#Global Drilling Machine Industry Report

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

Electric Motor Market - Forecast(2024 - 2030)

Electric Motor Market Overview

Electric Motor Market Size is forecast to reach $169 billion by 2030, at a CAGR of 5.6% during 2024-2030. The increase in global electricity consumption and the use of electrical equipment and machines in different industries and the renewables sector are major factors driving the growth in the electric motor market during the forecast period. An increase in awareness of green vehicles among customers has been a key factor leading the market. Besides this, a rising number of government incentives to encourage sales of green vehicles for safeguarding the environment from carbon emissions is analysed to drive the market. The growing interest in sustainable transportation has driven the demand for electric vehicles. Electric motors play a crucial role in powering EVs, and advancements in motor technology contribute to increased efficiency and range. The industrial sector is witnessing the integration of electric motors with the Internet of Things (IoT) and Industry 4.0 technologies. This integration allows for real-time monitoring, predictive maintenance, and improved efficiency in industrial processes.

Smart motor technologies, incorporating features like connectivity, sensors, and advanced control systems, are becoming more prevalent. These innovations contribute to better performance, remote monitoring, and enhanced automation in various applications. Developments in motor control systems, including advanced algorithms and power electronics, contribute to improved motor performance, reduced energy losses, and enhanced control precision. There is an increasing emphasis on developing more energy-efficient electric motors to meet sustainability goals and reduce energy consumption. Regulations and standards promoting energy efficiency also influence the design and manufacturing of electric motors. Additionally, Electric motors have been observing several advancements in technology over the past few years, owing to which its demand is set to gain higher traction during the forecast period 2024-2030.

Report Coverage

The report: “Electric Motor Market Report– Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Electric Motor market

By Product Type: AC Motor (Induction Motor, Synchronous Motor, Servo Motor, Stepper Motor), DC Motor (Brushed DC Motor, Brushless DC Motor, Servo Motor, Series Motor, Stepper motor, Compound Motor).

By Product Category: Permanent Magnet, Non-Permanent Magnet.

By Phase: Single Phase, Three Phase.

By Power Rating: Below 0.5W, 0.5W-1W, 1W to 100W, 100W to 1KW, 1KW to 10KW, 10KW and Above.

By Efficiency: IE1, IE2, IE3, IE4.

By Application: Commercial (Automated Doors, Elevators & Escalators, Blowers, Electric Sweepers, Hand Dryers, Data Center & UPS, Pumps, Power Tools, Water Coolers, Camera PTZ Control, Drones, Others), Consumer Products (Pumps, Hair Dryers, Lawn Mowers, Boilers, Dishwashers, Vacuum Cleaners, washing machine, Blenders & Mixers, Fans & Chimneys, Desktop & Laptops, Smartphones, Refrigerators, Others), Automotive (Body Control motors, EPS Motors, Brake Booster BLDC Motor, Seat Adjustment, Belt Tensioner, Car Window Motor, Door Lock Motors, Wiper Motor, Others), Medical & Healthcare (Diagnostic Equipment (CT Scanners, MRI, Biopsy Systems, Diagnostics Analyzers, Ultrasound Transducers, X-Ray, Others), Medical Centrifuges, Medical Pumps, Blowers and Compressors, Surgical Instruments (Saws, Drills, Surgical Robots, Others), Dental CAD/CAM Milling Machines, Exoskeleton & Prosthetics, Microscopes, Wheelchairs & Scooters, Stair Lifts, Hospital Beds & Exam Tables, Others).

By Geography: North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe(Germany, UK, France, Italy, Spain, Russia, Netherlands, Poland, Czechia, Belgium, Sweden and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle East and Africa)

Request Sample

Key Takeaways

• The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the electric motor market in APAC.

• The DC Motor segment is growing at a significant CAGR of 7.6% in the forecast period 2024-2030. A DC motor consists of a stator and a rotor.

• Medical & Healthcare sector is expected to witness a highest CAGR of 8.5% the forecast period 2024-2030, due to its extensive reliance on electrically powered devices and equipment. Diagnostic imaging equipment, such as MRI and CT scanners, demands high-performance electric motors for precise movements and accurate imaging.

• Electric Motor companies are strengthening their position through mergers & acquisitions and continuously investing in research and development (R&D) activities to come up with solutions to cater to the changing requirements of customers.

Electric Motor Market Segment Analysis - By Product Type

The DC Motor segment is expected to grow at a significant CAGR of 7.6% during the forecast period 2024-2030. Owing to the growing penetration of brushless DC motors across various industry verticals substituting brushed dc and even ac induction motors in certain applications such as home appliances. DC motors are used in electric vehicles in the automotive industry for various non-traction applications, contributing to the ongoing shift towards sustainable transportation. As the demand for electric vehicles grows, so does the demand for efficient and dependable DC motors. DC motors are also widely used in industrial automation, powering conveyor systems, robotics, and manufacturing equipment. Owing to the ease of control, they are suitable for accurate and regulated movements in automated processes.

Inquiry Before Buying

Electric Motor Market Segment Analysis - By Application

Medical & Healthcare sector is expected to witness a highest growth of CAGR 8.5% during the forecast period 2024-2030, owing to the increase in investments in healthcare and medical sector, along with growing penetration of advanced medical devices & equipment in the sector such as surgical robots, advanced imaging & diagnostic equipment, prosthetics and so on. Medical advances and technical improvements have resulted in the development of a wide range of medical instruments and gear that significantly rely on the precision and efficiency provided by electric motors. High-performance electric motors are required for precise motions and accurate imaging in diagnostic imaging equipment such as MRI and CT scanners. Electric motors provide stability and consistency to patient care and monitoring systems such as infusion pumps and monitoring equipment. Furthermore, the incorporation of electric motors in mobility aids such as electric wheelchairs and patient lifts improves accessibility for people who have mobility issues. Electric motors are used in laboratory equipment, robotic surgical systems, and a variety of medical tools, all of which contribute to the overall efficiency and improvement of healthcare techniques. The demand for electric motors is on the rise as the healthcare industry evolves and adopts more technologically sophisticated solutions, fueling additional innovation in this critical sector.

Electric Motor Market Segment Analysis - By Geography

Electric Motor market in Asia-Pacific region held significant market share of 38% in 2023. Increasing compliance for energy efficient motors and rising adoption of motor-driven electric vehicles are the key factors driving market growth. The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the electric motor market. In addition, advancements in the agriculture sector and enormous investments in industrialization in countries such as China, India, South Korea, and Australia is driving the market growth. Further, the increasing production and sales of electric vehicles in countries including China and Japan is also analyzed to drive the market growth.

Schedule a Call

Electric Motor Market Drivers

Rise in demand for Electric Vehicles

The electric car market has witnessed rapid evolution with the ongoing developments in automotive sector and favorable government policies and support in terms of subsidies and grants, tax rebates. Major manufacturers such as General Motors, Toyota, and BMW plan to release a potential of 400 models and estimated global sales of 25 million by 2025. In 2022, Ford Motor has committed to increase its investments in electric vehicles to $50 billion by 2026, up from a previous spend of $30 billion by 2025. Similarly, in 2020, Volkswagen, Chinese ventures has committed to invest $17.5 billion in electric vehicles by 2025. As electric vehicles use various types of electric motors for traction & auxiliary applications, the rising demand for electric vehicles globally is set to assist the market growth for electric motors used in the same.

Growing R&D activities

Manufacturers are continuously focusing on R&D to develop new and effective electric motors to meet consumer demand. Increasing concerns, such as environmental pollution and regulations, are forcing manufacturers to develop electric motors that reduce vibration and increase efficiency. For instance, a synchronous electric motor is around 80% more efficient than an induction electric motor. Similarly, the development of a new type of steel for electric motors, which reduces the weight of the electric motor and makes it more efficient and powerful. This new type of electric motor will be small in size and cost effective, which will raise demand from residential and commercial applications. Moreover growing developments from various companies is also analysed to drive the market growth. Hence these factors are analysed to drive the market growth in the forecast period 2024-2030.

Electric Motor Market Challenges

Easy availability of low-quality electric motors

The market for electric motors is highly fragmented, with a significant number of domestic and international manufacturers. Product quality is a primary parameter for differentiation in this market. The organized sector in the market mainly targets industrial buyers and maintains excellent product quality, while the unorganized sector offers low-cost alternatives to tap local markets. Local manufacturers of electric motors in most countries target the unorganized sector and compete strongly with the global suppliers in the respective markets. Leading market players are currently exposed to intense competition from such unorganized players supplying inexpensive and low-quality electric motors. This acts as a key challenge for the growth of the market.

Buy Now

Market Landscape

Product launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Electric Motor market. Electric Motor top 10 companies include:

ABB Ltd

Johnson Electric Holdings Limited

Siemens AG

Rockwell Automation

Nidec Corporation

Bosch Electric

Regal Rexnord

Franklin Electric Company Inc.

Teco Electric & Machinery Co. Ltd.

Wolong Electric Group co. ltd.

Acquisitions/Product Launches

• In July 2023, Nidec Corporation announced that it has successfully developed a new electric power steering motor power pack*1 (“EPS-PP”).

• In July 2023, WEG announced new investments for its motor manufacturing plant located in Manaus, Brazil. The Company will invest R$ 48 million, in the next three years, to expand production capacity and adapt the plant to produce a new line of permanent magnet electric motors for split-type air conditioners

• In December 2023, Johnson Electric Launches 48-Volt Cooling Fan Module with High Power and Efficiency. Johnson Electric is pleased to announce the launch of the 48-Volt Cooling Fan Module with power up to 1.5kW to meet the most demanding cooling requirements. The need to reduce emissions and increase the electrification of the vehicle, requires higher cooling performance and efficiency.

#Electric Motor Market#Electric Motor Market size#Electric Motor industry#Electric Motor Market share#Electric Motor top 10 companies#Electric Motor Market report#Electric Motor industry outlook

0 notes

Text

Global Top 5 Companies Accounted for 71% of total Rotary Tricone Drill Bits market (QYResearch, 2022)

The Tricone bits are primarily used for drilling into varied formations ranging from soft, medium to hard. They are especially well suited for hard rock formation. These bits are very reliable in a changing rock conditions.

The Global Rotary Tricone Drill Bits market comprises a wide range of products suitable for use within the Global domestic market. In order to quantify and analyse the market, our definition of the market includes the following key product sectors:

This report specifically excludes labour and measures the product values at manufacturers selling prices. value-added tax, import duties and transportation fees are excluded as well as labour other delivery charges. Whilst we have made every effort to exclude commercial applications, there may be some light commercial applications included within the overall market sizes quoted.

Where volume figures are illustrated for the overall market, these are provided as number of sales. The geographical coverage for this report is the Global and includes domestically manufactured and imported products.

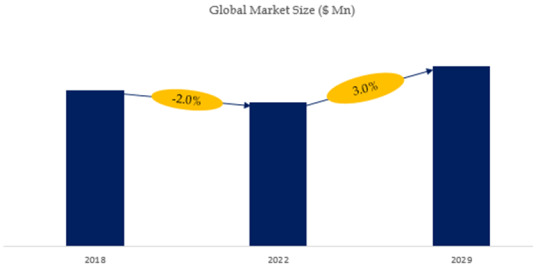

According to the new market research report “Global Rotary Tricone Drill Bits Market Report 2023-2029”, published by QYResearch, the global Rotary Tricone Drill Bits market size is projected to reach USD 2.89 billion by 2029, at a CAGR of 3.0% during the forecast period.

Figure. Global Rotary Tricone Drill Bits Market Size (US$ Million), 2018-2029

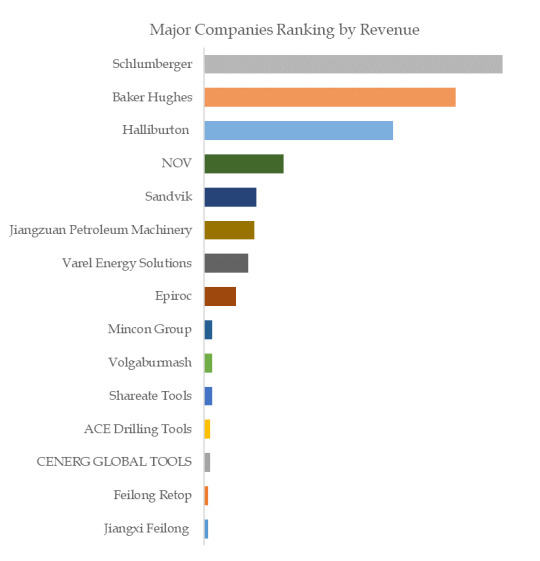

Figure. Global Rotary Tricone Drill Bits Top 15 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Rotary Tricone Drill Bits include Schlumberger, Baker Hughes, Halliburton , NOV, Sandvik, Jiangzuan Petroleum Machinery, Varel Energy Solutions, Epiroc, Mincon Group, Volgaburmash, etc. In 2022, the global top five players had a share approximately 71.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

1 note

·

View note

Text

Mining Equipment Market Overview: Growth Factors and Future Trends (2023-2032)

The global mining equipment market is anticipated to grow at a substantial CAGR of 5.5% in the upcoming years. The global Mining Equipment industry was estimated to be worth USD 131.8 billion in 2022 and was expected to be worth USD 191.7 billion by 2028.

Mining Equipment Market encompasses the manufacture, distribution, and service of machinery and tools used for extracting minerals and other geological materials from the earth. This market plays a critical role in the global mining industry, catering to the extraction of coal, metals like gold and iron, and minerals used in industrial applications. The demand for mining equipment is largely driven by factors such as the growth of the mining sector, increasing demand for resources, and the push for more sustainable and efficient mining practices. Technological advancements such as automation, remote operation, and real-time data monitoring are significantly transforming the market, enhancing both safety and productivity.

Additionally, the adoption of environmentally friendly technologies and electrification of mining equipment to reduce emissions are prominent trends. Despite challenges such as volatile commodity prices and regulatory changes, the market is expected to grow, driven by the rising economic development in emerging markets and the increasing demand for metals used in various sectors including construction, electronics, and energy.

Major Key Players-

Epiroc

China Coal Energy Group Co. Ltd

Boart Long year Ltd; Caterpillar Inc

Vipeak Mining Machinery Co. Ltd

Guangdong Leimeng Intelligent Equipment Group Co. Ltd

Mining equipment plays a crucial role in the extraction and processing of mineral resources.

Here are some key points about mining equipment:

Types of Mining Equipment:

Drills: Used to create holes in the ground for the extraction of minerals.

Excavators: Large machines used for digging, earth moving, and material handling.

Loaders: Designed to transport loose material such as dirt, gravel, or sand.

Crushing Equipment: Used to reduce the size of mined materials for further processing.

Blasting Tools: Employed for controlled explosions to break up hard surfaces like rock.

Conveyors: Systems used to transport materials across different stages of the mining process.

Screening Equipment: Used to separate different sizes of processed material.

Applications:

Surface Mining: Equipment like draglines, shovels, and loaders are used in open-pit mines.

Underground Mining: Specialized machinery such as longwall machines and continuous miners are employed below the earth's surface.

Metal Mining: Equipment designed specifically for metal ore mining like gold, silver, and copper.

Coal Mining: Machines such as coal cutters and roof bolters are used in the extraction of coal.

Safety and Regulations:

Safety Standards: High standards of safety to protect workers from mining hazards.

Regulatory Compliance: Compliance with local and international laws governing mining operations and equipment standards.

Future Trends:

Increased Focus on Sustainability: Development of more environmentally friendly mining practices and equipment.

Integration of AI and ML: Greater use of artificial intelligence and machine learning to optimize mining operations.

More About Report- https://www.credenceresearch.com/report/mining-equipment-market

Segmentation of Global Mining Equipment Market-

Global Mining Equipment Market – By Equipment Type

Underground Mining Equipment

Surface Mining Equipment

Crushing, Pulverizing & Screening Equipment

Drills & Breakers

Others

Global Mining Equipment Market – By Application

Metal Mining

Non-metal Mining

Coal Mining

Mining Equipment Market Dynamics-

Market Drivers

Increased Mining Activities: Rising demand for minerals and metals, driven by global economic growth and the expanding consumer electronics, construction, and automotive industries, fuels the need for mining equipment.

Technological Advancements: Innovations such as automation, remote control technologies, and electrification of mining equipment improve efficiency, reduce labor costs, and enhance safety, making these technologies highly desirable in mining operations.

Energy Cost Reductions: The push towards energy-efficient technologies in mining operations is driven by the need to reduce operational costs and comply with environmental regulations, which supports the adoption of modern mining equipment.

Regulatory and Safety Standards: Stricter safety regulations and environmental laws worldwide require mining companies to invest in upgraded equipment that complies with current standards, driving market growth.

Market Restraints

High Capital Investment: The high cost associated with purchasing and maintaining modern mining equipment can be a significant barrier, especially for small to medium-sized mining operations.

Market Volatility: Fluctuations in commodity prices can affect the profitability of mining operations, influencing the purchasing decisions related to new equipment.

Regulatory Challenges: Environmental regulations and land rights issues can delay or restrict mining activities, impacting the demand for mining equipment.

Market Opportunities

Emerging Markets: Rapid industrialization and urbanization in developing countries, particularly in Asia and Africa, present significant opportunities for the expansion of mining operations and, by extension, mining equipment.

Replacement of Obsolete Equipment: Aging infrastructure and outdated equipment in established markets create opportunities for the market as mining companies look to modernize their fleets with newer, more efficient models.

Integration of IoT and AI: The integration of Internet of Things (IoT) and artificial intelligence (AI) in mining equipment offers potential for predictive maintenance, real-time monitoring, and process optimization, providing significant growth opportunities.

Market Trends

Shift Towards Autonomous Equipment: There is a growing trend towards the use of autonomous and semi-autonomous equipment in mining operations, aimed at reducing human intervention and enhancing operational efficiency.

Electrification of Equipment: In response to environmental concerns, there is an increasing shift towards electric and hybrid mining equipment, which reduces emissions and noise compared to traditional diesel-powered machinery.

Advanced Material Handling: Innovations in material handling, such as advanced conveyor belt systems and robotic loading technologies, are improving the safety and efficiency of mining operations.

Browse the full report – https://www.credenceresearch.com/report/mining-equipment-market

Browse Our Blog: https://www.linkedin.com/pulse/mining-equipment-market-trends-opportunities-global-outlook-singh-v1pzf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Diamond Tools Market - Global Growth, Share, Trends, Demand and Analysis Report Forecast 2031

The global diamond tools market is set to experience substantial expansion, with projections indicating a surge from the estimated US$13 billion mark at the end of 2024 to a staggering US$25 billion by 2031. This remarkable growth trajectory is attributed to a confluence of factors driving demand and innovation within the industry.

For more information: https://www.fairfieldmarketresearch.com/report/diamond-tools-market

Technological Advancements Propel Market Momentum

The diamond tools market has witnessed an unprecedented surge in growth owing to technological advancements in manufacturing processes. Innovations such as laser cutting and 3D printing have revolutionized the production of diamond tools, enhancing their precision, durability, and versatility across various industries including automotive, aerospace, and construction. This surge in technological prowess is expected to sustain market expansion in the forecast period.

Construction Boom and Automotive Revolution Drive Demand

Rapid urbanization, infrastructure development projects, and a burgeoning automotive sector are key drivers propelling the demand for diamond tools. In the construction industry, these tools are indispensable for cutting, drilling, and grinding applications, particularly for materials like concrete, stone, and ceramics. Similarly, the automotive industry's shift towards lightweight materials necessitates the use of diamond tools for precision machining, creating a surge in demand and driving market growth.

Key Growth Barriers and Opportunities

While the diamond tools market presents immense growth prospects, it is not devoid of challenges. High initial investments pose a barrier to entry for new players, along with environmental concerns surrounding the extraction and processing of raw materials. Intense competition further adds pressure on market players, leading to price wars and reduced profit margins. However, opportunities abound, particularly in the adoption of Industry 4.0 technologies, the rise of synthetic diamonds, and expansion into emerging markets, offering avenues for sustainable growth and market dominance.

Regulatory Landscape: Balancing Innovation with Responsibility

The regulatory environment plays a pivotal role in shaping the diamond tools market, with stringent regulations driving innovation in responsible diamond sourcing and safety standards. While regulations pose challenges such as increased production costs, they also pave the way for advancements in eco-friendly manufacturing practices and sustainable sourcing methods, positioning compliant companies for long-term success.

Fairfield's Ranking Board Highlights Market Dynamics

Fairfield's ranking board sheds light on key segments and regional frontrunners within the diamond tools market. Synthetic diamond abrasives maintain dominance, while polishing pads and discs spearhead the finishing category, and diamond pastes and suspensions lead the lapping-based segment. North America retains a strong presence, with Asia Pacific emerging as a powerhouse due to rapid industrialization and infrastructure development.

Leaders in Global Diamond Tools Space

Leading the charge in the global diamond tools space are industry stalwarts such as Hilti Group, Sumitomo Electric Industries, Husqvarna AB, and Saint-Gobain Abrasives Inc., among others. These companies leverage extensive product portfolios, global presence, and strategic alliances to maintain competitive positions and drive market growth.

0 notes

Text

Multi-Tasking Machine Tools Market To Reach USD 1.98 Billion at a 5.78% CAGR by 2030 - Report by Market Research Future (MRFR)

According to Market Research Future (MRFR),” Multi-Tasking Machine Tools Market Information Report by Product Type (Milling, Drilling, Turning, and Others), by Application (Automotive, General Machinery, Aerospace, and others) and By Region - Forecast To 2030”, the global market is expected to reach USD 1.98 BN by 2030, growing at a 5.78% CAGR from 2022 to 2030.

Multi-Tasking Machine Tools Market Overview

The global multi-tasking machine tools market is growing continually. These tools can dramatically improve the machining process and allow for incredible ROI. Resultantly, multi-tasking technologies have become inevitable to offset higher wages & boost efficiency. The multi-tasking machine tools market witnesses huge demand from the global manufacturing industry that has accelerated the use of multi-tasking machine tools. Major manufacturers are fostering investments in R&D and production and adopting automated production processes. Resultantly, multi-tasking machine tools industries worldwide witness rising revenues.

Top Key Players Listed below:

Doosan Machine Tools Co. Ltd. (U.S.)

Yamazaki Mazak Corporation (Japan)

Nakamura-Tome Precision Industry Co. Ltd. (japan)

Jyoti CNC Automation Ltd. (India)

Takisawa machine tool co. ltd. (Japan)

0 notes

Text

Sensors and connectivity: A trend for 2024

Data is the new oil. It's valuable, but if unrefined it cannot really be used. — Clive Humby

In today's rapidly evolving manufacturing landscape, the integration of sensors and connectivity has become indispensable. Just like Clive Humby's analogy of data being akin to oil, sensors serve as the drill, extracting valuable insights from the manufacturing process, while connectivity acts as the pipeline, efficiently transporting this data to where it can be refined and utilized.

But what exactly are sensors and connectivity in the context of manufacturing? Sensors are devices that detect and respond to physical inputs from the environment. These inputs could range from temperature and pressure to motion and light. They are strategically placed throughout the manufacturing process to collect real-time data on various parameters. Connectivity refers to the ability of these sensors to communicate this data to other systems, typically through networks such as Wi-Fi, Bluetooth, or even the Internet of Things (IoT) platforms.

The integration of sensors and connectivity happens at various stages of manufacturing, from the raw material procurement to the final product assembly. Sensors are embedded in machines, equipment, and even products themselves, continuously monitoring and transmitting data. This data is then analyzed using advanced algorithms and machine learning techniques to optimize processes, improve product quality, and enhance overall efficiency.

The benefits of sensor and connectivity integration are manifold. Firstly, it enables predictive maintenance, allowing manufacturers to identify and address potential equipment failures before they occur, thereby minimizing downtime and reducing maintenance costs. According to a study by Deloitte, predictive maintenance can result in up to a 40% reduction in maintenance costs and a 25% increase in productivity.

Moreover, real-time monitoring provided by sensors helps manufacturers gain deeper insights into their processes, leading to better decision-making and optimization. This not only improves operational efficiency but also enhances product quality, resulting in higher customer satisfaction and reduced wastage. In fact, a report by McKinsey suggests that implementing IoT-enabled predictive maintenance can increase equipment uptime by up to 10-20% and reduce maintenance costs by 10-40%.

Additionally, the integration of sensors and connectivity facilitates the transition towards Industry 4.0, where smart factories leverage data-driven insights to drive automation and innovation. This not only improves competitiveness but also paves the way for new business models and revenue streams. According to a forecast by MarketsandMarkets, the global smart manufacturing market is expected to reach $314.7 billion by 2026, growing at a CAGR of 12.4%.

In terms of technology, advancements in sensor miniaturization, wireless communication protocols, and cloud computing have been instrumental in driving the adoption of sensor and connectivity solutions in manufacturing. For instance, the emergence of edge computing enables real-time processing of data at the source, reducing latency and enhancing responsiveness.

In conclusion, the integration of sensors and connectivity represents a paradigm shift in modern manufacturing, unlocking unprecedented levels of efficiency, productivity, and innovation. By harnessing the power of data, manufacturers can not only stay competitive in today's dynamic market but also pave the way for a more sustainable and resilient future. As the Fourth Industrial Revolution continues to unfold, the role of sensors and connectivity will only become more central in shaping the factories of tomorrow. These technologies are not just tools for optimization; they are the cornerstone of digital transformation solutions that will define the future of industry.

#digital transformation solutions#digital transformation in manufacturing#digital transformation company

0 notes

Text

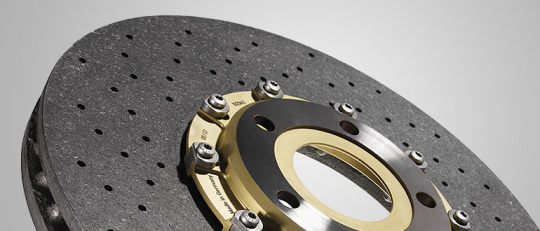

Ceramic Brakes Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Ceramic Brakes Market and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Ceramic Brakes Market scenario, and feasibility study are the important aspects analyzed in this report.

The Ceramic Brakes Market is experiencing robust growth driven by the expanding globally. The Ceramic Brakes Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Ceramic Brakes Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Ceramic Brakes Market Size, Share & Industry Analysis, By Rotor Type (Drilled, Slotted), By Vehicle Type (Passenger Cars, Commercial Vehicles) and Regional Forecast, 2022-2029

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/101889

Key Strategies

Key strategies in the Ceramic Brakes Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Ceramic Brakes Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Ceramic Brakes Market.

Major Ceramic Brakes Market Manufacturers covered in the market report include:

Some of the major companies in the automotive ceramic brakes market include Brembo SpA, Federal-Mogul Corporation, Akebono Brake Industry Co. Ltd., SGL Group, Aisin Seiki Co. Ltd., Fusion Brakes LLC, Wilwood Engineering Inc., and Surface Transforms, among the other players.

Carbon ceramics are expensive and high-performance material that is made from a mixture of fibers, powders, and resins. Previously it was used in the aerospace braking system. Nowadays, automobile manufacturers are using this in private and sports vehicles. Ceramic Brakes are less resistant to deformation at very high temperatures; they last longer than conventional brakes. Compared to conventional brakes, the ceramic brakes do not corrode even in the winter season.

Trends Analysis

The Ceramic Brakes Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Ceramic Brakes Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Ceramic Brakes Market Solutions.

Regions Included in this Ceramic Brakes Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Ceramic Brakes Market.

- Changing the Ceramic Brakes Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Ceramic Brakes Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Ceramic Brakes Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2024 to 2030?

► What are the key market dynamics influencing growth in the Global Ceramic Brakes Market?

► Who are the prominent players in the Global Ceramic Brakes Market?

► What is the consumer perspective in the Global Ceramic Brakes Market?

► What are the key demand-side and supply-side trends in the Global Ceramic Brakes Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Ceramic Brakes Market?

Table Of Contents:

1 Market Overview

1.1 Ceramic Brakes Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

308, Supreme Headquarters,

Survey No. 36, Baner,

Pune-Bangalore Highway,

Pune - 411045, Maharashtra, India.

Phone:

US:+1 424 253 0390

UK: +44 2071 939123

APAC: +91 744 740 1245

#Ceramic Brakes Market#Ceramic Brakes Market Share#Ceramic Brakes Market Size#Ceramic Brakes Market Trends

0 notes

Text

Segmenting the Power Tools Market: Strategies for Targeted Marketing Campaigns

Power Tools Market Overview:

In 2021, the power tools market was estimated to be worth USD 44.6 billion. According to projections, the power tools market will expand at a compound annual growth rate (CAGR) of 5.9% from USD 47.23 billion in 2022 to USD 73.8 billion by 2030.

Power tools play a pivotal role across various industries, providing efficiency, precision, and productivity in tasks ranging from construction and manufacturing to woodworking and DIY projects. The global power tools market has witnessed substantial growth driven by technological advancements, industrial automation, and increasing demand for high-performance tools. This article provides an in-depth overview of the power tools market, including segmentation analysis, key takeaways, and regional insights.

For latest news and updates, request a free sample report of Power Tools Market

By Segmentation:

1. Product Type:

a. Electric Power Tools: This segment includes corded and cordless electric tools such as drills, saws, sanders, grinders, and routers, powered by electricity for versatile and efficient operation.

b. Pneumatic Power Tools: Pneumatic or air-powered tools utilize compressed air to drive mechanisms such as impact wrenches, nail guns, and sanders, offering high power-to-weight ratios and durability in industrial applications.

c. Hydraulic Power Tools: Hydraulic tools use hydraulic fluid to generate power for tasks such as cutting, bending, and pressing, commonly found in heavy-duty construction, automotive, and manufacturing operations.

2. End-User:

a. Construction: Power tools are indispensable in construction activities, including drilling, cutting, fastening, and finishing tasks, contributing to efficiency, accuracy, and safety on construction sites.

b. Manufacturing: Industries such as automotive, aerospace, electronics, and metal fabrication rely on power tools for precision machining, assembly, and surface finishing processes, enhancing productivity and product quality.

c. Woodworking: Woodworkers and carpenters utilize a wide range of power tools such as saws, routers, planers, and sanders to craft furniture, cabinets, and other wooden products with speed and precision.

d. DIY Enthusiasts: Homeowners and hobbyists use power tools for various do-it-yourself projects, renovations, and repairs, driving demand for compact, user-friendly tools with advanced features.

3. Region:

The global power tools market is segmented into key regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Each region exhibits distinct market dynamics influenced by factors such as industrialization, infrastructure development, technological adoption, and regulatory environment.

Key Takeaways:

1. Technological Advancements: Continuous innovation in power tool design, materials, and functionality, including brushless motors, lithium-ion batteries, and digital controls, enhances performance, durability, and user experience.

2. Industry 4.0 Integration: The convergence of power tools with digital technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and cloud connectivity enables remote monitoring, predictive maintenance, and data-driven insights, optimizing operational efficiency and uptime.

3. Safety and Ergonomics: Manufacturers prioritize safety features and ergonomic designs in power tools to minimize user fatigue, reduce the risk of accidents and injuries, and enhance overall user comfort and productivity.

4. Market Expansion in Emerging Economies: Rapid urbanization, infrastructure development, and industrialization in emerging markets such as China, India, and Southeast Asia drive the demand for power tools, presenting growth opportunities for market players to expand their presence and product offerings.

Regional Insights:

1. North America: The United States and Canada lead the North American power tools market, driven by robust construction and manufacturing sectors, technological innovation, and a strong DIY culture.

2. Europe: Germany, the UK, and France are key markets in Europe, characterized by stringent safety regulations, emphasis on sustainability, and growing adoption of smart and connected power tools.

3. Asia Pacific: China, Japan, and India dominate the Asia Pacific market, fueled by rapid industrialization, urbanization, infrastructure investments, and increasing demand for high-quality power tools in manufacturing and construction sectors.

4. Latin America and the Middle East & Africa: These regions offer growth opportunities due to expanding construction activities, infrastructure projects, and investments in industrial development, driving demand for power tools and related equipment.

The power tools market continues to evolve with advancements in technology, changing end-user preferences, and evolving industry trends. Manufacturers, suppliers, and distributors need to adapt to these dynamics, focusing on innovation, safety, and market expansion to capitalize on growth opportunities globally. By understanding regional nuances and catering to diverse end-user needs, stakeholders can navigate the competitive landscape and drive sustainable growth in the dynamic power tools market.

Top trending report:

HVAC System Market

Industrial Hand Gloves Market

Water Purifier Market

Agriculture Equipment Market

Power Tools Market

0 notes

Text

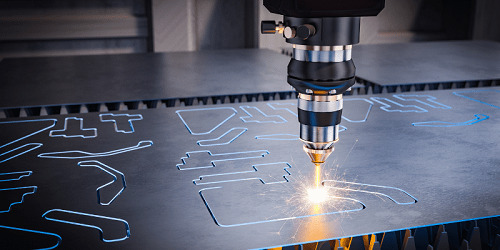

Laser Cutting Machine Market Evolution: Historical Analysis and Future Projections

The global laser cutting machines market size is expected to reach USD 10,351.0 billion by 2030, registering a CAGR of 5.5% over the forecast period, according to a study conducted by Grand View Research, Inc. Over the forecast period, it is anticipated that the growing trend of automation in the manufacturing sector and the rising demand for the end-use industry will increase demand for these machines. The growing application of CO2, fiber, and Yttrium Aluminum Garnet (YAG) lasers in various applications, such as industrial sectors and consumer electronics, is predicted to boost the demand for laser cutting machines. Industries such as consumer electronics are contributing to the market growth owing to the increasing use of lasers in material processing operations such as pruning, welding, and engraving. Furthermore, the requirement for high-power input and performance-based cutting tools drives demand and market growth for laser cutting machines over the forecast period.

Laser Cutting Machines Market Report Highlights

During the forecast period, the gas laser technology segment is expected to witness the highest CAGR of 6.1 %. The growth is attributed to the increasing demand for these lasers for better machine tools and equipment for laser printing, dye laser pumping, reading barcodes, and producing holograms

The fusion cutting is expected to register the highest CAGR of 6.1 % from 2023 to 2030. The advantage of fusion cutting is that it creates a cutting edge that is practically oxide-free and ideal for cutting thin sheets, which is expected to contribute to the growth of the segment

Over the course of the forecast period, the industrial sector is expected to dominate the laser cutting machine industry. It held a market share of 39.8 % in 2022. The need for laser cutting equipment is rising as industrial processes increasingly become automated. These tools consistently and quickly cut parts and patterns with precision

The rising GDP and quickening growth of the region's manufacturing sector, the Asia Pacific region is anticipated to continue growing. Additionally, businesses that use laser cutting to create semiconductors, consumer electronics, and automotive components are experiencing rapid regional growth. The need for laser cutting equipment in this area is rising along with the expansion of these industries

For More Details or Sample Copy please visit link @: Laser Cutting Machines Market Report

The development of innovative process lasers to maximize the manufacture of tailored three-dimensional glass elements, as well as a shift out of traditional semiconductor lasers and towards quantum cascade lasers, will likely drive up the demand for laser cutting machines. Continuous developments in laser technology enable manufacturers to engage in R&D to obtain a competitive advantage. Furthermore, due to the demand for high-speed and precision cutting and drilling the integration of the Internet of Things, Artificial Intelligence, and automation software with drilling machines is also supporting the laser cutting machine industry’s growth.

Major players are resorting to strategies such as product launches, mergers & acquisitions, and expansions to gain greater market shares. For instance, in May 2022, Yamazaki Mazak Pvt. Ltd. announced the launch of 3D based fiber laser cutting machine for cutting steel products- FG -400 NEO. The 3D laser is equipped with an efficient laser fiber oscillator which offers efficient energy conversion and enhanced productivity.

The laser is also compatible with cutting copper, brass, and aluminum. The laser is outfitted with a feature that enables users to easily modify the laser beam's diameter and form, enabling the cutting of sheets of different thicknesses. The oscillator's maximum output is limited to 4 kW, along with a rapid input rate on the X, Y, and Z axes is 60, 36, and 30 m/min, respectively. The continuous launch of advanced products is contributing to the laser cutting machine industry’s growth.

#LaserCuttingMachine#CuttingEquipment#CNCMachines#PrecisionCutting#MaterialProcessing#Metalworking#Fabrication#IndustryInsights#TechnologyTrends#MarketForecast#BusinessStrategy#InvestmentOpportunities#SupplyChain

0 notes

Text

Connected mining asset tracking market to Massive Growth by 2022-2028

Connected mining asset tracking market to Massive Growth by 2022-2028

Global Connected mining asset tracking market, Connected mining asset tracking market Demand, Connected mining asset tracking market Trends, Connected mining asset tracking market Analysis, Connected mining asset tracking market Growth, Connected mining asset tracking market Share, Connected mining asset tracking market Forecast, Connected mining asset tracking market Challenges, Connected mining asset tracking market Opportunity

The latest study released on the Global Connected mining asset tracking market by Intellect Markets, Research evaluates market size, trend, and forecast to 2030. The Connected mining asset tracking market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and self-analysed study to help understand market trends, growth drivers, opportunities and upcoming challenges and about the competitors.

Download Free Sample Report in PDF @

https://intellectmarkets.com/report/connected-mining-asset-tracking-market/request-sample

Key Players in This Report Include:

Some key players in the connected mining asset tracking market include Hexagon AB, Trimble Inc, Caterpillar Inc, GE Mining, IBM, SAP, Topcon Positioning Systems, Hexagon Mining, Rio Tinto, Komatsu, Hitachi Construction Machinery, Sandvik Mining and Rock Technology, Teck Resources Limited and Zebra Technologies..

Definition:

Connected mining asset tracking refers to the use of technology, such as GPS, RFID, and sensors, to track and monitor the location and status of mining equipment and assets in real-time. This includes equipment and machines such as haul trucks, excavators, and drilling equipment.

Market Drivers:

Increasing demand for improved efficiency and productivity in the mining industry is boosting global market growth for the connected mining asset tracking systems.Rising focus on safety and compliance is another driver for the Connected Mining Asset Tracking Market.Increasing demand for remote monitoring and control is also driving the Connected Mining Asset Tracking Market.Government initiatives to promote the use of connected mining asset tracking systems are driving the market rapidly.

Market Opportunity:

Increasing adoption of 5G networks: The deployment of 5G networks can provide faster and more reliable connectivity, which can support the growth of connected mining asset tracking systems.

Development of new technologies: The development of new technologies such as blockchain and edge computing can help improve the efficiency and security of connected mining asset tracking systems.

The titled segments and sub-section of the market are illuminated below:

By End User (Coal Mining, Metal Mining, Mineral Mining Others)

Global Connected mining asset tracking market report highlights information regarding the current and future industry trends, growth patterns, as well as it offers business strategies to helps the stakeholders in making sound decisions that may help to ensure the profit trajectory over the forecast years.

Have a query? Market an enquiry before purchase @ https://intellectmarkets.com/report/connected-mining-asset-tracking-market/enquire

Geographically, the detailed analysis of consumption, revenue, market share, and growth rate of the following regions:

• The Middle East and Africa (South Africa, Saudi Arabia, UAE, Israel, Egypt, etc.)

• North America (United States, Mexico & Canada)

• South America (Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, etc.)

• Europe (Turkey, Spain, Turkey, Netherlands Denmark, Belgium, Switzerland, Germany, Russia UK, Italy, France, etc.)

• Asia-Pacific (Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia).

Objectives of the Report:

• To carefully analyze and forecast the size of the Connected mining asset tracking market by value and volume.

• To estimate the market shares of major segments of the Connected mining asset tracking market

• To showcase the development of the Connected mining asset tracking market in different parts of the world.

• To analyze and study micro-markets in terms of their contributions to the Connected mining asset tracking market, their prospects, and individual growth trends.

• To offer precise and useful details about factors affecting the growth of the Connected mining asset tracking market

• To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Connected mining asset tracking market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

Key questions answered:

• How feasible is Connected mining asset tracking market for long-term investment?

• What are influencing factors driving the demand for Connected mining asset tracking market near future?

• What is the impact analysis of various factors in the Global Connected mining asset tracking market growth?

• What are the recent trends in the regional market and how successful they are?

Browse Complete Summary and Table of Content @ https://intellectmarkets.com/report/connected-mining-asset-tracking-market

Thanks for reading this article; you can also get individual chapter-wise sections or region-wise report versions like Global, North America, Middle East, Africa, Europe, South America, etc

Contact US:

Intellect Markets,

Unit No. 4, Lakshmi Enclave, Nizampet, Hyderabad, Telangana, India - 500090

Phone: +1 347 514 7411, +91 8688234923

[email protected]

1 note

·

View note

Text

The high-speed steel (HSS) tools market is expected to be worth US$ 5.6 billion in 2022. The market is expected to develop at a compound annual growth rate (CAGR) of 6% between 2023 and 2033. According to Future Market Insights, the high-speed steel (HSS) tools market is expected to reach US$ 10.6 billion by the end of the 2023 to 2033 forecast period.

The HSS tools market is expected to keep recording a positive trajectory owing to increasing demand across various manufacturing and production industries. Besides this, investments in machinery for Industrial sectors will guarantee growth through the forecast period.

Gain expert insights and supercharge your growth strategies. Request our market overview sample now

https://www.futuremarketinsights.com/reports/sample/rep-gb-9000

The unprecedented challenges triggered by the COVID-19 outbreak had a severe impact on the global economy. It has resulted in a complete shutdown of supply chain networks and manufacturing activities.

Amid the crisis, the HSS tools market recorded tepid growth in sales. However, it is expected to recover sharply through 2021 as economic activities resume post the containment of the pandemic.

Manufacturers are focusing on research and development for launching advanced products with higher levels of durability and improved life cycles. These factors are expected to positively influence growth in demand for HSS tools during the assessment period.

Key Takeaways of the HSS Tools Market Study

Drills are projected to account for over 30% of the HSS tools sold through 2031 owing to strong demand from the metal cutting industry.

Coated fabrication accounts for more than 67% of the market on the back of higher durability of end products.

Germany holds the lead in the Europe market accounting for a valuation of US$ 249.2 Million in 2021 owing to the presence of key manufacturing and processing facilities.

The U.S. holds 86% of the overall North American market, supported by robust supply chains and access to updated technologies.

India will account for a valuation of US$ 287.3 Million in 2021, driving the South Asia and Pacific market to surpass North America by the end of 2031.

Who is Winning?

The HSS tools market is moderately fragmented, in which the leading players account for more than 50% of the market share. The penetration of small regional players makes this market more competitive.

These players have higher shares in the global market, and have longstanding relationships with a number of distributors and end users, giving them an upper hand among their peers.

Some of the key players in the market are Sandvik AB, Mitsubishi Materials Corporation, OSG Corporation, Kennametal Inc., YG-1 Co., Ltd., TTI Group, Stanley Black & Decker, Inc, Tiangong International Co. Ltd., Sumitomo Electric Hartmetall GmbH, TDC Cutting Tools Inc., CERATIZIT S.A., KYOCERA Corporation, Gühring KG, Walter AG, RUKO GmbH, Tivoly SA, Alpen-Maykestag Gmbh, Izar Cutting Tools SaL, August Beck GmbH & Co. KG, Karnasch Tools, Krino Spa, Dürr AG, PT GmbH, Bohrcraft Werkzeuge GmbH & Co. KG, VÖLKEL Threading Solutions, PFERD GmbH & Co. KG, IMC International Metalworking Companies B.V., Allied Machine & Engineering Corp, Narex S.R.O. among others.

High-Speed Steel (HSS) Tools Market by Category

By Tool Type:

Drill Taps

Combo Taps

Spiral Flute Taps

Spiral Point Taps

Taper Pipe Taps

Fluteless Taps

Machine Taps

Hand Taps

Round Dies

Drills

Extra Length Drill

Double Ended Body Drill

Straight Flute Drill

Spiral Drill

Slow Helix

Taper Pin Drills

Straight Shank Drills

Taper Shank Drills

Parallel Shank Drills

Aircraft Extension Drills

Worm Pattern Drills

Central Drills

Spade Drills

Step Drills

Sheet Drill

Spot Drills

Slot Drills

Mills

End Mills

Hollow Mills

Threaded Mills

Countersinks

Single Flute Based

Three Flute Based

Deburring Countersinks

Cutters

Back Spot Face Cutters

Slot Cutters

Routing Cutters

Corner Rounding Cutter

Single Flute Deburring Cutter

Annular Cutter

Dovetail Cutter

Woodruff Cutters

Reamers

Drill Reamers

Socket Reamers

Ball Pin Reamers

Taper Shank Bridge Reamer

Angle Reamer

Sprue Bush Reamers

Extra Length Reamers

Chucking Reamers

Diemaker Based Reamers

Drill Blanks and Sets

Square Tool Bits

Counterbores

Round Bits

Rotary Burrs

Hole Saws

By Fabrication:

Coated

Non-Coated

By Configuration:

Hand Based

Machine Based

By End Use Industry:

Metal Fabrication

Automotive and Transportation

Automotive

Railways

Aerospace

Marine

Heavy Machinery

Construction

Furniture & Carpentry

Oil & Gas

DIY

Other Manufacturing

By Region:

North America

Latin America

Europe

East Asia

South Asia & Pacific

Middle East and Africa (MEA)

0 notes

Text

Hydraulic Intensifier Market: Global Demand Analysis & Opportunity Outlook 2036

Research Nester’s recent market research analysis on “Hydraulic Intensifier Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitors analysis and a detailed overview of the global hydraulic intensifier market in terms of market segmentation byproduct, end users, pressure range, and by region.

Growing Urbanization and Industrialization to Promote Global Market Share of Hydraulic Intensifier Market

Urbanization, growing industry, and the expansion of global infrastructure development are the main drivers of market growth. Currently, 56% of the world's population—roughly 4.4 billion people—live in cities. Due to this tendency, more than seven out of ten people will live in cities by 2050, when the number of people living in urban areas is expected to have more than doubled from its current level. The business is also anticipated to grow as a result of increased investments in the construction of infrastructure. Infrastructure development is receiving substantial funding from governments worldwide, particularly from those in developing countries. This has led to a sharp rise in demand for machinery and construction equipment, especially hydraulic intensifiers, which is driving market expansion.

Request Report Sample@

Some of the major growth factors and challenges that are associated with the growth of the global hydraulic intensifier market are:

Growth Drivers:

Surge in Technological Advancements in Hydraulic Intensifiers

Rising Need of Accuracy in Manufacturing

Challenges:

The high initial price of hydraulic intensifiers may prevent certain businesses from investing in them, which could be a barrier to market expansion. In addition, regular maintenance and repairs are required for hydraulic intensifiers to ensure optimal performance. This could lead to greater overall operating costs for businesses. The intricacy of installation and maintenance could impede the market's expansion. Market expansion is expected to be hindered by supply chain interruptions caused by the COVID-19 pandemic.

By end user, the global hydraulic intensifier market is segmented into construction, petrochemical, power & energy, auto industry and machine manufacturing. The construction segment is to garner the highest revenue by the end of 2036 by growing at a significant CAGR over the forecast period. The segment is growing as a result of increased global building activity, which is driven by urbanization, infrastructure expansion, and population growth. With an additional 1 billion since 2010 and 2 billion since 1998, the world's population grew from an estimated 2.5 billion in 1950 to 8.0 billion in mid-November 2022. For increasingly complex and demanding building projects, hydraulic intensifiers and other strong and efficient hydraulic systems are indispensable. These tools provide the force and pressure needed for a range of construction jobs, including drilling, cutting, and lifting large objects. In addition, high-rise buildings and tunnels—two examples of the methodological and technological advances in the field—need accurate and safe hydraulic systems for construction.

By region, the Europe hydraulic intensifier market is to generate the highest revenue by the end of 2036. The use of these hydraulic intensifier is expected to increase since they are essential components of automated systems, offering the required precision and power for a variety of uses. Hydraulic intensifiers are becoming increasingly used in sectors including manufacturing, transportation, and renewable energy in Europe as a result of the region's emphasis on sustainability and energy efficiency. The focus on modernization and infrastructure development initiatives in Europe also aided in the expansion of the business in this area.

Access our detailed report at:

0 notes

Text

Metalworking Fluids Market Size, Share, Trends And Forecast 2030

The global metalworking fluids market size is expected to reach USD 15.1 million by 2030, as per the new report by Grand View Research, Inc., registering a CAGR of 3.8% in the forecast period. The demand is attributed to arise in demand for automotive and industrial machinery. Individual end-use sectors, such as machinery, metal fabrication, and transportation equipment, are driving the expansion of the market.

The market is also expected to be driven by strong development in the machinery and transportation equipment end-use industries over the projected period. Manufacturing is one of the core industries in North America and Europe. Advances in the manufacturing methods for the production of sophisticated end-use products, coupled with the increase in the exports of construction machinery and power, agricultural, and automotive equipment, have fueled the market growth.

The sector is expected to benefit from increased production of construction machines and related parts for industrial, residential, and commercial construction. The rise in public-private partnerships is expected to boost the demand for a variety of construction components that use MWFs during their production. Because of the expanding building activities in these nations, emerging economies are likely to be critical for product growth.

The increasing demand for electricity and upgrading of the existing infrastructure for electricity generation, transmission, and distribution, is anticipated to fuel the market for electrical & power equipment and related components. These components are manufactured using ferrous and non-ferrous metal parts, which consume MWFs during manufacturing.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/metalworking-fluids-market

Metalworking Fluids Market Report Highlights

Mineral-based MWFs accounted for a revenue share of 48.1% in 2021 due to the increased consumption owing to their low cost

Water cutting oils application is anticipated to grow at the fastest CAGR over the forecast period due to product usage in operations, such as drilling, milling grinding, and mainly in heat dissipation for the proper machining process

The machinery segment dominated the market in 2021 due to the high demand for construction equipment and increased infrastructural development activities

The automobile industry is anticipated to witness a significant CAGR over the forecast period due to the high demand for automobile machinery

The growth of the construction and electrical & power equipment sectors in emerging economies is also expected to drive the product demand

Synthetic and mineral-based products aid in better tool performance, which has led to their high demand

Metalworking Fluids Market Segmentation

Grand View Research has segmented the metalworking fluids market report on the basis of product, application, end-use, industrial end-use, and region:

MWFs Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Mineral

Synthetic

Bio-based

MWFs Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Neat Cutting Oils

Water Cutting Oils

Corrosion Preventive Oils

Others

MWFs End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Metal Fabrication

Transportation Equipment

Machinery

Others

MWFs Industrial End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Construction

Electrical & Power

Agriculture

Automobile

Aerospace

Rail

Marine

Telecommunication

Healthcare

MWFs Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

Russia

France

Spain

Italy

U.K.

Switzerland

Denmark

Norway

Belgium

Poland

Czech Republic

Turkey

Sweden

Finland

Asia Pacific

China

India

Japan

South Korea

Singapore

Malaysia

Thailand

Australia

New Zealand

Central & South America

Brazil

Middle East & Africa

List of Key Players in Metalworking Fluids Market

Houghton International, Inc.

Blaser Swisslube AG

BP plc

Exxon Mobil Corp.

Total S.A.

FUCHS

Chevron Corp.

China Petroleum & Chemical Corp.

Kuwait Petroleum Corp.

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/metalworking-fluids-market

#Metalworking Fluids Market#Metalworking Fluids Market Size#Metalworking Fluids Market Trends#Metalworking Fluids Market Forecast

0 notes

Text

PinnacleMetalFab: Trailblazers in Metal Fabrication Tools and Equipment Manufacturing

Originally Published on: SpendEdge |Top 5 Metal Fabrication Tools and Equipment Manufacturers | SpendEdge

In the realm of towering skyscrapers and intricate machinery, metal fabrication tools play a pivotal role in crafting sheet metal, nuts, bolts, springs, and wires. These tools, utilized in metal fabrication shops, mold and structure metal components through cutting, burning, welding, machining, forming, and assembling. Lathes, boring machines, milling machines, and drilling machines are commonplace in this intricate process. The metal fabrication process, whether manual or automated, has undergone a transformative evolution, particularly post the fourth industrial revolution, witnessing a significant shift towards automation and the integration of IoT systems. The adoption of IoT is anticipated to propel the global metal fabrication equipment market's growth, creating synergy between manufacturing and information management systems.

##Pioneers in Metal Fabrication Tools and Equipment Manufacturing

###Trumpf A stalwart in metal fabrication equipment, Trumpf, a family-owned powerhouse, stands among the world's largest machine tool suppliers. With production facilities spanning Germany, France, the UK, China, Japan, and the US, Trumpf offers a diverse product and service portfolio, encompassing laser cutting machines, marking systems, punching machines, bending machines, and more. The company's commitment to Industry 4.0 solutions is evident through its $30 million investment in a technology center in Chicago in 2017.

###Shenyang Machine Tool As the largest machine tool and equipment manufacturer in China, Shenyang Machine Tool is a global leader in metal fabrication equipment. Boasting a comprehensive range of tools for cutting, milling, boring, and drilling, the company's annual production exceeds 80,000 small and large equipment. A Berlin-based R&D center ensures top-notch product design and performance accuracy.

###Amada Headquartered in Kanagawa, Japan, Amada is a global player in metal processing equipment and machinery, specializing in metal cutting, forming, punching, and shearing equipment. With over 8,000 employees worldwide, Amada not only provides metal fabrication tools but also offers software solutions for machine automation and training. Their innovative 3kW ENSIS product enables continuous processing of thin-to-thick materials without a lens change.

###Okuma Originating as Okuma Noodle Machine in 1898, Okuma has evolved into a renowned machine tool builder. Producing CNC lathes and machining centers, Okuma is recognized for excellence and groundbreaking technologies. Reporting revenues of $1.45 billion in 2016, the company continues to push the boundaries of CNC machine tools.

###DMG Mori Seiki Formed through a strategic partnership between Deckel-Maho-Gildemeister and Mori Seiki, DMG Mori Seiki has grown into one of the world's largest suppliers of machine and metal fabrication tools. Operating under the name DMG Mori, the Japanese company has developed over 200 models of CNC lathes and machining centers since its establishment.

Delve into comprehensive insights on key players in the metal fabrication tools and equipment market, along with dynamic market trends, pricing models, procurement challenges, and sourcing insights in SpendEdge’s forthcoming report on the global metal fabrication equipment market.

Contact us.

0 notes

Text

Wind Turbines to Radar: Examining the Varied Applications of Slewing Bearings