#Dodge ‘Zeder’

Text

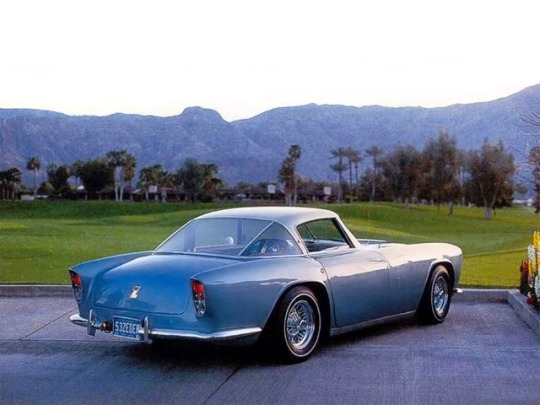

1953 Dodge ‘Zeder’ Storm Z-250

1953 Dodge ‘Zeder’ Storm Z-250 Concept with body by Bertone

One-off

The Storm Z-250 was developed by Chrysler engineer Fred Zeder to evaluate the feasibility of producing a vehicle that would capture a portion of the growing American sports car market.

Built on a rigid tube frame chassis (built mostly by Chrysler engineer, John Butterfield, in his basement), it was intended to be a dual-purpose sports/racing car because Zeder Jr. envisioned a car with swappable bodies.

In 1952, while on Christmas vacation in Europe, Zeder visited Fiat's Chief Engineer in Turin.

Dante Giacosa recommended a visit to Bertone.

Though they were busy designing and building the Alfa Romeo BAT series, they agreed to build the body for Zeder's new car and promised three months to finish the car.

It took nine months to finish.

Unique to the Storm Z-250 was that the comfortable ‘touring’ body could be removed by unscrewing four bolts and replaced with an ultralight 150-pound fiberglass body for ‘racing’.

The mechanical components of the car included a Dodge hemi V8 truck engine with 260hp and 330ft-lbs of torque.

Other parts came from Plymouth and Dodge vehicles, including brakes, radiator, clutch, fuel tank, rear axle, and the steering system.

The transmission was a new unit developed by the Spicer Division of Dana Corporation.

The Storm did not reach the assembly line because high production costs would have made it too expensive to sell in profitable quantities.

The Z-250 would have competed with the Ford Thunderbird, Chevrolet Corvette, and the Kaiser-Darrin.

Zeder drove the Z-250 for 16 years.

He loaned it to the Northwood University where it remained until 1992.

Unfortunately, water leaked into the cylinders so the engine was removed and replaced with a 1965 Dodge V8 with two four-barrel carburetors.

After the work was completed, Zeder continued to drive the car in his home in California.

#Dodge ‘Zeder’ Storm Z-250#Dodge ‘Zeder’#Dodge#Storm Z-250#car#cars#mopar#moparperformance#moparnation#moparworld

119 notes

·

View notes

Text

1953 Dodge ‘Zeder’ Storm Z-250 Concept with body by Bertone.

The Storm Z-250 was developed by Chrysler engineer Fred Zeder to evaluate the feasibility of producing a vehicle that would capture a portion of the growing American sports car market.

Built on a rigid tube frame chassis (built mostly by Chrysler engineer, John Butterfield, in his basement), it was intended to be a dual-purpose sports/racing car because Zeder Jr. envisioned a car with swappable bodies.

Unique to the Storm Z-250 was that the comfortable ‘touring’ body could be removed by unscrewing four bolts and replaced with an ultralight 150-pound fiberglass body for ‘racing’. The mechanical components of the car included a Dodge hemi V8 truck engine with 260hp and 330ft-lbs of torque. Other parts came from Plymouth and Dodge vehicles, including brakes, radiator, clutch, fuel tank, rear axle, and the steering system. The transmission was a new unit developed by the Spicer Division of Dana Corporation.

The Storm did not reach the assembly line because high production costs would have made it too expensive to sell in profitable quantities. The Z-250 would have competed with the Ford Thunderbird, Chevrolet Corvette, and the Kaiser-Darrin.

0 notes

Text

The Zeder Z-250, Dodge Storm or Bertone in May 1954. The vehicle remained as a concept car & was never produced.

2 notes

·

View notes

Photo

Dodge Storm Z-250 – 1953

Designer : Giovanni Michelotti

Carrozzeria : Bertone

Producer :Fred Zender

Motore : 8 cilindri a V di 90°

The Dodge Storm Z-250 was developed by Chrysler engineer Fred Zeder to evaluate the feasibility of producing a vehicle that would capture a portion of the growing American sports car market - absolutely fantastic.

658 notes

·

View notes

Photo

1953 Dodge Zeder 'Storm' Z-250 Bertone - fiberglass body, removable aluminum top, hemi V-8 via /r/Autos

2 notes

·

View notes

Text

Chrysler Parts-A Legacy of Innovation

Chrysler was established by a man who had gained notoriety for sparing foundering organizations. Walter Chrysler rose from the positions to turn into the leader of Buick. He left his position and was employed by Willy's Overland Motor Company to manage the restoration of its weak activities. He made a comparative showing by pivoting the Maxwell-Chalmers Company. In 1925, he bought Maxwell's resources for structure the firm that despite everything bears his name - Chrysler Corporation. Beside the Chrysler marque, the Plymouth and DeSoto marques were made to oblige the low estimated and medium evaluated parts of the bargains, separately. Chrysler procured The Dodge Brothers Motor Company and by turning off Imperial as a different extravagance brand in 1955, Chrysler has gathered a five-brand lineup to rival General Motors, which has a comparable contribution.

What sets Chrysler Corporation separated from other vehicle makers is its accentuation on car designing instead of styling. Walter Chrysler upheld building research and kept subsidizing the division even through the Depression time. Along these lines, Chrysler vehicles have been at the cutting edge of car building since Chrysler Six, Chrysler's first vehicle presented in 1924. The Chrysler Six is touted by numerous individuals as the principal present day vehicle, scoring a few firsts in the business, for example, an oil channel, air cleaner, high pressure motor, four-wheel water driven brakes, and other progressed Chrysler parts. Development additionally brought about part from the contribution of splendid designers since Chrysler's commencement who concocted those Chrysler parts and pushed the envelope of car building. The Three Musketeers, a trio of capable designers made out of Frederick Zeder, Owen Skelton, and Carl Breer set the course during Chrysler's initial years.

The Chrysler Corporation has experienced a progression of budgetary troubles, however it has consistently gotten through. The Plymouth and Dodge brands continued the organization during the Depression, when its presentation of the world's first streamlined vehicle, the Airflow, demonstrated a disappointment. National downturn again put the organization in the red in 1957 yet proceeding with developments like the now-standard unibody helped the organization recoup. The 1970's demonstrated expensive to Chrysler. Its huge speculation for another full-body lineup went down the channel as interest for enormous vehicles dove during the principal gas emergency in 1973. It was spared thus by a spike in deals of its old however littler compacts. Fruitless item dispatches and the second gas emergency would have killed Chrysler notwithstanding the 1 billion dollars the administration lent in 1979 to rescue the organization. With Lee Iacocca in charge and with another trio of skilled vehicle creators, the Gale-Herlitz-Creed group, Chrysler consistently recuperated and turned out to be by and by, a predominant power in the American car industry. in 1998, Chrysler converged with Daimler Benz to shape the Daimler Chrysler AG organization.

The Chrysler history is one in which development holds the key for long haul achievement. The energy for overhauling, refining, and searching for approaches to improve Chrysler parts and Chrysler all in all is the thing that the organization is about. Chrysler parts like the air channel, transmission modulator, torque converter, and slowing mechanisms all add to make Chrysler what it is today. A vehicle, all things considered, is an entirety of its parts.

0 notes

Text

RT @FoundV: 1953 Dodge Zeder Storm Z-250 by Bertone. Even available as a die-cast, I see. https://t.co/8IXdrhGfge

1953 Dodge Zeder Storm Z-250 by Bertone. Even available as a die-cast, I see. pic.twitter.com/8IXdrhGfge

— Peter Klobucar (@FoundV) April 14, 2019

via Twitter https://twitter.com/D_McNelly

April 15, 2019 at 09:09AM

0 notes

Text

392 Chrysler Hemi Build and Dyno Test: How Does the Whale Motor Respond to Bolt-On Speed Parts?

Fire Power Flirtations

In a 1952 presentation to the Society of Automotive Engineers titled “New Horizons in Engine Design,” Chrysler Engine Design Chief James Zeder wrote, “The power of an engine should be based on physique, not on stimulants.” Had Zeder been a sports coach addressing a locker room full of athletes, his message would have been akin to urging the guys to hit the gym instead of pumping steroids.

As we’ll see in this buildup of a Chrysler 392 Fire Power V8, there’s a lot of “physique” in the legendary whale motor. But who exactly was Zeder accusing of juicing with “stimulants” in his presentation? That would have been General Motors’ groundbreaking ’49 Caddy and Oldsmobile “Kettering” V8s (named after GM engine design boss Charles Kettering). No, GM wasn’t stashing hidden nitrous oxide systems in early Olds Rocket 88s and Coupe DeVilles; rather (in Zeder’s opinion), GM’s “Boss Kett’ was too reliant on high compression—and high-octane gasoline—to complete the picture.

In 1921, GM’s fuel research lab, led by Charles Kettering, discovered tetraethyl lead (TEL). The petroleum industry adopted it, and the problem of spark knock in car engines was greatly reduced. The addition of TEL to the nation’s fuel stocks allowed engine makers to nudge compression ratios upward from the Model T’s 3.98:1 into the 5s, 6s, and low 7s by 1940. The added compression was good for overall efficiency, not just peak power, as each drop of gas was better utilized.

So when GM conjured its new, post-WWII OHV V8s, it banked on ever-escalating compression ratios and publicly predicted the average passenger car engine would be as high as 12.5:1 by 1960. This was to be made possible by wartime advances in fuel quality, as the average octane jumped from 65 to 80 points after the war.

But Chrysler’s Zeder didn’t agree. He reasoned that relying on external factors like high-octane gas (the “stimulants”) would spell disaster if fuel shortages ever materialized and only low octane was available—which is what happened in the early 1970s with OPEC.

Elsewhere in Zeder’s 1952 SAE paper he wrote, “In recent years, so much attention has been paid to fuels that it is necessary to remind ourselves periodically that we work with a hot-air engine; and in order to get power out we must get air in…it is amazing how often the hot air finds its way into the advertising, and not into the engine.” Thus, instead of GM’s compression/octane-based strategy, Chrysler embraced the hemispherical combustion chamber for its “octane indifference,” i.e. ability to run on lousy gasoline.

Between July 1945 and December 1947, Chrysler built a group of experimental engines with many combustion chamber configurations, compression ratios, cylinder counts, and crankcase layouts. One of these engines would be chosen for mass production and play the key role of motivating Chrysler cars for the next decade. No pressure, right? Wedges, pent-roofs, Heron-style, and hemispherical combustion chambers were all evaluated, and through it all, the hemi-type proved its ability to make solid power without the need for high-quality fuel. “Physique” won out over “stimulants.”

In January 1948, the decision was made to bring the 331ci Hemi to reality for the ’51 model year. It was a humble start. With its single two-barrel carburetor, single exhaust system, and 7.5:1 compression, the inaugural ’51 Chrysler Fire Power delivered 180 hp at 4,000 rpm and 312 lb-ft at 2,000 rpm. But it was a full 20 hp ahead of Caddy’s top ’51 V8, which also utilized a 7.5:1 compression ratio, displaced the same 331 cubes, and inhaled through a single two barrel, but had wedge-type combustion chambers.

From there, the Hemi grew from strength to strength and spawned smaller DeSoto (1952) and Dodge (1953) siblings. By 1958, the Fire Power maxed out at 392 ci; and with a solid cam, dual Carter WCFBs, and 10:1 compression aboard the mighty 300D, it delivered 380 hp at 5,200 rpm and 435 lb-ft at 3,600 rpm.

But as history has shown, the octane race never materialized, and octane stabilized at 90 to 104 points for the next two decades. To suit these conditions, Detroit compression ratios languished in the 8.5 to 10.5:1 range, with sky-high numbers reserved for factory Super Stock applications. (Chrysler’s 413 Max Wedge tickled the 13.5:1 mark in 1962.) None of this validated—or discredited—either Kettering or Zeder’s strategy.

Seventy years later, we now know that the massive Hemi’s octane indifference was a largely unappreciated/unnecessary marketing feature. Instead, its breathing potential became the key selling point. Unfortunately, performance potential didn’t sell new cars, and the substantial added cost associated with its dual rocker shafts and jewel-like rocker arms triggered termination after the ’58 model year (though some ’59 Dodge trucks were Hemi equipped).

As the cheaper-to-produce wedge-head 413 big-block took over as Chrysler’s prime mover in 1959, the early Hemi became the go-to engine for nitro drag racers like Don “Big Daddy” Garlits and growing legions of rodders who simply appreciated its “physique.” With its broad shouldered look, there are few engines that gather a crowd when the hood goes up like a Hemi.

Let’s watch as Donnie Wood and the crew at R.A.D. Auto Machine exploit the whale’s physique with some interesting intake and exhaust goodies.

1. A 0.040-inch overbore brings the cylinders to 4.040 inches. The first-generation Hemi block lacks the crankcase skirt extensions of the second- (’64-’71) and third-generation (2003-present) blocks. This rules out cross-bolted main caps, but with quality machine work and assembly, it’ll handle 600 hp.

2. Like the post-WWII Cadillac 331, Oldsmobile 303, Studebaker 232, Ford Y-block, Buick nailhead, Pontiac 287, and Packard 320, the Fire Power’s tappet chamber is sealed by a baffled, stamped-steel cover. The CE57 stamping on the right-hand end of the block identifies this block as being from the ’57 model year.

3. The 68-pound, forged-steel 392 crank’s output flange is drilled for eight flywheel fasteners, just like the later 426 Hemi. But obviously, they’re not interchangeable. Key swap meet giveaways are the Fire Power’s non-threaded flange holes and absence of the raised flywheel/flexplate register ring seen on 426 Hemi cranks.

4. To set the thrust bearing, constant forward pressure is applied to the crank while the 2.6875-inch-diameter main caps are torqued to 90 lb-ft. Earlier 331 (’51-’54) and 354 (1955-1956) Hemi main- and rod-bearing diameters are smaller at 2.500 inches.

5. The pen points to the polishing work performed on the forged rod beams. For contrast, the factory-issue grainy surface texture (right) can trigger stress cracks. Earlier 331 and 354 rods are shorter than 392 units, 6.625 inches versus 6.951, and have smaller big ends, 2.250 inches versus 2.6875. The 392 block’s 10.865-inch deck height is also taller than the 331/354 block’s 10.38/10.32-inch respective spans. As such, 331/354 and 392 intake manifolds do not interchange without effort.

6. Spiral locks secure the floating pins within the KB Silv-O-Lite hypereutectic pistons. The 392’s “smallish” 103cc combustion chambers don’t require massive (and heavy) piston domes to achieve compression. By contrast, second-generation 426 Hemis have 172cc combustion chambers and require larger domes to achieve the same compression ratio.

7. The nearly flat pistons with valve relief notches yield a pump-gas-compatible 9.5:1 compression ratio, just half a point lower than the ’58 300D. With its 0.040 overbore, this 392 now displaces 398 ci. Rings are plasma-moly faced Speed Pro (PN 24122) gapped at 0.018/0.020 (top/second).

8. Lack of the rare and expensive adjustable rocker arms used in Chrysler 300D and certain marine/industrial applications forced us into a hydraulic cam. For this street-and-strip build, we opted for an Isky Mega 280 with 0.485-inch lift, 280/280 degrees advertised duration (232/232 @ 0.050-inch lift) on a 108-degree LSA. It’s hotter than the 300D cam’s 0.435/0.442-inch lift and 276/276 degrees of duration. The hydraulic lifters impose no penalties whatsoever at this level of performance.

9. A nifty vintage finned aluminum FGT multi-piece timing cover contains the Cloyes True Roller timing set (PN 9-1103). R.A.D. painted the engine black rather than the stain-prone silver paint originally used by Chrysler.

10. With the fresh ARP rod-cap fasteners torqued to 52 lb-ft, a stock 5-quart Chrysler center-sump oil pan and matched pickup tube work with the Hot Heads oil pump (PN 21920). Hot Heads offers a rear sump pan that’s ideal for most hot rod applications (PN 21811). Higher capacity oiling systems are also available from Hot Heads and Milodon, but the stock arrangement is adequate for this 6,000-rpm street machine.

11. Though 392 heads won’t spoil the recipe, earlier 331 heads are said to have better port floors. Bearing casting number 1556157-1, the stock 331’s 1.81/1.5-inch valves and seats are upsized to 2.00/1.75 inches, matching stock 392 dimensions. Metal was also removed from the throat area directly behind the valve heads.

12. Pop quiz: Which cylinder head is heavier, a 331 Hemi or a Chevy 454? Surprise! At 64.4 pounds bare, the Hemi is 3.8 pounds lighter than the fabled Rat! The free-flowing square intake (top) and ovoid exhaust ports (bottom) complemented the hemi chambers and have won countless races. Later 354 and 392 iron heads are also much lighter than Bow Tie goodies.

13. A set of Hot Heads dual valvesprings (PN 40062) works with the stock retainers and locks to deliver 135 pounds of pressure (closed) and 325 pounds at full lift. Installed height is 1.700 inches. P.C.-style seals control valve stem lubrication.

14. R.A.D.’s Donnie Wood carefully guides the heads into position atop the Best composite head gaskets (PN 585). Compressed, the gaskets are 0.040 inch thick and help deliver the 9.5:1 compression ratio. First-gen Hemi heads are interchangeable side to side as long as bolt-on caps seal the unused water passages at the firewall end of things.

15. Any Mopar 273, 318, 340, or 360 distributor will fit the 392 block as long as a Hot Heads intermediate shaft (PN 21930) and alignment collar are used, as shown here in the lifter galley.

16. Proven stable to more than 7,000 rpm (with sufficient valvesprings), the cast iron rocker-shaft stand hold-down bolts do double duty as head bolts. Though only four bolts pinch the head gasket atop each cylinder, the arrangement is bulletproof when naturally aspirated. Supercharged applications must employ studs and other tricks to increase clamping force.

17. For an extra measure of control, Hot Heads 3/8-inch diameter chrome-moly pushrods (PN 21086) with adjustable ends connect the lifters to the rocker arms. R.A.D. set them at half a turn beyond zero plunger lash.

18. R.A.D.’s Steve Chmura installs the vintage Mickey Thompson finned, cast-aluminum rocker covers. At 6.100 inches, second-generation (426-style) Hemi spark plug tubes are 0.250 inch too long for use on the 331-392. Hot Heads offers replacements for lost items.

19. Working with the Hot Heads driveshaft and alignment collar described earlier, a box-stock PerTronix Flame-Thrower billet aluminum distributor (PN D141700) fires the Autolite No. 65 plugs at 32 degrees BTDC. Though first- and second-generation Hemi spark plug tubes are not interchangeable, the wires and rigid insulators are. A set of 8mm Taylor wires (PN 75089) need only final trimming and terminal crimping for use.

20. The stock cast-iron 392 thermostat housing (in hands) is too short when 331 heads are used on a 392 block. Hot Heads remedies the hassle with a hose kit and adapter fittings (PN 21404). Though this dyno setup uses an electric water pump, Hot Heads offers numerous street- and strip-friendly alternates.

21. Hot Heads offers these adapter spacers (PN 20209) when using shorter 331 heads on the tall-deck 392 block. Two sets of gaskets are needed.

22. To evaluate the classic and the new, let’s compare a vintage 7263 Weiand dual-quad manifold (left) with a modern Hot Heads 50000 high-rise, single-four-barrel unit. With so much distance between the M/T rocker covers, will the single carburetor look naked compared to the dual-quad setup?

23. For the single-carb test, R.A.D. used a 750-cfm Quick Fuel double-pumper (PN HR-750) to meter fuel and air.

24. Exhaling through stock center-dump Chrysler New Yorker exhaust manifolds, the Quick Fuel carb delivered 408 hp at 5,500 rpm and 463.6 lb-ft at 3,300 rpm. Box stock metering is ideal.

25. Switching from stock manifolds (in hand) to Hot Heads 1-7/8-inch block-hugger headers (PN 60010) unleashed an extra 23 hp and 25.6 lb-ft. Hot Heads also offers a full line of under-chassis and equal-length headers as well as reproductions of the “big mouth” iron manifolds used on Chrysler 300 letter cars.

26. With the headers still in place, the old-school Weiand dual-quad intake manifold and tandem 500-cfm Edelbrock Performer carburetors (PN 1405) were installed. The twin Edelbrocks work just fine right out of the box, though the bottoms of the linkage arms interfere with the intake bolts. A simple trim solves the matter.

27. The dual carbs delivered 436.5 hp at 5,700 rpm and 440.4 lb-ft at 4,400 rpm. Sure, the extra 6.5 hp is nice, but losing 44.8 lb-ft of torque is a hard pill to swallow.

Sources

ARP; 800/826-3045; arp-bolts.com

Best Gasket; 888/333-2378; bestgasket.com

Edelbrock; 310/781-2222; edelbrock.com

Hot Heads; 336/352-4866; hothemiheads.com

Isky Racing Cams; 310/217-9232; iskycams.com

PerTronix; 909/599-5955; pertronix.com

Quick Fuel Technology/Holley; 866/464-6553; holley.com

R.A.D. Auto Machine; 413/583-4414; radautomachine.com

Weiand; 866/464-6553; holley.com

The post 392 Chrysler Hemi Build and Dyno Test: How Does the Whale Motor Respond to Bolt-On Speed Parts? appeared first on Hot Rod Network.

from Hot Rod Network http://www.hotrod.com/articles/392-chrysler-hemi-build-dyno-test-whale-motor-respond-bolt-speed-parts/

via IFTTT

0 notes

Photo

1953 Dodge Zeder 'Storm' Z-250 Bertone - fiberglass body, removable aluminum top, hemi V-8

Boston Car Service

0 notes