#Hydraulic Breaker Tools

Text

Industrial And Mining Breaker Tools

People choose hydraulic breakers for their convenience, safety, and quality. These tools are great for any kind of excavation work, and are especially popular in mining. Hydraulic breaker tools offer many benefits that other tools cannot provide. One of the many benefits is that they are easy to use. They are designed to be easy to use by anyone, so no matter what your experience level is, you can easily use them. They are also safer than other tools because they have a safety valve that prevents the tool from exploding and hurting anyone. Another benefit is that they are durable. Hydraulic breaker tools are made of tough materials, so they can withstand heavy duty use without breaking. Finally, these tools are high quality. They have a lifetime warranty, and can last for many years with regular use.

Rammer breaker tools are tools that can be used to break through drywall and other materials in a building. This tool is able to deliver a powerful blow that can break through drywall with ease. It is ideal for commercial use, such as breaking through walls in buildings to create a new doorway. These tools are able to deliver a lot of force in a single blow, and can be used to create a new doorway in a matter of minutes. The head of the tool is shaped like a hammer, which means that it can be used for tasks other than breaking through drywall. The head is made of steel, which means that it is durable and can be used for years. The head is also fitted with a safety cushion, which means that it is unlikely to cause injury. The head is also angled so that it can be used in a variety of positions. This means that Rammer breaker tools can be used by both left-handed and right-handed people.

The Cat hydraulic hammer tools are tools that provide powerful blows to the surface of an object, and are a part of the Cat construction machinery line. These tools are used for tasks such as breaking up asphalt and concrete, removing earth, and building foundations. It have a variety of power ratings and weights, and have many benefits that make them a popular choice for construction workers. Cat hydraulic hammer tools are strong, with a variety of power ratings. The lowest power rating is 1.5 tons, which is enough to break up asphalt and concrete. The highest power rating is 45 tons, which is enough to break up asphalt and concrete with the force of a jackhammer.

3 notes

·

View notes

Text

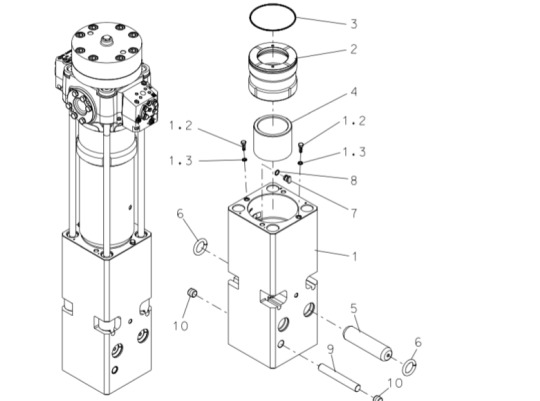

165464 Seal Set Rammer BR4099 Hydraulic Hammer Rock Breaker

162525 Wear Plate

165464 Seal Set

160020 Tool Retaining Pin

172307 Membrane

160008 Lower Tool Bushing

160009 Upper Tool Bushing

160010 Thrust Ring

160558 Seal

K14099 Service Kit

View On WordPress

#160008 Lower Tool Bushing#160009 Upper Tool Bushing#160010 Thrust Ring#160020 Tool Retaining Pin#160558 Seal#162525 Wear Plate#165464 Seal Set#165464 Seal Set Rammer BR4099 Hydraulic Hammer Rock Breaker#172307 Membrane#K14099 Service Kit

0 notes

Text

Hydraulic Tactical Door Breaching Tool

We provide you with the best solutions for door opening. SAN’s tactical breaching gear offers a big upgrade for the Police & HLS units, Firefighters & Rescue teams, Military & Special Forces in Multi-functionally, Weight, Design, and Speed.. Choose the best door breaching tools here.

0 notes

Text

The procedure of taking down buildings and various other man-made frameworks is referred to as demolition. There's a great deal of steel as well as concrete that collapse down creating a great deal of debris throughout demolition. Every demolition project has certain characteristics that make them unique and various from each various other. This is what makes it required to examine what approaches should be complied with and also what equipment ought to be utilized. The range, regional atmosphere, as well as place determine the type of construction tools to be used.

Demolition tasks are typically of 2 kinds-- reduced and also high level. Low-level demolitions entail single. tale buildings or various other little structures being taken down, while the latter involves the demolition of. huge structures like dams, multi-story buildings, etc. Regardless of what the category of demolition is,. certain kinds of tools are needed for their effective completion. Utilizing these pieces of. tools conserves time and gets the job done extra efficiently. Despite the progression made in. technology, specific devices still requires to be utilized. Allow'' s check out them.

Excavators.

These are one of one of the most important tools utilized in the demolition sector. With their. quickness as well as performance, they assist in the effective conclusion of demolition tasks. The different.items in an excavator show what they are used for. One of the most preferred excavator elements include. the cab, shoe, boom, dish, and also arm.

Excavators can be made use of for different functions and that explains why they locate an area in jobs of. several kinds. They can be made use of for knocking down structures, industrial systems, mobile homes, barns,. wetlands, floors, modern-day inground pools, pits, etc. Given that they are really versatile, excavators are made use of in. numerous industries, not simply demolition.

Shears.

Shears work devices for demolition, especially in big jobs. As the name suggests, these are. giant scissors that can puncture virtually anything and every little thing. Their major usage is breaking up steel. beam of lights as well as various other big parts of metal. It's possible to put a shear on an excavator or a product. trainer. Not just are shears perfect for taking down buildings, however they are also vital for reusing as they. assistance cut and refine steel. They help make the most out of a demolition project as they assist reuse. big parts of the structure being knocked down that are of steel.

Backhoe Loader

Backhoe loaders include a flexible shovel and also there's a container in the back. They are made use of. extensively in little as well as moderate jobs. Great for doing backfill work, this device can also be utilized. for gravel pressing and also installment of tubes. Since it proceeds tires, it can be made use of within urbane. areas and in trenches of numerous sizes.

Backhoe loaders

can run in tiny areas too. A range of device accessories can be made use of to furnish. these loaders. The most common of such devices are buckets that are utilized to take away debris from. a task site. The hydraulic breaker is an additional extremely helpful device made use of for breaking difficult products. like rocks or concrete.

Cranes.

Cranes are meant for high-level demolition tasks. A hefty damaging round is usually attached to a cord that. the crane swings back and forth to bring down huge structures. Three-dimensional weight movement. with a solitary tool is possible only with a crane.

A crane has wire ropes or chains, sheaves made use of to lift, relocate, and also reduced materials, and a hoist. Cranes are. of various categories-- mobile, tower, expenses or gantry, vacationer, stationary, or derrick cranes.

Dozers.

A lot of material requires to be gotten rid of in every demolition job. Dozers create the backbone of these. jobs. It's due to the fact that they can be utilized for ripping, bulldozing, scraper job, land clearing up, grading, as. well as numerous other tasks.

These machines are very powerful and they feature a big frontal blade managed by hydraulic. pistons. There's likewise a ripper in the back. There are numerous tire as well as track setups available.

Pulverizers.

With their cleverly tilted mass, pulverizers are really reliable in dividing rebar from concrete. The. right design of a pulverizer indicates that it's best for main as well as second demolition. They. are also appropriate for reinforced and also non-reinforced concrete structures.

The substantial jaws of a pulverizer when attached to an excavator are really effective for taking down. concrete slabs. The influence of the jaws aids crush concrete and separate it from the rebar. That makes. it simple to separate the concrete from the debris.

Discard Trucks and Articulated Trucks.

An area to go down materials is a need to for staffs associated with demolition projects. Expressed vehicles come. with a protected bed that assists hold plumbing pipes, rocks, support beam of lights, tree branches, and other products. discovered after a structure is lowered. The segmented develop makes it feasible to steer expressed.

trucks in minimal area. That's why these trucks are available in handy when transferring scrap as they can move. in and out of hectic websites with ease. Dump trucks may be needed for transporting recyclables as well as loose products in larger tasks. Hours of. manual labor can be saved as the automatic controls of these durable automobiles can empty heavy. loads fast as well as successfully.

Grapples.

Excavators can be transformed right into equipment with remarkable excavating ability with grapple. add-ons. Grapple accessories offer multiple alternatives at demolition sites helping accomplish jobs like. sorting garbage and moving loosened product that aids clean up the site promptly.

Grapples can turn excavators right into the excellent maker to raise the efficiency of demolition website clean-.ups. Grapples are of various types including orange peel grapples, woodland equipment grapples, garbage. grapples, and service providers' grapples.

Verdict.

Utilizing the equipment provided above intelligently can help finish demolition tasks with greater efficiency.in less time. The best size of tools and accessories needs to be determined for the most efficient. use of them. That's how tools can be made use of to its full possibility. The very first step is to figure out the. requirements of the demolition project. It's the requirements of a demolition job that make a decision which tools. shall have to be used.

2 notes

·

View notes

Text

Crushing Rocks Made Easy: The Ultimate Guide to Choosing and Using Rock Breakers

In the world of construction and mining, breaking and crushing rocks is often a critical task. To achieve this efficiently and effectively, the right tools are essential. DCS Techno understands the importance of equipping professionals with top-quality equipment tailored to their needs. Renowned for their customer-oriented approach, With a deep understanding that roads vary in conditions, their products are meticulously crafted to address these differences, ensuring optimal performance regardless of the surface. For anyone seeking reliable road milling tools, DCS Techno stands out as the go-to choice.

Introduction:

Rock crushing is a fundamental process in various industries, from construction to mining and quarrying. Whether you're excavating rocky terrain for a building foundation or extracting valuable minerals from underground deposits, the efficiency and precision of your rock-breaking equipment can significantly impact project timelines and costs. In this comprehensive guide, we'll delve into the world of rock breakers, exploring how to select the right equipment and maximize its performance for optimal results.

Understanding Rock Breakers:

Rock breakers, also known as hydraulic hammers or demolition tools, are specialized attachments designed to break oversized or hard materials such as rocks, concrete, and asphalt. They are commonly mounted on excavators, backhoes, or skid-steer loaders, providing the necessary force to fracture and fragment tough geological formations. Rock breakers come in various sizes and configurations, each suited to specific applications and operating conditions.

Choosing the Right Rock Breaker:

Selecting the appropriate rock breaker for your project requires careful consideration of several factors:

Size and Power: Assess the size and hardness of the rocks you'll be breaking, and choose a rock breaker with sufficient power and impact energy to handle the task efficiently.

Compatibility: Ensure that the rock breaker is compatible with your existing equipment, considering factors such as hydraulic flow and pressure requirements.

Attachments and Accessories: Explore additional features and accessories, such as moil points, chisels, or blunt tools, to optimize versatility and performance across different rock types and conditions.

Durability and Maintenance: Look for rock breakers constructed from high-quality materials and equipped with robust components to withstand the rigors of continuous use. Consider maintenance requirements and access to spare parts to minimize downtime and ensure long-term reliability.

Using Rock Breakers Effectively:

Once you've selected the right rock breaker for your needs, employing proper techniques and best practices is crucial to achieving optimal results:

Positioning and Angle: Position the rock breaker at the correct angle relative to the rock surface, maximizing the force applied to the target area while minimizing unnecessary wear and tear.

Controlled Force: Apply controlled bursts of force rather than continuous pounding to break the rock gradually and avoid excessive stress on the equipment.

Monitoring and Adjustment: Continuously monitor the progress of rock breaking operations, adjusting the position and settings of the rock breaker as needed to maintain efficiency and safety.

Safety Measures: Always prioritize safety, wearing appropriate personal protective equipment (PPE) and adhering to established safety protocols to prevent accidents and injuries.

Conclusion:

Crushing rocks may seem like a daunting task, but with the right equipment and expertise, it can be accomplished efficiently and effectively. By selecting the appropriate rock breaker for your needs, employing proper techniques, and leveraging high-quality tools such as those offered by DCS Techno, you can tackle even the toughest rock-breaking challenges with confidence. With careful planning, attention to detail, and a commitment to excellence, crushing rocks can be made easy, paving the way for successful construction and mining projects.

To know more information about DCS Techno Rock Breakers Visit: https://www.dcstechno.com/indeco-rock-breakers/

0 notes

Text

The increasing rate of natural disasters like wildfires, frigid colds, and hurricanes is leaving many Canadians and their insurers forking out billions of dollars, according to a new study from Statistics Canada.

From 1983 to 2008, insurance companies in the country spent about $400 million on average annually on catastrophic claims, but since 2009 that number has risen to almost $2 billion. Recent hurricanes, floods, and historical wildfires saw that number balloon to $3.4 billion in 2022 and $3.1 billion last year — 50 percent more than the yearly average.

In recent years, extreme weather events are increasingly going up, leading to a rise in natural disasters. Enhancing the related ability to resist disasters such as emergency response, urban drainage and flood prevention, as well as post-disaster rescue and reconstruction efforts have become more crucial. The improvement of these capabilities inevitably relies on specialized and agile equipment, such as portable hydraulic tools.

Why Choose Hydraulic Tools?

Hydraulic tools play an important role in post-disaster rescue, repair, and reconstruction efforts. Hydraulic tools like handheld hydraulic breakers, cut-off saws, ring saws, slurry pumps, and automatic drainage systems are generally used where need emergency rescue, debris clearing, temporary shelter setting up, and infrastructure repair. When the power supply has not been restored, these tools ensure the continuity and efficiency of reconstruction work.

Handheld hydraulic rescue tools offer significant advantages in natural disaster rescue and emergency response. Their unique design and operational characteristics make them key equipment in many rescue missions. The significant advantages are below:

№1 No need for electricity and convenient operation

Handheld hydraulic tools can be used in any environment without relying on electricity or fuel. This is particularly crucial in situations like earthquakes or floods, where power supply may be disrupted. Rescue personnel can deploy them immediately, unaffected by power supply limitations.

№2 Powerful demolition capabilities

Portable hydraulic tools generate immense demolition force through hydraulic principles, effectively cutting, prying, or expanding materials like reinforced concrete and metal. This enables quick clearance of obstacles in complex rescue environments, opening up rescue channels and saving trapped individuals.

№3 Portability and ease of operation

Portable hydraulic tools are typically designed to be compact and relatively lightweight, making them easy to carry and operate. Rescue personnel can easily transport them to disaster sites, even in narrow or inaccessible spaces. Their simple manual operation design allows rescue personnel to quickly get started without complex training.

№4 High reliability and low maintenance requirements

Portable hydraulic demolition tools have a simple, sturdy, and durable structure suitable for various harsh rescue environments. Their mechanical structure requires minimal maintenance, reducing the risk of equipment failure during emergencies. Additionally, these tools are durable and can operate efficiently for extended periods, ensuring the continuity of rescue missions.

№5 Versatility and flexibility

Many handheld hydraulic demolition tools have multiple functions, capable of cutting, expanding, squeezing, and more. This versatility allows rescue personnel to adapt to different types of obstacles and rescue tasks, improving rescue efficiency and safety. Furthermore, some tools can be equipped with different accessories to meet specific task requirements.

№6 High safety

Zondar hydraulic tools prioritize safety in their design, often equipped with non-slip handles and automatic locking devices to prevent accidental slipping or loss of control during operation. The low noise and vibration generated during operation reduce the risk of secondary injuries to rescue personnel and trapped individuals.

Why Zondar Hydraulic Tools?

Changsha Zondar Intelligent Technology Co., Ltd. is a professional design manufacturer of high-end hydraulic equipment in the fields of emergency, rescue, construction, and maintenance.

CS Zondar is located in the national-level Sany Industrial City in the Changsha Economic and Technology Development Zone. The development and management team is from Sany Heavy Industry, including more than 70% personnel possessing master's degree and above who have top technology development strength in the industry.

The rescue hydraulic equipment developed by CS Zondar is mainly hydraulic power units, slurry pumps, chainsaws, cut-off saws, breakers, which can be used for forcible entry, drainage, cutting, drilling, and tamping, etc., and are widely applied in rescue, municipal construction, and other fields.

The strong design development capability of CS Zondar can strictly control production processes and quality standards, ensuring that each product meets high-quality requirements, and providing you with customized solutions based on all kinds of specific conditions demand.

Conclusion

High-quality portable hydraulic tools from professional manufacturers offer invaluable assets in natural disaster rescue and emergency response efforts. Their reliability, portability, versatility, and safety features enable rescue teams to efficiently tackle various challenges encountered in rescue operations, ultimately saving lives and minimizing damage.

Contact us:

Website:http://e.zondargroup.com/

Email:[email protected]

Whatsapp:+8615973148822

1 note

·

View note

Text

Troubleshooting Common Issues with Tyre Changer Machines

Tire changer machines are essential tools in any automotive workshop, allowing mechanics to efficiently replace and repair tires. However, like any machinery, they can encounter issues that disrupt workflow and productivity. Here’s a guide to troubleshooting common problems with tire changer machines:

Problem 1: Bead Seating Difficulty

Symptoms: The tire bead refuses to seat properly onto the rim, making it challenging to inflate the tire.

Possible Causes and Solutions:

Low Tire Pressure: Ensure the tire is adequately inflated before attempting to seat the bead.

Rim or Bead Damage: Inspect the rim and tire bead for any damage or debris that could prevent proper seating. Clean and repair as necessary.

Incorrect Lubrication: Ensure you use appropriate tire lubricants to ease bead seating without causing slippage.

Problem 2: Tire Damage During Mounting

Symptoms: The tire sustains damage such as scratches, tears, or punctures during the mounting process.

Possible Causes and Solutions:

Inadequate Lubrication: Insufficient lubrication can cause excessive friction, leading to tire damage. Apply suitable tire mounting lubricants generously.

Improper Technique: Ensure mechanics are using correct mounting procedures and tools suitable for the tire and rim size.

Old or Worn Components: Check mounting heads and bead breakers for wear and tear. Replace worn parts promptly.

Problem 3: Bead Breaker Malfunction

Symptoms: The bead breaker fails to adequately break the tire bead from the rim.

Possible Causes and Solutions:

Hydraulic Pressure: Check hydraulic fluid levels and pressure settings. Adjust as needed according to manufacturer recommendations.

Bead Breaker Positioning: Ensure the bead breaker is correctly positioned to exert uniform pressure on the tire bead.

Mechanical Obstruction: Inspect for any obstructions or debris that may hinder the bead breaker’s operation.

Problem 4: Excessive Vibration or Noise

Symptoms: The machine exhibits unusual vibrations or noise during operation.

Possible Causes and Solutions:

Uneven Mounting: Ensure the tire is properly centered on the machine’s turntable to avoid imbalance.

Loose Components: Check and tighten all bolts, clamps, and fittings to eliminate potential sources of vibration.

Worn or Damaged Parts: Inspect moving parts such as bearings and bushings for signs of wear. Replace as necessary.

Problem 5: Inconsistent Bead Clamping

Symptoms: The tire bead does not clamp securely onto the turntable, causing slippage.

Possible Causes and Solutions:

Turntable Condition: Clean and inspect the turntable for debris or damage that may affect grip.

Bead Clamp Adjustment: Adjust bead clamp settings according to tire size and type.

Hydraulic Pressure: Ensure sufficient and consistent hydraulic pressure for reliable clamping.

Routine Maintenance Tips:

Regular Lubrication: Keep all moving parts well-lubricated to minimize friction and wear.

Inspect and Clean: Regularly inspect machine components for wear, damage, or debris buildup.

Training and Awareness: Ensure operators are trained in proper tire changer operation and safety protocols.

By addressing these common issues and implementing proactive maintenance practices, you can optimize the performance and longevity of your tire changer machine. Remember to refer to the manufacturer’s manual for specific troubleshooting steps and maintenance guidelines tailored to your machine model. Efficient tire changing processes contribute significantly to the overall efficiency and quality of automotive servicing operations.

0 notes

Text

The Benefits of Renting Demolition Equipment

When it comes to undertaking a demolition project, having the right equipment is essential to ensure that the job is done safely, efficiently, and within budget. While purchasing demolition equipment outright may be a considerable investment, renting the necessary tools can be a cost-effective and practical alternative. Renting demolition equipment offers a range of benefits that make it a popular choice for contractors and DIY enthusiasts alike. To learn more about demolishing equipments, click here!

One of the primary advantages of renting demolition equipment is the cost savings it provides. Instead of spending a large sum of money upfront to buy equipment that may only be needed for a single project, renting allows you to pay for equipment on a temporary basis. This can be particularly beneficial for smaller-scale projects or businesses looking to minimize overhead costs. Renting also eliminates the need for long-term maintenance, storage, and depreciation expenses, further reducing the overall cost.

Another key benefit of renting demolition equipment is access to a wider range of tools and machinery. Demolition projects can vary significantly in scope and requirements, and having the ability to rent specialized equipment for specific tasks ensures that you have the right tools for the job. From excavators and bulldozers to concrete crushers and hydraulic breakers, rental companies offer a diverse selection of equipment options to meet the needs of different projects.

Flexibility is also a major advantage of demolition equipment for rent. Renting allows you to scale up or down based on the requirements of each project without being tied down to owning specific equipment. If additional machinery or tools are needed to speed up the demolition process or tackle unexpected challenges, renting offers the flexibility to quickly adjust your equipment lineup. This agility can help improve project timelines and overall efficiency.

In conclusion, renting demolition equipment is a practical and cost-effective solution for both professionals and individuals looking to undertake demolition projects. With benefits such as cost savings, access to a wide range of equipment, and flexibility in equipment selection, renting allows you to complete your project efficiently and safely without the financial commitment of purchasing equipment outright. Next time you have a demolition project on the horizon, consider the advantages of renting equipment to make the most of your project. Find out more about this topic on this link: https://www.encyclopedia.com/manufacturing/encyclopedias-almanacs-transcripts-and-maps/construction-machinery.

1 note

·

View note

Text

These with special tools can break down buildings and bridges further added by JCB parts dealers in Delhi. These tools, like hydraulic breakers or shears, help the excavator smash through walls and cut metal. This is useful for getting rid of old structures safely and quickly. Demolition workers use these excavators carefully to remove buildings without causing harm to nearby areas or people.

0 notes

Text

Essential Tools and Equipment for Construction Projects

Construction endeavors demand a blend of expertise, dedication, and, crucially, the right tools and equipment. Ranging from simple hand tools to sophisticated heavy machinery, each equipment plays a vital role in the construction industry. With technological advancements, construction tools have evolved to be more efficient, safer, and capable of handling diverse tasks. Whether you're a seasoned contractor or a DIY enthusiast, having a grasp of the essential tools and equipment for construction is paramount. In this comprehensive guide, we'll delve into the indispensable tools and equipment required for every phase of a construction project, spanning from excavation to finishing touches.

Excavators:

Excavators stand as the powerhouse of construction, boasting the capability to move substantial amounts of earth and debris. These heavy-duty machines are indispensable for large-scale projects such as building bridges, highways, and skyscrapers. Available in various sizes and configurations, from mini excavators for narrow spaces to colossal machines capable of digging deep trenches, there's an excavator tailored for every task. Their versatility and power have revolutionized the construction industry, facilitating faster, safer, and more efficient completion of even the most challenging endeavors.

Backhoe Loaders:

Backhoe Loaders, often dubbed as the backbone of construction, offer versatility by serving as both a potent excavator and a loader. Featuring robust engines and hydraulic systems, they effortlessly tackle heavy-duty tasks like digging, trenching, and lifting. Moreover, their compatibility with an array of attachments including breakers, augers, and rakes, renders them ideal for diverse construction projects.

Bulldozers:

Bulldozers emerge as indispensable powerhouses in construction, proficient in moving substantial volumes of earth and debris with ease. Equipped with heavy-duty blades, they excel in pushing, pulling, and leveling terrain, making them indispensable for tasks like land clearing, road grading, and foundation creation. The exceptional strength and adaptability of bulldozers make them a staple in construction endeavors.

Draglines:

In large-scale construction projects, draglines play a pivotal role in excavating earth and relocating heavy materials. These machines feature a large bucket suspended from a boom, operated through cables and pulleys. Operating a dragline demands specialized equipment and highly skilled operators due to their potential hazards. Nonetheless, their effectiveness and efficiency make them indispensable for endeavors such as mining, land reclamation, and dam construction.

Electric Rope Shovels:

Electric Rope Shovels serve as heavy-duty excavation machines in mining and construction sectors, capable of excavating large quantities of materials. Powered by electricity, they boast environmental friendliness compared to traditional diesel-powered excavators. Operating these shovels necessitates various tools and equipment, along with safety gear for the operator. Their efficiency and eco-friendliness render them invaluable in resource extraction projects.

Hydraulic Mining Shovels:

Hydraulic mining shovels prove indispensable in large-scale building projects, leveraging hydraulic systems to transport soil, rocks, and debris effectively. They collaborate with bulldozers, loaders, and trucks to lay the groundwork for new structures, showcasing their significance in construction endeavors.

Motor Graders:

Motor graders excel in grading, leveling, and shaping land surfaces, making them indispensable for various construction tasks. Equipped with long blades, they cut, spread, and level materials like dirt or gravel. Motor graders, along with their components and tools, are essential for preparing the ground for construction operations such as laying foundations and creating roadways.

Pipelayers:

Pipelayers play a crucial role in construction projects involving pipe installation, facilitating the movement and installation of heavy pipes. These machines, coupled with specialized tools and equipment, streamline pipeline construction, enhancing efficiency and safety.

Track Loaders:

Track loaders emerge as versatile and efficient tools for construction projects, boasting tracks instead of wheels for enhanced maneuverability on rough terrain. Their ability to carry heavy loads and accommodate various attachments makes them indispensable for earthmoving tasks.

Pavers:

Pavers constitute an integral part of construction projects, whether for driveways, patios, or walkways. The tools and equipment required for paver construction, along with safety gear, ensure the smooth and efficient execution of the process, resulting in high-quality finished products.

In essence, successful construction projects hinge on the utilization of appropriate tools and equipment. Each piece, from hand tools to heavy machinery, plays a pivotal role in ensuring projects are completed safely and effectively. By investing in high-quality equipment and providing proper training to the crew, construction projects can be executed to the highest standards, on schedule, and within budget. Therefore, meticulous selection and utilization of tools are imperative for constructing a better future.

0 notes

Text

Minibooster Hydraulic Intensifiers, Minibooster Hydraulic Solutions

Minibooster Hydraulic Intensifiers, Minibooster Hydraulic Solutions, Manifold Blocks, Distributor, Supplier, Exporter, Mumbai, India.

Hydraulic Valves, Pressure Control Valves, Direct Acting Relief Valves, Pilot Operated Relief Valves, Dual Cross Over Relief Valves, Dual Cross Over Relief Valve, Accumulator Unloading Valves, High Low Pump Unloading Valves, Pressure Reducing Cum Relieving Valves, Load And Motion Control Valves, Single Pilot Operated Check Valve, Dual Pilot Operated Check Valve, Single Operated Overcenter Valves, Dual Operated Overcenter Valves, Flow Control Valves, Flow Divider Valve, Needle Valve, Check Valve, Flow Restrictor with Check Valve, Priority Valve, Shuttle Valve, Fixed Speed Pressure Compensated Cylinder Lowering Valve, Adjustable Speed Pressure Compensated Cylinder Lowering Valve, Sequence Valve, Directional Control Valve, 2 Way Solenoid Valve, Rotary Directional Control Valve, Safety Control Valve, Hose Burst Valve, Pilot Operated Pump Unloading Valve, Special Valve, Cable Reel Control Valve, Rock Breaker Valve, Motor Mounted Flange Faced Overcenter Valve, Forklift Bale Clamp Valve, Garbage Compactor Dual Pressure Valve, Boom Holding Block, Boom Lowering Block, Hot Flush Valves, Manifold Blocks, Hydraulic Manifold Blocks, Hydraulic Cylinders, Welded Construction With Threaded Gland Cylinder, Streamline Hydraulic Cylinder, Welded Flange Construction Cylinders, Tie Rod Construction Cylinders, Mill Duty Cylinders, Telescopic Cylinders, Custom Made Cylinders, Hydraulic Power Packs, Large Power Packs, Customized Power Packs, Small Powerpacks, Mini Power Packs, Compact Power Packs, Hydraulic Rotary Joints, Multi Passage Rotary Joint, Rotary Joint with Hydraulic Outputs, Rotary Joint with Electrical Outputs, 3 Customized Rotary Joint, Hand Pumps, Inline Body Hand Pumps, Inline Tank Mounted Hand Pumps, Hydraulic Pumps, High Pressure Hydraulic Tools, Hydraulic Intensifiers, Hydraulic Accessories, Hydraulic Systems, Hydraulic Actuators, Mumbai, Maharashtra, India.

0 notes

Text

Breaker Tools For Every Job Site

Hydraulic Breaker Tools are one of the most useful tools in the field of construction. These tools are capable of breaking up tough concrete and paving stones, which can be difficult to do with just a pick or shovel. These tools are typically sold in sets of two or three, and each one is designed to do a specific job. The set usually includes a 2-inch breaker, a 3-inch breaker, and a 5-inch breaker. The 2-inch breaker is designed for breaking up small rocks, pebbles, and concrete that is no more than 2 inches thick. The 3-inch breaker is designed for breaking up 3-inch-thick concrete, and the 5-inch breaker is designed for breaking up 5-inch-thick concrete. These tools are especially useful for landscaping and paving jobs, as they are capable of breaking up tough, uneven surfaces.

JCB rock breaker tools are also great for doing things like filling in cracks in pavement or repairing sidewalks. This is because they are able to break up uneven surfaces, which makes it easier to smooth out the surface. Hydraulic Breaker Tools are typically made of durable steel, which makes them strong enough to break up even the toughest concrete. They are also made to be lightweight and easy to use, which makes them perfect for any job site.

The Hydraulic Hammer Tools is a powerful tool that is used to break up rocks and other hard surfaces. These tools are used by construction companies and other professionals who need to break up hard surfaces in order to reach a desired material. Hydraulic hammers are most often used in the mining industry. They are also used in construction, where they are often used to break up concrete. The hydraulic hammer is a type of pneumatic hammer. A hammer drill is often used in conjunction with the hydraulic hammer. A hammer drill is an air-powered drill that can produce rotational and vibrational motion. A JCB rock breaker tools is often used to drill holes into the surface, while the hydraulic hammer is used to break up the surface and make it easier to access the material below.

0 notes

Text

Excavators are versatile machines used in construction, landscaping, and demolition projects. One key factor that makes excavators so versatile is the wide range of attachments available for them. These attachments can turn a standard excavator into a multipurpose tool capable of performing a variety of tasks. This guide will explore the different types of excavator attachments for hire, their uses, and the benefits they offer.

Types of Excavator Attachments for Hire

Excavator attachments can be broadly categorised into buckets, hydraulic hammers, drills, thumbs, grapples, and rippers. Each type of attachment is designed for specific tasks, allowing the excavator to dig, lift, break, or grab materials as needed.

Buckets: Buckets are the most common excavator attachments for digging and moving soil, gravel, and other materials. They come in various sizes and shapes, including digging, trenching, and grading buckets.

Hydraulic Hammers: Hydraulic hammers, also known as rock breakers, are used for breaking up rocks, concrete, and other hard materials. They are commonly used in demolition and construction projects.

Augers: Augers are used to drill holes in the ground, install posts and fences, or plant trees. They come in various sizes and can be used for different soil types.

Thumbs: Thumbs are used for gripping and lifting objects such as rocks, logs, or debris. They are commonly used in landscaping and demolition projects.

Grapples: Grapples are used to grab and lift large objects such as tree stumps, rocks, or debris. They are commonly used in forestry and construction projects.

Rippers: Rippers are used for breaking up hard soil, asphalt, or concrete. They are commonly used in road construction and land-clearing projects.

Benefits of Excavator Attachments for Hire

Using excavator attachments offers several benefits, including:

Increased Efficiency: By using the right attachment for the job, excavators can perform tasks more efficiently, saving time and labour costs.

Versatility: Excavator attachments allow a single machine to perform various tasks, reducing the need for multiple machines on a job site.

Cost-Effectiveness: Renting excavator attachments can be more cost-effective than purchasing specialised equipment for specific tasks.

Improved Safety: Using the right attachment for the job can improve safety by reducing the risk of accidents and injuries.

Environmental Benefits: Some excavator attachments, such as augers for tree planting, can have environmental benefits by reducing the need for manual labour and machinery.

Choosing the Right Excavator Attachment for Hire

Hire Depot Plant Hire offers a comprehensive range of excavator attachments for hire, providing solutions for various construction and landscaping needs. Their selection includes buckets, augers, hydraulic hammers, and more, which are designed to enhance the versatility and functionality of excavators on the job site. Whether you need to dig trenches, break up concrete, or lift heavy materials, Hire Depot has the proper attachment for the job. With their well-maintained equipment and flexible rental options, customers can easily find the perfect attachment to suit their project requirements.

What sets Hire Depot apart is its commitment to customer satisfaction and reliable service. They ensure that all attachments are well-maintained and ready for use, minimising downtime and maximising productivity. Their team of experts is on hand to provide advice and assistance, ensuring that customers have everything they need to complete their projects efficiently and safely. With Hire Depot, customers can trust that they get high-quality attachments and exceptional service every time.

Conclusion

Excavator attachments are valuable tools that can enhance excavators' capabilities and improve efficiency on construction, landscaping, and demolition projects. By understanding the different types of attachments available and their uses, you can choose the proper attachment for your needs and make the most of your excavator hire.

1 note

·

View note

Text

Rama Mining Tools: Innovating Construction Solutions

Rama Mining Tools stands out as a premier manufacturer, exporter, and supplier in the realm of construction tools, providing an extensive array of equipment tailored to meet the diverse needs of the construction industry. Let’s delve into the world of construction tools and explore the range offered by Rama Mining Tools.

Construction Tools Overview

Rama Mining Tools offers a comprehensive range of construction tools designed to enhance efficiency and productivity on construction sites. These tools include:

Paving Breaker

The paving breaker, a staple in construction, is adept at breaking up concrete, asphalt, and other hard materials, making it indispensable for road construction and demolition projects.

Rivet Buster

The rivet buster is a robust tool used for cutting and removing rivets, making it ideal for dismantling structures or equipment in various industrial applications.

Chipping Hammer

A versatile tool, the chipping hammer is utilized for chiseling, cutting, and shaping materials like concrete and stone, facilitating precision work in construction projects.

4 Bolt Chipping Hammer

This specialized chipping hammer, equipped with four bolts, delivers increased power and efficiency, making it suitable for heavy-duty chiseling and demolition tasks.

Clay Digger

Designed for excavating and digging in clay-rich soils, the clay digger boasts sturdy construction and superior digging capabilities, ensuring optimal performance in challenging environments.

Rotary Drill

The rotary drill is a cornerstone in drilling operations, offering high precision and reliability, making it indispensable for tasks such as boring holes and installing utilities.

Pick Hammer

The pick hammer, with its pointed end, is ideal for breaking up hard surfaces like concrete and rock, providing versatility and efficiency in construction and mining applications.

Hand Tools

Rama Mining Tools provides a range of hand tools including hammers, wrenches, and screwdrivers, crafted with precision to meet the demands of various construction tasks.

Hydraulic Rock Breaker

The hydraulic rock breaker offers immense power and efficiency in breaking and demolishing large rocks and concrete structures, ensuring swift progress on construction sites.

Scabbler

The scabbler, equipped with multiple heads, is designed for roughening surfaces and removing concrete, providing an effective solution for surface preparation and renovation projects.

Importance of Quality Construction Tools

In the construction industry, the quality of tools directly impacts project outcomes, efficiency, and safety. Investing in high-quality construction tools ensures enhanced performance, durability, and reliability, ultimately leading to cost savings and improved project timelines.

Rama Mining Tools' Commitment to Excellence

Rama Mining Tools is committed to delivering superior quality construction tools that adhere to stringent quality standards. With a focus on innovation and customer satisfaction, Rama Mining Tools continues to set benchmarks in the industry.

Conclusion

In conclusion, Rama Mining Tools stands as a trusted partner for construction professionals, offering a diverse range of high-quality tools engineered for excellence. With a relentless commitment to innovation and customer satisfaction, Rama Mining Tools continues to drive progress and efficiency in the construction industry.

1 note

·

View note

Text

SC Equipment Partner - TAKEUCHI

Renowned for their durability and performance, TAKEUCHI machines paired with SC Attachments create a powerhouse combination that excels across various excavation applications. From intricate landscaping to heavy-duty construction, the integration of TAKEUCHI and SC Attachments ensures top-tier efficiency and productivity on every project.

SC Excavator Attachments Suit for TAKEUCHI

Excavator Tilt Rotator

Excavator Tilt Coupler

Casting Quick Coupler

Elevating TAKEUCHI Precision with SC Attachments

Experience precision like never before with TAKEUCHI excavators enhanced by SC Attachments. SC's state-of-the-art precision technology elevates TAKEUCHI machines to execute tasks with unparalleled accuracy. Whether it's fine grading for foundation work or intricate trenching for utilities, TAKEUCHI excavators equipped with SC attachments ensure that every detail is executed perfectly. This precision minimizes rework, boosts project quality, and delights clients with impeccable results. Transform your excavation endeavors with the precision prowess of TAKEUCHI and SC.

TAKEUCHI's Utilization of SC Equipment

Takeuchi excavators have harnessed the innovation of SC Attachments, seamlessly integrating a range of SC's cutting-edge tools to elevate their performance. The combination of Takeuchi excavators and SC accessories enables the excavator to complete a range of tasks with precision and efficiency.

Among the array of SC Attachments, Takeuchi excavators have leveraged the prowess of hydraulic breakers for demolition tasks, grapples for efficient material handling, and trenching buckets for precise digging. These attachments are engineered to seamlessly integrate with Takeuchi machines, ensuring optimal compatibility and boosting versatility on the job site.

SC's hydraulic technology ensures that these attachments operate seamlessly with Takeuchi excavators, optimizing both control and power. This harmonious relationship enables operators to quickly switch between tasks, minimizing downtime and maximizing productivity.

0 notes

Text

Unleashing the Power: Exploring How Rock Breakers Revolutionize Modern Life

DCS Techno that sells construction and mining equipment. We offer a variety of road milling tools that can be used on many different surfaces. Our products are designed to address the specific needs of different jobs. We are a fast-growing company that is committed to providing innovative products and services to our customers. We have a wide range of experience in the mining and construction industries, and we have clients all over the world. We also offer a variety of other products, including foundation drilling equipment. Our products are designed to be time and cost-efficient, and we are always looking for new ways to improve our products.

INTRODUCTION

Rock breakers have become an integral part of modern industries, especially in the construction and mining sectors. These powerful machines have revolutionized the way we break and remove rocks, making it quicker, safer, and more efficient. In this article, I will delve into the world of rock breakers, exploring their importance, how they work, the different types available, advantages of using them, safety measures, maintenance and care, technological innovations, and the leading manufacturers and suppliers. By the end, you'll have a comprehensive understanding of rock breakers and their role in shaping modern industries.

Introduction to Rock Breakers

Rock breakers, also known as hydraulic hammers or rock hammers, are heavy-duty machines designed to break large rocks into smaller pieces. They are commonly used in construction, mining, demolition, and quarrying activities. These powerful tools utilize hydraulic pressure to deliver high impact blows to rocks, effectively breaking them apart.

The Importance of Rock Breakers in Construction and Mining

Rock breakers play a vital role in construction and mining industries. In construction, they are used to break rocks during the excavation process, making way for foundations, tunnels, and other structures. Without rock breakers, construction projects would be severely hindered, as manual methods of rock removal are time-consuming and inefficient.

In mining, rock breakers are essential for extracting valuable minerals from the earth. They are used to break down hard rock formations, allowing access to the minerals beneath. Without rock breakers, mining operations would be significantly limited, affecting productivity and profitability.

How Rock Breakers Work

Rock breakers operate on the principle of hydraulic power. They consist of a hydraulic system, a power source, and a breaker tool. The hydraulic system generates high-pressure oil, which is directed to a hydraulic cylinder. The cylinder pushes a piston, which in turn strikes the breaker tool against the rock surface.

The impact from the breaker tool creates cracks and fractures in the rock, eventually breaking it apart. The hydraulic system also controls the speed and frequency of the blows, providing operators with precise control over the breaking process. This allows for efficient rock breaking while minimizing the risk of damage to the surrounding structures.

Types of Rock Breakers

There are several types of rock breakers available, each designed to suit specific applications. The two main types are hydraulic breakers and pneumatic breakers.

Hydraulic breakers are the most commonly used type. They are powered by hydraulic systems and are capable of delivering high impact energy. Hydraulic breakers are versatile and can be attached to various types of machinery, such as excavators, skid-steer loaders, and backhoes.

Pneumatic breakers, on the other hand, utilize compressed air as their power source. They are lighter and more portable than hydraulic breakers, making them suitable for smaller-scale projects. Pneumatic breakers are commonly used in road construction and maintenance, as well as in demolition tasks.

Advantages of Using Rock Breakers

The use of rock breakers offers numerous advantages, making them indispensable in modern industries. Firstly, rock breakers increase efficiency and productivity. They can break rocks at a much faster rate than manual methods, saving valuable time and labor costs. This allows construction and mining projects to be completed more quickly, leading to increased profitability.

Additionally, rock breakers improve safety on worksites. Manual rock breaking can be hazardous, as it exposes workers to the risk of injury from flying debris or falling rocks. By using rock breakers, workers can maintain a safe distance from the rock-breaking process, reducing the likelihood of accidents.

Furthermore, rock breakers are highly versatile. They can be used for various tasks, such as breaking rocks, concrete, and asphalt. This versatility makes them a valuable tool in different industries, where they can be easily attached to different types of machinery, adapting to the specific needs of the project.

Safety Measures When Using Rock Breakers

While rock breakers are powerful tools, they also pose certain risks if not used correctly. It is essential to follow safety measures to ensure the well-being of operators and those working in the vicinity.

Firstly, proper training is crucial. Operators should receive comprehensive training on how to operate and maintain rock breakers safely. They should also be familiar with the specific safety features and precautions of the particular model they are operating.

Secondly, personal protective equipment (PPE) should be worn at all times. This includes safety goggles, ear protection, hard hats, and steel-toed boots. PPE helps protect against potential hazards, such as flying debris and noise-induced hearing loss.

Another important safety measure is to conduct regular inspections of the rock breaker and its components. Any signs of wear or damage should be addressed promptly to prevent equipment failure during operation.

Maintenance and Care for Rock Breakers

To ensure the longevity and optimal performance of rock breakers, regular maintenance and care are essential. This includes cleaning the breaker tool after each use to remove any debris or buildup. It is also crucial to inspect the hydraulic system and other components for leaks, cracks, or other signs of damage.

Regular lubrication of moving parts is necessary to minimize friction and ensure smooth operation. This should be done according to the manufacturer's guidelines and using the recommended lubricants.

Additionally, rock breakers should be stored in a clean and dry environment when not in use. Proper storage helps prevent corrosion and damage to the equipment.

Innovations in Rock Breaker Technology

As technology advances, so do rock breakers. Manufacturers are constantly innovating to improve the efficiency, performance, and safety of these machines.

One notable innovation is the incorporation of intelligent control systems. These systems use sensors and advanced algorithms to optimize the rock-breaking process. They can adjust the impact energy, frequency, and other parameters based on the rock type and conditions, maximizing productivity while minimizing wear and tear.

There have also been advancements in noise reduction technology, making rock breakers quieter and more environmentally friendly. This is particularly important in urban areas where noise pollution is a concern.

Rock Breaker Manufacturers and Suppliers

There are several reputable manufacturers and suppliers of rock breakers worldwide. Some of the leading companies in this industry include Atlas Copco, Caterpillar, Sandvik, Komatsu, and Montabert. These companies offer a wide range of rock breaker models, catering to different needs and budgets.

When choosing a rock breaker, it is essential to consider factors such as the application, rock type, and the compatibility with the machinery it will be attached to. Consulting with experts and reading customer reviews can help in making an informed decision.

The Future of Rock Breakers in Modern Industries

Rock breakers have undeniably revolutionized modern industries such as construction and mining. Their ability to break rocks quickly, efficiently, and safely has become indispensable. With ongoing technological advancements and the continuous commitment of manufacturers, the future of rock breakers looks promising.

As industries strive for increased productivity and sustainability, rock breakers will play an increasingly significant role. From intelligent control systems to noise reduction technologies, these machines will continue to evolve, meeting the ever-changing demands of modern industries. So, whether it's breaking rocks for construction projects or extracting valuable minerals, rock breakers will remain an essential tool, shaping the future of modern industries.

To know more information about DCS Techno Rock Breakers Visit: https://www.dcstechno.com/indeco-rock-breakers/

0 notes