#Global Hot Food Processing Equipment Market

Text

Hot Food Processing Equipment Market Primarily Driven By Increasing Demand For Bakery Products And Processed Foods

The global hot food processing equipment market size is expected to reach USD 35.72 billion by 2030, registering a CAGR of 6.3% during the forecast period, according to a new report by Grand View Research, Inc. The market is primarily driven by increasing demand for bakery products, processed foods, and rising meat consumption coupled with innovation in food processing.

The increasing proportion of the younger population with higher spending capacity is expected to drive the demand for processed food. Rising preference for healthy meals and increasing adoption of a vegan diet among the younger population is projected to have a positive impact on the processed food market, thereby, benefiting the hot food processing equipment market growth.

Gain deeper insights on the market and receive your free copy with TOC now @: Hot Food Processing Equipment Market Report

The favorable growth of the food & beverage industry, particularly in the emerging economies, coupled with the growing consumption of packaged food & beverages in households is expected to drive the demand for hot food processing equipment. Furthermore, new product launches, expansion of the retail network, and population growth are the factors, expected to complement the market growth.

Various technological advancements are taking place in the food processing industry so as to meet the food demand of the growing population. The continuously rising investments in R&D activities for the incorporation of advanced technologies such as automation and Internet 4.0 in hot food processing equipment are expected to fuel the growth of the market.

Cloud kitchens and food vending machines have emerged amid pandemic-induced closures, hygiene issues, and high retail pricing. People are increasingly looking at embracing contactless means for everyday activities boosting the demand for vending machines. The demand for cloud kitchens and vending machines is expected to create demand for hot food processing equipment.

Companies are undertaking strategic acquisitions to strengthen their product portfolio. In December 2021, The Middle by Corporation acquired Master built Holdings, LLC, and Char-Griller. The acquirement is in line with the company’s strategic acquisitions and is expected to strengthen its household product portfolio in roasting and cooking technologies.

#Hot Food Processing Equipment Market Size & Share#Hot Food Processing Equipment Market Latest Trends#Hot Food Processing Equipment Market Growth Forecast#Hot Food Processing Equipment Industry Insights#COVID-19 Impacts On Hot Food Processing Equipment Market#Hot Food Processing Equipment Market Revenue Value#Global Hot Food Processing Equipment Market

0 notes

Text

A few years ago, I noticed that a number of factories in China had started opening TikTok accounts and posting footage from their assembly lines. The videos offered a rare glimpse into global supply chains, and millions of Western TikTok users marveled at teddy bears being stuffed with polyester fiberfill, machines dipping gardening gloves into hot liquified nitrile rubber, and quality assurance testers seeing whether cheap cigarette lighters worked. (My friend and former colleague Andrew Deck wrote a great story about factory TikTok for Rest of World in 2021.)

Since then, hundreds of other Chinese factories have joined TikTok. Some of them produce industrial equipment that would never be bought by normal people, like dump trucks or bottle labeling machines. And while the older factory accounts were often created by marketing agencies, these newer ones seem to largely be the work of earnest salespeople trying to find new customers. Many of them are relying on AI translation and text-to-speech tools, making the videos unintentionally sound very funny.

One of these manufacturers is a company called Donghua Jinlong, which is headquartered in Hebei province about 200 miles from Beijing. It sells “high quality industrial grade glycine,” a type of nutritional additive that evidently sounds silly and abstract to people who never need to think about how processed food is made. Donghua Jinglong and its glycine have become a relatively big meme on TikTok, Instagram, and X over the last few days, and some of the company’s videos are getting over 100,000 views (even though its official account only has roughly 4,400 followers).

Donghua Jinlong itself, however, doesn’t seem to have any idea what’s going on. People in the comments keep begging it to make official merch, but the company doesn’t understand why anyone would want a sweatshirt or t-shirt with the name of an industrial manufacturer on it. Shitposters have also started referencing the Donghua Jinlong meme in the comments of videos from other Chinese factories.

A company called HengYuan, for example, posted a video of what can only be described as a machine for filling Tide Pods, and one of the top comments is someone asking “Could you pack food grade glycine in this?”

Clearly baffled, HengYuan responded, “No. This is used to pack detergent in PVA Film.”

The Donghua Jinlong meme is a great microcosm of what’s actually happening on TikTok when it comes to content from China. Some people might argue that Chinese manufacturers are choosing to post on the app because its parent company, ByteDance, is also from China. In other words, these factories could be held up as an example of TikTok allowing Chinese influence to grow in the US (albeit a bizarre one).

But Donghua Jinlong also has a Facebook page with even more followers, it’s just that no one is engaging with its posts there. That’s because there are likely very few people searching social media for a new glycine supplier at any given time. TikTok, however, doesn’t rely on users to actively seek out content, it serves videos to them via an algorithm. So now tons of random people are coming across glycine manufacturers and Tide Pod machines by accident, and they’re happily turning the whole thing into a joke.

I personally find these videos to be fascinating, both because It’s cool to learn how things are made, and because they provide the opportunity to watch in real time what happens when random Chinese companies come into contact with American social media users. I don’t think this is the type of Chinese influence lawmakers are imagining when they worry about TikTok, but it’s arguably much more interesting and human.

398 notes

·

View notes

Text

Ice Cream Hardener: Its importance and benefits for Ice Cream manufacturer

There’s so much madness for ice creams. Why do people love ice creams? What is so special about the dessert? People wait in long serpentine lines for their turns during wedding ceremonies. Such is the attraction for the world over famous sweet. Ice Cream hardener manufacturer, and supplier is reinventing their product line to keep abreast with the market demands.

It wouldn’t be an exaggeration to call this delicious ice candy dessert a hot favourites of millions globally. In this short blog, we are going to highlight a few main reasons why plenty of people relish the cold dessert and the importance of the ice cream hardener machine.

No matter what you like, or which flavour you prefer, there's an option for everyone. There are hundreds of flavours and varieties.

Who doesn’t enjoy a mouth-watering scoop of their ice cream? The answer is almost all!

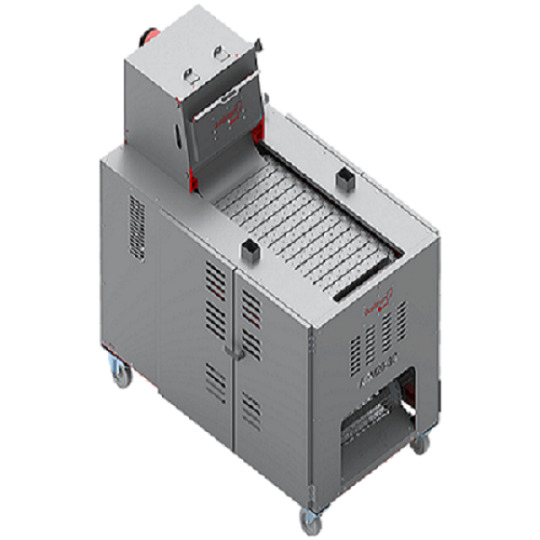

Before we take a deep dive into the subject, it makes sense to introduce the machine in simple language as it will help readers to relate the content better.

Learning about the Ice Cream Hardener

It is a scientifically designed product that helps in hardening ice cream and frozen food. The machine has found usage in various applications, including:

Applications

Ice Candy

Frozen food

Unique features of the machine

A quality-driven machine is identified by numerous salient features. These include:

Energy efficient

Sturdy design

Durable

Easy to use

Whenever you plan to buy this machine, don't forget to examine the above salient features. At the end of the day, production matters.

An inferior quality will hamper the production process of your ice cream plant. As a businessman, you would not like to face this situation. That’s why quality is important. Only buy the product from a prominent ice cream hardener manufacturer, supplier in Ahmedabad.

Types of ice cream hardener

Ice cream hardener manufacturer, supplier is manufacturing a wide range of ice cream hardener. Bharat Refrigerations, a leading manufacturer, supplier of ice cream hardener is manufacturing two types of machines:

Static

Tunnel

Ice Candies change your mood

When your mood is down, you want to do away with sadness, just relax, and order your favourite ice candy. You will experience the change immediately. According to research, ice cream has all the ingredients to lift your sad mood. Whether you face sorrow or are defeated in a recent cricket match, just have ice candy. And relax!

Summary

Ice Candies and frozen food have become hot favourties among foodies globally. Preparation may vary from company to company. Foundation remains the same. Wherever you are, have it. And it's affordable.

If you are planning to set up an ice cream factory or a hangout joint, ensure that the ice cream hardener machine you are planning to buy meets industry standards.

Let’s collaborate for a mutually beneficial partnership

Bharat Refrigerations is a wholly-owned subsidiary of Ice Make Refrigeration Ltd., an acclaimed name in Refrigeration Products and Equipment since 1993. Our excellence-driven total cold chain solutions comprise Cold Room & Storage Room, Transport Refrigeration, Commercial Refrigeration, Refrigerated Container, Ice cream Hardener, etc.

If you are searching for industrial and business chillers for your business, then end your search with Bharat Refrigerations! The company’s expertise in offering chilling plant solutions has been helping numerous businesses to meet their business requirements.

Let’s collaborate for a mutually beneficial partnership.

9 notes

·

View notes

Text

Global Top 4 Companies Accounted for 39% of total Curing Bladder market (QYResearch, 2021)

Curing is the process of applying pressure to the green tire in a mold in order to give it its final shape, and applying heat energy to stimulate the chemical reaction between the rubber compounds and other materials.

In this process the green tire is automatically transferred onto the lower mold bead seat, a rubber bladder is inserted into the green tire, and the mold closes while the bladder inflates. As the mold closes and is locked the bladder pressure increases so as to make the green tire flow into the mold, taking on the tread pattern and sidewall lettering engraved into the mold. The bladder is filled with a recirculating heat transfer medium, such as steam, hot water, or inert gas. At the end of cure, the pressure is bled down, the mold opened, and the tire stripped out of the mold.

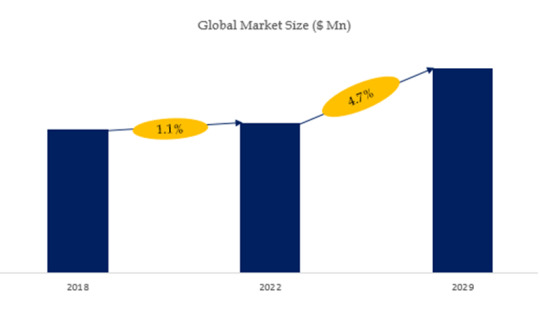

According to the new market research report “Global Curing Bladder Market Report 2023-2029”, published by QYResearch, the global Curing Bladder market size is projected to reach USD 0.72 billion by 2029, at a CAGR of 4.7% during the forecast period.

Figure. Global Curing Bladder Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Curing Bladder Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch..

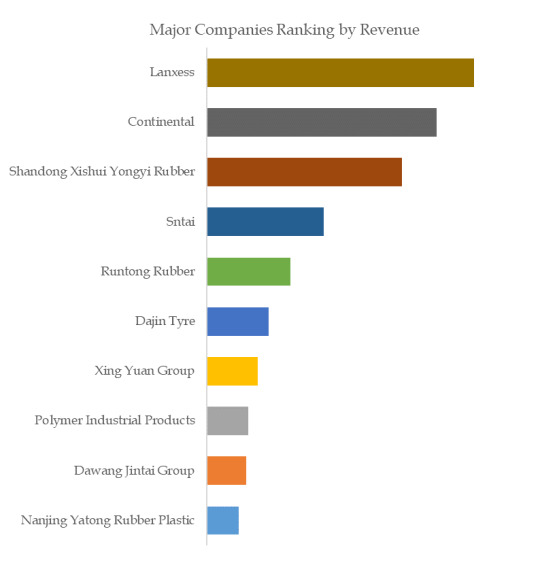

Figure.�� Global Curing Bladder Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Curing Bladder Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

The global key manufacturers of Curing Bladder include Lanxess, Continental, Shandong Xishui Yongyi Rubber, Sntai, Runtong Rubber, etc. In 2022, the global top four players had a share approximately 39.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Molded Pulp Packaging Market Share 2024 Global Industry Analysis, Opportunities & Forecast by 2031

Molded Pulp Packaging Market Share Scope & Overview

The relevance of categories as well as regional markets is discussed in the Molded Pulp Packaging Market Share research study. On the basis of market size and growth rate, an exact overview for all segments and regions has been developed (CAGR). The material contained in this research report has been checked and evaluated by many industry specialists and research analysts from various areas. The primary goal of this study is to assist the reader in better understanding the market in terms of definition, segmentation, market potential, significant trends, and the problems that the industry faces in major regions and nations.

Aside from that, the Molded Pulp Packaging market research report includes a detailed analysis of the predicted statistics, significant advancements, and revenue. It also includes guidelines for performing an in-depth market chain analysis for the worldwide market, including information on raw material suppliers, distributors, consumers, and production equipment suppliers.

Get a Sample Report https://www.snsinsider.com/sample-request/2809

Market Key Players:

Genpak LLC, Brodrene Hartmann A/S, Sabert Corporation, Fabri-Kal, Eco-Products Inc, Huhtamaki Oyj, Hentry Molded Products Inc, Thermoform Engineered Quality LLC, Pro-Pac Packaging Limited, CKF Inc

Market Segmentation

The study report also includes a comprehensive examination of the core industry, including categorization and definition, as well as the structure of the supply and demand chain. Global research includes global marketing statistics, competitive climate surveys, growth rates, and essential development status information. The Molded Pulp Packaging research study discusses market segmentation by product type, application, end-user, and geography. The study investigates the industry's growth objectives, cost-cutting strategies, and manufacturing processes.

By Source

• Wood Pulp

• Non-Wood Pulp

By Molded type

• Thick Wall

• Transfer

• Thermoformed

• Processed

By Product

• Trays

• End Caps

• Bowls & Cups

• Clamshells

• Plates

• Others

By Application

• Food packaging

• Food Service

• Electronics

• Healthcare

• Industrial

• Others

Regional Analysis

The Molded Pulp Packaging market research report includes profiles of leading industry players from various regions. However, when studying the market and estimating its size, the report took into account all market leaders, followers, and new entries, as well as investors. Increasing R&D activity in each region differs, with an emphasis on the regional impact on treatment costs and advanced technology availability. The paper concludes with recommendations for future hot spots in the APAC region.

Competitive Outlook

The purpose of this study is to provide stakeholders in the industry with a complete insight of the Molded Pulp Packaging market. The study includes an analysis of complicated data in simple language, as well as the industry's past and current state, as well as anticipated market size and trends. The report examines all areas of the industry, with a focus on significant companies such as market leaders, followers, and newcomers.

By examining market segments and projecting market size, the research also aids in understanding market dynamics and structure. The research is an investor's guide because it clearly depicts competitive analysis of key players in the Molded Pulp Packaging market by product, price, financial situation, product portfolio, growth strategies, and regional presence.

Buy the Research Report Now https://www.snsinsider.com/checkout/2809

About Us:

SNS Insider is one of the leading Market Size research and consulting agencies that dominates the Market Size research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate Market Size data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

0 notes

Text

Top Groundnut Oil Exporters in Tanzania: A 2024 Overview

Tanzania, positioned as the second largest groundnut producer in East Africa after Sudan, boasts an impressive annual production of approximately 700,000 metric tonnes. Endowed with fertile lands and conducive climatic conditions, Tanzania stands as a prominent player in the global groundnut oil market.

In this blog, we will take a deep dive into the top groundnut oil exporters in Tanzania in 2024, highlighting their contributions to the industry's expansion and the country's export prowess.

Top 3 Groundnut Oil Exporters in Tanzania

Here is a list of the top three groundnut oil exporters in Tanzania:

Agrocrops

In the realm of groundnut oil export, Agrocrops stands as a beacon of reliability and excellence. With a diverse range of premium oils sourced from top origins worldwide, Agrocrops offers groundnut oil sourced from diverse origins. This global reach ensures access to a wide variety of groundnut oils, each with its unique flavour profile and characteristics. Whether you're looking for natural or refined, cold-pressed or hot-pressed variants, Agrocrops has you covered.

The company operates 15 distribution subsidiaries, facilitating efficient and seamless delivery to clients worldwide. With a dedication to quality, reliability, and customer satisfaction, Agrocrops continues to set the standard for quality and performance.

Selina Wamucii

Selina Wamucii operates as an end-to-end platform renowned for its proficiency in sourcing food and agricultural produce, predominantly from smallholder cooperatives and other trusted producers. Selina Wamucii equips farmers with advanced digital tools tailored to boost productivity and aid in decision-making processes.

Mtanga Foods Limited

Mtanga Foods Limited is known for its innovative approaches to groundnut oil production and export. The company's vertically integrated supply chain ensures control over every stage of production, from farming to processing and packaging. By investing in modern technologies and a skilled workforce, Mtanga Foods maintains consistency in product quality while meeting the evolving demands of global consumers.

Opportunities and Challenges for Groundnut Oil Exporters in Tanzania

The teams at Tanzania Agricultural Research Institute (TARI), Accelerated Breeding, and Market Intelligence have started working together to improve Tanzania's groundnut industry's sustainability and competitiveness.

Their mission is to elucidate both the known factors and the unknown variables that influence the groundnut market dynamics, thereby informing strategic decisions and fostering innovation across the value chain.

By engaging relevant stakeholders and leveraging collective expertise, these collaborative efforts aim to drive transformative changes in Tanzania's groundnut sector, ensuring alignment with market segments and target product profiles.

Bottom Line

Tanzania's groundnut oil industry continues to thrive, thanks to the concerted efforts of leading exporters such as Agrocrops, Selina Wamucii, and Mtanga Foods Limited. Their emphasis on quality, innovation, and sustainability not only drives industry growth but also contributes to the nation's economic development and social welfare.

As Tanzania strengthens its position in the global market, Agrocrops, a groundnut exporter, remains steadfast in its pursuit of excellence. With over 55 years of unparalleled experience in the peanut industry, Agrocrops has a vast network of six peanut factories worldwide.

0 notes

Text

Streamlining Chapatti Production With The Chapatti Maker

A groundbreaking appliance that takes the hassle out of making one of the most beloved Indian staples is a roti maker. Let us explore how this innovative device is transforming kitchens and making traditional cooking easier than ever before. A fully automatic roti maker is an electric appliance designed to streamline the process of making rotis, also known as Indian flatbreads. Unlike traditional methods that require manual rolling and cooking, this device automates the entire process, from dough preparation to cooking the rotis to perfection. The roti maker typically consists of a dough container, dough-kneading mechanism, roiling system and cooking plate. Users simply add the required ingredients for the dough into the deigned contained and select their preferred settings. The machine kneads the dough, shapes it into perfect rounds and then cooks the rotis evenly on both sides, all with minimal user intervention. Here are some of the key benefits of using a roti maker: this machine can significantly reduce the time and effort required to make rotis compared to traditional methods. With just a press of a button, the roti maker can knead the dough, flatten it into perfect rounds and cook the rotis evenly on both sides, saving you precious time in the kitchen. One of the biggest challenges in making rotis manually is achieving uniform size and thickness. Roti makers ensure consistent results every time, producing perfectly round and evenly cooked rotis with minimal variation.

Roti makers are easy to use and require minimal skill or experience. Whether you are a novice cook or a busy professional, you can effortlessly make fresh rotis with the push of a few buttons, eliminating the end for manual rolling and cooking. Many roti makers are designed to be energy-efficient, consuming less power those traditional cooking methods such as stovetop or tawa cooking. This not only helps save electricity but also reduces the heat generated in the kitchen, especially during hot weather. While roti makers are primarily designed for making rotis, may models offer additional features and settings that allow you to prepare other flatbreads such as paranthas, puri and naans. This versatility makes the roti maker a versatile kitchen appliance that can cater to a variety of culinary preferences. This machine typically requires less oil or ghee compared to traditional methods, resulting in healthier rotis with lower fat content. Additionally, since roti makers cook rotis evenly on both sides, there is less risk of over cocking or burning, preserving the nutritional values of the rotis. Roti makers are compact and lightweight, making them ideal for kitchens with limited counter space or storage. Their sleek and portable design allows you to easily store them when not in use, freeing up valuable space in your kitchen overall, using roti maker offers convenience, consistency and time-saving benefits, making it a valuable kitchen appliance for households of all sizes. Some of the industries, which are benefited by a roti maker, are hospitality industry, hotels, and catering services often serve chapattis alongside various dishes, catering to diverse culinary preferences. With the ability of control factors such as size, thickness and cooking time, a chapatti maker help maintain high quality standards and meet the demands of a busy kitchen. Export market, chapattis are increasingly gaining popularity in international markets, driven by the growing interest in ethnic cuisines and convenience foods.

Chapatti making machines equipped with advanced technology and customizable features cater to the specific requirements of global consumers. By investing in chapattis making machines, manufactures can capitalize on the export potential of chapattis and expand their market reach. Retail and distribution, chapatti-making machines are utilized by food manufactures and distributors to produce packaged chapattis for retail sale. These machines enable consistent production of chapattis with uniform size and texture, meeting the standards of discerning consumers. Retailers benefit from the convenience of sourcing pre-made chapattis, which can be sold fresh or frozen to meet consumer demand. Institutional caterings, institutions like school, hospitals and corporate cafeterias serve chapatti as part of their daily meal offerings. Chapatti maker enable these facilities to produce large volume of chapattis consistently to meet the needs of their patrons. By automating the chapattis maker process, institutions can minimize labour costs and ensure hygienic food preparation practices. Chapatti making machines, fully automatic are indispensable tools for various industries involved in chapatti production, from hospitality and food processing to institutional catering, retail and export. By automating and optimizing the chapatti making process, these machines offer efficiency, consistency and scalability, meeting the diverse needs of consumers worldwide. As the demand for chapattis continues to grow, chapatti making machines will plays a crucial role in shaping the future of chapatti production across industries. Streamline your chapatti production with the state of the art chapatti making machines and elevate your business to new heights of success. Bon appétit!

0 notes

Text

The Authority of Steel Plate Manufacturing - Pipingprojects.us

Piping Projects follow strict quality control procedures and standards that guarantee good surface and near dimensional tolerances. We manufacture Steel plates using top-quality materials. Steel Plate Manufacturers is a metal plate which uses steel, that can be cut and fabricated into a more complex product. Steel plates offer a variety of thicknesses and can be produced to whatever length or width you desire. We are also a leading Coated Pipes Manufacturer in USA

Piping Projects is one of the leading Steel Plate Manufacturers in USA. We are a market-leading provider of carbon steel, alloy steel, and stainless steel plate solutions on a global scale, having obtained ASME Quality and ISO 9001:2015 Certifications. In addition to producing the best-quality steel plates, we are an official Jindal and ISMT dealer for providing carbon and alloy steel plates.

The Importance of Steel Plate Manufacturing

For a construction to be reliable and durable overall, Steel Plates manufacturing is essential. These plates are highly durable and robust, making them essential in manufacturing, shipbuilding, and construction. Also, Check Our Steel Plate Weight Chart

Steel Plates in Construction:

Steel plates provide the required strength to support buildings, bridges, and other infrastructure, serving as the basis for the construction sector.

The stability and durability of buildings against external factors like wind, earthquakes, or large loads are guaranteed by the high tensile strength of these plates.

Steel plates also provide better resistance to corrosion, which keeps structures intact and guarantees longevity.

Steel Plates in Automotive:

Steel plates are used in the automobile industry to produce car bodywork, construction, and other essential parts.

Due to its strength-to-weight ratio, steel plates reduce weight and provide a strong foundation, which improves vehicle safety.

These plates also provide impact resistance, which safeguards individuals in the event of an accident.

The Manufacturing Process

The manufacturing process of steel plates involves several stages, each contributing to the final product's quality and reliability.

Raw Material Selection:

The initial material is usually high-quality steel, usually in the shape of slabs or coils. The plate's features primarily depend on this steel's composition and qualities.

Steel comes in various grades, each designed for a particular use, such as wear resistance, corrosion resistance, or structural strength.

Material Composition:

Generally, materials with specific ratios of iron, carbon, and other elements like manganese, silicon, and nickel make high-quality steel plates.

The alloy's structure impacts properties like hardness, strength, and corrosion resistance.

Manufacturing Process:

Quality steel plates are produced using advanced manufacturing processes such as hot rolling, cold rolling, or forging.

Stringent quality control measures are implemented throughout production to ensure consistent thickness, flatness, and surface finish.

Surface Finish and Cleanliness:

The texture is defect-free surfaces devoid of rust, scale, or surface contaminants that characterize excellent steel plates.

To confirm its quality and performance attributes, steel plates go through extensive testing.

Cities We Supply Steel Plate

Steel Plate Manufacturer in Texas

Steel Plate Manufacturer in California

Steel Plate Manufacturer in Florida

Steel Plate Manufacturer in New York

Steel Plate Manufacturer in Los Angeles

Common Uses For Steel Plate

Architecture includes designing and constructing building exteriors, such as facades, roofs, railings, doors, and windows.

Foodservice includes tables, countertops, sinks, appliances, and food preparation equipment.

Industrial: Chemical processing equipment, pharmaceutical equipment, marine equipment, oil and gas equipment.

Other: Manufacturing Automation, Energy Management, and Application.

To Know More Visit,

Website: pipingprojects.us

Source: Steel Plate Manufacturers USA

#Steel Plate Manufacturers in USA#Steel Plate Manufacturers USA#Steel Plate Manufacturers#Steel Plate#Steel Plates

0 notes

Text

Industrial Dryer Market Expected To Witness Significant Growth Due To Rapid Industrialization

Industrial dryers are machines or devices that are utilized for moisture removal from materials and various products by using hot air or steam. They are commonly used across diverse industries such as food, pharmaceutical, chemical, construction, paper, and others. Industrial dryers help enhance product quality, improve production efficiency, reduce wastage, and decrease processing time. Some key uses of industrial dryers include drying fruits and vegetables in the food industry, drying paper and wood products, and removing moisture from synthetic materials in the chemical sector. The global industrial dryer market is estimated to be valued at US$ 1.37 Bn in 2023 and is expected to exhibit a CAGR of 6.1% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

Rapid industrialization across emerging economies is one of the major drivers propelling the growth of the industrial dryer market. Increased manufacturing and production activities are leading to higher demand for industrial dryers from diverse end-use industries. Furthermore, industrial dryers help improve productivity by reducing drying time significantly. This assists industries in enhancing their output without compromising on quality. Rising need for moisture removal from raw materials and finished goods is also fueling the sales of industrial dryers globally.

Another key factor augmenting the market growth is favorable government policies and initiatives to promote domestic manufacturing. Various countries are offering subsidies and tax incentives to boost manufacturing. This, in turn, is driving installations of various production machinery including industrial dryers. However, high initial capital investments for industrial dryers may hinder market expansion, especially in price-sensitive developing nations. Ongoing innovations focusing on cost reductions could help overcome this challenge in the coming years.

SWOT Analysis

Strength: Industrial dryers are highly efficient in removing moisture from diverse materials. They offer advantages like high production rates, low energy usage, and minimal product damage. The latest dryer technologies allow for precise moisture content control and uniform drying.

Weakness: Industrial dryers entail sizable capital investments and have high installation and maintenance costs. Frequent equipment failures and breakdowns can disrupt production schedules. Stringent safety and emissions regulations increase compliance burdens on manufacturers.

Opportunity: Growing demand for processed food and pharmaceutical products worldwide is driving the need for industrial drying equipment. New applications in manufacturing industries like chemicals, minerals, and electronics present new revenue avenues. Adoption of energy-efficient dryer models can help lower operating expenses.

Threats: Volatility in raw material prices poses input cost risks. Changing environmental policies around the globe add regulatory uncertainties. Competition from local players offering low-cost drying solutions can impact profit margins. Supply chain disruptions due to geopolitical tensions affect availability of critical components.

Key Takeaways

The global industrial dryer market size is expected to witness high growth.

Regional analysis: The Asia Pacific region urrently dominates the market and is projected to grow at the fastest pace during the forecast period. This can be attributed to rapid industrialization and expansion of manufacturing industries in China and India.

Key players related content comprises Key players operating in the Industrial Dryer Market are PepsiCo, Inc., Nestle SA, The Coca-Cola Company, Groupe Danone, Abbott Laboratories, Bernard Food Industries, Inc, Zydus Wellness Ltd., Dr. Pepper Snapple Group Inc., McNeil Nutritionals LLC, Cargill, Incorporated, and Ajinomoto Co., Inc. These companies have extensive experience in manufacturing industrial drying equipment and possess strong distribution networks globally.

Get more insights on this topic: https://www.newsstatix.com/industrial-dryer-market-industry-insights-trends-industrial-dryer-market/

Explore more information on this topic, Please visit: https://allmeaninginhindi.com/fiber-reinforced-concrete-the-construction-material-of-future/

#Industrial Dryer#Industrial Dryer Market#Industrial Dryer Market size#Industrial Dryer Market share#Industrial Dryer Market demand#Industrial Dryer Market analysis

0 notes

Text

Enhancing Agricultural Sustainability, The Role of Irrigation Water Tanks

Enhancing Agricultural Sustainability, The Role of Irrigation Water Tanks

In the realm of agriculture, efficient water management is paramount for sustainable crop production. As global demand for food continues to rise, the need for effective irrigation systems becomes increasingly crucial. Irrigation water tanks have emerged as indispensable components in modern agricultural practices, offering a reliable and sustainable solution for storing and distributing water to crops. This article explores the significance of irrigation water tanks and their role in promoting agricultural sustainability. Water scarcity poses a significant challenge to agriculture, with unpredictable rainfall patterns and changing climatic conditions affecting crop yields. Irrigation water tanks provide a strategic response to these challenges by allowing farmers to collect and store water during periods of abundance, ensuring a steady and controlled supply during dry spells.

As a leading storage tank manufacturer in China. Center Enamel can provide GFS Tanks, SS Tanks, Epoxy Coated Bolted Steel Tanks, Galvanized Tank, Aluminum Dome Roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

GFS tanks are assembled on-site from specialized enamel steel plates, hoops, self-locking bolts, sealing glue, and other components. The steel plate raw material utilizes titanium alloy-specialized enamel hot-rolled plates developed in collaboration with leading domestic iron and steel enterprises, and it is shaped using fast and low-consumption on-site assembly technology. After high-temperature enameling at 820°-930°, the enamel glaze fuses with the surface of the steel plate, forming a solid and chemically inert inorganic coating with outstanding corrosion resistance. The enamel process is currently an advanced coating and corrosion protection technology in the steel tank market.

GFS tank parameters

Category

Specification

Coating Color

Black blue, Grey olive, Forest green, Cobalt blue, Desert tan etc.

Coating thickness

0.25-0.45mm

Acid and alkalinity proof

Standard PH: 3~11, Special PH:1~14

Adhesion

3450N/cm²

Hardness

6.0 (Mohs)

Service life

≥30 Years

Holiday test

>1500V

Permeability

Gas liquid impermeable

Easy to clean

Smooth, glossy, inert, anti-adhesion

Corrosion resistance

Excellent, suitable for harsh environment

GFS Tank Advantages

Superior Corrosion Protection Technology

Center Enamel independently developed a double-sided double-layer enameling technology, filling the gap in the field of hot-rolled double-sided enameling in the Chinese enamel industry. This technology is currently the most effective coating and corrosion protection technology in the steel tank market, offering superior corrosion resistance advantages.

Wide Range of Applications

Center Enamel independently developed over 200 enamel formulas and patents, allowing for customized enamel formula development based on customer requirements for the storage medium of enamel-assembled tanks. This customization makes the tanks widely applicable in different fields.

Site-Specific Design

Tailored designs for enamel-assembled tanks take into account factors such as wind resistance and earthquake resistance, ensuring that the tanks are not susceptible to damage from natural factors like earthquakes or typhoons, depending on the project's construction location.

Environmentally Conscious Design

Enamel-assembled tanks can be flexibly designed in terms of tank size and color customization based on customer needs and environmental requirements, saving space and meeting the requirements of modern construction.

High Standardization Level

Enamel-assembled tank steel plates and major components undergo standardized production in the factory using automated equipment. After packaging, they are transported to the project site for standardized assembly. From production to installation, strict adherence to the design plan ensures the tanks' standardized manufacturing.

Simple and Fast Installation

Enamel-assembled tanks are assembled on-site, making installation simple, fast, less affected by weather conditions, and with a short and controllable installation period. After completion and operation, the tanks can be dismantled and reinstalled, facilitating easy relocation and expansion.

Center Enamel is a comprehensive high-tech enterprise primarily engaged in the research, development, manufacturing, and sales of enamel-assembled tanks and diversified environmental protection equipment, as well as undertaking environmental protection EPC projects and anaerobic process segments. Throughout its project practices, the company continuously increases research and development efforts, gathers scientific and technical forces, and establishes a service system covering everything from research and development to after-sales, providing tailored solutions to customers quickly and with high quality.

The measurement standards for projects not only need to meet technical and quality requirements but also must shift towards overall standards of sustainability, quality improvement, energy efficiency, and carbon reduction. In response to market and policy changes, Center Enamel actively leverages its rich experience and research and development strength to empower innovative research and development technologies for enamel-assembled tanks, contributing to the smart manufacturing of diversified environmental protection equipment and environmental protection EPC projects. This aims to meet the diverse needs and project requirements of customers.

Currently, Center Enamel's business covers areas such as kitchen waste, leachate, municipal sewage, biogas projects, aquaculture wastewater, industrial wastewater, drinking water, and firefighting water. In the future, the company's research and development achievements will be further promoted and applied in more projects, striving to achieve a win-win situation for economic, environmental, and social benefits, driving the high-quality development of the environmental protection industry.

0 notes

Text

"Asia-Pacific's Nuclear Power Boom: Catalyst for Cooling Tower Rental Market Expansion"

The cooling tower rental market is poised for rapid growth in the coming years, driven by the increasing demand for efficient heat rejection mechanisms in various industries. A cooling tower plays a crucial role in dissipating waste heat into the atmosphere, making it an essential piece of equipment for enterprises seeking to manage excess heat with minimal water usage. Businesses often face challenges with permanent cooling towers, particularly during high-demand periods like hot summer months, leading to potential productivity losses. To address this, many industries opt for cooling tower leasing systems to bridge the gap until permanent solutions can be repaired or replaced.

𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐁𝐫𝐨𝐜𝐡𝐮𝐫𝐞 : https://www.alliedmarketresearch.com/request-toc-and-sample/16146

Cooling tower rentals offer fully pre-assembled systems ready for immediate use in diverse settings. Industries such as food processing, petroleum refining, natural gas plants, and petrochemical plants widely utilize these cooling towers. The classification of cooling towers into natural draught or mechanical draught depends on the air circulation mechanism employed. The advantages of cooling tower rentals include supplementing cooling water flows, supporting planned system turnarounds, increasing capacity, reducing cold water temperatures, and maintaining peak output.

Market Scope and Structure Analysis

Market Size Available for Years: 2020–2030

Base Year Considered: 2020

Forecast Period: 2021–2030

Forecast Unit: Value (USD)

Segments Covered: Type, Capacity, Design, End User, Region

COVID-19 Impact Analysis: The COVID-19 pandemic disrupted global industries, including power generation and refining, negatively affecting the cooling tower rental market. Supply chain interruptions, raw material scarcity, and restrictions on movement led to a decline in production. Power-generating industries and refineries faced shutdowns, impacting the cooling tower rental market. However, with the easing of lockdowns and the resumption of production activities, the market is expected to rebound.

𝐄𝐧𝐪𝐮𝐢𝐫𝐲 𝐁𝐞𝐟𝐨𝐫𝐞 𝐁𝐮𝐲𝐢𝐧𝐠 : https://www.alliedmarketresearch.com/purchase-enquiry/16146

Top Impacting Factors:

The rise in construction activities worldwide, especially in developing and developed countries, is driving the demand for cooling tower leasing.

Expansion of transportation infrastructure, such as ports and airports, contributes to increased demand for HVAC systems, supporting market growth.

The use of advanced technology, which optimizes energy usage, is a key factor in boosting production and, consequently, the cooling tower rental market.

However, challenges such as the preference for renewable energy sources and high installation costs for short-term use may limit market growth.

Fluctuations in oil prices, affecting industries like oil and gas, electricity generation, and manufacturing, pose challenges to the global cooling tower rental market.

Opportunities for market expansion are anticipated through Asia-Pacific's growing nuclear power industry, high energy demand, and increased environmental regulations.

Market Trends:

Integration of "Smart Cooling Tower" technology in construction projects, providing automatic detection and operational information.

Adoption of advanced cooling tower designs, such as the fiberglass-reinforced plastic cooling tower with automated louvre systems, contributing to continuous operation at low temperatures.

Focus on the Asia-Pacific region's nuclear power sector as a driver for cooling tower rental market growth.

Investment in very low-temperature (VLT) cooling equipment, emphasizing energy efficiency and reduced environmental impact.

𝐆𝐞𝐭 𝐚 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐞𝐝 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭 : https://www.alliedmarketresearch.com/request-for-customization/16146

Key Market Players: United Rentals, Inc., Midwest Cooling Tower Services, LLC, Aggreko, GOHL-KTK GmbH, Jacir, Engie Refrigeration, Finning International Inc, SPX Corporation, Carrier Rental Systems, Johnson Controls, Inc.

Key Benefits of Report:

Analytical depiction of the cooling tower rental market trends, future estimations, and investment opportunities.

In-depth analysis of key drivers, restraints, and opportunities, along with market share insights.

Quantitative analysis of market growth from 2020 to 2030.

Porter’s five forces analysis illustrating buyer and supplier potency.

Detailed cooling tower rental market analysis based on competitive intensity and future competition dynamics.

Cooling Tower Rental Market Report Highlights:

By Type: Wet, Dry, Hybrid

By Capacity: 500-1000 Tons, up to 500 Tons, 1000-1500 Tons, 1500-3000 Tons, above 3000 Tons

By Design: Mechanical Draft, Natural Draft

By End User: Industrial, Commercial

By Region: North America, Europe, Asia-Pacific, LAMEA

𝐊𝐞𝐲 𝐌𝐚𝐫𝐤𝐞𝐭 𝐏𝐥𝐚𝐲𝐞𝐫𝐬: United Rentals, Inc., Midwest Cooling Tower Services, LLC, Aggreko, GOHL-KTK GmbH, Jacir, Engie Refrigeration, Finning International Inc, SPX Corporation, Carrier Rental Systems, Johnson Controls, Inc

0 notes

Text

Commercial Boiler Market Trends: A Detailed Examination of Market Developments and Industry Shifts

The commercial boiler market is estimated to be valued at US$ 2.02 Bn in 2023 and is expected to exhibit a CAGR of 4.3% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Commercial boilers are essential equipment used in facilities to provide space heating, domestic hot water, and process steam. They are used widely in various commercial buildings like hospitals, hotels, offices, educational institutions, retail stores, food industries and more. Commercial boilers offer benefits like higher efficiency, lower operating cost, easier installation and maintenance. They prove vital for comfort heating and various industrial processes.

Market key trends:

One of the key trends witnessed in the commercial boiler market is increased efficiency requirements. With growing need to conserve energy and reduce carbon footprint, regulators across regions have implemented stricter norms regarding boiler efficiency. This has prompted manufacturers to focus on developing modern condensing and non-condensing boiler models with thermal efficiencies over 80-85%. Advanced technologies like modulating controls and condensing heat exchangers are helping commercial boilers achieve higher efficiencies. Their ability to conserve fuel and lower energy bills is a major driver for adoption.

Porter’s Analysis

Threat of new entrants: The threat of new entrants is low due to high capital requirements and established brands. Bargaining power of buyers: Buyers have high bargaining power due to the availability of several product options from different manufacturers. Bargaining power of suppliers: Suppliers have moderate bargaining power due to the availability of substitute materials. Threat of new substitutes: The threat of new substitutes is moderate due to the emerging alternate heating technologies. Competitive rivalry: High due to presence of major players.

SWOT Analysis

Strength: Wide product portfolio and technical expertise. Weakness: High operational costs and vulnerability to economic cycles. Opportunity: Growing demand from commercial sectors and replacement of aging boilers. Threats: Stringent regulations and rising raw material prices.

Key Takeaways

The global commercial boiler market is expected to witness high growth, exhibiting CAGR of 4.3% over the forecast period, due to increasing energy demands from the industrial and commercial sectors. Regionally, Asia Pacific dominate the market and is expected to maintain its dominance during the forecast period, growing at the fastest CAGR of around 5%, attributed to rapid industrialization and urbanization.

Key players operating in the commercial boiler market incorporate A.O. Smith Corporation, Bosch Thermotechnology, Cochran Limited, Cleaver-Brooks, Fulton Boiler Company, Parker Boiler, Slant/Fin Corporation, Superior Boiler Works, Inc., Vaillant Group, and Weil-McLain.

The global commercial boiler market size for 2023 is US$ 2.02 Bn. Regional analysis, Asia Pacific region is the fastest growing market for commercial boilers, mainly due to rapid industrialization and growth of the manufacturing sector in economies like China and India.

0 notes

Text

Steam Condensate Piping Forecast to 2031 with Key Companies Profile, Supply, Demand and SWOT Analysis

Steam Condensate Piping Market Research, 2031

The global steam condensate piping market size was valued at $4.3 billion in 2020, and is projected to reach $6.3 billion by 2031, growing at a CAGR of 3.3% from 2022 to 2031. Steam condensate piping is an important component of steam infrastructure systems that are installed in various industries such as paper & pulp, food processing, oil & gas refining and other manufacturing industries.

Steam is extensively used in various industrial applications such as sterilization, chemical cracking, and other heating processes. Hence, to transfer the steam from boiler assembly to desired process location, a network of pipes is extensively used. However, during the passage of steam through pipelines, some of it cools down and condensates. This condensate is often responsible for corroding inner walls of steam pipes. This creates a need for condensate piping for draining the condensate. Steam condensate piping system collect condensate from steam pipes and delivers it either for reuse or discards it into sever. These factors positively influence the steam condensate piping market.

Accumulated condensate can lead to premature degradation of main steam pipes and form an obstacle for the flow of steam. This can be prevented by draining condensate by using steam condensate piping. Steam condensate piping system makes the process more energy efficient enabling the reuse of collected hot steam condensate in other processes, such as for pre heating feed water and space heating. Such highly desirable benefits of steam condensate piping system are is expected to contribute significantly toward growth of the steam condensate piping market.

Novel coronavirus had rapidly spread across various countries and regions, causing an enormous impact on lives of people and the overall community. It began as a human health condition and later became a significant threat to global trade, economy, and finance. The COVID-19 pandemic halted production of many components of steam condensate piping, owing to the lockdown. The economic slowdown initially resulted in reduced spending on various industrial machineries including steam related equipment by industrial and commercial users. However, owing to introduction of various vaccines, severity of the COVID-19 pandemic has significantly reduced. As of mid-2022, the number of COVID-19 cases have reached an insignificant number, and it is expected to completely subside in the coming years. This has led to full-fledged reopening of steam condensate piping manufacturing companies at their full-scale capacities. Furthermore, it has been two years since the outbreak of this pandemic and many companies have shown significant signs of recovery.

The steam condensate piping market is segmented into Piping Material and Application. By piping material type, the market is categorized into stainless steel, carbon steel, and others. By application, it is categorized into commercial and industrial. Region wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. Asia-Pacific held the largest steam condensate piping market share in 2020, accounting for the highest share, and is anticipated to maintain this trend throughout the forecast period. This is attributed to rapid growth of various manufacturing and processing industries.

Full Report With TOC:-https://www.alliedmarketresearch.com/steam-condensate-piping-market-A16415

0 notes

Text

Global Top 3 Companies Accounted for 81% of total Gas Turbine market (QYResearch, 2021)

A gas turbine is a type of internal combustion engine. Essentially, the engine can be viewed as an energy conversion device that converts energy stored in the fuel to useful mechanical energy in the form of rotational power. The term “gas” refers to the ambient air that is taken into the engine and used as the working medium in the energy conversion process.

This air is first drawn into the engine where it is compressed, mixed with fuel and ignited. The resulting hot gas expands at a high velocity through a series of airfoil-shaped blades transferring energy created from combustion to turn an output shaft. The residual thermal energy in the hot exhaust gas can be harnessed for a variety of industrial processes.

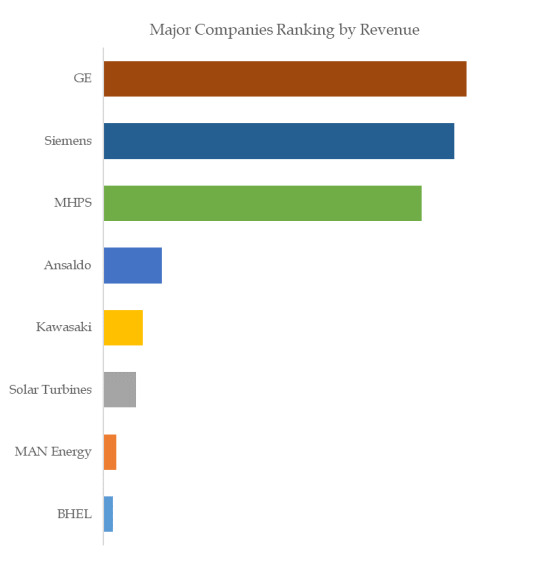

According to the new market research report “Global Gas Turbine Market Report 2023-2029”, published by QYResearch, the global Gas Turbine market size is projected to reach USD 36.58 billion by 2029, at a CAGR of 7.3% during the forecast period.

Figure. Global Gas Turbine Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Gas Turbine Market Report 2023-2029.

Figure. Global Gas Turbine Top 8 Players Ranking and Market Share(Based on data of 2020, Continually updated)

Based on or includes research from QYResearch: 2020 data information of Global Gas Turbine Market Report 2023-2029.

The global key manufacturers of Gas Turbine include GE, Siemens, etc. In 2020, the global top three players had a share approximately 81.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Environment Equipments/ Ambient Air Quality Monitoring Equipments

These tough industrial grade equipment's gather and analyse, process, and measurements quickly and effectively whether employed in laboratories or for on-site industrial use.

At KDM Business, we understand that dedication to quality is essential to achieving client satisfaction. Our company's objective is to give customers products with the highest performance and features, backed by first-rate services. We make an effort to uphold the global quality standards.

In Delhi, Kolkata, Patna, Ranchi, Jharkhand, Bihar, and West Bengal, KDM Global is a well-known and well-respected manufacturer, supplier, and exporter of environmental testing lab equipment. Its success in the electrical and electronics markets has been based on a solid foundation of 17 years in the business.

Our infrastructure is effectively divided into different sections to facilitate the production of scientific equipment. Our extensive selection of electrical and electronic laboratory equipment satisfies the most demanding specifications and is vital to research facilities, governmental agencies, colleges, universities, schools, and a variety of other businesses.

KDM is a well-known manufacturer of laboratory testing equipment with a passion for meeting all of your unique quality testing requirements. We offer a wide selection of cost-effective premium measurement tools, spare parts, and cutting-edge testing equipment.

Our commitment to accuracy, creativity, and technology is attested to by our customers. Also, we strictly stick to the highest quality assurance procedures, giving you dependable fantastic long-term service support. KDM Global began operations in a modest manner in 2013 and over time grew into a potent group of designers, producers, and suppliers of "Precision Testing Instruments," primarily for evaluating the characteristics of pulp, paper, and paperboard for the paper, conversion, and allied industries. Its capabilities increased so dramatically that it is now a highly regarded Its capabilities increased so dramatically that it is now a highly regarded corporation in the domestic and international markets for these instruments.

KDM Global is a top producer of high-quality lab testing equipment. With more than 40 years of expertise, we have created a variety of products to satisfy the requirements of many sectors. To help customers get the most out of their investment, in addition to manufacturing testing equipment, our technical professionals will also offer training and after-sales support services.Our products are built to offer precise and dependable results, and they are supported by our dedication to quality and customer service. For a variety of industries, including electronics, automotive, food & beverage, pharmaceutical, and more, we provide a wide selection of goods.

Presto provides the ideal solution for your needs, regardless of whether you have a simple need for product testing or are dealing with significant product rejection rates. To fit your unique needs, we can also modify our goods. Presto is the product that will serve 11,436 and many more clients around the world because it won a national award for quality products from the Government of India. We offer a variety of testing equipment, including the Universal Tensile Testing Machine, Color Matching Cabinet, Index Tester, Round Cutter, Ph Testers, Horizontal Flammability Tester, Oxygen Index Apparatus, Air Permeability Tester, Launder O Meter, Water Repellency Tester, Martindale Abrasion Tester, Dry ARC Resistance Tester, Light Fastness Tester, Hot Air Oven, Toxicity Chamber, Piling Machine, Toys Testers

For more details contact us:

Email : [email protected]

Website:https://kdmglobal.business.site , https://sites.google.com/view/kdmglobal/home

Contact :8218470498

0 notes

Text

How To Choose The Best Pharmaceutical Instruments Supplier

Choosing the right pharmaceutical instrument supplier is crucial to ensuring that you have access to high-quality equipment and supplies. Here are some factors to consider when selecting a pharmaceutical instruments supplier:

Quality

Quality should be a top priority when choosing a pharmaceutical instrument supplier. Look for suppliers that provide equipment and supplies from reputable manufacturers and have strict quality control procedures in place.

Product Range

Consider the supplier's product range and whether they offer a wide variety of instruments and supplies that meet your needs. The supplier should offer a comprehensive range of products that are relevant to your area of research, testing, manufacturing, and processing.

Cost

Cost is always a consideration when purchasing equipment and supplies. Look for a supplier that offers competitive pricing without compromising on quality.

Reputation

Look for a supplier that has a good reputation within the industry. Consider reading reviews from other customers or seeking recommendations from colleagues.

Compliance

Ensure that the supplier meets regulatory compliance requirements and adheres to industry standards.

VJ Instruments is a company that supplies scientific instruments with a focus on the field of Pharmacy and Preclinical research. VJ Instruments offers pharmaceutical instruments with the highest quality and cost-effectiveness that comply with modern and global industry standards. VJ Instruments has a truly wide product range that includes R&D equipment, transdermal patch machines, behavior instruments, clinical instruments, mazes to study animal behavior, and more.

VJ Instruments supplies a range of world-class products that comply with quality standards and “ease in use”. VJ Instruments is operated by a team of professionals who have great experience in the pharma industry and understand its specific requirements. The company continuously carries out process testing, software development, and R&D, which helps them understand prevailing market trends, technological advancements, and customer requirements.

For example, here are a few pharmaceutical instruments that VJ Instruments supplies.

Plethysmometer

A plethysmometer analyses inflammation and edema by measuring the volume changes in a rat's paw. It measures micro-volume changes caused by the displacement of water when a rat paw is inserted. The Digital Water Plethysmometer is a very useful tool that is used to measure small volume changes. It is used to follow the evolution of the inflammatory response experimentally induced in rodents. A plethysmometer is also used to screen potential anti-inflammatory or anti-edema properties of pharmacological substances.

VJ Instruments' Plethysmometer instrument consists of a U-shaped glass cell filled with water into which a rat paw is dipped. On the other side of the unit, a camera is fixed. With the help of VJ Instruments Plethysmometer video analysis software, edema is accurately measured.

fbd fluid bed dryer

An fbd fluid bed dryer is a pharmaceutical instrument used to reduce the moisture content of food, pharmaceutical products, chemical powders, and granules.

The functioning of the fbd fluid bed dryer is straightforward. Ambient air is drawn in through a filter, while a blower moves the air across the heating elements. The blower forces the heated air through the perforated plate and into the detachable drying container. The solid particles are blown upward and dispersed and thus kept separate from one another. This helps to avoid caking and sticking. The hot stream of air from the fluid bed dryer extracts moisture from the particles and then exits through the filter bag in the cover. The final product is moisture and liquid-free.

VJ Instruments' fbd fluid bed dryer is used in quality control, sample preparation, and R&D departments. It permits the gentle drying of pharmaceutical bulk materials without localized overheating. Suitable materials can be coarse, fine, crystalline, fibrous, or leafy. The fbd fluid bed dryer ensures that the end product is dried, loosened up, and thoroughly mixed in short drying times. With the interval operation, the fluidized bed is mixed even better. Temperature, drying time, and air volume can be set through PLC & HMI and adjusted continuously.

Ball mill machine

A ball mill machine is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. A ball mill machine is useful for grinding crystalline material and mixing dry materials and wet materials. It works on the principle of impact and attrition. The size of the products is reduced by impact as the balls drop from near the top of the shell. The small and average capacity of a ball mill machine is used for the final grinding of drugs or grinding suspensions. The maximum capacity ball mills are used for milling ores before manufacturing pharmaceutical chemicals.

The VJ Instruments' ball mill machine has an emergency stop switch, an auto stop feature when process time completes, and several more useful features that are showcased on the website vjinstruments.com The VJ Instruments' ball mill machine boasts several advantages over other systems. The cost of installation and grinding medium is low, the capacity and fineness can be adjusted by adjusting the diameter of the ball, it is suitable for both batch and continuous operation, and it is applicable for materials of all degrees of hardness.

VJ Instruments supplies scientific instruments with a focus on the field of Pharmacy and Preclinical research. The products supplied by VJ Instruments comply with world-class standards and are easy to use. VJ Instruments offers R&D equipment, transdermal patch machines, behavior instruments, clinical instruments, and mazes to study animal behavior. Visit the website vjinstruments.com for more information and specifications about the fluid bed dryer, ball mill machine, plethysmometer, and more.

0 notes