the powder should be different according to the animal species, age, etc. And it is not the thinner the better. Too thick will affect digestion. But too thin, it is easy to form a strong cohesive mass in the digestive tract, and it is not easy to digest.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: [email protected]

Whatsapp: 0086 18037508651

0 notes

Text

Shampoo Bottle Manufacturers & Suppliers | UshaPolycrafts

Explore top Shampoo Bottle manufacturers offering premium packaging solutions for the cosmetics industry. Discover a wide range of innovative and customizable shampoo bottle designs to enhance your product's appeal and functionality. Get the best in quality, sustainability, and design expertise with our trusted shampoo bottle suppliers.

Shampoo, an essential part of our daily hygiene routine, has undergone significant transformations over the years. One of the most noticeable changes has been in the packaging of this liquid gold. Shampoo bottles play a crucial role in preserving the product's quality and ensuring consumer satisfaction. In this article, we delve into the world of shampoo bottle manufacturing, with a special focus on UshaPolycrafts, a leading manufacturer in the field.

The Evolution of Shampoo Bottle Design

Shampoo bottles have come a long way since their inception. Early versions were often made of glass, which posed safety hazards in bathrooms. They were also heavy and fragile. As consumer preferences evolved, plastic became the preferred material for shampoo bottle manufacturing. It offered a lightweight, safe, and cost-effective alternative.

Over time, shampoo bottle design has become an art form. Bottles now come in various shapes, sizes, and colors, each designed to cater to specific consumer needs and preferences. UshaPolycrafts, a pioneer in the field, has been at the forefront of innovative design, ensuring that their products meet the evolving demands of the market.

Materials Used in Shampoo Bottle Manufacturing

Plastic, specifically high-density polyethylene (HDPE) and polyethylene terephthalate (PET), is the most common material used in shampoo bottle manufacturing. These materials are preferred due to their durability, versatility, and recyclability. HDPE is often used for traditional bottle designs, while PET is favored for clear, transparent bottles, allowing consumers to see the product inside.

UshaPolycrafts recognizes the importance of sustainable manufacturing practices. They are committed to using recyclable materials and reducing their environmental footprint. This commitment aligns with the growing global awareness of the need for sustainable packaging solutions.

Shaping the Perfect Shampoo Bottle

Designing the perfect shampoo bottle requires careful consideration of several factors, including:

Ergonomics: Bottles should be easy to grip and squeeze, ensuring that consumers can use the product without hassle.

Dispensing: The design should allow for easy and controlled dispensing of the shampoo, preventing wastage.

Branding: The bottle is a canvas for branding and marketing. It should reflect the brand's identity and appeal to consumers.

Safety: Bottles should be tamper-proof and child-resistant, ensuring product integrity and safety.

Sustainability: As mentioned earlier, sustainability is a growing concern. Shampoo bottle design should minimize waste and be environmentally friendly.

UshaPolycrafts invests heavily in research and development to create bottles that meet these criteria while maintaining aesthetics and functionality.

Manufacturing Process

The manufacturing process for shampoo bottles involves several key steps:

Material Selection: As mentioned earlier, HDPE and PET are the most common materials. The manufacturer selects the appropriate material based on the bottle's design and function.

Injection Molding: This process involves melting the chosen plastic material and injecting it into a mold to create the bottle's shape. UshaPolycrafts uses state-of-the-art injection molding machines to ensure precision and consistency.

Blow Molding: In the case of PET bottles, blow molding is used to create the desired shape. This process involves inflating a heated plastic preform into a mold to form the bottle.

Labeling and Printing: After the bottles are formed, labels and printing are applied to convey branding and product information.

Quality Control: Stringent quality control measures are in place to ensure that each bottle meets the specified standards. This includes checking for defects, leaks, and proper sealing.

Packaging: Once the bottles pass quality control checks, they are packaged and prepared for distribution.

UshaPolycrafts prides itself on its advanced manufacturing processes, ensuring that each bottle meets the highest quality standards.

Innovation in Shampoo Bottle Manufacturing

Innovation is the driving force behind any successful business. UshaPolycrafts understands this and continuously strives to push the boundaries of shampoo bottle manufacturing. Some recent innovations in the field include:

Eco-Friendly Materials: UshaPolycrafts has been at the forefront of using recycled plastics and biodegradable materials in their bottles. This not only reduces their carbon footprint but also appeals to eco-conscious consumers.

Smart Packaging: Incorporating technology into packaging has been on the rise. UshaPolycrafts is exploring options like QR codes for product information, enabling consumers to make informed choices.

Customization: Tailoring bottles to fit specific brands and product lines is becoming increasingly popular. UshaPolycrafts offers customization options, allowing brands to stand out on the shelves.

Minimalist Design: In a bid to reduce waste, minimalist bottle design is gaining popularity. UshaPolycrafts is designing bottles that use fewer materials while maintaining functionality.

Conclusion

Shampoo bottle manufacturing is a dynamic field that has evolved significantly over the years. UshaPolycrafts, with its commitment to quality, innovation, and sustainability, has played a pivotal role in shaping the industry. As consumer preferences continue to evolve, so will the art and science of shampoo bottle manufacturing. The future holds exciting possibilities, from eco-friendly materials to smart packaging solutions. UshaPolycrafts, with its dedication to excellence, is well poised to lead the way into this exciting future.

UshaPolycrafts - Other Manufacturers & Suppliers Like:-

Dropper Bottle Manufacturers

Tablet Container Manufacturers

Plastic Cap Manufacturers

0 notes

Text

Fully Automatic Glass Bottle Washer | Bottle Washer - Seppasolutions.com

The automatic glass bottle washing machine is an invention that saves time and water. This machine uses a bottle brush and a detergent dispenser to clean the bottles. The machine also has a separate compartment for rinsing the bottles. This machine can be used for various sizes of bottles, including those with handles. If you need your own automatic bottle washing machine you are at right place Seppa solution is the best manufacturer in Chennai serving clients all over the world, call us now at +91 9384806103 or just log on to https://www.seppasolutions.com/

#PET blowing machine#PET blowing machine manufacturer#PET blowing machine supplier#PET bottle making machine#PET bottle blowing machine#PET blow moulding machine

0 notes

Link

Fully Automatic Glass Bottle Washer | Bottle Washer - Seppasolutions.com

The automatic glass bottle washing machine is an invention that saves time and water. This machine uses a bottle brush and a detergent dispenser to clean the bottles. The machine also has a separate compartment for rinsing the bottles. This machine can be used for various sizes of bottles, including those with handles. If you need your own automatic bottle washing machine you are at right place Seppa solution is the best manufacturer in Chennai serving clients all over the world, call us now at +91 9384806103 or just log on to https://www.seppasolutions.com/

#PET blowing machine#PET blowing machine manufacturer#PET blowing machine supplier#PET bottle making machine#PET bottle blowing machine#PET blow moulding machine

0 notes

Text

Leading Blow Moulding Plastic Suppliers In UAE

We are the top Blow Moulding Plastic Suppliers UAE. We specialize in offering a variety of blow-moulded products, including PET bottles, HDPE bottles, jerry cans, containers, and other unique plastic packaging options. Our goods can be used in a range of industries, including the packaging of food and drinks, pharmaceuticals, the automotive industry, and more. We have a group of highly qualified experts who can give you the finest guidance on the appropriate plastic packaging option for your requirements. For any special requirements, we also provide customized packaging solutions. We promise to provide the highest-quality items at reasonable prices thanks to our cutting-edge technology and knowledge. Contact us right away to find out more about our products and services.

How Do Plastics Used in Blow Moulding Operate?

Heat is applied to softened plastic polymer pellets before they are shaped into tubular shapes to begin the blow moulding plastics process. Then, a hole is created in the tube's one end so that pressurized air can enter the plastic. It enters a specially made mould and is fastened into place after being softened and having the hole created.

As a result, the plastic may remain perfectly still as pressurized air is pumped within, forcing the sides outward and forming the hollow, moulded portion. The component is then cooled and solidified, removed from the mould, sent for quality check, and shipped.

Various Blow Moulding Styles

A softened plastic tube serves as the structure for the moulded product when using the extrusion blow moulding technique. This is put into a blow moulding machine, where hot plastic melts to conform to the shape of the cavity in the mould. Following this step, pressurized air is added to hollow out the interior of the plastic. About three-quarters of all blow-moulded products use this common blow-moulding technique.

Second, rather than beginning with a softened polymer tube, injection blow moulding uses a premade plastic shape. It is hollowed out by pressured air and secured inside the machine by a core metal pin. In stretch injection blow moulding, the softened plastic prefabricated shape is stretched into its final design prior to compressed air being injected, as opposed to being held in place by a pin as it is in injection blow moulding. PVC and PET goods can be processed using stretch injection blow moulding because of the unique characteristics of these two extremely adaptable plastic materials.

Why Choose the Blow Moulding Method?

The vast number of items that may be produced using any of the three adaptable and effective approaches makes adopting the blow-moulding plastics process in manufacturing operations advantageous. While shampoo bottles and soap dispensers have good chemical resistance and the capacity to take on complex shapes, plastic food containers can maintain their hygienic qualities and beautiful branding. For use in heavy industry, construction, and other demanding areas, industrial tubs and drums and automotive ducting offer strong, long-lasting construction. The manufacturing process is highly valued in the medical industry for its lightweight and simple sanitization capabilities. Simply put, objects made of plastic that have been blow-moulded are widely used in both household and business settings.

There are limitations on how much the wall thickness can be adjusted because the goods must be hollowed out while maintaining acceptable strength and integrity. Products may be harder to recycle if thermosetting polymers are used. And we are the top Injection Mould Plastic Manufacturers in UAE. This is because such materials can only be reshaped once before they can no longer be melted or softened for reforming or recycling.

0 notes

Text

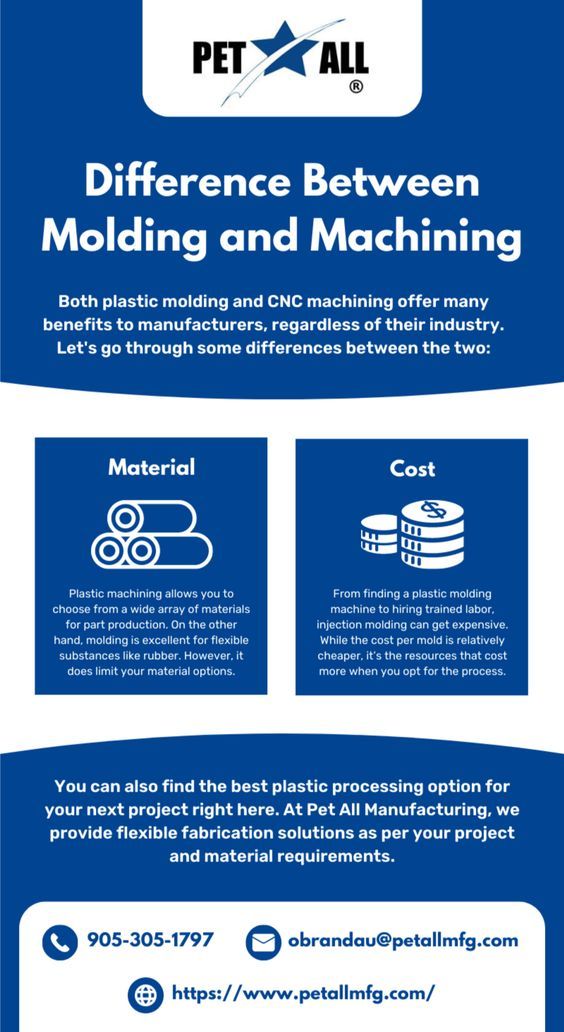

Difference Between Molding and Machining

Both plastic molding and CNC machining offer many benefits to manufacturers, regardless of their industry. At Pet All Manufacturing, we provide flexible fabrication solutions as per your project and material requirements.

1 note

·

View note

Text

SP Flex 01-02 Semi-Automatic Pet Blow Moulding Machine by Shyam Plastic

SP Flex 01-02 is Semi-Automatic Pet Blow Moulding Machine for Wide Mouth Jars. Check-out technical specs, production rate and other details online.

0 notes