#HydrogenInfrastructure

Text

Ecological Hydrogen Economy

The green hydrogen market is expected to reach $7,314 million by 2027, growing at a 61.0% CAGR. By 2027, the transportation industry is expected to have a USD 4,550 million value share in the green hydrogen market, having grown from its 58% value share in 2022 at a compound annual growth rate (CAGR) of 63.4%. According to projections, the electricity sector would expand from USD 88.5 million in 2022 to USD 1018 million by 2027 at the second-highest pace feasible, or 63.0%. The development of electrolysis technologies, the declining cost of creating renewable energy from all sources, the increasing demand from FCEVs and the power industry, among other factors, are anticipated to drive market expansion throughout the course of the forecast period.

In the worldwide green hydrogen market, wind-powered hydrogen holds the biggest market share. The global green hydrogen market was led by the end-use transportation sector.

Download- https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=92444177

IMPACT OF GREEN HYDROGEN

Green hydrogen has the potential to make a significant impact on various sectors and industries, including:

Energy: Green hydrogen has the potential to decrease dependence on fossil fuels and raise the proportion of renewable energy sources in the energy mix. It can offer a dependable, steady energy supply that is portable across great distances.

Transportation: Transportation vehicles such as cars, buses, trains, and even airplanes can run on green hydrogen as fuel. It can improve energy security and aid in the reduction of greenhouse gas emissions and air pollution.

Industry: Green hydrogen can take the role of fossil fuels in a number of industrial processes, including the manufacturing of chemicals, steel, and refinement. It can enhance the sustainability of industrial processes and aid in the reduction of greenhouse gas emissions.

Agriculture: Fertilizers, which are necessary for contemporary agriculture, can be made from green hydrogen. It can enhance agricultural sustainability and lessen dependency on fertilizers derived from fossil fuels.

Climate change: Green hydrogen has the potential to significantly lessen the effects of climate change by cutting greenhouse gas emissions and raising the proportion of renewable energy in the energy mix.

However, there are also some challenges in green hydrogen economy associated with the adoption of green hydrogen, including:

Cost: Because of the low electrolysis efficiency and high cost of renewable energy sources, green hydrogen is now more expensive than hydrogen derived from fossil fuels.

Infrastructure: Infrastructure projects involving production sites, storage tanks, and transportation networks must be funded in large quantities if green hydrogen is to be widely used.

Scale: To fulfill the increasing demand, the production of green hydrogen must be scaled up, which will require considerable investments. Currently, the scale of green hydrogen production is quite limited.

Efficiency: Higher energy consumption and expenses are the outcome of the comparatively low efficiency of electrolysis, which is the process used to make green hydrogen.

Competition: The market potential of green hydrogen may be constrained by competition from other clean energy sources like renewable energy and battery storage.

Technological Developments in Green Hydrogen Production

Growing awareness of the potential of green hydrogen and the growing demand for clean energy are driving the rapid evolution of technological advancements in the production of green hydrogen. The following are a few recent technological advancements in the production of green hydrogen:

Electrolysis Technology: An efficient and economical way to produce green hydrogen is by electrolysis, which is becoming more and more popular due to technological developments in the field. The energy consumption and cost of electrolysis are being reduced by developments in electrolyzer materials and designs, as well as in system integration and control.

Renewable Energy Integration: The availability of renewable energy sources like solar and wind power is closely related to the creation of green hydrogen. The efficiency and dependability of renewable energy systems are rising due to recent technological developments in renewable energy integration, which in turn is improving the efficiency and economics of green hydrogen production.

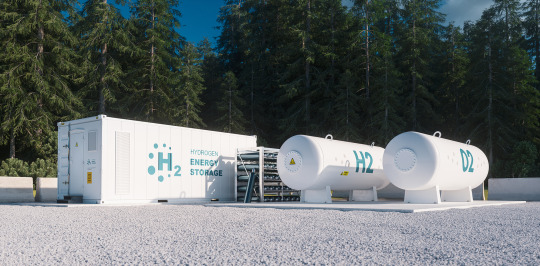

Green Hydrogen Storage: One major obstacle for green hydrogen is cost-effective and efficient storage, however new developments in technology are making storage solutions more affordable and efficient. The capacity and adaptability of green hydrogen storage are growing because to new storage technologies including hydrogen carriers and subterranean hydrogen storage facilities.

Carbon Capture and Utilization: A crucial technology in the decarbonization of industries, carbon capture, utilization, and storage (CCUS) is being used more and more in the creation of green hydrogen. The production of green hydrogen is made even more environmentally beneficial by the use of CCUS technology, which enables the capture and storage of carbon dioxide emissions.

Green Hydrogen Infrastructure: A comparable infrastructure must be in place to facilitate the rise of green hydrogen. The creation of massive green hydrogen production facilities, the development of new pipeline networks, and the integration of green hydrogen into current energy systems are examples of recent technological advancements in green hydrogen infrastructure.

Leading players in Green Hydrogen Economy

Some of the leading players in the green hydrogen industry are:

Air Liquide: A French business that serves numerous sectors by offering industrial gases and other products. Offering solutions for hydrogen production and delivery, it has a major position in the green hydrogen industry.

Linde: An international provider of industrial gas services and products to a range of sectors. Linde is focused on building hydrogen infrastructure and has made investments in green hydrogen initiatives.

Siemens Energy: An organization based in Germany that offers energy solutions to different sectors. It is working on developing green hydrogen generation and storage technologies, among other hydrogen-related technologies.

ITM Power: A UK-based business that creates green hydrogen production systems and other integrated hydrogen energy solutions.

Nel Hydrogen: A Norwegian business that offers hydrogen production, delivery, and storage options. With its electrolysis method for hydrogen production, it has a major position in the green hydrogen business.

Plug Power: A US-based business that offers stationary power and transportation applications among its many hydrogen fuel cell uses. It works on creating green hydrogen solutions for several sectors of the economy.

Ballard Power Systems: A Canadian business that offers fuel cell systems for stationary power and mobility, among other uses. It works to lower the cost of hydrogen fuel cells and is engaged in the development of green hydrogen technology.

McPhy Energy: A French business that offers systems for the generation, distribution, and storage of hydrogen. It is attempting to lower the cost of producing hydrogen and is engaged in the development of green hydrogen technology.

Enapter: Based on anion exchange membrane technology, this German company offers solutions for hydrogen production. Green hydrogen solutions, including stationary power and mobility, are being developed by this organization.

Green Hydrogen Systems: A Danish business offering hydrogen generating technologies based on electrolysis. It is engaged in the creation of green hydrogen technologies and is attempting to bring down the price of producing hydrogen.

STRENGTHS AND LIMITATIONS OF GREEN HYDROGEN

Strengths of Green Hydrogen:

Renewable: Green hydrogen is a sustainable energy source that doesn't increase greenhouse gas emissions because it is made using renewable energy sources like solar, wind, or hydropower.

Versatile: Green hydrogen is a multipurpose energy source that can be utilized as fuel for industry, transportation, and heating.

Energy Storage: Managing the erratic nature of renewable energy sources like solar and wind power requires the usage of energy storage solutions, such as hydrogen.

High Energy Density: Green hydrogen has a lot of energy per unit of weight or volume, making it have a high energy density.

Clean: Hydrogen is a clean and environmentally friendly energy source because its only byproduct is water.

Limitations of Green Hydrogen:

Cost: Green hydrogen production is now less economically viable due to its high cost when compared to traditional fossil fuel-based energy options.

Infrastructure: The infrastructure for hydrogen generation, distribution, and storage is currently lacking, which makes it difficult to increase the usage of green hydrogen.

Efficiency: Because of the low process efficiency, a large quantity of energy is needed to produce a tiny amount of hydrogen. This is known as green hydrogen production.

Safety: The cost and complexity of using hydrogen as an energy solution can increase due to its high flammability and the need for specific safety precautions during production, transit, and storage.

Carbon Intensity of Grey Hydrogen: Grey hydrogen, which is produced by using fossil fuels, is far more carbon-intensive and emits a lot of greenhouse gases than green hydrogen, while being a clean energy source.

Green hydrogen technologies

In contrast to conventional fossil fuel-based approaches, green hydrogen technologies refer to the several techniques and procedures used to manufacture hydrogen using renewable energy sources, such as wind, solar, and hydro power.

Some of the key green hydrogen technologies include:

Electrolysis: Using an electric current, water molecules are split into hydrogen and oxygen during the process of electrolysis. This procedure is referred to as a "green hydrogen production method" when it is fuelled by renewable energy sources like solar or wind.

Biomass gasification: This technique turns organic materials into a gas that can be utilized to create hydrogen, such as wood chips or agricultural waste. This process may alternatively be referred to as a "green hydrogen production method" if the organic matter is obtained responsibly and renewable energy sources are used to power the gasification process.

Solar thermochemical: Utilizing concentrated solar energy, this technique raises the temperature to a point where water molecules can split into hydrogen and oxygen. Although this process is currently in the research and development phase, it has the potential to be a very effective and environmentally friendly way to produce hydrogen.

Algae production: Hydrogen can be extracted from algae by harvesting them, which can be grown with carbon dioxide emissions and sunshine.

Waste-to-hydrogen: Hydrogen can be created by the processing of certain waste products, such as sewage and landfill gas. Although this process is still in its infancy, it has the potential to be a green method of producing hydrogen that contributes to waste reduction and the reduction of greenhouse gas emissions.

Green hydrogen technology and the green hydrogen economy are anticipated to become more and more significant in the world's energy mix as the demand for renewable energy sources rises.

HYDROGEN AS CLEAN ENERGY

Meeting the world's climate goals might be greatly aided by the growing use of hydrogen, a clean, sustainable energy source. Energy carriers that are adaptable in nature can be created using a variety of low-carbon sources, including fossil fuels with carbon capture and storage (CCS), nuclear energy, and renewable energy sources including solar, wind, and hydro.

When burned or utilized in fuel cells to generate power, hydrogen produces no carbon dioxide (CO2) or other hazardous pollutants, in contrast to conventional fossil fuels. Consequently, it has drawn interest as a possible replacement for fossil fuels, especially for industries and sectors like heavy transportation, heating, and manufacturing that are challenging to decarbonize.

Applications for hydrogen as a fuel include electricity generation (fuel cells), industry (chemicals, refining, and steel production), and transportation (cars, buses, trucks, and trains). Green hydrogen is the purest form of hydrogen when it is created from sustainable resources. Green hydrogen has the potential to function as a renewable energy storage medium, mitigating the variability of solar and wind power.

At the moment, manufacturing hydrogen from green sources is more costly than producing hydrogen from conventional fuels. On the other hand, the cost of green hydrogen is anticipated to approach parity with fossil fuels in the upcoming years as the cost of renewable energy continues to decline and advances in hydrogen manufacturing technology. Hydrogen has the potential to play a big part in the energy transition as people search for greener, more sustainable energy options to cut carbon emissions and fight climate change.

Green hydrogen energy solutions

Green hydrogen energy solutions are a new category of renewable energy technologies that power different applications with hydrogen generated from renewable sources like sun, wind, and hydropower. Electrolysis, a process that uses renewable electricity to separate water molecules into hydrogen and oxygen, is how green hydrogen is created.

The potential of green hydrogen to decarbonize hard-to-electrify industries including heavy industrial, transportation, and heating is one of its main benefits. Green hydrogen can be used as a feedstock for chemical reactions, as fuel for fuel cell vehicles, or in substitution of fossil fuels in industrial processes like cement and steel manufacturing.

In addition to these advantages, green hydrogen energy solutions also provide higher energy security, better air quality, and the creation of jobs in the clean energy sector.

Hydrogen Renewable Energy

The creation of hydrogen as an energy carrier by renewable energy sources, such as solar, wind, hydropower, or other clean and sustainable energy sources, is referred to as "hydrogen renewable energy" in general. "Green hydrogen" production is the term used to describe the process of manufacturing hydrogen with renewable energy.

Green Hydrogen Potential

"Green hydrogen potential" is the amount of energy that can be produced by the "green hydrogen" production process, which includes generating hydrogen and oxygen from water using electrolysis powered by renewable energy sources.

Green Hydrogen Premium Use Cases

The expression "green hydrogen premium use cases" describes particular situations or applications in which using green hydrogen which is created using environmentally friendly processes offers special advantages over other hydrogen production methods. Because of its environmental sustainability and possibly better qualities in some applications, the "premium" feature usually denotes a higher value or attractiveness connected with the green hydrogen.

Green Hydrogen Gas

"Green hydrogen gas" is the term used to describe hydrogen gas generated by the "green hydrogen" production process, which produces hydrogen and oxygen from water by electrolyzing it with the help of renewable energy sources. The production method is considered "green" because it uses clean, renewable energy, usually from hydropower, solar, or wind power. This indicates that the process is environmentally sustainable. Hydrogen derived from fossil fuels is thought to be dirty and emits less carbon than green hydrogen gas.

Hydrogen Upstream Companies

"Hydrogen upstream companies" are enterprises that are primarily engaged in the production, extraction, and processing of hydrogen feedstocks, and are situated at the early stages of the hydrogen value chain.

Harnessing Green Hydrogen

"Harnessing green hydrogen" is the process of obtaining and making use of hydrogen gas produced in an environmentally sustainable manner, frequently with the help of renewable energy sources. Using energy, usually from renewable sources like solar, wind, or hydropower, water is divided into hydrogen and oxygen through a process known as electrolysis to produce green hydrogen.

Green Hydrogen Systems

"Green hydrogen systems" are integrated systems or networks developed to generate, store, and use hydrogen gas in an environmentally responsible manner, usually with the help of renewable energy sources. A low-carbon energy sector shift can be supported and environmental impact can be minimized by focusing on the full hydrogen lifecycle, from production to end-use applications.

Green Hydrogen Electrolysis

The term "green hydrogen electrolysis" describes the electrolysis method of splitting water into hydrogen and oxygen using electricity produced from renewable energy sources. Because this process produces pure, or "green," hydrogen instead of using fossil fuels, it is regarded as environmentally sustainable.

Green Hydrogen Business Opportunities

"Green hydrogen business opportunities" encompass a range of financial potential and pathways for investment, growth, and innovation within the nascent green hydrogen sector. Green hydrogen generation, distribution, and consumption present businesses with opportunities as the need for low-carbon and sustainable energy solutions grows.

Green Hydrogen Process

"Green hydrogen process" describes a low-carbon, environmentally friendly technique of manufacturing hydrogen gas, usually with the use of renewable energy sources. In order to contribute to the larger goals of clean and sustainable energy, the green hydrogen process aims to reduce or eliminate greenhouse gas emissions related to the manufacturing of hydrogen.

Green Hydrogen Fuel

Hydrogen gas produced using ecologically friendly processes, usually with the help of renewable energy sources, is referred to as "green hydrogen fuel". When hydrogen is produced in a "green" manner, it means that no fossil fuels are used and that the carbon footprint is kept to a minimum. Green hydrogen fuel can be used in place of traditional fuels in a variety of applications as a clean, renewable energy source to help cut down on greenhouse gas emissions.

Hydrogen Downstream Companies

"Hydrogen downstream companies" often denote enterprises and organizations that operate in the later phases of the hydrogen value chain, with an emphasis on distributing, storing, and applying hydrogen for diverse purposes. In the context of the hydrogen business, the phrase "downstream" refers to activities that take place following the manufacture of the primary product; it is a term adopted from the oil and gas sector.

Green h2

The term "green hydrogen" is often shortened to "green H2." Green hydrogen is hydrogen that has been produced with consideration for the environment. It is usually produced by electrolysis, which is fueled by renewable energy sources. Hydrogen is represented chemically by the letter "H2".

Business Opportunities in Green Hydrogen

Potential paths for financial expansion, investment, and innovation in the developing green hydrogen sector are referred to as "business opportunities in green hydrogen". There are a number of opportunities in the green hydrogen market for companies at different phases of the value chain, as efforts to decarbonize and switch to sustainable energy sources gain momentum globally.

Green Hydrogen Uses

The term "green hydrogen uses" describes the range of industries and applications in which green hydrogen which is produced in an ecologically responsible manner is used as a flexible and clean energy source. The phrase highlights how environmentally benign the process of producing hydrogen is, which usually involves electrolysis using renewable energy sources.

Electrolyzer Technologies

The term "electrolyzer technologies" describes the range of systems and technologies utilized in the electrolysis process, which is a technique for producing hydrogen gas by utilizing an electric current to divide water (H2O) into hydrogen (H₂) and oxygen (O₂).

World Energy gh2

This phrase usually refers to the entire amount of energy produced and consumed worldwide. It includes a range of energy sources, including nuclear energy, renewable energy (like solar, wind, and hydropower), fossil fuels (such coal, oil, and natural gas), and others. Green hydrogen is usually referred to as "green H2". Using an electrical process known as electrolysis, water (H2O) is split into hydrogen (H₂) and oxygen (O₂) to generate green hydrogen.

Green Hydrogen Trends

"Green hydrogen trends" include the current advancements, changes, and patterns in the fields of green hydrogen generation, technology, and application. As an essential component of the global drive to shift to a more sustainable and low-carbon energy system, these trends indicate how the field of green hydrogen is developing.

Hydrogen Business Models

The term "hydrogen business models" describes the range of methods and tactics used by companies in the hydrogen sector in order to produce income, add value, and maintain their operations. These models include a broad spectrum of hydrogen-related operations, including production, delivery, storage, and use. Various business models arise in response to market demands, technological breakthroughs, and regulatory frameworks as the hydrogen sector undergoes evolution.

Green Hydrogen Generation

"Green hydrogen generation" is the term used to describe the environmentally sustainable and renewable energy-based method of producing hydrogen gas. The word "green" sets this technology apart from conventional methods of producing hydrogen, which frequently entail the burning of fossil fuels. Renewable energy sources like sun, wind, or hydropower are the main energy source for the hydrogen synthesis process in green hydrogen generation.

Green Hydrogen Future

"Green Hydrogen Future" describes how green hydrogen is expected to develop and play a part in the world's energy system going forward. It includes projections, patterns, and future advances concerning the creation, application, and transfer of green hydrogen. Reducing carbon emissions, attaining sustainability, and switching to a greener, more sustainable energy system are all directly related to the idea.

A "green hydrogen future" is a potential state of affairs in which hydrogen produced by electrolysis fueled by renewable energy sources plays a major role in fostering a low-carbon and sustainable economy. In this futuristic vision, the decarbonization of several industries, including transportation, manufacturing, and energy production, is largely dependent on green hydrogen. It signifies a move away from greenhouse gas-emitting fossil fuel-based hydrogen generation techniques and toward a greener, more sustainable substitute. To fully realize the potential of hydrogen as a flexible and carbon-neutral energy carrier, developments in electrolysis technology, infrastructure development for hydrogen, supportive policies, and enhanced stakeholder collaboration are all necessary components of the green hydrogen future.

The "Green Hydrogen Future" is a comprehensive plan for moving toward a sustainable and eco-friendly hydrogen-based economy. The following are some salient features and ramifications of this vision:

Renewable Energy Integration: With the use of electrolysis and sustainable energy sources like solar, wind, or hydroelectric power, green hydrogen is created. By resolving the issue of intermittency and easing the transition to a more dependable and sustainable energy system, this integration makes it possible to store and use excess renewable energy.

Decarbonization: The urgent need to decarbonize the transportation, industrial, and heating sectors of the economy is one of the main forces behind the green hydrogen future. Greenhouse gas emissions can be greatly decreased by switching to green hydrogen from fossil fuels, aiding in the worldwide effort to slow down climate change and reach net-zero carbon emissions.

Energy Storage and Grid Stability: Green hydrogen has the potential to be a flexible energy carrier and storage medium that can help the electrical grid balance supply and demand. When demand is low, excess renewable energy can be used to make hydrogen, which can then be used directly in fuel cells or converted back into electricity when demand is high. This flexibility improves the stability and dependability of the grid, especially as renewable energy sources proliferate.

Industrial Applications: There are several industrial uses for green hydrogen, such as chemical synthesis, steel production, and ammonia generation. These sectors can drastically lower their carbon footprint and environmental impact by switching to green hydrogen instead of fossil fuels or hydrogen made from natural gas (often referred to as "grey hydrogen").

Transportation: Green hydrogen is an environmentally friendly fuel that can be used for buses, trucks, trains, and fuel cell vehicles (FCVs). While conventional vehicles release pollutants from their internal combustion engines, FCVs produce no emissions at all; the only byproduct of hydrogen combustion is water vapor.

Global Energy Transition: Global energy transition might be accelerated by the green hydrogen future, which would offer clean and sustainable energy to all nations. Realizing this ambition and tackling the common challenge of climate change on a global scale depend on building a strong green hydrogen infrastructure and encouraging international cooperation.

Ultimately, the green hydrogen future offers a way forward for a more resilient and sustainable energy system that puts social welfare and environmental preservation first. It signifies a paradigm shift in the production, storage, and use of energy. However, in order to overcome technological, financial, and legal obstacles and hasten the shift to a hydrogen-based economy, governments, businesses, and society at large will need to work together in order to realize this goal.

Green Hydrogen Opportunities

The term "green hydrogen opportunities" describes the advantageous circumstances, opportunities, and growth paths found in the green hydrogen industry. These prospects are brought about by a number of factors, such as the worldwide push for low-carbon and sustainable energy solutions, supportive legislation, market demand, and technological breakthroughs. Businesses, financiers, and other interested parties should investigate these chances to support the development and uptake of green hydrogen as a flexible and clean energy source.

Green hydrogen energy options are anticipated to become more significant as the globe moves toward a more sustainable energy future. Targeting net-zero emissions and mitigating the effects of climate change, numerous nations and businesses worldwide are investing in the advancement of green hydrogen technologies within the framework of a green hydrogen economy.

Fundamentally, clean, renewable energy sources such as green hydrogen energy solutions offer a way out of fossil fuels and toward a more just and sustainable energy future for all.

Read More-https://www.marketsandmarkets.com/industry-practice/hydrogen/green-hydrogen

#GreenHydrogen#RenewableEnergy#EcoHydrogen#SustainableFuture#CleanEnergy#HydrogenEconomy#ZeroEmissions#ClimateAction#HydrogenRevolution#CleanTech#RenewableHydrogen#CarbonNeutral#HydrogenInfrastructure#GreenTechnology#EcoInnovation

0 notes

Text

Hydrogen Vehicle Market Size, Demand and Trends Analysis by 2024-2030

The Hydrogen Vehicle Market Research Report 2024 begins with an overview of the market and offers throughout development. It presents a comprehensive analysis of all the regional and major player segments that gives closer insights upon present market conditions and future market opportunities along with drivers, trending segments, consumer behaviour, pricing factors and market performance and estimation and prices as well as global predominant vendor’s information. The forecast market information, SWOT analysis, Hydrogen Vehicle Market scenario, and feasibility study are the vital aspects analysed in this report.

The Hydrogen Vehicle Market is expected to grow at 64.7% CAGR from 2023 to 2030. It is expected to reach above USD 49.81 billion by 2030 from USD 0.56 billion in 2023.

Access Full Report:

https://exactitudeconsultancy.com/reports/14020/hydrogen-vehicle-market/

#HydrogenVehicle#HydrogenTechnology#FuelCellVehicle#CleanEnergy#ZeroEmission#SustainableTransport#GreenMobility#RenewableEnergy#HydrogenPower#FutureOfMobility#AlternativeFuel#HydrogenInfrastructure#HydrogenEconomy#TransportationInnovation#EcoFriendlyVehicles#ClimateAction#HydrogenFuel#FuelCellTechnology#ZeroEmissionVehicle#HydrogenCars

0 notes

Text

0 notes

Text

Hydrogen Fuel Cell Vehicle Market Worldwide Demand and Growth Analysis Report 2024-2030

The Hydrogen Fuel Cell Vehicle Market Research Report 2024 begins with an overview of the market and offers throughout development. It presents a comprehensive analysis of all the regional and major player segments that gives closer insights upon present market conditions and future market opportunities along with drivers, trending segments, consumer behaviour, pricing factors and market performance and estimation and prices as well as global predominant vendor’s information. The forecast market information, SWOT analysis, Hydrogen Fuel Cell Vehicle Market scenario, and feasibility study are the vital aspects analysed in this report.

The Hydrogen Fuel Cell Vehicle Market is expected to grow at 59.40% CAGR from 2023 to 2030. It is expected to reach above USD 27.09 Billion by 2030 from USD 0.40 Billion in 2023.

Access Full Report:

https://exactitudeconsultancy.com/reports/13965/hydrogen-fuel-cell-vehicle-market/

#FuelCellVehicle#CleanTransportation#HydrogenTechnology#ZeroEmission#RenewableEnergy#GreenMobility#FuelCellCars#HydrogenPower#SustainableTransport#AlternativeFuel#FutureOfTransport#EnergyTransition#HydrogenEconomy#FuelCellTechnology#TransportationInnovation#EcoFriendlyVehicles#ClimateAction#HydrogenInfrastructure#HydrogenVehicle

0 notes

Text

Hydrogen Market Penetration

The decision to enter new markets directly or through partners in the hydrogen sector is based on a number of industry-specific variables.

Download-https://www.marketsandmarkets.com/industry-practice/RequestForm.asp

Here are some considerations:

Local Market Knowledge: Policies, rules, and infrastructure needs at the municipal level have an impact on the hydrogen business. Engaging in a partnership with local entities can offer significant insights and assistance in navigating the unique dynamics of the hydrogen business in a location you are unfamiliar with.

Access to Infrastructure: Infrastructure for hydrogen production, distribution, storage, and transportation must be accessible in order to establish a foothold in a new market. Since building new infrastructure can take time and money, partnering with businesses or organizations that already have infrastructure can let them enter the market much more quickly.

Technological Expertise: The hydrogen market is changing quickly, and different markets might have different needs or preferences in terms of technology. Working with partners who are knowledgeable about target market-specific hydrogen technology can assist make sure your products and services meet local demands and preferences.

Supply Chain Integration: Many parties are involved in the hydrogen value chain, from the manufacturing of hydrogen to its final uses. As they may already have established ties with suppliers, consumers, and industry players, partnering with local businesses that are already integrated into the supply chain can help expedite an efficient introduction into the market.

Government Relations and Incentives: Government incentives and policies are very important in determining the direction of the hydrogen sector. By collaborating with regional organizations, one can gain access to government networks, improving participation and maximizing the use of grants, incentives, and other funding sources for projects pertaining to hydrogen.

Risk Sharing: Risks associated with entering new markets include those related to financial uncertainty, market acceptance, and regulatory compliance. A more robust entry strategy and risk sharing can be achieved by partnering with well-established local players.

The term "hydrogen market penetration" describes how well-established and marketable hydrogen-based goods, services, and applications have become. In different economic areas, it evaluates the degree to which hydrogen has been accepted as a competitive and workable alternative. The amount of market penetration that hydrogen technologies have compared to their existing alternatives can be expressed as a percentage of the overall market demand.

Key components of hydrogen market penetration include:

Adoption in End-Use Sectors:

The incorporation of hydrogen technology into fields like electricity generation, industry (chemical processes, manufacturing, and refinement), transportation (hydrogen fuel cell vehicles, buses, trucks, etc.), and residential applications.

Market Share:

The percentage of the total market share that hydrogen-based solutions hold relative to traditional or rival options for a certain set of goods or services.

Infrastructure Development:

The availability and expansion of hydrogen infrastructure, such as pipelines for hydrogen transportation, storage facilities, and vehicle refueling stations, all help to enable the widespread usage of hydrogen.

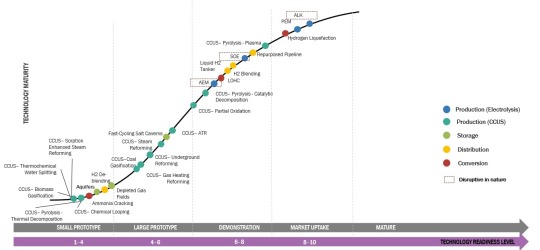

Technological Maturity:

The development and maturation of technology pertaining to hydrogen, such as fuel cell, storage, and hydrogen production techniques (electrolysis, steam methane reforming, etc.).

Government Policies and Incentives:

The effect of laws, rules, and subsidies that promote or require the use of hydrogen and thereby enhance market penetration.

Talking about the market penetration of the hydrogen industry, It is imperative to carry out comprehensive market research and assess the particular opportunities and challenges present in the intended market. Take into account a hybrid strategy wherein direct entrance may be pursued in certain areas while collaborating with local companies for particular competencies or market niches. The best course of action may change based on the objectives of the business, the state of the market, and the resources at hand, therefore flexibility and adaptability are essential.

Read More- https://www.marketsandmarkets.com/industry-practice/hydrogen/market-penetration

#HydrogenRevolution#CleanEnergyFuture#HydrogenEconomy#GreenHydrogen#HydrogenNow#ZeroEmissions#RenewableHydrogen#FuelCellTechnology#HydrogenInfrastructure

0 notes

Text

Hydrogen Market Penetration

The decision to enter new markets directly or through partners in the hydrogen sector is based on a number of industry-specific variables.

Download-https://www.marketsandmarkets.com/industry-practice/RequestForm.asp

Here are some considerations:

Local Market Knowledge: Policies, rules, and infrastructure needs at the municipal level have an impact on the hydrogen business. Engaging in a partnership with local entities can offer significant insights and assistance in navigating the unique dynamics of the hydrogen business in a location you are unfamiliar with.

Access to Infrastructure: Infrastructure for hydrogen production, distribution, storage, and transportation must be accessible in order to establish a foothold in a new market. Since building new infrastructure can take time and money, partnering with businesses or organizations that already have infrastructure can let them enter the market much more quickly.

Technological Expertise: The hydrogen market is changing quickly, and different markets might have different needs or preferences in terms of technology. Working with partners who are knowledgeable about target market-specific hydrogen technology can assist make sure your products and services meet local demands and preferences.

Supply Chain Integration: Many parties are involved in the hydrogen value chain, from the manufacturing of hydrogen to its final uses. As they may already have established ties with suppliers, consumers, and industry players, partnering with local businesses that are already integrated into the supply chain can help expedite an efficient introduction into the market.

Government Relations and Incentives: Government incentives and policies are very important in determining the direction of the hydrogen sector. By collaborating with regional organizations, one can gain access to government networks, improving participation and maximizing the use of grants, incentives, and other funding sources for projects pertaining to hydrogen.

Risk Sharing: Risks associated with entering new markets include those related to financial uncertainty, market acceptance, and regulatory compliance. A more robust entry strategy and risk sharing can be achieved by partnering with well-established local players.

The term "hydrogen market penetration" describes how well-established and marketable hydrogen-based goods, services, and applications have become. In different economic areas, it evaluates the degree to which hydrogen has been accepted as a competitive and workable alternative. The amount of market penetration that hydrogen technologies have compared to their existing alternatives can be expressed as a percentage of the overall market demand.

Key components of hydrogen market penetration include:

Adoption in End-Use Sectors:

The incorporation of hydrogen technology into fields like electricity generation, industry (chemical processes, manufacturing, and refinement), transportation (hydrogen fuel cell vehicles, buses, trucks, etc.), and residential applications.

Market Share:

The percentage of the total market share that hydrogen-based solutions hold relative to traditional or rival options for a certain set of goods or services.

Infrastructure Development:

The availability and expansion of hydrogen infrastructure, such as pipelines for hydrogen transportation, storage facilities, and vehicle refueling stations, all help to enable the widespread usage of hydrogen.

Technological Maturity:

The development and maturation of technology pertaining to hydrogen, such as fuel cell, storage, and hydrogen production techniques (electrolysis, steam methane reforming, etc.).

Government Policies and Incentives:

The effect of laws, rules, and subsidies that promote or require the use of hydrogen and thereby enhance market penetration.

Talking about the market penetration of the hydrogen industry, It is imperative to carry out comprehensive market research and assess the particular opportunities and challenges present in the intended market. Take into account a hybrid strategy wherein direct entrance may be pursued in certain areas while collaborating with local companies for particular competencies or market niches. The best course of action may change based on the objectives of the business, the state of the market, and the resources at hand, therefore flexibility and adaptability are essential.

Read More- https://www.marketsandmarkets.com/industry-practice/hydrogen/market-penetration

#HydrogenEconomy#CleanEnergyRevolution#HydrogenNow#RenewableHydrogen#GreenTech#H2Market#HydrogenInfrastructure#SustainableEnergy

0 notes

Text

Comparison of Hydrogen and Other Sources of Energy

Unit Economics Comparison of Hydrogen and Other Sources of Energy

Hydrogen's unit economics, including cost, price, power output, and emission reduction, vary depending on factors such as the production method, hydrogen storage and transportation infrastructure, end-use application, and regional dynamics.

Overview of how hydrogen compares to other energy sources:

Cost and Price:

Hydrogen Production: Depending on the process, producing hydrogen can be expensive. Gray or blue hydrogen, which are sourced from fossil fuels with carbon capture or other emissions reduction technologies, are typically less expensive than green hydrogen, which is created through electrolysis using renewable electricity. Green hydrogen will, however, become more affordable over time as the cost of electrolyzer technology and renewable electricity is anticipated to decline.

Retail Price: Region and scale can have an impact on the retail price of hydrogen at refueling stations. In comparison to traditional fuels like gasoline or diesel, hydrogen is currently typically more expensive. But in the future, cost savings and price competitiveness can be aided by regulations that are supportive, economies of scale, and improvements in production technologies.

Power Output:

Energy Density: Applications needing large power outputs and long-term energy storage find hydrogen to be an appealing alternative due to its high energy density per unit mass. It has benefits in industries like transportation where heavy-duty or extended driving ranges require energy-dense fuels.

Power-to-Weight Ratio: High power-to-weight ratios from hydrogen fuel cells make them appropriate for uses where weight is a crucial consideration, including electric cars and portable power systems.

Emission Reduction:

Carbon Emissions: Green hydrogen, or hydrogen generated from renewable resources, has the potential to significantly lower emissions when compared to alternatives that rely on fossil fuels. Hydrogen emits no direct emissions when employed in fuel cell applications since it only creates water vapor as a byproduct. However, the method of production and the energy source employed can affect the emissions related to the creation of hydrogen.

Lifecycle Emissions: The lifecycle emissions related to the manufacturing, storage, and transportation of hydrogen determine its overall potential for reducing emissions. This includes things like the production process's efficiency, the carbon intensity of the electricity utilized in electrolysis, and the emissions brought on by the extraction and delivery of feedstocks.

The complete lifecycle and operational expenses are taken into account when estimating the total cost of ownership (TCO) for different end-use sectors. Variations in TCO can be observed depending on factors including technology maturity, scale, regional dynamics, and application needs. Total Cost of Ownership (TCO) encompasses not just the initial capital expenditures but also the ongoing maintenance, fuel or energy input, and operating costs over the system's lifetime.

It is noteworthy that the economics of hydrogen are undergoing a swift evolution, propelled by technological breakthroughs, economies of scale, and policy incentives. As the hydrogen business develops and grows, lower costs, more efficiency, and better performance are anticipated. Attaining cost competitiveness with alternative energy sources and realizing the full potential of hydrogen need sustained innovation, research, and commercial development.

Read More - https://www.marketsandmarkets.com/industry-practice/hydrogen/comparison-hydrogen-other-energy

#HydrogenStorage#HydrogenTransport#H2Storage#RenewableHydrogen#CleanEnergyTransport#HydrogenInfrastructure#FuelCellTech

0 notes

Text

What are 3 real world uses of hydrogen?

Hydrogen Uses

Three practical applications of hydrogen are listed below, along with information on their potential for expansion, use cases, and supporting data.

Hydrogen Fuel Cell Vehicles:

Fuel cell vehicles (FCVs) powered by hydrogen are a substitute for traditional gasoline or diesel automobiles. Fuel cell vehicles (FCVs) use hydrogen to produce electricity, which powers the electric motor in the vehicle. These cars provide zero-emission mobility and can be utilized for commercial fleets, personal transportation, and public transportation.

Growth Opportunities: One major source of greenhouse gas emissions is the transportation industry. Due to their zero tailpipe emissions, hydrogen fuel cell vehicles (FCVs) present a viable way to reduce carbon emissions. In the upcoming years, a large growth in the global market for hydrogen fuel cell vehicles is anticipated.

Use Cases: Electric motors are powered by hydrogen-fueled fuel cells (FCVs), which use a chemical reaction to produce energy. In comparison to battery-electric vehicles, these cars can travel farther between charges and can be refueled fast. Hydrogen fuel cell vehicles (FCVs) that are sold commercially include the Hyundai Nexo and Toyota Mirai.

Statistics: More than 10,000 hydrogen fuel cell vehicles (FCVs) were in use worldwide as of 2021. In terms of FCV adoption, Japan is leading the way, followed by the US, Korea, and Germany. Governments and automakers are also making significant investments in hydrogen infrastructure and vehicle development, which shows a strong commitment to the expansion of hydrogen fuel cell vehicles (FCVs).

Hydrogen has several real-world uses across various industries.

Hydrogen Industrial Applications:

In many different industrial processes, hydrogen is a common ingredient. Here are a few particular instances:

Ammonia Production: Ammonia is mostly utilized in fertilizer manufacturing and is produced by the Haber-Bosch process, which uses hydrogen to mix nitrogen and hydrogen.

Refineries: Refineries use hydrogen to purge petroleum-based products like gasoline and diesel of contaminants.

Chemical Industry: A vital component in the synthesis of methanol, a feedstock for numerous chemicals and fuels, is hydrogen. Other compounds, such as hydrochloric acid and hydrogen peroxide, are also produced using it.

Growth Opportunities: With its many industrial uses, hydrogen is predicted to become more and more in demand as a result of decarbonization initiatives. For example, hydrogen is utilized in the chemical industry to produce methanol, ammonia, and other compounds. According to a McKinsey report, the worldwide hydrogen industry is expected to increase at an annual pace of 5-8%, reaching $300 billion by 2030.

Use Cases: An essential raw material for the synthesis of ammonia, which is mostly utilized to make fertilizers, is hydrogen. Hydrogen is also utilized in the processing of metal, glass, electronics, and food items. It is also employed in oil refining.

Statistics: The industrial sector supplied over 60% of the world's hydrogen needs as of 2021. Almost half of the hydrogen available worldwide is used in the manufacturing of ammonia alone.

Hydrogen - Renewable Energy Storage:

Overproduction of renewable energy is stored in hydrogen. The procedure entails using electrolysis to transform excess electricity from renewable energy sources, including solar or wind power, into hydrogen. Hydrogen created can be stored and used for a variety of purposes in the future.

Power Generation: During times when the production of renewable energy is limited, hydrogen can be used in turbines or transformed back into electricity using fuel cells.

Heating: It is possible to use hydrogen as a fuel for home as well as commercial heating purposes.

Transportation: Vehicles driven by hydrogen, such as cars, lorries, buses, and even trains, can run on hydrogen as fuel.

Growth Opportunities: The grid needs effective energy storage options since renewable energy sources like solar and wind power are sporadic. Abundant renewable energy can be stored and utilized through the use of hydrogen as an energy storage medium. In 2021, the global market for green hydrogen is anticipated to expand at a compound annual growth rate (CAGR) of approximately 30%, as per a report published by Global Market Insights.

Use Cases: Electrolysis can be used to create hydrogen from surplus electricity produced by renewable sources. When the production of renewable energy is low, the created hydrogen can be stored and used as a fuel for heating, power generating, or transportation. As a result, a more sustainable energy system is created and numerous sectors benefit from decarbonization.

Statistics: Over 500 MW of power-to-hydrogen projects were installed globally as of 2021, with a large amount of those projects being used for renewable energy storage. Germany, Australia, and the Netherlands are among the nations that have spearheaded the implementation of extensive power-to-hydrogen initiatives.

These illustrations show the variety of applications and growth prospects for hydrogen, from transportation to industry and renewable energy storage. In the upcoming years, the demand for hydrogen is anticipated to be driven by the growing emphasis on decarbonization and the switch to sustainable energy sources.

Read More-https://www.marketsandmarkets.com/industry-practice/hydrogen/real-world-uses-hydrogen

#HydrogenEconomy#HydrogenTech#CleanEnergy#RenewableHydrogen#FuelCells#HydrogenInfrastructure#GreenHydrogen

0 notes

Text

Hydrogen Market Penetration

The decision to enter new markets directly or through partners in the hydrogen sector is based on a number of industry-specific variables.

Here are some considerations:

Local Market Knowledge: Policies, rules, and infrastructure needs at the municipal level have an impact on the hydrogen business. Engaging in a partnership with local entities can offer significant insights and assistance in navigating the unique dynamics of the hydrogen business in a location you are unfamiliar with.

Access to Infrastructure: Infrastructure for hydrogen production, distribution, storage, and transportation must be accessible in order to establish a foothold in a new market. Since building new infrastructure can take time and money, partnering with businesses or organizations that already have infrastructure can let them enter the market much more quickly.

Technological Expertise: The hydrogen market is changing quickly, and different markets might have different needs or preferences in terms of technology. Working with partners who are knowledgeable about target market-specific hydrogen technology can assist make sure your products and services meet local demands and preferences.

Supply Chain Integration: Many parties are involved in the hydrogen value chain, from the manufacturing of hydrogen to its final uses. As they may already have established ties with suppliers, consumers, and industry players, partnering with local businesses that are already integrated into the supply chain can help expedite an efficient introduction into the market.

Government Relations and Incentives: Government incentives and policies are very important in determining the direction of the hydrogen sector. By collaborating with regional organizations, one can gain access to government networks, improving participation and maximizing the use of grants, incentives, and other funding sources for projects pertaining to hydrogen.

Risk Sharing: Risks associated with entering new markets include those related to financial uncertainty, market acceptance, and regulatory compliance. A more robust entry strategy and risk sharing can be achieved by partnering with well-established local players.

The term "hydrogen market penetration" describes how well-established and marketable hydrogen-based goods, services, and applications have become. In different economic areas, it evaluates the degree to which hydrogen has been accepted as a competitive and workable alternative. The amount of market penetration that hydrogen technologies have compared to their existing alternatives can be expressed as a percentage of the overall market demand.

Key components of hydrogen market penetration include:

Adoption in End-Use Sectors:

The incorporation of hydrogen technology into fields like electricity generation, industry (chemical processes, manufacturing, and refinement), transportation (hydrogen fuel cell vehicles, buses, trucks, etc.), and residential applications.

Market Share:

The percentage of the total market share that hydrogen-based solutions hold relative to traditional or rival options for a certain set of goods or services.

Infrastructure Development:

The availability and expansion of hydrogen infrastructure, such as pipelines for hydrogen transportation, storage facilities, and vehicle refueling stations, all help to enable the widespread usage of hydrogen.

Technological Maturity:

The development and maturation of technology pertaining to hydrogen, such as fuel cell, storage, and hydrogen production techniques (electrolysis, steam methane reforming, etc.).

Government Policies and Incentives:

The effect of laws, rules, and subsidies that promote or require the use of hydrogen and thereby enhance market penetration.

Talking about the market penetration of the hydrogen industry, It is imperative to carry out comprehensive market research and assess the particular opportunities and challenges present in the intended market. Take into account a hybrid strategy wherein direct entrance may be pursued in certain areas while collaborating with local companies for particular competencies or market niches. The best course of action may change based on the objectives of the business, the state of the market, and the resources at hand, therefore flexibility and adaptability are essential.

Read More - https://www.marketsandmarkets.com/industry-practice/hydrogen/market-penetration

#HydrogenEconomy#CleanEnergyRevolution#H2Market#GreenHydrogen#FuelingTheFuture#HydrogenInfrastructure#RenewableGas

0 notes

Text

Hydrogen Production Cost Analysis

A cost analysis of hydrogen production is a crucial step towards determining the viability and sustainability of hydrogen as a clean energy source. A detailed examination of the expenses associated with producing hydrogen is necessary in order to encourage advancements in this field. We can identify opportunities for cost optimization by examining several production methods, such as electrolysis or steam methane reforming, and calculating the expenses related to each stage.

Download - https://www.marketsandmarkets.com/industry-practice/RequestForm.asp

Our ability to plan ahead and make educated decisions that will support the hydrogen industry's growth into a more competitive and viable business is made possible by the data obtained from the hydrogen production cost study.

Hydrogen is thought to be a viable energy source for the future because of its efficiency, adaptability, and cleanliness. However, the cost of creating hydrogen currently exceeds that of producing conventional fossil fuels. Hydrogen must become a cost-competitive energy source by lowering production costs at every level through Hydrogen Production Cost Analysis.

The cost of producing hydrogen is dependent on various elements such as feedstock, plant capacity, technology type, power price, and other considerations.

Three primary methods are utilized to manufacture hydrogen: steam methane reforming (SMR), electrolysis, and coal gasification.

Steam Methane Reforming (SMR): SMR is currently the most widely used method of producing hydrogen, accounting for over 75% of all hydrogen produced globally. The primary feedstock for SMR, natural gas, has an impact on the price of hydrogen production. When natural gas and steam combine, carbon dioxide and hydrogen are released. By absorbing and storing carbon dioxide, greenhouse gas emissions can be reduced. SMR produces hydrogen at a cost per kilogram that ranges from $1.5 to $3.5.

Electrolysis: Hydrogen and oxygen are separated from water by an electrical process known as electrolysis. The cost of creating hydrogen using electrolysis is determined by the type of electrolysis process used and the cost of electricity. The two primary subcategories of electrolysis technology are alkaline and proton exchange membrane (PEM) technologies. Alkaline electrolysis can produce hydrogen for $2 to $4 per kilogram, making it a cost-effective and well-established method. PEM electrolysis is a more expensive and modern technique that costs $4 to $6 each kilogram of hydrogen produced.

Coal Gasification: The process of coal gasification involves the reaction of coal with steam and oxygen to produce hydrogen and carbon monoxide. Further reaction between the carbon monoxide and steam can provide more hydrogen and carbon dioxide. The cost of creating hydrogen by coal gasification is heavily dependent on the cost of coal and the type of technology that is used. Coal gasification produces hydrogen for between $2 and $6 per kilogram.

To make the generation of hydrogen more affordable, the Hydrogen generation Cost Analysis technique can make use of many tactics. Growing output volume is one tactic, as economies of scale enable the construction of larger facilities at lower costs. Optimizing current processes or using state-of-the-art technologies are two alternative approaches to increase production process efficiency. In addition, the cost of electrolysis hydrogen can be significantly reduced by using renewable energy sources such as wind or solar energy.

Hydrogen from Renewables

The method of producing hydrogen gas using renewable energy is explained in "Hydrogen from Renewables". This usually involves using electricity generated from renewable sources, such solar, wind, or hydropower, to fuel an electrolysis process. Hydrogen (H₃) and oxygen (O₃) are produced during the electrolysis process by splitting water (H2O) with an electric current.

In order to reduce greenhouse gas emissions and reliance on fossil fuels, the main goal of hydrogen from renewables is to produce hydrogen in an environmentally responsible and sustainable manner. The use of this green hydrogen as a clean energy carrier in a range of industries and sectors, such as transportation, energy storage, and manufacturing, can therefore facilitate the overall transition to a more sustainable and low-carbon energy system.

Green Ammonia Production Process

The process of creating ammonia by the use of renewable energy sources, such as solar, wind, or hydropower, is known as "green ammonia production." This creates the hydrogen needed for ammonia synthesis. The Haber-Bosch process, the typical way of generating ammonia, is mostly reliant on fossil fuels and results in a considerable contribution to greenhouse gas emissions. Environmental issues are addressed in the manufacture of green ammonia by utilizing clean energy. The following is a summary of the steps needed to produce green ammonia:

Electrolysis for Hydrogen Generation:

Description: Starting with the electrolysis of water (H2O) to produce hydrogen gas (H₃), green ammonia is produced.

Renewable Energy Input: Examples of renewable energy sources that supply the electricity required for the electrolysis process are solar, wind, and hydropower.

Advantages: Renewable energy sources are considered "green" sources of hydrogen because they don't release carbon dioxide when produced using standard methods.

Ammonia Synthesis:

Description: When green hydrogen from electrolysis is combined with nitrogen, which is usually extracted from the air, in a reactor, the Haber-Bosch synthesis is employed to produce ammonia (NH3).

Renewable Energy Input: Since the hydrogen used in this step is derived from renewable sources, the process is generally environmentally friendly.

Advantages: The resulting ammonia is "green" or "sustainable" because it is produced without the use of fossil fuels.

Upstream and Downstream Processes:

Description: The production process involves several downstream and upstream steps, such as gas purification, ammonia synthesis loop optimization, and compression.

Renewable Energy Input: The carbon footprint of the entire manufacturing chain can be further reduced by ancillary operations that use renewable energy.

Advantages: Provides assurance of a holistic approach to sustainable ammonia production.

Integrated Renewable Energy Systems:

Description: Renewable energy sources are directly linked to the electrolysis process in integrated systems commonly used in the production of green ammonia.

Renewable Energy Input: Renewable energy can be produced steadily and sustainably by systems that combine wind, solar, or hydropower.

Advantages: Increases the overall environmental benefits of the ammonia production process by making the most of renewable energy sources.

Transportation and Distribution:

Description: Green ammonia can be produced, then distributed and transported for use in a variety of applications, such as fertilizers, energy storage, and clean fuel.

Renewable Energy Input: The sustainability of the entire value chain is increased when distribution and transportation are powered by renewable energy.

Advantages: Ammonia's green credentials are expanded by considering the environmental impact of its entire lifecycle.

Green ammonia production is an essential component of sustainable and low-carbon initiatives, particularly in industries where the usage of conventional ammonia results in significant increases in carbon emissions. It supports the transition to a carbon-neutral and more sustainable economy and is consistent with global efforts to reduce the negative environmental effects of industrial activity.

Hydrogen Investment

"Hydrogen Investment" refers to the allocation of financial resources by individuals, organizations, or governments with the intention of participating in or supporting sector-related activities. This industry includes producing, transporting, storing, and using hydrogen as a fuel source. The majority of hydrogen investments seek to create a hydrogen economy, which uses hydrogen as a clean, sustainable energy source across a variety of enterprises.

The following are some essential components and focus areas for hydrogen investments:

Production Technologies:

Investing in technologies and infrastructure to generate hydrogen energy. Funding electrolysis for green hydrogen, steam methane reforming for blue hydrogen, or other state-of-the-art production methods could be necessary.

Infrastructure Development:

Committing funds to the development and maintenance of infrastructure that will allow hydrogen to be transported, stored, and distributed. It might be necessary to invest in pipes, storage facilities, and transportation networks.

Research and Development:

Promoting research aimed at improving hydrogen production and utilization methods, applications, and storage technologies. This contributes to the development of hydrogen solutions that are more affordable and efficient.

End-Use Applications:

Investing in ideas and projects that use hydrogen for a variety of uses, such as fuel cells for mobility (such as hydrogen-powered cars), industrial processes, and power generation.

Renewable Energy Integration:

Encouraging programs that integrate the production of hydrogen with renewable energy sources, such as solar or wind power. In keeping with this objective is making sure that "green hydrogen" is produced in a way that has minimal influence on the environment.

Policy Advocacy:

Supporting or participating in initiatives that advocate for legislation and regulations that support the growth of the hydrogen sector. Reaching out to business associations and political entities may be necessary to create a friendly investment climate.

Hydrogen Infrastructure Funds:

Funds or financial vehicles devoted to hydrogen-related initiatives. These funds might be managed by banking institutions, private equity firms, or other investment companies.

Carbon Capture and Storage (CCS):

Investing funds in new ideas and projects that employ carbon capture and storage methods, particularly those that generate "blue hydrogen," a substance obtained by absorbing and storing carbon emissions from fossil fuels.

Global Supply Chains:

Encouraging financial investments in global supply chains for hydrogen, advancing cross-border trade and collaboration, and cultivating global market cooperation.

In light of the global shift towards low-carbon and more sustainable energy options, hydrogen has attracted significant interest as a versatile and environmentally benign energy source. A more sustainable and low-carbon energy environment can be reached more quickly with the support of investments in hydrogen. Hydrogen technologies must be developed and widely applied.

Read More - https://www.marketsandmarkets.com/industry-practice/hydrogen/hydrogen-production-cost-analysis

#HydrogenEconomics#H2CostAnalysis#RenewableHydrogen#GreenHydrogenCost#HydrogenInfrastructure#EconomicAnalysis#H2ProductionCost#HydrogenInvestment

0 notes

Text

Solutions for High-Pressure Hydrogen Storage

Hydrogen storage is one component of the hydrogen economy that is crucial. Because of its extreme flammability and low density, hydrogen needs to be stored in a solid state or at low temperatures. There exist multiple alternatives for storing hydrogen, each with pros and cons of their own.

Download - https://www.marketsandmarkets.com/industry-practice/RequestForm.asp

Compressed Hydrogen Storage: Compressed hydrogen storage is the most widely used and widely accepted method of storing hydrogen. This method compresses hydrogen gas, which is then stored in high-pressure tanks. The tanks can be constructed out of metal or composite materials. The storage pressure range is 350–700 bar; greater pressures result in greater storage capacity. Compressed hydrogen storage is useful for stationary applications such as industrial operations, backup power, and refueling stations. Unfortunately, due to their size and weight, the tanks cannot be utilized in mobile applications.

Liquid Hydrogen Storage: Hydrogen gas must first be cooled to its boiling point (-253˒°C) in order for it to liquefy before being kept in insulated tanks. Compressed hydrogen storage has a higher energy density than liquid hydrogen storage. However, because it requires cryogenic temperatures, the tanks must be well insulated to avoid boil-off and venting. Although liquid hydrogen storage is not ideal for general applications due to its high cost and complexity, it is often used in space applications and some specialized ones, such as high-performance automobiles.

Metal Hydride Storage: Metal hydride storage involves the utilization of metal alloys that possess the capacity to both absorb and release hydrogen gas. Often utilized lightweight metals for creating metal alloys are magnesium, titanium, or aluminum. The low operating pressure, safety, and enormous storage capacity of metal hydride storage are just a few advantages. The high cost and high temperature required for hydrogen to be released from the alloys are disadvantages. Metal hydride batteries are useful for portable devices, backup power systems, and small fuel cells.

Chemical Hydrogen Storage: Chemical hydrogen storage uses materials with the ability to release hydrogen gas when activated. Among the substances, which can be either organic or inorganic, are sodium borohydride, ammonia borane, and formic acid. Chemical hydrogen storage has the advantages of high storage capacity, low operating pressure, and portability. The compounds' disadvantages are their high cost, byproduct production, and catalyst requirement for hydrogen release. Chemical hydrogen storage has use in small fuel cells, backup power systems, and portable electronics.

Storage is a crucial link in the hydrogen supply chain. It allows hydrogen to be produced and delivered to the consumption site during off-peak hours. The choice of hydrogen storage methods is influenced by the different applications, energy density, safety, and cost considerations.

The primary objectives of continuing research and development are cost reduction and increased hydrogen storage efficiency.

High-Pressure Hydrogen Storage

High-Pressure Hydrogen Storage is crucial for hydrogen-based energy systems, particularly for fuel cell vehicles, industrial operations, and energy storage. The following information relates to high-pressure hydrogen storage.

Importance of High-Pressure Storage: Given its low volumetric energy density, hydrogen gas needs to be compressed in order to acquire a sizable storage volume for a number of uses. Storage at high pressure is one of the finest solutions to this issue.

Storage Technologies: High-pressure hydrogen storage solutions include gas cylinders, composite overwrapped pressure vessels (COPVs), and tube trailers. These technologies are used in many fields, depending on the specific requirements and applications.

Safety Considerations: Hydrogen storage at high pressure raises numerous safety issues. Containment systems must abide by stringent safety rules to prevent leaks or ruptures since hydrogen is extremely flammable.

Advantages: The ability to store more hydrogen in a given area, speedier refueling for hydrogen-powered cars, and simpler design are only a few advantages of high-pressure storage over cryogenic storage.

Challenges: A significant challenge may be the energy required for compression. Furthermore, the strain and fatigue caused by cyclic loading must be tolerated by the materials used to construct high-pressure storage systems.

High-pressure hydrogen storage is crucial to the hydrogen economy because it enables the safe and efficient storage and transportation of hydrogen for a range of applications, which is necessary for the pursuit of cleaner and more sustainable energy solutions.

Hydrogen Storage Materials

The development of technologies and systems based on hydrogen energy is heavily dependent on Hydrogen Storage Materials. These materials are used to store and release hydrogen in an efficient and secure manner. The following information explains the materials used to store hydrogen:

Hydrogen Storage Mechanisms:

There are several ways to store hydrogen, including chemisorption (chemical bonding), physisorption (physical adsorption), and mixtures of these methods. While choosing a material, consideration is typically given to the planned storage capacity, release kinetics, and thermodynamic considerations.

Types of Hydrogen Storage Materials:

Metal Hydrides: These compounds are known as metal hydrides; they are composed of metal atoms combining with hydrogen. Sodium alanate (NaAlH4), magnesium hydride (MgH2), and complex metal hydrides are a few examples. Metal hydrides have a relatively large capacity to hold hydrogen, which is released at ambient temperature.

Porous Materials: Activated carbon, covalent organic frameworks, and metal-organic frameworks (MOFs) are among the porous materials that can adsorbe hydrogen using physisorption techniques. They have a wide surface area and can be modified for storing hydrogen.

Thermodynamics and Kinetics: The thermodynamics of hydrogen storage materials must be understood in relation to the energy changes caused by hydrogen adsorption and desorption. Kinetics deals with the speeds of these processes. Good thermodynamic and kinetic properties are desirable for materials used in practical hydrogen storage devices.

Operating Conditions: Materials for storing hydrogen may need a variety of operating environments. Some materials may require heating, while others can work at ambient temperature. Gaining an understanding of and honing these factors are necessary for practical implementation.

Challenges and Research: The objective of current research is to develop materials with improved properties such as increased storage capacity, faster kinetics, and lower operating temperatures for the storage of hydrogen. Reversibility, cost, and safety issues must all be addressed before these materials be employed extensively.

The category of hydrogen storage materials includes a wide range of compounds with varying capacities, operating circumstances, and storage procedures. These materials are crucial for the development of hydrogen-based energy systems, and research and development efforts are ongoing to improve their efficacy, safety, and utility.

Hydrogen Fuel Storage

Fuel storage for hydrogen-based energy systems and technologies is essential. Hydrogen needs to be stored carefully and efficiently in order to be used in combustion engines or fuel cells. The following information relates to the fuel storage for hydrogen:

Hydrogen Storage Methods:

Gaseous Hydrogen Storage: With this method, hydrogen is stored as a gas at pressures typically between 350 and 700 bar (5,000 and 10,000 psi) in high-pressure containers. Lightweight materials such as metal alloys or composite materials are commonly employed in these containers in order to ensure their survival under high pressure.

Liquid Hydrogen Storage: Liquid hydrogen is stored at very low temperatures roughly 253°C or -423°F. Gaseous hydrogen has a lower energy density than liquid hydrogen, but gaseous hydrogen requires cryogenic storage tanks, which can be huge and energy-intensive to maintain.

Metal Hydride Storage: Certain metal hydrides possess the ability to absorb and release hydrogen gas in a reversible manner. Because they offer a compact and safe method of storing hydrogen, they are suitable for both fixed and mobile power generation.

Chemical Hydride Storage: Sodium borohydride and ammonia borane are examples of chemical hydrides that can hold hydrogen. They release hydrogen when heated or in the presence of a catalyst. Chemical hydrides are used in applications like backup power systems.

Liquid Organic Hydrogen Carriers (LOHCs): The reversible binding and release of hydrogen is a property of organic compounds called LOHCs. For the mobile storage and transportation of hydrogen, these carriers are extremely well-suited.

The hydrogen economy, which enables the practical use of hydrogen in a range of applications, depends critically on hydrogen fuel storage. The ideal storage solution will depend on the specifics of the application and the need for efficiency, portability, and safety. The advancement of hydrogen storage technology is the aim of ongoing research and development.

Leading businesses that focus on hydrogen storage systems include the following:

Air Liquide: Air Liquide offers a variety of hydrogen storage solutions, including bulk storage tanks, tube trailers, and compressed gas cylinders.

Linde: Linde offers a range of hydrogen storage solutions, including high-pressure gas cylinders, tube trailers, and cryogenic storage tanks.

Hexagon Purus: Type 4 tanks are strong and lightweight composite high-pressure hydrogen storage tanks that are the specialty of Hexagon Purus.

McPhy Energy: Two hydrogen storage solutions offered by McPhy Energy are solid-state hydrogen storage and hydrogen refueling stations.

Plug Power: Plug Power offers fuel cell hydrogen storage alternatives in addition to metal hydride-based storage systems.

Worthington Industries: Worthington Industries offers a variety of hydrogen storage systems, compressed gas cylinders and bulk storage tanks being only two.

Chart Industries: Chart Industries is a specialist in building cryogenic storage tanks, which have the capacity to hold large amounts of hydrogen at low temperatures.

Hydrogenics: Two hydrogen storage solutions offered by Hydrogenics are hydrogen refueling stations and compressed gas cylinders.

The storage of hydrogen has proven to be a major technical barrier to the widespread use of hydrogen as fuel. Some major problems with hydrogen storage are as follows:

Low energy density: The energy density of hydrogen is lower per unit volume than that of conventional fuels such as gasoline and diesel. This suggests that in order to store the same amount of energy as conventional fuels, more hydrogen must be stored.

Storage at high pressures: Hydrogen must be compressed to extremely high pressures in order to acquire the energy density required for practical application. This poses a safety risk due to the extreme pressure that could result in leaks and explosions.

Cryogenic storage: Hydrogen can also be stored by cooling it to very low temperatures and turning it into a liquid state. Unfortunately, this means that very low temperatures (-253˂°C) are required, which complicates and increases the cost of the storage process.

Material compatibility: Gas can cause embrittlement and corrosion in certain materials, so materials that are compatible with hydrogen must be used to build storage tanks and pipes.

Cost: It is still somewhat expensive to store hydrogen when compared to other fuels. The cost of high-pressure tanks, materials compatible with hydrogen, and cryogenic storage could raise the overall cost of storing hydrogen.

Hydrogen storage system problems must be resolved before hydrogen can be used as a fuel on a large scale. New, affordable, high-energy-density hydrogen storage technologies are the aim of current research and development.

Read More - https://www.marketsandmarkets.com/industry-practice/hydrogen/hydrogen-storage-solution

#HydrogenStorageSolutions#HighPressureHydrogen#CleanEnergyStorage#HydrogenInnovation#RenewableEnergyTech#HydrogenInfrastructure#PressureVesselTech

0 notes

Text

Hydrogen Supply Chain Optimization

The process of planning and overseeing the many tasks involved in the production, distribution, storage, and transportation of hydrogen in the most economical and efficient manner is known as hydrogen supply chain optimization. Optimization is the process of locating and fixing inefficiencies, bottlenecks, and other obstacles that can prevent hydrogen from moving freely throughout the supply chain.

Download - https://www.marketsandmarkets.com/industry-practice/RequestForm.asp