#Emulsion Styrene Butadiene Rubber Market Demand

Text

Emulsion Styrene Butadiene Rubber Market: Customized Solutions for Specific Industries

Emulsion Styrene Butadiene Rubber Market: A Comprehensive Analysis

The global Emulsion Styrene Butadiene Rubber (ESBR) market has been experiencing significant growth and transformation in recent years. ESBR, a synthetic rubber derived from the copolymerization of styrene and butadiene, is a crucial component in the manufacturing of various products, including tires, adhesives, footwear, and more. This article delves into the key factors driving the ESBR market, its applications, regional trends, and future prospects.

Market Overview:

The ESBR market has witnessed substantial expansion, primarily due to its versatility and wide-ranging applications. ESBR offers excellent performance characteristics, such as high abrasion resistance, good aging stability, and high resilience, making it a preferred choice in the tire industry. Additionally, its cost-effectiveness and environmental friendliness have further boosted its demand across various sectors.

Key Drivers:

Growing Automotive Industry: The automotive industry is one of the largest consumers of ESBR, primarily in tire manufacturing. The rising demand for automobiles worldwide, driven by population growth and urbanization, has directly contributed to the growth of the ESBR market.

Environmental Regulations: Stringent environmental regulations have prompted manufacturers to adopt eco-friendly materials. ESBR is considered environmentally friendly compared to its alternatives, as it reduces the overall carbon footprint in tire production.

Infrastructure Development: Infrastructure development projects, including road construction, have surged globally. ESBR is used in road pavements and sealants, further augmenting its demand.

Footwear and Adhesive Industries: ESBR is widely used in the footwear and adhesive industries due to its excellent bonding properties and durability.

Applications:

Tire Manufacturing: The tire industry accounts for a significant share of the ESBR market. ESBR's ability to enhance tire performance and reduce rolling resistance aligns with the increasing demand for fuel-efficient vehicles.

Adhesives: ESBR is a key component in adhesive formulations, making it indispensable in industries such as construction, packaging, and automotive assembly.

Footwear: In the footwear industry, ESBR is used to create durable, long-lasting soles and other components.

Others: ESBR finds applications in the production of conveyor belts, hoses, and various molded rubber products.

Regional Trends:

Asia-Pacific: Asia-Pacific dominates the global ESBR market, owing to its thriving automotive and manufacturing sectors. China, in particular, plays a pivotal role as both a major producer and consumer of ESBR.

North America: The North American ESBR market has experienced steady growth due to the resurgence of the automotive industry and infrastructure development projects.

Europe: Europe is witnessing increased ESBR adoption, driven by the automotive industry's focus on reducing emissions and improving fuel efficiency.

Future Outlook:

The future of the ESBR market growth looks promising, with several factors contributing to its growth:

Green Initiatives: Continued emphasis on sustainability and reduced environmental impact is likely to drive the adoption of ESBR, especially in industries striving to meet stringent green standards.

Research and Development: Ongoing research into improving ESBR properties and applications will open up new opportunities for the market.

Technological Advancements: Innovations in ESBR production techniques and formulations will enhance its performance characteristics, expanding its reach into new industries.

In conclusion, the Emulsion Styrene Butadiene Rubber market is poised for sustained growth, driven by its versatility, eco-friendliness, and increasing demand in various industries. As global industries continue to evolve and prioritize sustainability, ESBR will remain a vital component in manufacturing processes, shaping the future of multiple sectors. Market players should keep a close watch on emerging trends and invest in research and development to stay competitive in this dynamic landscape.

#Emulsion Styrene Butadiene Rubber Market Share#Emulsion Styrene Butadiene Rubber Market Growth#Emulsion Styrene Butadiene Rubber Market Demand#Emulsion Styrene Butadiene Rubber Market Trend

0 notes

Text

The ABCs of ABS: Unraveling the Characteristics and Uses of Acrylonitrile Butadiene Styrene (2023-2034)

This blog will focus on Acrylonitrile Butadiene Styrene (ABS). ABS is comprised of three monomers: Acrylonitrile, Butadiene, and Styrene. In this article, we'll look at how the polymer's unique properties work together to give ABS its exceptional strength, toughness, as well as the manufacturing process. The global Acrylonitrile Butadiene Styrene (ABS) market is likely to flourish at a moderate CAGR of 5.90% by the year 2034.

Introduction

Styrene Acrylonitrile has existed since the 1940s. While they improved toughness over pure styrene, their limits necessitated the addition of rubber (butadiene) as a third monomer. ABS consists of three major monomers: acrylonitrile, butadiene, and styrene.

Acrylonitrile contributes to ABS's chemical resistance and heat stability.

Butadiene enhances the toughness and impact strength of ABS.

Styrene provides ABS with rigidity and facilitates its processability.

Manufacturing Process

ABS copolymers exhibit notable toughness, superior thermal resistance, and properties that surpass those of polystyrene plastics. ABS is produced through three distinct polymerization techniques: emulsion, suspension, and mass processes.

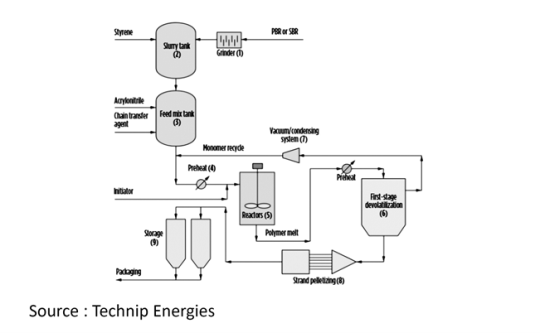

In the Mass Process, ABS is produced by the continuous copolymerization of styrene and acrylonitrile monomers with Polybutadiene Rubber (PBR) or Styrene-Butadiene Rubber (SBR) using a series of reactors, aided by organic peroxide. In a sequential process, chopped PBR or SBR is added to a slurry tank containing styrene monomer. The resultant mixture is then transferred to the ABS feed batch tank for complete rubber dissolution. This concentrated rubber solution is diluted with acrylonitrile, recycled monomer, and a chain transfer agent according to product requirements before preheating prior to entering the polymerization reactors.

Polymerization Section

The polymerization section employs a unique combination of plug flow and boiling stirred tank reactors arranged in series. Organic peroxide is introduced to initiate polymerization. This reactor setup allows precise control over various parameters such as rubber grafting, phase inversion, and molecular weight. Monomer conversion increases progressively throughout the reactor system, reaching final levels between 60% to 75%. Devolatilization is achieved through either extrusion or flash chamber methods.

Devolatization

In the extrusion devolatilization approach, the product from the last reactor undergoes stripping of unreacted monomers and byproducts in an extruder devolatilization system. Alternatively, the reactor product is subjected to volatile removal in a multistage flash devolatilization system operating under vacuum. Vapors are condensed, and the resulting mixture is recycled. The devolatilized polymer melts and then pelletizes and then dried.

Applications of Acrylonitrile Butadiene Styrene (ABS):

ABS (Acrylonitrile Butadiene Styrene) finds numerous applications across various industries. High impact grades are utilized in the production of travelling bags, helmets, furniture, sports goods, and automotive components, while medium impact grades are employed in radiator and air conditioner grills, heavy-duty domestic appliances, and control panels. Electroplating grades find their place in TV and radio knobs, bathroom fittings, refrigerator handles, and nameplates. High flow grades are ideal for housing domestic appliances, office equipment, and cabinets of electronic devices. High heat-resistant grades are utilized in automobile components and housing for electrical heaters and dryers. Transparent grades are sought after for areas requiring high transparency and impact strength, while impact modifier grades serve as modifiers for PVC compounding across various formulations. Glass-filled grades cater to applications demanding high flexural strength and stiffness, maintaining impact and tensile properties, while extrusion grades are used in refrigerator linings and luggage production.

Automotive

The automotive industry demands stringent standards from its materials. They must remain dimensionally stable and resist warping even when subjected to extreme stresses and significant temperature fluctuations.

Electronics & Electricals

ABS stands out in this regard due to its outstanding antistatic properties, providing a distinct advantage in meeting these requirements.

Appliances

ABS finds extensive applications in appliances, encompassing appliance control panels, housings for various devices such as shavers, vacuum cleaners, and food processors, as well as refrigerator liners, among others. Household and consumer goods represent the primary domains where ABS is widely utilized. Additionally, ABS is commonly employed in the manufacturing of keyboard keycaps.

Pipes & Fittings

ABS pipes and fittings are highly liked due to their ease of installation and rust resistance, making them a popular choice in a variety of applications.

Market Outlook:

ABS is an invariable thermoplastic polymer made up of three distinct monomers: acrylonitrile, butadiene, and styrene, which can change in proportion. They are also referred to as engineering plastics. Acrylonitrile provides chemical and thermal stability, styrene gives the plastic a glossy sheen, and butadiene provides strength and durability. These materials are widely used in the electronic appliance and automobile industries for vehicle and auto components production. The rapid growth of the medical business has increased demand for medical equipment, which is driving market growth. Furthermore, the growing construction and aerospace industries are predicted to significantly boost the ABS sector during the projection period. The global Acrylonitrile Butadiene Styrene (ABS) market is anticipated to reach approximately 15.7 million tonnes by 2034.

Acrylonitrile Butadiene Styrene (ABS) Major Manufacturers

Significant companies in the Global Acrylonitrile Butadiene Styrene (ABS) market are Formosa Chemicals and Fiber Corporation, LG Chem, LOTTE Chemical Corporation, Jilin Petrochemical Company, Toray Industries, CHIMEI Corporation, Tianjin Dagu Chemical Co., Ltd., and Others.

Challenges and Opportunities

While ABS possesses numerous advantageous properties, there are several restraining factors that could impact its market growth:

Environmental Concerns: ABS is derived from petrochemical sources, and its production and disposal can contribute to environmental pollution. Increasing environmental consciousness, combined with strict laws on plastic waste management and recycling, may present difficulties to the ABS market.

Competition from Alternative Materials: ABS faces competition from other engineering thermoplastics, such as polycarbonate (PC) and polypropylene (PP), which offer similar or enhanced properties in certain applications.

Conclusion:

Acrylonitrile Butadiene Styrene (ABS) is a versatile polymer with numerous useful applications. It is an essential in automotives and Electrical & Electronics industries owing to its unique set of properties. The surging demand for Acrylonitrile Butadiene Styrene (ABS) from Automotive, Home Appliances, Electrical & Electronics, and Building & Construction end-use industries, is anticipated to play a role in the demand-supply dynamics of the Acrylonitrile Butadiene Styrene (ABS) market.

0 notes

Text

Styrene Butadiene Rubber (SBR) Latex Market 2024 Incredible Possibilities, Growth With Industry Study, Detailed Analysis And Forecast To 2032

Market Overview/Outlook (2022 to 2032)

The global market for SBR Latex is expected to grow between 2023 and 2032, due to the demand for sealant and adhesive applications, growth of the construction industry, applications of paper coating, and tire manufacturing.

The Global Styrene Butadiene Rubber (SBR) Latex Market was valued at USD 9.51 Billion in 2022 and is projected to reach USD 14.75 Billion by 2032, registering a CAGR of 3.70% for the forecast period 2023-2032.

The report offers an in-depth examination of the global Styrene Butadiene Rubber (SBR) Latex market for the years 2024 – 2032, wherein 2022 is the base year and, 2024 to 2032 is the forecast period. Data for 2018-2022 has been included as historical data. The study gives a comprehensive viewpoint on market development, throughout the forecast period in terms of revenue estimates (in US$ Mn), across various regions, such as North America, Europe, Asia Pacific, Middle East & Africa and Latin America.

The report aims to offer a comprehensive analysis on the global Styrene Butadiene Rubber (SBR) Latex Market. It concentrates on the market dynamics, technological inclinations, and understandings on different end-user industries and product types. Additionally, it examines the key players and the competitive landscape in the global Styrene Butadiene Rubber (SBR) Latex market.

Get Report Sample @ https://isayresearch.com/sample/2291

List of Prominent Players:

Rockwood Lithium

AkzoNobel

Chemtura

Asahi Kasei

Bridgestone

LANXESS

MICHELIN

China Petroleum & Chemical

JSR

Reliance Industries Limited

Zeon Corporation

LG Chem

Trinseo

KUMHO Petrochemical

Goodyear Rubber Company

Others

Read Full Report Summary @ https://isayresearch.com/report/2291/global-sbr-latex-market/

Segmentations:

The global Styrene Butadiene Rubber (SBR) Latex market is categorized depend on types, applications, and regions. The segmental analysis emphases on revenue and forecast by region, by type, and by application for the period 2018-2028. The geographical segmentation consists of the historic as well as forecast demand for North America, Europe, Asia Pacific, Latin America, and Middle East & Africa.

Segmentation of Global SBR Latex Market:

By Type:

Emulsion SBR Latex

Solution SBR Latex

By Application:

Paper Processing

Fiber Processing

Glass Fiber Processing

Mortar Additives

Paints and Coatings

Adhesive

Regional Analysis:

The global Styrene Butadiene Rubber (SBR) Latex market report provides in-depth assessment of the growth and other aspects in important regions, such as United States, Canada, United Kingdom, Germany, France, China, Japan, India, Mexico, Brazil, GCC Countries, and South Africa etc. Key regions covered in the report are North America, Europe, Asia-Pacific, Latin America and Middle East and Africa. The report provides detailed valuation of the development and other aspects of the global Styrene Butadiene Rubber (SBR) Latex market in important countries (regions), including:

North America (U.S., Canada)

Europe (UK, Germany, France, and Rest of Eu)

Asia-Pacific (China, Japan, India, Rest of APAC)

Latin America (Mexico, Brazil, and Rest of LA)

Middle East and Africa (GCC countries, South Africa, and Rest of MEA)

Read More Insight @ https://www.linkedin.com/pulse/sbr-latex-market-analysis-key-technologies-industry-insights-ramsey-earjf

Key Benefits of the Report

This study presents the analytical depiction of the global Styrene Butadiene Rubber (SBR) Latex industry along with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global Styrene Butadiene Rubber (SBR) Latex market share.

The current market is quantitatively analyzed from 2021 to 2028 to highlight the global Styrene Butadiene Rubber (SBR) Latex market growth scenario.

Porter’s five forces analysis illustrates the potency of buyers & suppliers in the Styrene Butadiene Rubber (SBR) Latex market.

The report provides a detailed global Styrene Butadiene Rubber (SBR) Latex market analysis depending on competitive intensity and how the competition will take shape in coming years.

Company Profile

iSay Research is the leading research company offering both tactical and strategic support to all our customers. Customer satisfaction is our goal and that is why, we have a team of skilled and experienced specialist with the ability to do data mining, information management, and revenue enhancement solutions to ensure that our clients make informed decisions when coming to investing in the market.

Contact

iSay Solutions LLC

166 Geary St. 15th Floor Suite #212,

San Francisco, California 94108,

United States

Tel: +14156709191

Email: [email protected]

0 notes

Text

United States Styrene Butadiene Rubber (SBR) Market Industry Trends, Share, Forecast 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the United States styrene butadiene rubber (SBR) market size at USD 1.41 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects United States styrene butadiene rubber (SBR) market size to grow at a significant CAGR of 6.45% reaching a value of USD 2.06 billion by 2029. Major growth drivers for the United States styrene butadiene rubber (SBR) market include an increasing interlinking of polymer chains brought on by oxidation. Unlike natural rubber, which tends to harden with time, SBR retains its softness due to this cross-linking, rendering it a favorable material for manufacturing tires. This distinctive property underscores SBR's prominence as a preferred option within the market. The demand for SBR is particularly significant in the tire industry due to these attributes. Also, as the population grows, leading to higher vehicle demand and subsequently increased tire production, the demand for SBR is expected to rise in the USA. Also, its non-slip attributes make SBR suitable for producing footwear soles and heels, contributing notably to market expansion. It is projected that the USA's styrene butadiene rubber (SBR) market will likely reach a volume of 1500 thousand tons throughout the forecast period. However, fluctuations in prices of raw materials and limited supplies of natural rubber are anticipated to restrain the overall market growth during the forecast period.

United States Styrene butadiene rubber (SBR) Market – Overview

Styrene butadiene rubber (SBR) is a synthetic rubber derived from the copolymerization of styrene and butadiene. The predominant method for its production is emulsion polymerization. SBR boasts exceptional mechanical attributes, including high heat resistance, strong tensile strength, resistance to cracking and tearing, and notable resilience. Consequently, it finds widespread application, notably in tire manufacturing. Often combined with natural rubber for enhanced resilience, SBR is employed in various industries, such as tire production, conveyor belts, foam articles, adhesives, sealants, domestic mats, footwear soles, chewy candy, food container adhesives, car mats, brake pads, tubing, V-belts, floor coverings, military tank pads, and rubberized battery box cases.

Sample Request @ https://www.blueweaveconsulting.com/report/united-states-styrene-butadiene-rubber-market/report-sample

Impact of COVID-19 on United States Styrene butadiene rubber (SBR) Market

COVID-19 pandemic adversely affected the United States styrene butadiene rubber (SBR) market. It led to disruptions in supply chains, reduced manufacturing capacities, and shifts in consumer demand. Lockdown measures and reduced economic activity during the pandemic's peak resulted in decreased demand for automotive and industrial products, influencing SBR utilization. While the gradual recovery in economic activities led to a rebound in demand, challenges remained due to supply chain bottlenecks and labor shortages. The pandemic emphasized the need for resilient supply chains and adaptive production strategies to navigate uncertainties and ensure the United States SBR market's sustained growth amidst such unprecedented challenges.

United States Styrene butadiene rubber (SBR) Market – By Application

Based on application, the United States styrene butadiene rubber (SBR) market is divided into Tires, Industrial, Footwear, Polymer Modification, and Adhesives segments. The tires segment held the highest share in the United States styrene butadiene rubber (SBR) market by application. SBR's unique blend of mechanical properties, such as durability, abrasion resistance, and high tensile strength, make it a preferred material for tire production. As the automotive sector continues to grow, the demand for high-quality, long-lasting tires has surged. SBR's ability to enhance tire performance and safety while meeting stringent industry standards has propelled its widespread adoption. This strong alignment between SBR's properties and tire manufacturing requirements underscores its dominant position in the United States SBR market within the tires application segment.

Competitive Landscape

Major players operating in the United States styrene butadiene rubber (SBR) market include Goodyear Tire and Rubber, LANXESS AG, Lion Elastomers, Bridgestone Corporation, Trinseo, Zeon Chemical, Dow Chemical, INEOS Styrolution, Chevron Phillips Chemical Company, and Sinopec. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Styrene Butadiene Rubber Market Size, Share, Demand and Trends by 2022-2032

The global styrene butadiene rubber market is anticipated to create an absolute dollar opportunity by exhibiting a healthy CAGR of 5.5% between 2022 and 2032. The market is expected to reach US$ 10,584.3 Mn in 2022 and is anticipated to surpass US$ 18,079.6 Mn by 2032.

As per the historic analysis of FMI, styrene-butadiene rubber sales grew at a CAGR of 5.2% between 2016 and 2021, owing to the use of rising applications including tires, footwear, and polyurethane adhesives among other. The rising demand for synthetic and processed rubber is predicted to improve the sales of styrene-butadiene.

End-use industries are rapidly inclining towards synthetic rubber over natural rubber in the automotive tire industry which is expected to bolster growth in the styrene butadiene rubber market. Over recent years, the use of synthetic rubbers such as styrene-butadiene has witnessed impressive growth due to technological advancements coupled with rising applications in the industrial and automotive sectors. Backed by these factors, Future Market Insights (FMI) expects styrene butadiene rubber sales to reach US$ 18,079.6 Mn in 2032.

Key Factors

The styrene-butadiene rubber is becoming the consumer’s preferable choice because of its impeccable properties such as excellent heat resistance, low rolling resistance, wear resistance, and abrasion resistance. Therefore, end-users are inclining toward styrene butadiene rubber in the automotive industry. These above factors are expected to fuel the expansion of the global styrene butadiene rubber market in the coming years.

Get Your 30% Discount Now! Request for Sample @ https://www.futuremarketinsights.com/reports/sample/rep-gb-5756

Due to the rise in sales of automobiles all over the world, the demand for styrene butadiene rubber is predicted to surge over the forecast period (2022-2032). As per the segmentations, the solution SBR segment is likely to witness the fastest growth during the forecast period.

Demand for solution SBR is predicted to increase in the footwear application, fueling the sales in the market. As per the studies, styrene-butadiene rubber is considered to be the most processed and synthetically manufactured rubber.

The production of products and parts of products including car tires, mechanical rubber equipment or machine parts, and shoe soles, among others, are all made of this product. One of the major key factors expected to drive its growth in the styrene butadiene rubber (SBR) market is rising demand from the tire manufacturing industry.

In addition to that, surging demand for new automobiles and replacement tires along with the rising interest for synthetic rubber over industrial rubber is expected to fuel market growth. Styrene butadiene rubber has inherent advantages in terms of stability and physical properties, driving growth in the market.

Competitive Landscape

Leading manufacturers of styrene butadiene rubber primarily focus on developing sustainable butadiene in order to avoid being impeded by stringent government rules that restrict the use of chemically manufactured butadiene in various regions. To efficiently fit into the increasingly popular circular economy trends, SBR manufacturers are focusing on achieving sustainability in their business models.

Styrene Butadiene Rubber Market by Category

By Type:

Emulsion SBR (E-SBR)

Solution SBR (S-SBR)

By Application:

Tires

Footwear

Gaskets & Hoses

Adhesives & Sealants

Conveyor Belts

Electric

By Region:

North America

Latin America

East Asia

Europe

South Asia & Pacific

Middle East & Africa

More Insights into the Styrene Butadiene Rubber Market

The U.S. is considered to dominate the global styrene butadiene rubber market in the North American region. Due to the rising popularity of electric vehicles, the overall sales of automobiles in the U.S. are expected to spur over the estimation period. This will also surge the demand for tires, which will in return boost sales of styrene butadiene rubber and styrene butadiene rubber latex.

Styrene butadiene rubber suppliers in the U.S. will also be benefitted from lucrative business opportunities brought on by the presence of leading industry players in the country. These aforementioned factors are anticipated to boost the growth in the U.S. styrene butadiene rubber market during the forecast period.

Attributed to the strict government initiatives and thriving automotive industry has encouraged the growth of the manufacturing sector, opportunities for suppliers of styrene butadiene rubber are expected to boost the market. Styrene butadiene rubber (SBR) demand witnessed a noticeable increase in China by registering a growth of 6.3% throughout the forecast period.

Browse Full Report: https://www.futuremarketinsights.com/reports/styrene-butadiene-rubber-market

0 notes

Text

Styrene Butadiene Rubber Market Size, Share, Industry Analysis, Future Growth, Segmentation, Competitive Landscape, Trends and Forecast by 2026

According to Future Market Insights, over US$ 5.6 Bn worth of styrene butadiene rubber will be sold across the globe by the end of 2017. The forecast study further reveals that by the end of the forecast period, 2017-2026, the global styrene butadiene rubber market will have expanded at a moderate CAGR of 4.3% to reach a value of US$ 8.2 Bn.

The demand for synthetic rubbers continues to witness an upsurge as companies fail to find competent natural substitutes. In the view of changing industrial applications, styrene butadiene rubber has emerged as one of the greatest synthetic rubbers used in the automotive industry. With exceptional properties, products made of styrene butadiene rubber are finding applications across multiple industrial verticals.

A range of factors influencing the dynamics of the global styrene butadiene rubber market have been analysed in the study. Environmental concerns are addressed as the key restraint that will limit styrene butadiene rubber from incurring high sales. Being one of the highest forms of synthetic rubbers, production of styrene butadiene rubber is strictly regulated and companies are compelled to comply with the standards set by environmental protection agencies around the world. Despite the compliance, manufacturers of styrene butadiene rubber are forced to constrain their production in the face of growing demands. Companies namely, Asahi Kasei, Lanxess, LG Chem, Polimeri Europa, Sinopec, and Lion Elastomers are expected to be active as leading manufacturers in the expansion of the global styrene butadiene rubber market through 2026.

In addition, the global styrene butadiene rubber market is also witnessing flak of industrial regulatory bodies that coerce manufacturers for not enforcing strong recycling measures. Styrene butadiene rubbers being dumped in the ground or in the open are becoming one of the world’s gravest problems with respect to environmental pollution. Nevertheless, robust growth in the global automotive industry continues to bolster the sales of styrene butadiene rubber as they are predominant used in production of automotive tyres.

Automotive Tyre Applications of Styrene Butadiene Rubber to Register Highest Sales

The study has forecasted that in 2017 and beyond, the use of styrene butadiene rubber emulsions and solutions in the automotive industry will record the highest growth, particularly with respect to their tyre application. Effectiveness of styrene butadiene rubber in affixing tyres to the wheel rims will continue to drive the sales in the coming years. By the end of the forecast period, sales of styrene butadiene rubber in automotive tyre applications will rake in over US$ 5.8 Bn in global revenues.

The study also projects that the demand for styrene butadiene rubber solutions will be comparatively higher than that of styrene butadiene rubber emulsions. By the end of 2026, more than US$ 5.7 Bn worth of styrene butadiene rubber solutions are expected to be sold in the global market.

APEJ to Represent Largest Market for Styrene Butadiene Rubber

With respect to the global production of automotive vehicles and components, countries such as India, China, and South Korea are at the forefront. The booming automotive industry in the Asia-Pacific excluding Japan (APEJ) region is estimated to factor the brimming sales of styrene butadiene rubber in this region. During the forecast period, the APEJ styrene butadiene rubber market is anticipated to expand at a CAGR of 4.6%. The demand for styrene butadiene rubber is also expected to be high in parts of Europe, North America, and Middle East & Africa (MEA).

For More Info - https://www.futuremarketinsights.com/reports/styrene-butadiene-rubber-market

0 notes

Text

The Tackifier Resin Dispersions Market to move around with green innovation between 2017 - 2025

Global Tackifier Resin Dispersions Market: Introduction

Tackifier resin dispersions are aqueous, solvent-free dispersions which are mainly used in the manufacturing of pressure-sensitive adhesives based on natural rubber and acrylic or carboxylated styrene-butadiene rubber (SBR) emulsions. These resin dispersions are recommended as environment-friendly in various applications, especially in adhesion to polyethylene and polypropylene packaging substrates.

Different types of Tackifier resin dispersions such as rosin ester series, terpene phenolic resin series, and polymeric rosin are used in adhesives for automotive, building & construction and so on. Depending on their end-use, different kinds of Tackifier resin dispersions are employed in different end use industries. For example, natural rubber based, acrylic and SBR based Tackifier resin dispersions are used in the manufacturing of waterborne pressure-sensitive adhesives, which are used in paper label & tape and waterborne adhesives are used in automotive and building & construction.

Request For Report Sample@ https://www.persistencemarketresearch.com/samples/13789

Global Tackifier Resin Dispersions Market: Market Dynamics

Tackifier resin dispersions are used across various end-use industries such as packaging, building & construction, automotive, and nonwovens. Upsurge in different end-use product demand & industrial development are the crucial factors boosting the demand for tackifier resin dispersions, which in turn, is propelling the overall growth of global tackifier resin dispersions market. With the strengthening of government rules and regulations to protect the environment, demand for environment friendly solvent free resin dispersions is expected to increase in upcoming years that drives the overall tackifier resin dispersions market over the forecast period.

The transportation of tackifier resin dispersions is not easy as it has limited shelf life, low water content, and low freeze resistance. Hence, it is difficult to make this resin dispersions available in right time and at right place. This is an important factor restraining growth of the global tackifier resin dispersions market.

Today, the use of adhesives based on water dispersions of polymers become more crucial part of the global adhesive industry, which directly impacts the overall tackifier resin dispersions market. When the base polymer for the adhesive is dispersed in water, the tackifier resin dispersions and other components of the system disperse readily in the latex or it is to be supplied in dispersed form.

Request For Report Table of Content (TOC)@ https://www.persistencemarketresearch.com/toc/13789

Global Tackifier Resin Dispersions Market: Market Segmentation

The global tackifier resin dispersions market can be segmented on the basis of product type, chemistry, tackifier families, application, and end use industries. On the basis of product type, global tackifier resin dispersions market can be segmented into rosin acid based dispersions, rosin ester based dispersions, hydrocarbon resin-based dispersions, resin dispersions based on hybrid feedstock, and others. On the basis of chemistry, global tackifier resin dispersions market can be segmented into rosin ester series, terpene phenolic resin series, polymeric rosin, hydrocarbon resin(C5/C9), acrylic based, VAE (Vinyl acetate-ethylene) latex, water-borne polyurethane, Chloroprene (chlorobutadiene) rubber latex, natural rubber latex, and others. On the basis of application, global tackifier resin dispersion market can be segmented into assembly adhesives, bookbinding adhesives, footwear & leather, tapes & labels, etc. On the basis of end use industry, global tackifier resin dispersion market can be segmented into automotive, building & construction, nonwovens, and packaging.

Global Tackifier Resin Dispersions Market: Region-wise Outlook

North America and Europe are expected to remain key regions in the global tackifier resin dispersions market throughout the forecast period. Asia-Pacific is also expected to account for a significant market share over the forecast period.

Global Tackifier Resin Dispersions Market: Market Participants

Examples of some of the market players identified across the value chain, who are involved in the manufacture of tackifier resin dispersions include ,

Eastman Chemical Company

Lawter

a Harima Chemicals, Inc.

Dyna-Tech Adhesives

RESPOL RESINAS, S.A.

GUANGXI TONE RESIN CHEMICAL CO., LTD

BAOLIN Chemical Industry Co., Ltd.

DANQUINSA GmbH

Kraton Corporation

Schill + Seilacher “Struktol” GmbH

VALPAC, Inc.

DRT- The Resiniques Derivatives and Terpeniques

Teckrez, Inc.

Wakol GmbH (U.S. subsidiary of Loba Chemie)

Arkema Coating Resins

Aquaspersions Limited

For in-depth competitive analysis, buy now@ https://www.persistencemarketresearch.com/checkout/13789

About us:

Persistence Market Research is always way ahead of its time. In other words, it tables market solutions by stepping into the companies’/clients’ shoes much before they themselves have a sneak pick into the market. The pro-active approach followed by experts at Persistence Market Research helps companies/clients lay their hands on techno-commercial insights beforehand, so that the subsequent course of action could be simplified on their part.

Contact us:

Persistence Market Research

305 Broadway, 7th Floor

New York City, NY 10007

United States

Ph.no. +1-646-568-7751

E-mail id- [email protected]

0 notes

Text

Polymerized Styrene Butadiene Rubber Market Analysis By Requirements, Demands and Supply 2020-2026

The global research report titled “Polymerized Styrene Butadiene Rubber Market” has recently been published by The Research Insights which helps to provide guidelines for the businesses. It has been aggregated based on different key pillars of businesses such as drivers, restraints, and global opportunities. This Polymerized Styrene Butadiene Rubber Market research report has been compiled by using primary and secondary research techniques. Finally, researchers direct their focus on some significant points to give a gist about investment, profit margin, and revenue.

(Get Impressive Discount)

Download a Sample Copy of This Report(including full TOC, Tables and Figures):

https://www.theresearchinsights.com/request_sample.php?id=369374&mode=Arundhati

The report presents the market competitive landscape and a corresponding detailed analysis of the major vendor/key players in the market. Top Companies in the Global Polymerized Styrene Butadiene Rubber Market: LANXESS, Firestone, Asahi Kasei, JSR, LANXESS, Michelin, Goodyear, Trinseo, Kumho Petr, Dynasol

This report segments the global Polymerized Styrene Butadiene Rubber Market based on Types are:

Emulsion SBR

Solution SBR

Others

Based on Application, the Global Polymerized Styrene Butadiene Rubber Market is segmented into:

Tires

Adhesives

Footwear

Bitumen modification

Othe

Buy Exclusive Report @:

https://www.theresearchinsights.com/checkout?id=369374&mode=Arundhati

Regional analysis of Global Polymerized Styrene Butadiene Rubber Market:

Geographically, the global Polymerized Styrene Butadiene Rubber Market has been fragmented into several regions such as North America, Latin America, Asia-Pacific, Africa, and Europe based on the productivity of several companies. Every segment along with its sub-segments is analyzed in the research report. The competitive landscape of the market has been elaborated by studying numerous factors such as top manufacturers, prices, and revenue.

The information on the global Polymerized Styrene Butadiene Rubber Market is accessible to readers in a logical chapter-wise format. Driving and restraining factors have been listed in this research report, which helps to understand positive and negative aspects in front of the businesses.

Access Full Report information with TOC, here:

https://www.theresearchinsights.com/reports/COVID19-Global--China-Polymerized-Styrene-Butadiene-Rubber-Market-Research-by-Company-Type--Application-20152026-369374?mode=Arundhati

What are the market factors that are explained in the report?

-Key Strategic Developments: The Polymerized Styrene Butadiene Rubber Market study also includes the key strategic developments of the market, comprising R&D, new product launch, M&A, agreements, collaborations, partnerships, joint ventures, and regional growth of the leading competitors operating in the market on a global and regional scale.

-Key Market Features: The Polymerized Styrene Butadiene Rubber Market report evaluated key market features, including revenue, price, capacity, capacity utilization rate, gross, production, production rate, consumption, import/export, supply/demand, cost, market share, CAGR, and gross margin. In addition, the study offers a comprehensive study of the key market dynamics and their latest trends, along with pertinent market segments and sub-segments.

-Analytical Tools: The Global Polymerized Styrene Butadiene Rubber Market report includes the accurately studied and assessed data of the key industry players and their scope in the market using several analytical tools. The analytical tools such as Porter’s five forces analysis, SWOT analysis, feasibility study, and investment return analysis have been used to analyze the key players' growth in the market.

Customization of the Report: This report can be customized as per your needs for additional data up to 3 companies or countries or 40 analyst hours.

About us:

The Research Insights – A global leader in analytics, research, and advisory that can assist you to renovate your business and modify your approach. With us, you will learn to take decisions intrepidly. We make sense of drawbacks, opportunities, circumstances, estimations, and information using our experienced skills and verified methodologies. Our research reports will give you an exceptional experience of innovative solutions and outcomes. We have effectively steered businesses all over the world with our market research reports and are outstandingly positioned to lead digital transformations. Thus, we craft greater value for clients by presenting advanced opportunities in the global market.

Contact us:

Robin

Sales manager

Contact number: +91-996-067-0000

https://www.theresearchinsights.com

0 notes

Text

Persulfates Market Size Forecast to Reach $862.83 Million by 2025

Persulfates Market size is forecast to reach $862.83 million by 2025, after growing at a CAGR of 3.40% during 2020-2025. Persulfates are an inorganic compound with more oxygen than normal sulphates. It acts as an oxidizing agent and produced by the electrolysis of a sulfate solution. It is also known as peroxysulfate. It decomposes the material into harmless metal sulfates. Persulfates have many properties like current density, low temperature, strong oxidants with a temperate shelf life using acidic solution owing to oxidation of water. Increasing demand of persulfates in pulp, paper and textiles and the Cosmetics & personal care industry is expected to drive the persulfates market during the forecast period.

Persulfates Market Overview Segment Analysis - By Type

Sodium persulfate segment held a significant share in persulfates market in 2019. Sodium persulfate is a strong oxidizing agent and is used extensively in polymers. Moreover, it is used as an etchant and cleaning agent in PCB manufacturing. It is the second most expensive chemical after ammonium persulfate. The demand for sodium persulfate in cosmetics & personal care end-use industry is projected to grow at the highest rate during the forecast period. On the other hand, ammonium persulfate is a strong oxidizing agent with a slight acrid odor.

Request for Sample of the Report @ https://www.industryarc.com/pdfdownload.php?id=16549

Report Price: $ 4500 (Single User License)

Persulfates Market Overview Segment Analysis - By Application

Bleaching and sizing agent segment held a significant share in persulfates market in 2019. Persulfates are used as bleaching agents in cosmetic & personal care products and in the pulp & and paper and textile industries. Persulfates are used as initiators in the emulsion polymerization reactions for synthesizing polymers of neopropene, polystyrene, acrylics, and polyvinyl chlorides. They are also used as initiators in the production of latex polymers used in applications such as paints, coatings, carpet backing etc. Another most common use of persulfates in the polymer industry is in the manufacturing of synthetic rubbers such as styrene butadiene and isopropene.

Persulfates Market Overview Segment Analysis - By End User Industry

Electronics segment held a significant share in persulfates market in 2019 growing at a CAGR of 3.58% during the forecast period. A persulfate also known as peroxysulfate, is a compound containing the anions of sulfur in normal tetrahedral geometry typical for S(VI) oxidation state. The persulfate salts are strong oxidizers. The growing demand of persulfates in electronics industry owing to usage in cleaning and etching of printed circuit substrates is projected to propel the persulfates market during the forecast period. Persulfates are used for surface cleaning of metals like brass, copper, nickel, aluminum, zinc, and titanium prior to coating, plating and adhesive bonding on electronic components, which is expected to boost the persulfates demand and stimulate its market.

However, with the ongoing COVID-19 outbreak, the end-use industries will be slowing down, except from some applications such as the gloves where latex polymer is used for manufacturing, polymer in food packaging and tissue papers. These slowing down of end-use industries will have an impact on the persulfate demand until 2021. China being the epicenter of COVID-19 has also impacted the persulfates market as more the 70% of the persulfates production capacity is in China.

Persulfates Market Overview Segment Analysis - Geography

Asia Pacific dominated the persulfates market with a share of more than 39%, followed by North America and Europe. In countries like China, India and Japan owing to the increasing demand from various end-user industries such as polymer, electronics, and cosmetics & personal care, the demand for persulfates has been increasing in the region. Growing preference of polymers over metals and rising consumer appliances demand in the region is boosting the polymer initiator sector in the region which is stimulating the persulfates market in the region.

Persulfates Market Drivers

Increasing usage of persulfates in various end user industries

Ammonium persulfate is a strong oxidizing agent with a slight acrid odor. Under the cosmetics & personal care segment, ammonium, potassium, and sodium persulfates are used as oxidizing agents in hair colorants and lighteners. These persulfates are used as preservative agents in food and as initiators in polymerization reactions. They are also useful as boosters in the stimulation of oil & gas wells. In electronics, persulfates act as etching agents for zinc and Printed circuit boards. They are also used as bleaching agents in cosmetic & personal care products and in the pulp & and paper and textile industries. Ammonium persulfate is used as a component of paper and paperboard in contact with aqueous, fatty, and dry foods and in cellophane films. Persulfates are also used for oxidative degradation of toxic substances and chemicals in waste water, which makes the water treatment process easy. Due to this, there is surge in the demand of persulfates for water treatment application.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=16549

Persulfates Market Challenges

Health effects

Allergic reactions, irritations, and rhinitis associated with cosmetic products made from ammonium persulfate are anticipated to restrict the growth of ammonia persulfates to some extent. Precautionary measures are needed to be taken care of during the handling, storage, and disposal of persulfate compounds as they pose health hazards. Issues related to handling, storage, and transportation of persulfates is anticipated to hinder the growth of persulfates to some extent. Persulfates exposure in dust form might cause irritation in throat, lungs, nose eyes and skin. Prolonged exposure may lead to breathing issues leading to asthmatic effects.

Persulfates are slightly irritating to the human skin at higher concentrations. They cause irritation to the human skin and the respiratory tract of occupationally exposed individuals. Therefore, their usage is regulated in developed countries such as the U.S. The toxicity of potassium persulfates is mild, but continuous exposure to them can cause negative effects on human health. The adverse effects caused by exposure to potassium persulfates include cancer, issues related to one’s reproductive systems, etc. Sodium sulfate is a well-known substitute for potassium persulfate in few analytical processes due to the similar qualities that are seen in both compounds.

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the persulfates market. In 2019, the market of persulfates has been consolidated by the top five players accounting for xx% of the share. Major players in the persulfates market are PeroxyChem, United Initiators, Mitsubishi Gas Chemical Company, Ak-Kim Kimya, Adeka Corporation and Fujian Zhanhua Chemical Company among others.

Geographical Expansion/ Acquisition

In 2020, Evonik has acquired PeroxyChem, which is a manufacturer of hydrogen peroxide, peracetic acid and persulfates for USD 625 million.

In 2019, United Initiators opened a new plant with 10 KT annual production capacity of sodium persulfates in Huaibei, China.

In 2018, United Initiators entered into a joint venture with VR Persulfates from India for the manufacturing of persulfates.

In 2017, PeroxyChem launched the Klozur series of sodium persulfate, as it is expected to be advantageous for use in-situ chemical oxidation (ISCO).

Key Takeaways

Growing application of persulfates in cosmetics & personal care industry and rising demand of soil remediation techniques are expected to offer various lucrative opportunities for the growth of market.

By end user industry, electronics segment is expected to dominate the market owing to the increase in the usage of persulfates in printed circuit boards to remove moisture.

Asia Pacific dominated the persulfates market.

Related Reports :

A. Ammonium Sulfate Market

https://www.industryarc.com/Report/15396/ammonium-sulfate-market.html

B. Ferric Sulfate Market

https://www.industryarc.com/Report/15853/ferric-sulfate-market.html

About IndustryARC: IndustryARC primarily focuses on Cutting Edge Technologies and Newer Applications market research. Our Custom Research Services are designed to provide insights on the constant flux in the global supply-demand gap of markets. Our strong team of analysts enables us to meet the client research needs at a rapid speed, with a variety of options for your business. Any other custom requirements can be discussed with our team, drop an e-mail to [email protected] to discuss more about our consulting services.

0 notes

Text

Polymer Emulsion Market Size, Analysis with Covid-19 Impact, Trends, Key Players Analysis, Top Vendors by 2030

The polymer emulsion market refers to the global industry involved in the production and distribution of polymer emulsions, which are colloidal suspensions of polymers in water. Polymer emulsions are widely used in various applications such as paints and coatings, adhesives, textiles, paper and paperboard coatings, and construction materials.

Here is some comprehensive information about the polymer emulsion market:

Market Overview:

• The polymer emulsion market has experienced significant growth in recent years, driven by increasing demand from end-use industries and the shift towards water-based formulations.

• The market is characterized by a wide range of polymer types, including acrylics, styrene-butadiene rubber (SBR), vinyl acetate polymers, and others.

• The market is segmented based on application, polymer type, end-use industry, and region.

Key Drivers and Trends:

• Environmental regulations and the need for sustainable solutions have led to a shift from solvent-based to water-based formulations, boosting the demand for polymer emulsions.

• Growing construction activities, particularly in emerging economies, have increased the demand for polymer emulsions in applications such as architectural coatings, sealants, and adhesives.

• The automotive industry's emphasis on lightweight materials and increased focus on water-based coatings in the automotive refinish segment have further contributed to market growth.

• Rising disposable incomes, urbanization, and changing consumer preferences for aesthetically appealing products have driven the demand for paints and coatings, thereby augmenting the polymer emulsion market.

• Technological advancements, such as the development of bio-based and eco-friendly polymer emulsions, are expected to create new opportunities for market expansion.

Market Segmentation:

• Based on polymer type, the market is segmented into acrylics, SBR, vinyl acetate polymers, polyurethane dispersions, and others.

• Application-wise, the market is divided into paints and coatings, adhesives and sealants, paper and paperboard coatings, textiles and nonwovens, and others.

• End-use industries for polymer emulsions include construction, automotive, textiles, packaging, and others.

• Geographically, the market is analyzed across regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

Competitive Landscape:

• The polymer emulsion market is highly competitive, with several key players operating on a global scale. Some of the prominent companies in the market include BASF SE, Dow Chemical Company, Arkema Group, Synthomer PLC, Celanese Corporation, and Wacker Chemie AG, among others.

• Companies are focusing on research and development activities to develop new and innovative polymer emulsions to cater to evolving customer needs.

• Mergers and acquisitions, collaborations, and strategic partnerships are common strategies adopted by market players to strengthen their market presence and expand their product portfolios.

Challenges:

• Fluctuating raw material prices, particularly for monomers used in polymer emulsion production, can impact the profitability of market players.

• Stringent environmental regulations and compliance requirements pose challenges in terms of formulating eco-friendly and low-VOC (volatile organic compound) products.

• Intense competition from alternative technologies such as powder coatings and solvent-based systems can hinder market growth.

Future Outlook:

• The polymer emulsion market is expected to witness steady growth in the coming years, driven by the increasing adoption of water-based coatings and adhesives across industries.

• The demand for bio-based polymer emulsions is likely to rise, owing to the growing emphasis on sustainability and environmental consciousness.

• Emerging economies, particularly in the Asia Pacific region, are anticipated to offer lucrative opportunities for market expansion due to rapid industrialization and infrastructure development.

0 notes

Text

Styrene Butadiene Rubber (SBR) Market Worth,Size, Trends, SWOT, PEST, Porter’s Analysis, For 2020–2028

The recent study, Styrene Butadiene Rubber (SBR) Market forecasts the business performance of the Styrene Butadiene Rubber (SBR) market for the forecast period, 2021 to 2028. The study considers the estimated period as the base duration and brings to light the important information associated with the market size, share and growth rate of the Styrene Butadiene Rubber (SBR) market. Apart from this, the research closely examines the market share occupied by some of the prominent market players in the Styrene Butadiene Rubber (SBR) market for the forecast period, 2021 to 2028. Researchers behind the research unmask vital statistics on market segmentation including product types, application, sale and geography.

This study relies on the evolution of the industry to derive the trends that are observed. A significant increase in the Asian and the Middle Eastern market is visible, which promises the expansion of the market in the coming years. The chemical industry has witnessed vast growth in the Chinese chemicals sector, which is in turn affecting the value-chain of the European chemicals market. Europe’s chemical market decline could also be blamed on slow innovation rates. The mobility trends that have been observed in the industry are indicative of a drop in the development of transportation fuels, which is pushing the manufacturers to rethink their petrochemical strategy, owing to the chemical and petrochemical integration. A global initiative to ban plastics widely in the market is stemming from the environmental impact of the resins. The Chinese market is highly influenced by the economic transitions, fuel regulations, technological developments, private ownership, capital cost advantage, international trade and progress in the specialty chemicals among others. North America is attracting massive investment for its gas-based chemicals. The growing uncertainties regarding the prices of crude oil will affect the competitive landscape. Meanwhile, factors such as fluctuating prices of crude oil, fiscal policies, rising geopolitical tensions, trade disputes coupled with currency fluctuations might cause a decline in the global growth of the market.

The Global Styrene Butadiene Rubber (SBR) market is forecast to reach USD 9,779.5 Million by 2028, according to a new report by Reports and Data. Styrene-Butadiene rubber (SBR) is one of the commonly used synthetic rubber consisting of butadiene and styrene monomers. There are various benefits associated with the use of this synthetic rubber, which are supporting the continuous growth of the market. Some of these mentionable traits are impact strength, excellent resilience, abrasion resistance, high tensile strength, among others.

For More Information | Request a Sample Copy @ https://www.reportsanddata.com/sample-enquiry-form/2502

In market segmentation by manufacturers, the report covers the following companies-

Sinopec, Lanxess, Michelin, The Goodyear Tire & Rubber Company, Eastman, JSR Corporation, LG Chemicals, SIBUR, Dynasol Elastomer, and LCY Chemicals.

Growth Prospects:

The packaging sector has been attempting to gain momentum in the past couple of years on the back of the massive boom of the e-commerce industry. The market growth will be credited to the e-commerce transport and shipment, personal care, household, food and beverage, and healthcare sectors for convenience packaging.

These aspects have pushed leading players to dedicate their resources towards new packaging designs or to reinvent existing packaging designs to accommodate higher convenience and manageability, which will drive the global Styrene Butadiene Rubber (SBR) market growth. The vintage packaging sector is also experiencing high demand, and even though it targets a limited consumer base, it is expected to grow at a rapid pace in the coming years.

In market segmentation by types of Styrene Butadiene Rubber (SBR), the report covers-

Emulsion Styrene Butadiene Rubber

Solution Styrene Butadiene Rubber

In market segmentation by applications of the Styrene Butadiene Rubber (SBR), the report covers the following uses-

Tire

Polymer modification

Footwear

Adhesive and sealant

Others

Get Your Copy at Discounted Price@ https://www.reportsanddata.com/discount-enquiry-form/2502

Apart from e-commerce, the growth of the packaging market is also subject to other promising applications such as food and beverage, healthcare, and fast moving consumer goods (FMCG). Packaging applications in each of these sectors are expected to grow individually at a stable growth rate. The competition in the packaging industry is getting fiercer with new entrants building a place for modern packaging concepts and established players trying to keep up with the evolving demands of the consumers.

This study on the Global Styrene Butadiene Rubber (SBR) market elaborates on the key expansion tactics adopted by leading participants to stay ahead in the competition. Additionally, the report also sheds light on growth opportunities existing in the market, which have piqued the interests of new players to enter the industry. The insightful information in the report will allow the reader to understand the competitive scenario focused on both big and small companies.

Key market trends:

The increasing prevalence of biodegradable plastics promises to be a popular trend dominating the industry in the forecast years. The growing environmental awareness and the stringent government-imposed regulations for governing the consumption of plastics are pushing the overall industry towards the use of biodegradable packaging.

Another major packaging market trend that is speedily gaining momentum is the introduction of innovative lightweight glass packaging aimed at improving end-user usability and waste reduction. These packaging designs offer recyclability, easy transportability, and cost-effectiveness, which has urged manufacturers to produce water-resistant and eco-friendly corrugated box packaging solutions.

Another significant packaging market trend quickly gaining momentum is the development of new lightweight glass packaging to improve end-user usability and reduce wastage. These packaging designs are recyclable, economical, and easy-to-transport, urging manufacturers to produce water-resistant, eco-friendly, and smart corrugated packaging technology.

Reasons for Purchasing the Global Styrene Butadiene Rubber (SBR) Market Report:

The report gives a detailed description of different market elements and the changing competitive landscape, helping the reader gain a competitive edge.

It also takes a holistic approach to give a 360° view of the industry, listing the drivers and restraints existing in the market.

The Global Styrene Butadiene Rubber (SBR) Market intelligence report offers accurate market insights for a period of eight years, which have been derived after an in-depth evaluation of industry-wide data.

The data provided in the report is intended to help readers make business decisions to capitalize on the existing opportunities in the key market segments and sub-segments.

The growth of this Styrene Butadiene Rubber (SBR) market across the globe is dependent on multiple factors; including consumer base of several Styrene Butadiene Rubber (SBR) products, inorganic growth models adopted by companies, price volatility of feedstocks, and product innovation, along with their economic prospects in both producer and consumer nations.

Browse Table of Contents with Facts and Figures of Styrene Butadiene Rubber (SBR) Market Report@ https://www.reportsanddata.com/report-detail/styrene-butadiene-rubber-sbr-market

Overall, this report provides a clear view of every vital factor of the market without the need to refer to any other research reports or data sources. Our report will equip you with all the strategically vital facts about the past, present, and future of the market.

Read More Related Reports:

Quartz Crucible Market Overview

Proteolytic Enzymes Market Revenue

About Us:

Our in-house experts assist our clients with advice based on their proficiency in the market that helps them in creating a compendious database for the clients. Our team offers expert insights to clients to guide them through their business ventures. We put in rigorous efforts to keep our clientele satisfied and focus on fulfilling their demands to make sure that the end-product is what they desire. We excel in diverse fields of the market and with our services extending to competitive analysis, research and development analysis, and demand estimation among others, we can help you invest your funds in the most beneficial areas for research and development.

Contact Us:

John W

Head of Business Development

Reports And Data | Web: www.reportsanddata.com/

Direct Line: +1-212-710-1370

E-mail: [email protected]

Browse More Related Reports:

https://world.einnews.com/pr_news/552028647/medical-adhesives-market-drivers-shaping-future-growth-revenue-usd-14-78-billion-by-2027-cagr-7-0

0 notes

Text

Global Styrene Butadiene Rubber Market Outlook

Buy Now

Styrene-butadiene rubber or SBR is a synthetic, processed rubber with the highest volume. This type of rubber is usually used to manufacture various products & parts of a product for instance car tires, driving couplings, shoe soles, automatic & mechanical rubber equipment or part of a machine, etc. Additionally, key properties of styrene-butadiene rubber account for its growing demand & usages like good aging ability, excellent heat resistance & wear resistance, low rolling resistance and abrasion resistance.

The global styrene-butadiene rubber market is growing faster due to its higher energy savings and lower fuel consumption, which favors the principle of sustainability. The global rubber market, in which styrene-butadiene rubber has a significant share, is growing at a higher CAGR over the forecast period, which is expected to drive demand for styrene-butadiene rubber in the next few years.

Referring to the study, ‘Global Styrene Butadiene Rubber (SBR) Market, 2021-2027’ the key companies operating in the global SBR market include LG Chem Ltd., Asahi Kasei Corporation, Sumitomo Chemical Asia Pte Ltd., Arlanxeo Holding B.V., Versalis S.p.A., Kumho Petrochemical Co., Ltd., China Petroleum & Chemical Corporation, Trinseo S.A. and among others. Key market players regularly adapt to new strategies and market scenarios in order to publicize the development of the styrene butadiene rubber market. The major market players are collaborating with several companies to continue their research on the expansion of the market. In addition, large companies tend to take over smaller companies and companies to expand their business.

Based on product type, styrene butadiene rubber market can be segregated as solution SBR and emulsion SBR. Emulsion SBR segment dominates the global market owing to wide arena of applications like in food contact & pharmaceutical articles, footwear, flooring adhesives, tires, and light-colored mechanical goods. In addition, based on application type, market can be segregated as footwear, adhesive, tire and polymer modification.

Rise in demand from the new automobile as well as replacement tires, followed by increase in application of styrene-butadiene rubber in different industries, rise in demand in emerging economies and increase in use of low rolling-resistance tires for reducing the fuel consumption are some major factors, which are responsible for growth of the styrene butadiene rubber market. Apart from this, strict regulatory implications to regulate the industry and limited application of styrene-butadiene may impact the market. Moreover, increase in need for lighter vehicles and rise in demand for synthetic rubber in various industries are leading opportunities for market.

Based on regional analysis, the Asia-Pacific region dominates the Global Styrene Butadiene Rubber Market owing to growth in automobile industry and highest number of emerging economies across the region. The Europe and North-America regions are estimated to witness higher growth rate due to increase in awareness regarding environmental protection, growth in footwear industry coupled with surge in tire manufacturing industry over the forecast period. It is projected that future of the global styrene butadiene rubber market will be bright on account of increase in usage of natural rubber and SBR crossover products during the forecast period.

For More Information, refer to below link:-

Global Styrene Butadiene Rubber (SBR) Market Growth Rate, 2021-2027

Related Reports

Global Polymerized Styrene Butadiene Rubber Market 2020 by Manufacturers, Regions, Type and Application, Forecast to 2025

Styrene-Butadiene Rubber (SBR) Industry Outlook in China to 2022 - Market Size, Company Share, Price Trends, Capacity Forecasts of All Active and Planned Plants

Contact Us:-

Ken Research

Ankur Gupta, Head Marketing & Communications

+91-9015378249

#Styrene Butadiene Rubber Market#Global Styrene Butadiene Rubber Market#Global Styrene Butadiene Rubber Market Analysis#Global Styrene Butadiene Rubber Market Revenue#Global Styrene Butadiene Rubber Market Share#Global Styrene Butadiene Rubber Market Size#Global Styrene Butadiene Rubber Market Growth#Global Styrene Butadiene Rubber Market Trends#Global Styrene Butadiene Rubber Market Forecast#Global Styrene Butadiene Rubber Market Competition#Global Styrene Butadiene Rubber Market Growth Strategy Report#Global Styrene Butadiene Rubber Market Revenue Forecasting

0 notes

Text

Adhesive Formulating Technology Market Analysis by Current Industry Status and Growth Opportunities, Top Key Players, Target Audience and Forecast to 2028

The increase in demand for adhesives from the building and construction industry is likely to influence the growth of the adhesive formulating technology market. In line with this, the high growth in the appliance industry is also acting as a key determinant which will favor the growth of the adhesive formulating technology market over the forecast period of 2021 to 2028. Furthermore, the favorable government regulations and rise in the demand for adhesives in the medical industries are also expected to positively impact the growth of the adhesive formulating technology market. The major factor which is expected to forward the growth of the market is the rapid industrialization, strong GDP growth as well as increase in manufacturing output.

The adhesive formulating technology market is expected to grow at a compound annual growth rate of 8.85% for the forecast period of 2021 to 2028. Data Bridge Market Research report on adhesive formulating technology market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecasted period while providing their impacts on the market’s growth.

Get Sample Copy of Report@ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-adhesive-formulating-technology-market

Adhesives can be defined as social substances that are capable to join permanently to surfaces, by an adhesive process. The purpose of formulating technology is to optimized employment of technologies so as to save the costs of complex structures in industrial businesses.

However, the fluctuating raw material prices and environmental regulations are expected to act as key restraint towards adhesive formulating technology market growth rate in the forecast period of 2021 to 2028. Whereas, the shifting rules and changing standards is expected to challenge the growth of the adhesive formulating technology market in the above mentioned forecast period.

Furthermore, the high demand for non-hazardous, green, and sustainable adhesives and the growth of hybrid resins for manufacturing high-performance adhesives are expected to offer a variety of growth opportunities for the adhesive formulating technology market in the above mentioned forecast period.

This adhesive formulating technology market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on adhesive formulating technology market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Browse Complete Report@ https://www.databridgemarketresearch.com/reports/global-adhesive-formulating-technology-market

The adhesive formulating technology market is segmented on the basis of technology type, product and application. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target markets.

Based on technology type, the adhesive formulating technology market is segmented into water-based, solvent-based, hot-melt, reactive and others. Water-based has further been segmented into PVA emulsion adhesives, PAE emulsion adhesives, VAE emulsion adhesives and others. Others have further been sub-segmented into polyurethane dispersion adhesives and water-based rubber adhesives. Solvent-based has further been segmented into styrene-butadiene styrene rubber (SBSR) adhesives, chloroprene rubber (CR) adhesives, polyvinyl acetate (PVA) adhesives, polyamide adhesives and others.

Hot-melt has further been segmented into EVA adhesives, styrenic block copolymer (SBC), copolyamides (COPAS), amorphous poly alpha olefins (APAOS) and others. Reactive has further been segmented into polyurethane adhesives, epoxy adhesives and cyanoacrylate adhesives. Polyurethane adhesives have further been sub-segmented into liquid and reactive hot-melt (RHMs) adhesives.

Enquire About Report@ https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-adhesive-formulating-technology-market

On the basis of product, the adhesive formulating technology market is segmented intoacrylic, PVA, polyurethanes, styrenic block, epoxy, EVA and others.

The application segment for adhesive formulating technology market is segmented into paper and packaging, building and construction, woodworking, consumer and DIY, automotive and transportation, leather and footwear, assembly, medical, electronics and others.

The adhesive formulating technology market is analyzed and market size, volume information is provided by country, technology type, product and application type as referenced above.

The countries covered in the market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

North America leads the adhesive formulating technology market because of the rapid change in the consumer behavior and rapid shift in the inclination towards more recyclable products. Europe is expected to expand at a significant growth rate over the forecast period of 2021 to 2028 due to the increase in the high demand from automobile, medical, engineering, and electronics and strict environment regulations.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as consumption volumes, production sites and volumes, import export analysis, price trend analysis, cost of raw materials, down-stream and upstream value chain analysis are some of the major pointers used to forecast the market scenario for individual countries. Also, presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

The adhesive formulating technology market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to adhesive formulating technology market.

The major players covered in the adhesive formulating technology market report are Henkel AG & Co. KGaA, H.B. Fuller Company, SIKA AG, Arkema, 3M, Huntsman International LLC, Dow, Wacker Chemie AG, AVERY DENNISON CORPORATION, BASF SE, Bostik, Uniseal, Inc., Ashland, Beardow Adams, Master Bond Inc., DuPont, Akzo Nobel N.V., PPG Industries, Inc., PARKER HANNIFIN CORP., and Dymax among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Global Adhesive Formulating Technology Market, By Technology Type (Water-Based, Solvent-Based, Hot-melt, Reactive, Others), Product (Acrylic, PVA, Polyurethanes, Styrenic Block, Epoxy, EVA, Other), Application (Paper and Packaging, Building and Construction, Woodworking, Consumer and DIY, Automotive and Transportation, Leather and Footwear, Assembly, Medical, Electronics, Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Browse Chemical Related Report:

Non-woven Adhesives Market – Industry Trends and Forecast to 2028

Instant Adhesives Market – Industry Trends and Forecast to 2028

Label Adhesive Market – Industry Trends and Forecast to 2028

Acrylic Adhesives Market – Industry Trends and Forecast to 2028

Aerospace Interior Adhesive Market – Industry Trends and Forecast to 2028

0 notes

Text

Styrene Butadiene Rubber Market By Product Types And Application, Top Manufacturers Analysis Forecast 2020 to 2026 : LCY Chemicals, Versalis, Asahi Kasei Chemical Corporation, Styron-Trinseo