#MetalSolutions

Text

The Power of Wire Rods

the versatility and strength of wire rods! From reinforcing concrete structures to powering electrical systems, wire rods are essential components across industries.

0 notes

Text

Custom Metal Fabrication Techniques to Increase Overall Value - Sarda Metals: A Leading Metals Manufacturer in India

In the world of metalworking, custom metal fabrication stands out as a versatile and invaluable process. It allows businesses to create tailor-made metal products that cater to specific needs and requirements. Whether it's for construction, automotive, or any other industry, custom metal fabrication techniques play a pivotal role in enhancing the overall value of the final product. In this article, we will delve into the intricacies of custom metal fabrication, exploring various techniques that can elevate the quality and functionality of metal products.

1. Setting Design Intent

The journey of custom metal fabrication begins with setting a clear design intent. This involves understanding the purpose of the metal product and the specifications it needs to meet. Metals manufacturers in India, like Sarda Metals, often excel at this stage, collaborating closely with clients to establish the design parameters, ensuring that the final product aligns perfectly with the intended use. This step is crucial as it lays the foundation for the entire fabrication process, guaranteeing that the end result fulfills the client's expectations.

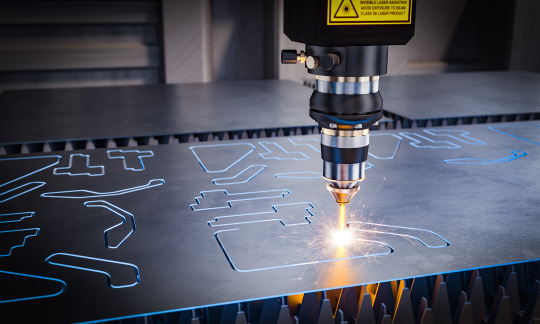

2. Metal Cutting & Forming

One of the fundamental aspects of custom metal fabrication is cutting and forming. Advanced cutting technologies, such as laser cutting and waterjet cutting, enable precision in shaping metal sheets and bars. This ensures that every component fits together seamlessly, reducing the need for extensive modifications later in the process. Efficient metal forming techniques, including bending and rolling, further refine the metal's shape, contributing to the product's structural integrity.

3. Custom Welding & Assembling

Welding is a critical skill in custom metal fabrication. Metals manufacturers in India often employ skilled welders who use various techniques like MIG, TIG, and spot welding to join metal pieces together securely. Custom welding ensures that the joints are robust and aesthetically pleasing. Assembling multiple components into a coherent whole is another aspect that demands precision and attention to detail. Proper assembly ensures that the final product functions optimally and has a longer lifespan.

4. Finishing to Add Value

The finishing touches in custom metal fabrication can significantly enhance the product's value. This includes processes like sandblasting, powder coating, and painting. These not only improve the product's appearance but also provide essential protection against corrosion and wear. A well-finished metal product not only looks better but also lasts longer, making it a valuable investment for clients.

Conclusion

Custom metal fabrication is an art that combines precision, creativity, and technical expertise. By setting clear design intent, employing advanced cutting and forming techniques, mastering welding and assembling, and applying meticulous finishing, fabricators can create metal products that not only meet but exceed expectations. This not only adds value to the products themselves but also enhances the reputation and trustworthiness of companies like Sarda Metals, a leading metals manufacturer in India.

FAQs

What industries benefit most from custom metal fabrication? Custom metal fabrication serves a wide range of industries, including construction, automotive, aerospace, and manufacturing, among others. Any industry that requires specialized metal components can benefit from these techniques.

How long does a typical custom metal fabrication project take? The timeline for a custom metal fabrication project varies depending on its complexity and size. Simple projects may take a few days, while more intricate ones could extend to several weeks.

Is custom metal fabrication cost-effective for small businesses? Yes, custom metal fabrication can be cost-effective for small businesses. It allows them to order precisely the components they need, reducing waste and unnecessary expenses.

What materials can be used in custom metal fabrication? Custom metal fabrication can be performed on a variety of metals, including steel, aluminum, copper, and stainless steel, among others.

Do custom metal fabricators offer design services? Many custom metal fabricators offer design services or work closely with design professionals to ensure the client's vision is realized.

For inquiries, contact us today at Sarda Metals, your trusted metals manufacturer in India.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#SardaMetals#MetalFabrication#CustomMetalWork#MetalCraftsmanship#MetalProducts#MetalDesign#PrecisionWelding#MetalArtistry#MadeInIndia#MetalInnovation#QualityMetalwork#MetalEngineering#MetalSolutions#MetalManufacturing#MetalFinishing#BespokeMetal#MetalCreators#IndustrialMetal#MetalDesigners#SustainableMetal

0 notes

Text

METAL FABRICATION PRODUCTS.....

One Stop Solution For All Kind Of Metal Fabricated Products.....

#fabricationproducts#steel#metal#fabrication#products#metalsolutions

#fabricated#fabrication#metalfabricationproducts#aarshnik#Hmsteels

Email Now: [email protected] / [email protected]

0 notes

Photo

Connect with Indian Manufacturers Suppliers Exporters. We connect 𝟏,𝟎𝟎,𝟎𝟎𝟎+ Global Verified 𝐁𝐮𝐲𝐞𝐫𝐬 and 𝐒𝐮𝐩𝐩𝐥𝐢𝐞𝐫𝐬. Trade with 𝟐𝟎𝟎+ 𝐜𝐨𝐮𝐧𝐭𝐫𝐢𝐞𝐬.

𝑹𝒆𝒈𝒊𝒔𝒕𝒆𝒓 𝒘𝒊𝒕𝒉 𝒖𝒔:📩E-mail us - [email protected]📲Call us - 1800 57205 58🌐Visit- www.go2bng.com

.

.

.

.

.#buyers #exporters #ExportersIndia #Filteration #PallBiotech #Biotech #Lifescience #Separation #Purification #PallIndia #Pallcorporation #Steel #Steelsupplier #Metal #Metalsupplier #Construction #Metalwork #Steelwork #Customizedmetal #Steelsolutions #Metalsolutions #basilexporter #basil #driedbasil

1 note

·

View note

Quote

PLASMA CUTTING

Metal Solution CNC plasma cutting services offer automated, high-efficiency and precision metal cutting solutions for variable shapes, sizes and thickness of materials that include aluminum, steel, stainless steel, and carbon steel. We deliver commercial, industrial and custom metal cutting services with a minimal lead-time from prototype to production. As a result of this, Metal Solutions will continuously produce quality parts, at competitive pricing by maximizing productivity, without compromising quality.

1 note

·

View note

Photo

@Longworthuk: A progress shot of our Greencoat PLX mountain grey snaplock roof installation at Mayfield Primary School in Oldham. Materials supplied by Metal Solutions. #longworth #teamlongworth #snaplock #greencoat #roofing #facade #rainscreen #buildingenvelope #metalsolutions #oldham https://t.co/3acLhHVZB2

0 notes

Text

Top Ferro Manganese Producers in India | Sarda Metals

Ferro manganese is a vital element that strengthens the foundation of numerous enterprises in the world of industrial metals. India, a global leader in the manufacturing of steel, is home to many prominent ferro manganese companies who make major contributions to the growth and development of the country. Sarda Metals emerges as a prominent player, with a legacy of excellence and a profound impact on the steel landscape.

Unveiling Sarda Metals: Pioneering Excellence in Ferro Alloys

The Genesis and Evolution

The story of Sarda Metals, a company whose name is synonymous with quality and innovation, began in the center of India's industrial landscape. The company has an extensive record of pushing the limits of Ferro manganese production and setting new benchmarks for effectiveness and quality. Its constant dedication to innovation has resulted in the creation of cutting-edge methods that have completely changed the Ferro Manganese marketplace.

Cutting-edge Infrastructure

The modern manufacturing facilities of Sarda Metals are the foundation of its success. These facilities, which are staffed by a knowledgeable staff and equipped with cutting-edge technology, guarantee accuracy throughout the whole production process. In line with international sustainability standards, the company places a high priority on technological innovation, which not only improves the quality of its goods but also helps to lessen environmental effect.

Quality Assurance and Compliance

Sarda Metals takes pride in its stringent quality assurance protocols. Each batch of Ferro Manganese undergoes rigorous testing to ensure that it meets industry standards and customer expectations. The company's commitment to quality has earned it certifications from renowned regulatory bodies, further solidifying its position as a trusted and reliable Ferro Manganese producer.

Revolutionizing the Ferro Manganese Landscape

Innovations Driving Excellence

The history of Sarda Metals has been marked by ground-breaking inventions that have changed the Ferro Manganese industry. The company's research and development division works diligently to find new ways to improve the characteristics of ferro manganese, producing alloys with better performance and longer durability. From construction to the production of automobiles, these technologies have found use in a variety of industries.

Collaborative Approach

One of Sarda Metals' distinguishing factors is its collaborative approach. The company actively engages with clients to understand their specific requirements and tailor its offerings accordingly. This customer-centric mindset has not only nurtured long-standing partnerships but has also facilitated the co-creation of customized Ferro Manganese solutions that cater to unique industrial needs.

The Road Ahead: Sarda Metals' Vision

Sustainability and Responsibility

As environmental concerns take center stage globally, Sarda Metals remains committed to sustainable practices. The company continuously invests in eco-friendly technologies, aiming to minimize its carbon footprint. This commitment to sustainability extends beyond operations and influences the entire value chain, making Sarda Metals a torchbearer of responsible industrial practices.

Empowering Through Knowledge Sharing

Sarda Metals influence transcends its role as a Ferro Manganese producer. The company actively contributes to knowledge sharing initiatives, conducting workshops and seminars to educate industry stakeholders about the latest advancements in Ferro Alloys. This commitment to education and empowerment underscores Sarda Metals' role as a thought leader in the domain.

Conclusion

Sarda Metals stands itself as a leading metals producer in India's vibrant ferro manganese industry, demonstrating excellence, innovation, and sustainability. A resounding tribute to its relentless commitment to uncompromising quality, persistent technological improvement, and the embodiment of the highest ethical standards is the path of its development from humble beginnings to an unchallenged industry leader. India's steel industry is a lively tapestry that is flourishing.

As a major producer of metals in India, Sarda Metals has the potential to lead innovation and seamlessly weave its story into the fabric of the country's long-term growth trajectory. Sarda Metals maintains its position as a pillar of India's industrial landscape through its relentless dedication to quality and innovation, supporting the growth of the country and enhancing its reputation as a leader in the field of metals manufacturing in India.

Head Office 🏢 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

Contact 📞 Phone: 9493549632

Email ✉️ Email: [email protected]

#ferromanganese#steelmanufacturer#alloyproducer#metalsindustry#industrialinnovation#sustainablemanufacturing#qualityassurance#technologicaladvancements#steelproduction#metalsolutions#industryexcellence#manufacturinginnovation

0 notes

Text

GRINDING

Metal Solutions grinding services are designed to eliminate rough edges and imperfections after cutting and sawing of materials that include iron, aluminum, steel, alloys and stainless steel in preparation for a polished finish. Metal Solutions offers a flexible capacity for variable volumes and metal grinding specifications perfect for industrial grinding and custom metal grinding projects that are an essential part of our complete custom metal fabrication process.

Link: https://metalsolutionshouston.com/services/

0 notes

Text

WELDING

Metal Solutions offers expert welding in Houston with a wide-variety of welding services available for existing metal pieces as well as innovative production designs and metal assemblies. Our fully qualified welders are equipped with all the tools and technology necessary to make precise cutting and welding according to the highest industry standards. We offer custom welding services from design to production on various material types and are a go-to for high quality welds and built-to-spec products in many industries

Link: https://metalsolutionshouston.com/services/

0 notes

Text

BENDING

Our comprehensive metal bending services cater to industries and artists seeking consistent and accurate metal formations with custom bending and rolling of materials that include steel, aluminum, carbon steel, and various alloys. We also specialize in designing custom bends and shapes ideal for architecture, artist designs and custom metal products with an adaptive capacity for any project size or complexity.

Link: https://metalsolutionshouston.com/services/

0 notes

Text

POWDER COATING

Whether as a standalone service or as part of our complete metal fabrication solution, powder coating offers optimized durability and protection for a wide-range of material types in your choice of customized colors, textures and finishes. Powder coating is essential for protection from corrosion, scratches, chemicals, fading and the elements and comes with aesthetic features that add value to metal products and creative pieces. It can also give used metal products a new lease on life when combined with our expert sandblasting services and metal fabrication and repairs. At Metal Solutions, we offer only the highest-quality powder coating products from world-class manufacturers through an expert application process resulting in uniform coverage and a high-end finish.

Link: https://metalsolutionshouston.com/services/

0 notes

Text

PLASMA CUTTING

Metal Solution CNC plasma cutting services offer automated, high-efficiency and precision metal cutting solutions for variable shapes, sizes and thickness of materials that include aluminum, steel, stainless steel, and carbon steel. We deliver commercial, industrial and custom metal cutting services with a minimal lead-time from prototype to production. As a result of this, Metal Solutions will continuously produce quality parts, at competitive pricing by maximizing productivity, without compromising quality.

Link: https://metalsolutionshouston.com/services/

0 notes

Quote

GRINDING

Metal Solutions grinding services are designed to eliminate rough edges and imperfections after cutting and sawing of materials that include iron, aluminum, steel, alloys and stainless steel in preparation for a polished finish. Metal Solutions offers a flexible capacity for variable volumes and metal grinding specifications perfect for industrial grinding and custom metal grinding projects that are an essential part of our complete custom metal fabrication process.

0 notes

Quote

WELDING

Metal Solutions offers expert welding in Houston with a wide-variety of welding services available for existing metal pieces as well as innovative production designs and metal assemblies. Our fully qualified welders are equipped with all the tools and technology necessary to make precise cutting and welding according to the highest industry standards. We offer custom welding services from design to production on various material types and are a go-to for high quality welds and built-to-spec products in many industries

0 notes

Quote

BENDING

Our comprehensive metal bending services cater to industries and artists seeking consistent and accurate metal formations with custom bending and rolling of materials that include steel, aluminum, carbon steel, and various alloys. We also specialize in designing custom bends and shapes ideal for architecture, artist designs and custom metal products with an adaptive capacity for any project size or complexity.

0 notes