#Digital Integrated Circuit Temperature Sensor Market

Text

Digital Integrated Circuit Temperature Sensor Market

0 notes

Text

Digital Integrated Circuit Temperature Sensor Market Future Aspect Analysis and Current Trends by 2017 to 2032

A digital integrated circuit temperature sensor is a type of sensor that is built into an integrated circuit and is used to measure the temperature of the surrounding environment. It uses various physical phenomena such as the temperature coefficient of resistance or the voltage-temperature characteristics of a diode to measure temperature. The output of the sensor is in the form of a digital signal that can be read and processed by a microcontroller or other digital circuitry.

Digital integrated circuit temperature sensors are widely used in a variety of applications, including temperature monitoring and control systems, environmental monitoring, and consumer electronics. They are often used in conjunction with microcontrollers or other digital circuitry to provide accurate and reliable temperature measurements in real-time.

This report provides a wide range of research and data that will assist users in understanding niches and focusing on key market channels in the regional and worldwide Digital Integrated Circuit Temperature Sensor market. For the goal of understanding competition, the study provides market details such as size, share, current and projected market trends, supply chain information, trading concerns, competitive analysis, and prices, as well as vendor information..

Click Here, To Get Free Sample Report : https://stringentdatalytics.com/sample-request/digital-integrated-circuit-temperature-sensor-market/318/

Market Segmentations:

Global Digital Integrated Circuit Temperature Sensor Market: By Company

• Analog Devices

• Texas Instruments

• Microchip

• NXP Semiconductors

• STMicroelectronics

• ams-OSRAM

• ROHM

• Silicon Laboratories

• TE Connectivity

• Panasonic

• ON Semiconductor

• Innovative Sensor Technology IST

• MinebeaMitsumi

• Würth Elektronik

• Shandong Huake Semiconductor Research Institute Co., Ltd

• Sensylink Microelectronics Co., Ltd.

Segment by Temperature Accuracy

• 0.2 Degrees

• 0.2-0.5 Degrees

• 0.5-1 Degrees

• Other

Global Digital Integrated Circuit Temperature Sensor Market: By Application

• Consumer Electronics

• Automotive Electronics

• Industrial Manufacturing

• Other

Global Digital Integrated Circuit Temperature Sensor Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Digital Integrated Circuit Temperature Sensor market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/digital-integrated-circuit-temperature-sensor-market/318/

Objectives of Digital Integrated Circuit Temperature Sensor Market Study:

The objectives of Digital Integrated Circuit Temperature Sensor market research report may vary depending on the specific needs and goals of the business or organization commissioning the report. However, some common objectives of market research reports include:

• Understanding the market size and potential: One of the primary objectives of Digital Integrated Circuit Temperature Sensor market research is to understand the size and potential of a particular market. This includes analyzing market trends and dynamics, identifying key players and competitors, and assessing the demand for products or services.

• Identifying target customers and segments: this market research reports can help businesses identify and understand their target customers and market segments, including their preferences, behaviors, and demographics. This information can be used to develop targeted marketing and advertising strategies.

• Evaluating product or service performance: this market research reports can provide valuable insights into the performance of products or services, including customer satisfaction, product usage, and product quality. This information can be used to improve products or services and enhance customer satisfaction.

• Assessing market opportunities and threats: this market research reports can help businesses identify potential market opportunities and threats, including emerging trends, competitive threats, and new market entrants. This information can be used to develop strategic plans and make informed business decisions.

• Developing effective marketing and advertising strategies: this market research reports can help businesses develop effective marketing and advertising strategies by providing insights into customer preferences and behavior, competitive dynamics, and market trends. This can help businesses improve brand awareness, customer engagement, and overall marketing effectiveness.

Overall, the objectives of Digital Integrated Circuit Temperature Sensor market research report are to provide businesses and organizations with valuable insights and data-driven recommendations that can help them make informed business decisions and stay competitive in their industry.

More Reports:

Global Bisphenol A-Based Epoxies Market:

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Contact US:

Stringent Datalytics

Contact No - 91-9763384149

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Digital Integrated Circuit Temperature Sensor Market#Global Digital Integrated Circuit Temperature Sensor Market#market research report

0 notes

Text

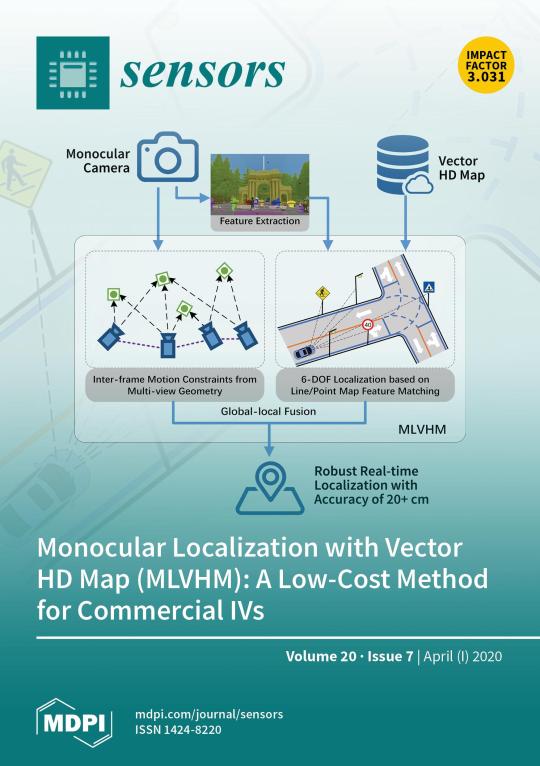

Revolutionizing Connectivity: The Booming Era of Analog Integrated Circuits

The analog integrated circuit (IC) market has been witnessing steady growth and is a crucial segment of the overall semiconductor industry. Analog ICs are electronic components that process and manipulate continuous signals, such as sound, temperature, and voltage, as opposed to digital ICs that handle discrete signals. These circuits play a vital role in a wide range of applications, including consumer electronics, automotive, industrial automation, telecommunications, and healthcare.

The increasing demand for smart devices, the proliferation of Internet of Things (IoT) devices, and the growing need for efficient power management solutions are key factors driving the growth of the analog IC market. With the rise in consumer electronics, such as smartphones, tablets, and wearable devices, the demand for power management ICs, audio amplifiers, and analog-to-digital converters (ADCs) has surged. Additionally, the automotive sector is witnessing a rapid integration of advanced driver-assistance systems (ADAS), electrification, and connectivity, creating a strong demand for analog ICs for applications like powertrain control, infotainment systems, and sensors.

Furthermore, the industrial automation sector is embracing digitalization and Industry 4.0, resulting in increased adoption of analog ICs for applications like motor control, sensor interfaces, and process control. Moreover, the healthcare industry is experiencing a transformation with the advancement of medical devices, wearables, and remote patient monitoring systems, which rely on analog ICs for accurate data acquisition and processing.

Overall, the analog IC market is poised for significant growth due to the increasing demand for smart devices, automotive advancements, industrial automation, and healthcare applications. Companies in the semiconductor industry are investing heavily in research and development to introduce innovative analog ICs that offer enhanced performance, lower power consumption, and miniaturization to meet the evolving market needs.

Read More: https://thetechnologynews-24.blogspot.com/2023/06/the-thriving-analog-ic-market-pillar-of.html

0 notes

Text

Industrial Chips Market Size, Emerging Trends, Technological Advancements, and Business Strategies 2023-2029

The global Industrial Chips market was valued at US$ 61510 million in 2022 and is projected to reach US$ 98370 million by 2029, at a CAGR of 6.9% during the forecast period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes.

Get Full Report @ https://semiconductorinsight.com/report/industrial-chips-market/

Industrial chips, also known as industrial microchips or industrial integrated circuits (ICs), are electronic chips specifically designed for use in industrial applications. These chips are built to withstand tough conditions commonly found in industrial environments, such as high temperatures, humidity, vibration, and electromagnetic interference.

Industrial chips are crucial in various industrial sectors, including manufacturing, automation, energy, transportation, and telecommunications. They are used in a wide range of industrial equipment and systems like programmable logic controllers (PLCs), motor drives, sensors, power supplies, robotics, and communication devices.

When it comes to design and architecture, industrial chips prioritize reliability, durability, and performance. They are created to handle extreme temperatures, protect against electrical noise and voltage fluctuations, and have a long lifespan.

These chips often include specialized features such as real-time operating systems (RTOS), advanced communication protocols (e.g., CAN, Ethernet), and industrial fieldbus interfaces (e.g., PROFIBUS, Modbus). These features facilitate smooth integration with industrial control systems and efficient data exchange between different devices.

This report aims to provide a comprehensive presentation of the global market for Industrial Chips, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Industrial Chips.

This report contains market size and forecasts of Industrial Chips in globally, including the following market information:

Global Industrial Chips Market Revenue, 2018-2023, 2024-2029, ($ millions)

Global Industrial Chips Market Sales, 2018-2023, 2024-2029, (M Pcs)

Global top five Industrial Chips companies in 2022 (%)

Global key players of industrial chips include Texas Instruments, Infineon, Intel, Analog Devices, STMicroelectronics, etc. The top five players hold a share about 49%. North America is the largest market, has a share about 29%, followed by Europe and China, with share 24% and 22%, separately.

We surveyed the Industrial Chips manufacturers, suppliers, distributors and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks.

Total Market by Segment:

Global Industrial Chips Market, by Type, 2018-2023, 2024-2029 ($ Millions) & (M Pcs)

Global Industrial Chips Market Segment Percentages, by Type, 2022 (%)

Computing and Control Chips

Communication Core

Analog Chip

Memory

Sensor

Security Chips

Microcontrollers (MCUs)

Digital Signal Processors (DSPs)

Application-Specific Integrated Circuits (ASICs)

Field-Programmable Gate Arrays (FPGAs)

System-on-Chip (SoC)

Power Management ICs

Global Industrial Chips Market, by Technology, 2018-2023, 2024-2029 ($ Millions) & (M Pcs)

Global Industrial Chips Market Segment Percentages, by Technology, 2022 (%)

Electricity and Energy

Rail and Transportation

Factory Automation and Control Systems

Medical Electronics

Others

Global Industrial Chips Market, by Application, 2018-2023, 2024-2029 ($ Millions) & (M Pcs)

Global Industrial Chips Market Segment Percentages, by Application, 2022 (%)

Programmable Logic Controllers (PLCs)

Motor Drives and Control Systems

Human-Machine Interfaces (HMIs)

Industrial Communication (e.g., Ethernet, CAN, Fieldbus)

Industrial IoT (IIoT) and Edge Computing

Industrial Robotics and Automation

Power Supplies and Converters

Sensing and Measurement Systems

Process Control and Monitoring

Safety and Security Systems

Global Industrial Chips Market, By Region and Country, 2018-2023, 2024-2029 ($ Millions) & (M Pcs)

North America is currently the largest market for industrial chips, followed by Europe and the Asia Pacific region. The growth of the industrial chips market in North America can be attributed to the rising demand for industrial automation, particularly in the automotive and aerospace sectors. The increasing need for streamlined processes and advanced technologies has fueled the demand for industrial chips in these industries.

In Europe, the industrial chips market is experiencing growth primarily due to the increasing demand for industrial automation in the manufacturing and energy sectors. As businesses strive for greater efficiency and productivity, the adoption of automation technologies has surged, leading to an increased requirement for industrial chips to power these automated systems.

The Asia Pacific region is also witnessing significant growth in the industrial chips market, driven by the escalating demand for industrial automation in the manufacturing and consumer electronics industries. With the region being a manufacturing hub and the presence of a vast consumer electronics market, the need for industrial chips has soared to support automated manufacturing processes and the development of advanced consumer electronic devices.

Global Industrial Chips Market Segment Percentages, By Region and Country, 2022 (%)

North America

U.S.

Canada

Europe

U.K.

Germany

France

Spain

Rest of Europe

Asia-Pacific

India

Japan

China

Australia

South Korea

Rest of Asia-Pacific

Latin America

Brazil

Mexico

Rest of Latin America

The Middle East & Africa

South Africa

GCC Countries

Rest of the Middle East & Africa (ME&A)

Further, the report presents profiles of competitors in the market, key players include:

Texas Instruments

Infineon

Intel

Analog Devices

STMicroelectronics

Renesas

Micron Technology, Inc.

Microchip

onsemi

Samsung

NXP Semiconductors

Broadcom

Xilinx

Taiwan Semiconductor Manufacturing Company (TSMC)

SK Hynix Inc.

The global top five industrial chips companies in 2022, ranked by market share, are:

Infineon Technologies: With a market share of 24%, Infineon Technologies is a German semiconductor company specializing in power management, security, sensors, and automation solutions. They offer a diverse range of products for various industrial applications.

Texas Instruments: Holding 18% of the market share, Texas Instruments is an American semiconductor company known for its expertise in analog and embedded processing solutions. They have a rich history of innovation and are prominent suppliers of industrial chips for automation, control, and communications.

STMicroelectronics: Accounting for 15% of the market share, STMicroelectronics is a Swiss-Italian semiconductor company focusing on microelectronics. Their extensive product portfolio caters to a wide range of industrial applications. They excel in providing microcontrollers, memory chips, and analog chips.

Renesas Electronics: With a 12% market share, Renesas Electronics is a Japanese semiconductor company specializing in microcontrollers, analog chips, and power management solutions. Renesas Electronics stands out as a leading supplier of microcontrollers for automotive and industrial applications.

NXP Semiconductors: NXP Semiconductors, a Dutch company, holds a 10% market share and specializes in microcontrollers, security solutions, and automotive chips. Their broad product range caters to diverse industrial applications, making them a significant player in the market.

Key Drivers:

Increasing demand for industrial automation: Industries are increasingly adopting automation solutions to enhance productivity, improve efficiency, and streamline operations.

Need for more reliable and efficient electronic devices: As industrial processes become more complex, there is a growing demand for robust and high-performance electronic devices to ensure smooth and uninterrupted operations.

Growth of the automotive and aerospace industries: The automotive and aerospace sectors are witnessing substantial growth, creating a greater demand for advanced industrial chips to power various applications, including vehicle control systems and avionics.

Rise of the Internet of Things (IoT): The proliferation of IoT devices in industrial settings necessitates the use of industrial chips for connectivity, data processing, and control, driving the market growth.

Government initiatives to promote the use of electronic devices in industries: Governments worldwide are implementing policies and incentives to encourage the adoption of electronic devices, fostering the expansion of the industrial chips market.

Restraints:

High cost of industrial chips: The development and manufacturing of industrial chips involve complex processes, resulting in higher production costs, which can limit their widespread adoption.

Shortage of skilled labor: The industry faces a shortage of skilled professionals capable of designing, developing, and maintaining industrial chips, which can hinder market growth.

Complexity of the manufacturing process: The intricate nature of manufacturing industrial chips poses challenges in terms of yield, quality control, and scalability, leading to potential manufacturing constraints.

Intellectual property (IP) issues: Protecting intellectual property rights and preventing counterfeiting and piracy is a concern in the industrial chips market, which can impact market growth and profitability.

Opportunities:

Development of new technologies, such as 5G and artificial intelligence (AI): The integration of 5G connectivity and AI capabilities in industrial applications presents opportunities for the development of innovative industrial chips to enable advanced functionalities and higher data processing speeds.

Growth of the renewable energy sector: The expanding renewable energy sector, including solar and wind power, creates avenues for the utilization of industrial chips in energy management, power conversion, and grid integration systems.

Expansion into new markets, such as Asia Pacific and Latin America: The emerging economies in Asia Pacific and Latin America offer untapped market potential, driven by industrialization, infrastructure development, and increasing adoption of automation technologies.

Get Full Report @ https://semiconductorinsight.com/report/industrial-chips-market/

0 notes

Text

https://ymtsindia.com/embedded-system-design

Best Embedded System Design Services Provider “YoungMinds”

What is an Embedded System?

An embedded system is a combination of computer hardware and software designed for a specific function. Embedded systems may also function within a larger system. The systems can be programmable or have a fixed functionality.

For example, a fire alarm is a common example of an embedded system which can sense only smoke.

Examples of standalone embedded systems include:

Digital cameras.

Digital wristwatches.

MP3 players.

Appliances, such as refrigerators, washing machines, and microwave ovens.

Temperature measurement systems.

Calculators.

History of Embedded system

In 1960, embedded system was first used for developing Apollo Guidance System by Charles Stark Draper at MIT.

In 1965, Auto-netics, developed the D-17B, the computer used in the Minuteman missile guidance system.

In 1968, the first embedded system for a vehicle was released.

Texas Instruments developed the first microcontroller in 1971.

In 1987, the first embedded OS, VxWorks, was released by Wind River.

Microsoft’s Windows embedded CE in 1996.

By the late 1990s, the first embedded Linux system appeared.

The embedded market reach $140 billion in 2013.

Analysts are projecting an Embedded market larger than $40 billion by 2030.

Various Types of Embedded System: -

A Raspberry Pi an embedded system: Raspberry Pi single-board computer (SBC) was originally designed as a platform to teach computer science to students, but it has expanded into other applications, including use as an embedded platform.

ATM an embedded system: An Automated Teller Machine (ATM) - is an embedded system which utilizes a crowded computer to set up a network between a bank computer and an ATM itself. It also has a microcontroller to bear both input and output operations

Alexa an embedded system: The Amazon Echo is the epitome of an Internet of Things (IoT) device. It combines an embedded applications processor from Texas Instruments, MEMS microphones from Knowles, Wi-Fi and Bluetooth wireless connectivity, an AWS cloud backend, and support for diverse applications.

Smart TV an embedded software: Embedded software comes into play in “smart TVs.” Smart TVs still have firmware for the low-level signal processing tasks, and more firmware to operate the wired or wireless network interface and communications with the remote control (which also now has firmware)

Embedded System Design: -

Embedded system is a self-contained, microprocessor-based computer system typically implemented as a component of a larger electrical or mechanical system. At the core of the embedded system is an integrated circuit that performs computational tasks.

Majorly Embedded System Design helps all kinds of manufacturing industries to control a specific function within a device. They are usually designed to only perform this function repeatedly, but more developed embedded systems can control entire operating systems.

If anyone searching Embedded System Design Solutions to make your ideas into reality – my best suggestion is “Youngminds” - Realizing product and software development for a wide range of application areas on cutting-edge technologies like below mentioned…

“Young Minds” Embedded System Design Solutions: -

Firmware Development and Optimization of Embedded Designs for a wide range of processors.

Various Embedded Processor/FPGA/SoCs:

ARM

TI

Microchip

nVIDIA

Xilinx FPGA

Intel FPGA

3rd Party SoCs

Target Applications:

AI

Multimedia

IoT

Security

Automotive

Image Processing

Medical Services

Target Technologies:

Wireless Technologies like WiFi, Bluetooth

Storage Interfaces

Sensor Interfaces

Display Interfaces

Wired Technologies like Ethernet, PCIe, SATA

Still need more information about “Young Minds” – Visit https://ymtsindia.com/

Embedded System Design Solutions: - https://ymtsindia.com/embedded-system-design

0 notes

Text

Hall Effect Sensor Market - Forecast 2022-2027

Hall Effect Sensor Market Overview

The Hall Effect Sensor Market size is forecast to reach US$ 2.1 billion by 2027, growing at a CAGR of 8.6% from 2022 to 2027. Hall effect sensors use ‘Hall Effect’ principle to convert magnetically encoded information into electrical signals. The principle of Hall effect sensors depends on the electron mobility. These devices have a range of applications, with Hall effect sensors often used in automotive systems to sense position, distance and speed. They are commonly used in automotive control systems like proximity sensing, speed detection, anti lock braking systems and others, electronics, and measurement devices. The factors such as rise in industrial automation, growing application of hall effect sensor in robotics, increasing use of programmable and fully integrated current sensors and transducers and wide temperature stability in extreme environments in wide range of industry verticals are helping in the growth of this market. However, the factors such as high cost of raw materials for hall effect sensors and technical issues like inconsistent.

Request Sample

Hall Effect Sensor Market Report Coverage

The report: “Hall Effect Sensor Industry Outlook – Forecast (2022-2027)”, by IndustryARC covers an in-depth analysis of the following segments of the Hall Effect Sensor industry.

By Type of Loop :Open-Loop Sensor, Closed-Loop Sensor

By Rotor:Magnetic rotor, Ferrous vane rotor

By Magnetic field:Unipolar, Bipolar, Omnipolar

By Technology:BiCMOS, CMOS

By Material:Gallium Arsenide (GaAs),Indium Arsenide (InAs),Indium Phosphide (InP),Indium Antimonide (InSb),Graphene

By Output: Analog ( Linear ), Digital ( Switching )

By Application:Position sensing, Motion sensing, Wireless Communication, Pressure Sensing, Flow rate Sensing, Vibration sensing, Others

By End user: Industrial Equipments, Power & Energy, Oil, gas and petrochemical, Automotive, Consumer Electronics, Telecommunication, Healthcare, Aerospace & Defense, Manufacturing, Robotics, Others

By Geography: North America (U.S, Canada, Mexico), Europe(U.K, Germany, France, Italy, Spain,Others), APAC (China, Japan, South Korea, India, Australia, Others), South America (Brazil, Argentina, Others), RoW (Middle East, Africa)

Key Takeaways

The open loop sensor segment is predicted to grow at a faster rate than closed loop sensor overthe forecast period of 2002-2027 in the Hall Effect Sensor Market segmented by type of loop. This is owing to more precise results with simple design, cost effective circuit and easy to maintain and tune.

The industrial segment held the largest share in Hall Effect Sensor Market by application, in 2021. This is attributed toadvent of industrial automation and need of accurate production lines for safety and efficiency.

Asia-Pacific (APAC) market held the largest market share of 35%, in 2021. This is due to growing research in Hall Effect sensor technologies, rise in industrial automation and robotics and government policies to boost the semiconductor sensor industry.

The increasing smart grids and robotics in industries, growing use of electric vehicles and smart automotive systems and growing research in Hall Effect sensors for improved performance are the contributing factors in the growth of Hall Effect Sensor Market.

Inquiry Before Buying

Hall Effect Sensor Market Segment Analysis - By Type of Loop

The Hall Effect Sensor Market by type of loop has been segmented into open loop sensor and closed loop sensor. The open loop segment is predicted to grow at a faster rate with CAGR of 9.8%, over the forecast period 2022-2027. This is owing to growing application of open loop hall effect sensors in industrial equipments, ease of implementation of the mechanism and galvanic isolation effect. Open loop current sensors consist of a Hall sensor mounted in the air gap of a magnetic core. An open-loop Hall-effect sensor uses the Hall voltage directly to produce its output signal making it simpler to implement and exhibits a faster response time. These sensors help improve the overall efficiency and productivity of an automation process due to galvanic isolation effect. It is a major factor in the selection of a open loop hall effect sensor mainly for current measurement applications. Thus, open loop hall sensors have several benefits in industrial applications which are mainly promoting the growth of this open loop hall sensor segment. In July 2021, a customized version of LEM’s HAH1, an open loop hall effect sensor, was developed. It significantly reduces the assembly footprint compared to previously available solutions and allows a higher integration level within the control infrastructure. Thus, growing use of open loop Hall Effect sensor with integrated systems and customized structure as per requirement is fuelling the growth of this market

Hall Effect Sensor Market Segment Analysis - By End User

The Hall Effect Sensor Market by end user has been segmented into industrial equipments, automotive, consumer electronics, telecommunication, healthcare, aerospace & defense, manufacturing, others. The industrial equipment segment held the largest share of 32%, in 2021. This is owing to the increasing need of precision production line processes and wide working temperature range in extreme industrial environments. Current sensor, pressure sensors and rate of flow sensors are some of the extensively used applications of Hall Effect sensors in industrial and manufacturing. In Industrial equipments, Hall Effect sensors are used in security systems, alignment controls, micrometers, machine tools, key switches, linear potentiometers, rotary encoders, and brushless DC motor commutators. Thus, a large scale of equipment and process line requirement of Hall Effect sensor in industrial applications is assisting the industrial equipments segment growth. In October 2021, Texas Instruments has introduced TMAG5170, the first device in a new family of 3D Hall-effect position sensors for real-time control in factory automation and motor-drive applications. The sensor is promoted as providing integrated functions and diagnostics to maximize design flexibility and system safety while saving energy. Such growing advancements in hall effect sensor technologies for industrial requirements and other applications is driving the growth of this market

Schedule a Call

Hall Effect Sensor Market Segment Analysis - By Geography

The Hall Effect Sensor Market by geography is segmented into North America, Europe, Asia-Pacific (APAC), South America, and the rest of the world (RoW). Asia Pacific (APAC) held the largest Hall Effect Sensor Market share with 35% of total market size. This is due to increasing government policies supporting industrial automation and growing research in new technological integration in Hall effect sensors such as 3D sensing or bipolar complementary metal-oxide-semiconductor (BiCMOS) technology in countries such as China, India, South Korea, and Japan. The recent developments of graphene-based Hall Effect sensors, programmable hall effect sensors are also boosting the growth in Asian countries. In June 2020, Melexsis announced an automotive grade monolithic sensor that uses Hall Effect to provide contactless sensing in three-dimensional environment. The dual die version of MLX90395 is defined through system processor, rather than hardwires into device. Such, growing innovations in the Hall Effect sensors is accelerating the growth of this market in Asian countries.

Hall Effect Sensor Market Drivers

The rising industrial automation and increasing use of smart grids in production line boosts the growth of Hall Effect Sensor market

The Hall Effect Sensor Market is growing due to the rise in demand for sensors with higher accuracy levels, wide working temperature ranges and accurate results. The increasing use of smart grids and rising safety concerns within industrial applications drive the demand of hall effect sensors. The rise in implementation of industry 4.0 technologies such as industrial internet of things (IIoT) and cloud-computing has created high demand for variety of sensors. Another essential part, DC motors, and switches, controls also use Hall Effect sensors for automation which are increasingly used by various industries. Hall effect sensors are also an effective, contactless way to measure DC magnetic flux in current transformers. These sensors dedicated for different kinds of industrial applications are available for example, sealed Hall Effect devices are water-proof and are made in such a way to resist any vibration. Thus, customization of these sensors is assisting in the growth of this market. In January 2022, Allegro MicroSystems, Inc., a global leader in sensing and power solutions for motion control and energy-efficient systems, announced its new A33230 3D sine/cosine Hall-effect position sensor IC. The A33230 is the smallest 3D sine/cosine sensor currently available in the market, and offers system designers a cost-effective solution for automotive and industrial applications with a quick time to market. Thus, growing industrial applications is driving the Hall Effect Sensor Market growth.

Buy Now

The increasing research in bipolar complementary metal-oxide-semiconductor (BiCMOS) technology, intelligent hall effect sensors and three-dimensional sensors is boosting the hall effect sensors market growth.

There are growing advancements in the Hall Effect sensor technologies such as BiCMOS, three-dimensional and many others. BiCMOS offers a high current drive per unit, low input density, high power dissipation, and low noise compared to conventional or CMOS technology. A BiCMOS chopper stabilization circuit is utilized to reduce signal offset and to stabilize the output of the IC over its operating temperature range. with BiCMOS technology, features fast power-on time and low-noise operation. A family of Hall-effect sensors optimized for automotive and mechatronic applications that demand accuracy and flexibility combined with low cost. It includes a microcontroller, a temperature sensor, advanced on-chip compensation, and a digital interface. The latest automotive designs require smart sensors to deliver the high level of precision and robustness linked with the capability of local pre-processing of the measured data. In May 2022, Synaptics Inc. has launched the FlexSense family of sensor processors that captures and intelligently handles input from up to four sensors in a tiny, ultra-low-power form factor that is up to 80% smaller than existing solutions. Integrating a mix of capacitive, inductive, Hall effect and ambient sensing into a single processor with proprietary algorithms, the FlexSense family brings reliable, low-latency, and context-aware force, proximity, and touch sensing to Internet of things (IoT) devices. Such innovations in integration of hall effect sensors with intelligent technologies is driving the growth of this market.

Hall Effect Sensor Market Challenges

The issue of uneven strength of magnetic fields in Hall Effect sensors is restricting the growth of this market

Hall effect sensors produce an output voltage directly proportional to the strength of the magnetic field generated by the current supplied. It is connected to an analog to digital (A/D) converter, microprocessor, or microcontroller to maintain the voltage. Hall-Effect sensors work on the concept of magnetic field, which makes them more vulnerable to external magnetic fields, leading to inconsistent measurement of the current flow. These sensors are not suitable for measuring the flow of current if the distance between the generated magnetic field and the current-carrying conductor is beyond certain limits which is expected to hinder the market growth. In May 2022, Titan Enterprises Ltd, explains some of the reasons for sensor failures. High quality Hall effect sensors are typically used within Titan’s pulse precision flow measurement devices. The sensors operate between 4.0Vdc and 30Vdc, however, exceeding the maximum 30Vdc to the Hall Effect sensor will damage the unit. A good quality regulated DC power supply is recommended for powering a pulse flow meter. Thus, due to the technical limitations and need to maintain certain distance and current flow restricts the growth of this market.

Hall Effect Sensor Market Landscape

Product launches, acquisitions, and R&D activities are key strategies adopted by players in the Hall Effect Sensor industry. The Hall Effect Sensor top 10 companies include:

ABB Ltd

Allegro MicroSystems LLC

TE Connectivity Ltd

Bartington Instruments Ltd

Honeywell International Inc.

Analog Devices, Inc.

Robert Bosch GmbH

NXP Semiconductors N.V.

TDK Corporation

Infineon Technologies AG

Recent Developments:

In July 2020, Texas Instruments announced the industry’s first zero-drift Hall-effect current sensors. The TMCS1100 and TMCS1101 enable the lowest drift and highest accuracy over time and temperature while providing reliable 3-kVrms isolation, which is especially important for AC or DC high-voltage systems such as industrial motor drives, solar inverters, energy-storage equipment and power. This product with unique feature and varied applications will aquire a significant market share

In May 2021, Paragraf continues to push performance boundaries with its graphene Hall Effect sensors. Oxford Instruments, a leading provider of high technology tools and systems for research and industry, have employed a modified version of the Paragraf GHS09CC sensor device to carry out measurements at temperatures and magnetic field strengths far beyond the scope of any other sensing solution. Thus, this breakthrough innovation of using graphene will help in gaining a significant market share.

In October 2021, Texas Instruments has introduced TMAG5170, the first device in a new family of 3D Hall-effect position sensors for real-time control in factory automation and motor-drive applications. The sensor is promoted as providing integrated functions and diagnostics to maximize design flexibility and system safety while saving energy. Thus, expanding the integration and advanced features will assist in capturing the market of hall effect sensors.

In November 2021, TDK Corporation announced the portfolio expansion of its Micronas direct-angle Hall-effect sensor family with the HAR 3927. This product uses proprietary 3D HAL® pixel-cell technology and addresses the need for ISO 26262-compliant development. Various configuration options of HAR 3927 increase customers’ flexibility during development and enable one sensor to be used in multiple applications, which reduces costs and effort for re-qualification. Thus, compliance with certification and improved results will help in market growth of hall effect sensors.

0 notes

Text

Knowing More About Printed Electronics

Printed electronics is the integration of organic semiconductor electronics in print products. It is one of the primary applications in the field of functional printing and is a complement to conventional electronics.

The following features distinguish printed electronics:

It is based on flexible substrates made of specifically functionalized polymer films (plastic semiconductors).

It can be designed over a large area.

It is less than a millimeter thick.

In which processes are printed electronics produced?

Printed electronics - to be more precise: the semiconductors made of plastic - can be produced efficiently and increasingly cost-effectively in mass printing.

Three methods are essentially used for this:

Screen printing

Flexographic printing

Inkjet printing

Electronics printed using the screen-printing process

Screen printing can produce thick layers of impasto materials and is therefore used for printed electronics' industrial production. This process has, for example:

Conductor tracks made of inorganic materials, e.g., B. for circuit boards, antennas, or glucose test strips

insulating passivation layers

Electronics printed using flexographic printing

The flexographic printing process offers several properties that benefit the production of printed electronics:

The flexible printing forms are produced using direct laser engraving, which enables very fine structures.

The cleaning of the printing forms after lasering is done with water. This means that no solvents are needed.

Inks and pastes with conductive, magnetic, hydrophobic, photoconductive, or corrosive properties can be printed.

For example, printed circuit boards, sensors, or memory labels are produced in flexographic printing. But the process can also be used for RFID antennas or smart packaging, for example, for pharmaceuticals.

Electronics printed using the laser inkjet process

Examples of printed electronics using the laser inkjet process are applications from the circuit board and ceramic industries. The special thing about the process - the so-called lasersonic process - is that the drop is emitted directly from a color film's surface instead of from a nozzle by laser bombardment and is thus transferred directly and without contact to the printing material. Besides commercially available printing inks, lasersonic can also print many functional pigments.

With the laser inkjet process, the entire color space that conventional printing presses also use can be used digitally for the first time. Expensive printhead changes should be a thing of the past with lasersonic technology, as should expensive special inks.

What are applications Printed electronics needed for?

There are now several applications where printed, and organic electronics are needed and are even on their way into broad mass markets. Integrated systems printed off the roll are inexpensive, compact, and energy-efficient. Conductive polymers are already being produced in large quantities using printing technology.

Examples of electronic applications are:

Consumer goods

Industrial controls

printed antennas and sensors for the automotive industry

Antistatic coatings

OLED displays (organic light-emitting diode displays), e.g., B. for navigation devices or air conditioning systems

Electroluminescent displays

organic photovoltaics (OPV), i.e., the production of solar cell elements

electronic product label to protect against counterfeiting

Temperature sensors for food packaging

The transition from micro to nanotechnology will probably open up entirely new perspectives for print applications.

1 note

·

View note

Text

Buy Word Class Equipment and Tools for Electronics in Delhi

Ionised air gun neutralise static fees on several materials as well as clean the surface area using ionised compressed air. Neutralising the static charges makes it easier to blow-clean the surface and avoids dust as well as dirt fragments from being re-attracted.

Static eliminators or static ionizers remove static as well as dust as well as can counteract and clean surface areas at remote ranges. Static neutralization is a functional technique of static reduction; nevertheless complete static elimination is not readily possible.

Electrostatic field meter is utilized to situate as well as measure static charges. It is extremely small, pocket dimension and also basic to use. It has the adhering to functions which are operated by pushbuttons: Power on/off, absolutely no adjustment, Ion Equilibrium and also Hold. Utilize the hold switch to retain the display screen of the analysis.

Ion bars are developed to regulate static charge in mini-environments, laminar flow hoods and also workstations. Ionizing bars include distinct aerodynamic layout that ionizes an area without interrupting laminar circulation. Installation is quickly.

We provide Static Charge Removal system with Static System Guard. Made using luxury technology, this system is made use of to remove all opportunities of dangerous results on personnel as well as product, therefore help in providing high effectiveness in terms of manufacturing, top quality, less male hour and higher revenues. Our system is utilized by customers in various markets, ranging from Textiles.

A digital multimeter or DMM is one of the most widely utilized pieces of test devices today. DMMs are available extremely inexpensively as well as these digital multimeter can provide extremely high levels of precision when measuring the specifications within an electronics or electrical circuit. Because of this, DMMs are just one of the most vital items of test devices offered today.

A Digital clamp meter is an electric examination device that integrates a standard digital multimeter with a current sensor. Probes gauge voltage. Having a hinged jaw incorporated right into an electrical meter allows service technicians to secure the jaws around a cord.

A digital tachometer is a digital device that determines and shows the speed of a turning object. A turning object might be a bike tyre, an auto tire or a ceiling fan, or any kind of various other motor, and so on. A digital tachometer circuit comprises LCD or LED reviewed out and also a memory for storage space.

Lux meters are made use of for gauging brightness in lux, fc or cd/m ². Some lux meters are outfitted with an interior memory or data logger to document as well as conserve measurements. The dimension of light intensity with a Lux Meter is Lux meter Review ending up being increasingly essential in the office because of security worries.

Portable insulation resistance testers and also megohmmeters are designed to aid avoid hazards such as electrical shock as well as short-circuits triggered when the insulation in electric gadgets, components, and also devices made use of in plants, structures, as well as various other setups deteriorates over extended periods of use.

A soldering iron is a hand tool made use of in soldering. It provides warm to melt solder so that it can stream right into the joint between 2 job pieces. A soldering iron is made up of a warmed metal idea and also a protected handle. Home heating is usually achieved electrically, by passing an electric current (provided via an electric cable or booster cable) via a repellent heating element.

Flux Cleaner is created to remove the burnt or clear deposit that flux leaves after the heat-treating procedure is complete. When is made use of as a change for soldering electrical calls especially those that accuracy parts snugly surround taking advantage of an aerosol change eliminator gives a number of advantages over making use of a Flux cleaner in tidy kind.

A soldering station Appears complicated-- and expensive. But it's not. It's simply a soldering iron with a built-in thermostat and a huge external power supply to maintain it at a constant, hot-but-not-too-hot temperature level as it melts solder as needed. And now they're available for under $50.

The Digital Soldering as well as Desoldering Station is a high performance and multi-function station for electronic product research, manufacturing as well as rework. We generate the very best soldering as well as desoldering options including digital soldering station in India.

In any SMD Rework Station or warm air blower, there are two control handles. One control knob is to regulate circulation of Hot Air while the various other control handle is made use of to control temperature level. Hot air flows through nozzle attached to the take care of.

Soldering without any No Clean Flux is a useful option for getting rid of the tedious message solder cleaning utilizing pricey as well as also contaminating CFC solvent cleaning. No Clean Change are reduced strong (much less than 5%) changes, especially produced for SMDs and also blended technology soldering.

VOC-free Flux use water as the leading solvent. Along with restricting the quantity of volatile organic compounds (VOC) right into the atmosphere, sometimes associated with international warming, VOC-free Flux is also non-flammable.

An Electric screwdriver is a tool, guidebook or powered, for screwing as well as helping to loosen (positioning as well as additionally eliminating) screws. A regular simple Electric screwdriver has a take care of along with a shaft, ending in a suggestion the individual takes right into the screw head prior to changing the handle.

Pneumatic Screwdriver use compressed air and also ideal for low-torque applications such as woodworking or sheet steel repairing.

Digital screwdrivers made for accuracy application as well as measurement of torque in manufacturing as well as lab settings. Digital as well as dial torque screwdrivers in supply for a wide variety of applications.

Torque meter is readily available in two different versions: portable meters or table leading meters. Torque meter have a wide variety of applications. Portable torque meter is generally made use of for industry while table leading torque meter is the suitable tool Torque meter summary for research laboratories.

Epoxy Dispenser Option

The Epoxy Dispenser is a regulated system. The epoxy dispenser has a Rotating Layout Positive Variation Pump with a brand-new better resolution electric motor. This indicates has even far better performance.

Use of Desoldering Wick

Use of Disordering Wick variety from actually minute straight-forward jobs to tough applications based upon the need as well as additionally application, numerous Wick are conveniently available, varying in power usage, temperature level array, microcontroller (MCU) based control as well as additionally various other features.

Soldering robo automate the Manual soldering process. A soldering iron installed throughout effect of the robotic is relocated to previously configured placements, where it will certainly solder the joint. The required solder in the kind of readily available solder cable is being fed through solder cord feeders to the joint to be made.

How to Use of a Solder Pot

Solder pots are little, temperature-controlled pots or containers with flared lips that are made use of two tin cords as well as soldering tips. Solder pots also are especially useful for dipping electronics such as printed motherboard (PCBs) with through-hole leaded elements. Solder pots are utilized in smaller sized commercial applications or in nations where modern technology isn't as easily accessed.

If you have any questions, please contact us at [email protected] or +91-9599592691. We at Advance Tech Services (P) Ltd, offers Equipment, Tools & Consumables for Electrical, Electronics, Automobile, Pharma Industry and other commercial applications, including Electronic Maintenance at reasonable cost in Delhi.

#soldering robo#desoldering wick#epoxy dispenser#torque meter#Digital screw driver#pneumatic screwdriver#electric screwdriver#voc free flux#no clean flux#SMD Rework station#desoldering station#soldering station#flux cleaner#Soldering Iron#Insulation Resistance Tester#Lux Meter#digital tachometer#Digital clamp meter#digital multimeter#static charge removal systems#ion Bar#electrostatic field meter#static eliminator#ionised air gun

1 note

·

View note

Text

Painting Masking Tapes Market:2027 Report Analysis by Growing Demands, Current and Future Trends

Painting Masking Tapes Market was worth US$ 34.81 Bn in 2020 and total revenue is expected to grow at a rate of 9.56 % CAGR from 2021 to 2027, reaching almost US$ 65.96 Bn in 2027.

Painting Masking Tapes Market Overview:

Image sensors, control circuits, and interfaces such as Ethernet are all integrated into a Painting Masking Tapes. It is used to monitor traffic and applications that require digital signal processing. Painting Masking Tapess allow high-resolution films and photos to be taken. Smartphone manufacturers have begun to place a larger emphasis on the quality of their cameras in order to differentiate their products. At the Qualcomm Tech Summit in Hawaii, Motorola said that its flagship 5G smartphones with enhanced photography capabilities would be available by 2020. (held recently in December 2019).

In September 2019, One Plus announced the One Plus 7T, which features a spherical Painting Masking Tapes on the back with three horizontally aligned cameras. On the rear, a 48-megapixel primary sensor is joined by 16-megapixel and 12-megapixel cameras that can all shoot wide-angle and 960 frames-per-second slow-motion videos.

The MMR report on the Painting Masking Tapes Market provides Size Analysis and forecasts 2020 to 2027. Industry Research Report is detailed, with all the important factors, to help you in business decisions making and develop crucial strategies. Regardless of a manufacturing process or cost structures, this report provides a comprehensive understanding of the progression strategies and ways.

Market Trends:

The report has analyzed many features which are impacting the growth of Painting Masking Tapes market. Thriving factors are positively impacting the demand and restraining factors obstructing the growth of the market are discussed in detail along with their impacts on the global market. Furthermore, the trends which are driving the market and impacting the growth of the market are identified and discussed in detail in the reported study. Other qualitative and quantitative factors such as risks taking with the operations and major challenges faced by the players in the market are included in the report.

Request for free sample:

https://www.maximizemarketresearch.com/request-sample/64270/

Painting Masking Tapes Market Segmentation:

Global Painting Masking Tapes Market by Type

• Acrylic-based • Silicone-based • Rubber-based • Others

Global Painting Masking Tapes Market by Backing Material

• Foam • Foil • Plastics • Glass Fiber • Paper • Foil

Global Painting Masking Tapes Market by Application

• Painting • General Purpose • High Temperature Applications • Spraying • Metal Working

Global Painting Masking Tapes Market by End-user

• Automotive • Building & Construction • Electricals & Electronics • Packaging • Aerospace • Consumer Goods • Furniture & Decorations • Others

Global Painting Masking Tapes Market by Region

• North America • APAC • Europe • MEA& Africa • South America

Key Players:

• 3M Company

• Berry Global, Inc.

• Nitto Denko Corp.

• Saint-Gobain Performance Plastics Corporation

• Scapa Group PLC

• Intertape Polymer Group, Inc.

• Beiersdorf Aktiengesellschaft

• Shurtape Technologies LLC

• Bolex (Shenzhen) Adhesive Products Co. Ltd.

• Advance Tapes International Ltd.

• Lintec Corporation (Japan)

• Avery Dennison Corporation (US)

• Lohmann GmbH

• abro

• sumax Enterprises

Ask your queries regarding the Report:

https://www.maximizemarketresearch.com/market-report/global-painting-masking-tapes-market/64270/

Regional Analysis:

Asia-Pacific(Vietnam, China, Malaysia, Japan, Korea, Thailand, India, Philippines, Indonesia, and Australia)

Europe(Turkey, Russia UK, Italy, Germany, France, etc.)

North America(the United States, Mexico, and Canada.)

South America(Brazil etc.)

The Middle East and Africa(GCC Countries and Egypt.)

COVID-19 Impact Analysis on Painting Masking Tapes Market:

The COVID-19 pandemic has had an impact on the method of life across the globe. Each business, the industry has got to fight the battle on each front—health and economic. The only reply to this spiral is to strategize through this pandemic disruption, and that we believe that firms shall profit an excellent deal from our report into the market. Our report provides probable solutions to the problems caused by the COVID-19 pandemic

About Us:

Maximize Market Research provides syndicate as well as custom made business and market research on 12,000 high growth emerging technologies & opportunities in Chemical, Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact us:

MAXIMIZE MARKET RESEARCH PVT. LTD.

3rd Floor, Navale IT park Phase 2,

Pune Banglore Highway,

Narhe,Pune, Maharashtra 411041, India.

Email: [email protected]

Phone No.: +91 20 6630 3320

0 notes

Text

ADS6445IRGCR Analog to digital converter

Analogue-to-Digital Converters (ADCs) allow microprocessor-controlled circuits, Arduinos, Raspberry Pi, and other digital logic circuits to communicate with the real world. In the real world, analog signals have continuously changing values from various sources and sensors to measure sound, light, temperature, or movement. Many digital systems interact with their environment by measuring the analog signals from such transducers. There are different types of ADC when it comes to structuring. The ADS6445IRGCR is a pipeline structured ADC. Pipeline converters determine the digital world through under-sampling with sample/gain algorithm topology or larger cycle-latency.

The ADS6445IRGCR is a high-performance 14-bit pipeline dual-channel A-D converters. The ADS6445IRGCR offers a variety of sampling rates, such as 125/105/80/65 Mega samples per second. The ADS6445IRGCR comes in a compact 48-pin QFN package (7mm × 7mm) with high system integration density. This compact packaging of ADS6445IRGCR is only possible because of Serial Low Voltage Differential Signaling (LVDS) data outputs that reduce interface lines. The ADS6445IRGCR includes a 3.5 dB coarse gain option that can be used to improve spurious-free dynamic range (SFDR) performance with little degradation in signal-to-noise ratio (SNR). In addition to the coarse gain, good gain options exist in the ADS6445IRGCR, programmable in 1dB steps up to 6dB. For convenience, The ADS6445IRGCR also includes the traditional 1-wire interface used at lower sampling frequencies.

Compared with different alternatives available in the market, the ADS6445IRGCR has a few distinct advantages and some drawbacks. The ADS6445IRGCR structure falls into the pipeline category of ADC. The ADS6445IRGCR has one of the fastest sampling rates, up to 1 GHz second only to Flash type ADC. There is usually a trade-off between sampling rate and bit resolution. The ADS6445IRGCR offers a bit resolution of up to 16 Bits which is when compared to other ADCs. However, if a specific application requires a fast sampling rate with minimal bit resolution, then pipeline structured ADC the ADS6445IRGCR is the most suitable candidate.

A few distinct features/Advantages that gives The ADS6445IRGCR an edge over its competitors include

· 14-Bit Resolution with No Missing Codes

· Simultaneous Sample and Hold

· Serialized LVDS Outputs with Programmable Internal Termination option

· Internal Reference with External Reference support

· No external decoupling is required for references

Due to these characteristics of the

ADS6445IRGCR

, they are used in various applications that require fast sampling rates. These applications include Medical Imaging (Oscilloscopes), Diversity Receivers, Base station If receivers, and test pieces of equipment

0 notes

Text

Analog and Mixed Signal Device Market Segmentation And Opportunity Analysis Report till 2022

September 14, 2021: Mixed signal devices are those that can process both analog and digital systems in a single system. The system can be in the form of a hybrid microcircuit, single integrated circuit chip or a printed circuit board. DACs and ADCs are applications of mixed signal processors as both digital and analog functions are implemented in each. Very large scale Integration(VLSI) is another application that employs processing complex digital signals and analog processing on the chip simultaneously.

Improving technology trends and current markets have increased the demand for mixed signal integration. They have significant benefits and can result in innovative System on chip (SoC) solutions. Integrating analog with digital modules have efficient functionality and power consumption owing to better distribution Single chip solutions. Mixed Signal devices have reduced system noise and faster switching times. They also have simple system designs. Analog modules within these devices can be easily controlled by installing inbuilt software.

Creating special functions by leveraging analog modules and integrating it with mixed signals can push performance to new levels and can spur many innovations. These modules available in the market can be integrated into systems to produce special system function solutions can provide high degree of analog integration variables along with low power performance that can reduce costs. These enhancements in the system can provide unique solutions that are fully programmable that are accountable for a substantial cost savings.

Request a Free Sample Copy of this Report @ https://www.millioninsights.com/industry-reports/analog-mixed-signal-device-market/request-sample

Crossover filters in loudspeakers, stereos and controls on TV are other applications of analog processing. Capacitors, resistors, inductors and transistors are common analog processing elements. Analog signal devices can be used in a various market that include aerospace, communication, healthcare, automotive, motor power control, instrumentation and measurement, security and surveillance, Consumer market and Energy sector. Analog processors are significantly cheaper than other technologies available. One challenge with analog system that are exposed to high temperatures is managing their complexity while maintaining the stability of the system.

They play a crucial role in the semiconductor industry where analog to digital conversions are extensively used for the purpose of micro-controllers and signal processing.

One of the important examples of Mixed Signal devices is the mixed single Integrated chips that form a necessary part of the FM tuning in digital devices such as music players that have amplifiers. Introduction of 3G cell phones along with other technologies that are handy, with their increasing usage have a scope of significant growth in the telecommunications market. Availability of ADC and DAC provide a flexible platform for mixed Signal devices as per requirements and are energy efficient.

Considering the advancements in the Mixed signal device market, the task of combining analog and digital signals to optimize performance and integrate them into a single technology has been simplified. New technologies like CMOS, BiCMOS, CMOS SOI and SiGe have nullified many complexities that were faced previously. Availability of different alternatives to cancel out noise disturbances such as fully differential amplifiers, P+ guard rings and on chip coupling have also simplified tasks.

Every industry has specific requirements and configurations. The consumer electronics include touchscreen devices, display drivers, LED drivers, audio and video codes. The Industrial sectors includes devices like energy monitoring, LED Lighting, ADC, RF and line drivers. The automobile industry includes ADC and sensors. In the computer and storage devices market, Analog and mixed signal devices can be found in SATA, HDMI and Thunderbolt. Communications sector constitutes clock and timing control.

Power management sector, Signal processing sector are segments than can be expected to have high growth. The power sector accounted for over 52% of Analog Integrated Circuit Consumption. This sector emphasizes on efficient utilization of power used by electronic devices. Analog ICs are majorly used in portable devices which are extensively used. Other major functionality includes reduction in the battery drain that indirectly reduce costs. Hence with the growth in the wireless communication market can lead to growth in the Analog IC market.

Increase in the usage of application specific Analog ICs can bring about a sales growth of these devices. They constitute for 60% of the Analog ICs Market. With the advent of new technologies in Sensor ASICs and Power Management ASICs, there are wide variety of applications in each of them which include consumer electronic devices such as digital cameras, LCD and LED screens, cell phones and other devices that work on battery.

Market pertaining to analog and mixed signal devices have a diversified customer base. New product innovation and launch of sophisticated instruments can provide new avenues for growth in this industry. Health care industry has wide application of analog and mixed signal devices. They are used as monitoring equipment, medical instrumentation and diagnosis. Firms can differentiate their products by collaborating and integrating different functionalities of design tools and application support systems. Increasing usage of smart phone devices is also a major market for analog and mixed signal devices they are used as chips within smartphones.

Browse Full Research Report @ https://www.millioninsights.com/industry-reports/analog-mixed-signal-device-market

New product Developments are expected to play a major role with the introduction of EDA tools that are specifically made for analog/mixed signal market. The Market is expected to grow at a rate of 5%. Costs associated with processes are usually balanced out with the new avenues in the various product developments in the market.

With the focus of these technologies seen in Europe, Asia, Japan and U.S., the market is majorly driven by best.tools and methodologies that can be employed in the field of aviation, automobiles, communications, multimedia sectors and telecommunications. Opportunities include new modelling techniques, Analog Modeling and RF Modeling. Modularizing capabilities and enhanced integration with different systems of advanced packaging and SoCs.

Competitors in this market include Analog devices that is a market leader in National Semiconductors, Maxim Integrated Products Inc., and Texas Instruments, BroadComm QualComm, Linear and Maxim. Most competitors are characterized by high operating margins and gross margins. Analog and Mixed device manufacturing firms are highly resource intensive employing many applications that are involved in development, sales, sales reps, and distributors.

Get in touch

At Million Insights, we work with the aim to reach the highest levels of customer satisfaction. Our representatives strive to understand diverse client requirements and cater to the same with the most innovative and functional solutions.

Contact Person:

Ryan Manuel

Research Support Specialist, USA

Email: [email protected]

0 notes

Text

Advances in Real-Time Soil Fertility Determination- Juniper Publishers

Rapid advances in sensor technology are enabling aggressive use of informatics in agriculture. This paper focuses on applying the newly developed soil electrical impedance spectrum sensor combined with artificial intelligence to predict soil fertility. The described method determines the type and amount of fertilizer to be used. The proposed sensor system is portable and fast enough for real-time measurements in the field using a slow-moving tractor. It is affordable, battery-powered and allows wireless data transmission to the farmer’s soil database. Such a database allows the farmer to create a reliable fertilizer plan. The crop is of better quality because fertilizer is applied only where it is needed on the plot. The use of fertilizer is optimized, costs are reduced, and the environment is preserved. Many papers report more or less credible results on this problem, but they lack verification of real conditions in the field.

Keywords: Soil analysis; Real-time fertilization plan; Electrical impedance spectrum of the soil; Soil classificatory

Abbreviations: Application Specific Integrated Circuit (ASIC); Deionized (DI); Agriculture Institute of Slovenia (KIS); Principle of Component Analysis (PCA)

Introduction

The diversity of soil conditions in terms of its moisture, composition, texture, and temperature makes soil analysis very difficult. The deterministic methods, such as chemical analysis, cannot be used in the field because it requires a chemical laboratory. It is time consuming, expensive and unreliable as it only relates to a particular soil sample. Dozens of soil samples must be collected and analyzed per acre. In the recent article [1], the authors described their vision about the future development of digital agriculture. They listed several possible sensors that would monitor the agricultural plot and collect a soil and crop status database below and above the surface. The analysis of this data would pave the way for the optimization of agricultural activities. Many methods have been described [2-4], but none are accurate enough or acceptable for real-time applications. We want to collect soil fertility results in a few seconds while driving the tractor over the field. In this section, we will briefly review some of the most promising soil characterization technologies. Optical methods were investigated using spectral analysis in both the visible and visible-infrared spectra, analyzing either reflectance or transmittance results. Our investigation of these methods did not meet our expectations. We tried an interesting approach to study the residual of tiny dried droplets of soil extraction fluid and found promising results. This approach is shown in Figure 1. Figure 2 shows the optical spectra of such a soil solution. Some other impressive results can be obtained under laboratory conditions, but field application is not feasible. Raman spectroscopy or mass spectroscopy analysis is too expensive and too slow for on the fly analysis. The non-contact methods using microwaves and terahertz waves are too expensive and not convincingly reliable. Unfortunately, these methods have not met the expected criteria. We need a better approach that is marketable and accepted by farmers. In our study, we decided to develop a sensor system that meets the following criteria for acceptance:

a.accuracy, reliability, and repeatability,

b.fast, on the spot, portable, battery-powered,

c.easy to use, robust and user-friendly,

d.low cost, and

e.ready for wireless communication.

The closest technology to meet the listed requirements seemed to measure and analyze the soil’s electrical impedance spectrum. The soil electrical impedance spectrum method [4] is the most promising, but it requires significant extensions to meet the listed acceptance criteria. In the following sections we will describe these extensions.

Materials and methods

In the field, the soil sample has unknown composition, texture, and moisture. These values significantly affect the soil spectrum and affect soil classification and fertilizer prediction accuracy. In laboratory experiments, these conditions are known and held constant. However, to classify an unknown soil sample, some additional soil parameters must be recorded. These are the relative soil viscosity, the temperature, the value PH and the DC resistivity. These values are used to pre-select a reference database for the classification algorithm. The resulting classification algorithm is then significantly improved. These improvements mean that the soil database of known chemical parameters must be expanded to include the listed parameters. Figure 3 shows the flow-chart of the classification algorithm procedure. Figure 4 shows a simplified schematic of the soil impedance spectrometer Application Specific Integrated Circuit (ASIC). It consists of a mixed-signal design of the front-end electronics, a programmable clock generator to excite the soil sample, and the signal processing unit to calculate the impedance’s real and imaginary parts. Figure 5 shows the simplified interface diagram between the ASIC of the soil impedance spectrometer and the processing unit, like a personal computer or similar. Soil samples are collected from 0-30 cm soil surface and then prepared in the laboratory for characterization and classification. The soil samples were air-dried and sieved 2 mm. They were then mixed with the required amount of Deionized (DI) water to obtain a soil mass with the required viscosity. The amount of DI water is different for each soil and is estimated automatically. A certified laboratory performed a chemical analysis of all soil samples in the Agriculture Institute of Slovenia (KIS) [4]. The comprehensive characterization of each soil sample contains information on all common soil constituents, and only the analyzed nutrients are listed in Table I. Reading and storing the imaginary and real parts of signals corresponding to a soil sample or reference circle is performed using Matlab software. The Matlab script is created to read the controller Analog to Digital Converter (ADC) data and store it in a personal computer or database for further processing.

Data preprocessing is performed to calibrate the obtained imaginary and real parts of soil impedance with the imaginary and real parts of the reference circuit impedance. This procedure is necessary to ensure accurate data acquisition. The reference circuit signals for the final sensor design are measured only once and used to correct other signals acquired with this sensor. We use the corrected signals corresponding to the soil samples to calculate the impedance magnitude and impedance phase. A training set for machine learning is formed from the research dataset measurements corresponding to soil with known chemical properties of phosphorus, potassium and magnesium. The research dataset consists of impedance strengths and impedance phases corresponding to a soil sample. The chemical analysis of soil sample properties performed at KIS includes nutrient values for phosphorus, potassium and magnesium. Tables 2&3 and Figure 6 show the principles of soil sample code formation. Following the fertilizer planning recommendations, the A-E classification was used for each soil component (e.g., phosphorus, potassium, and magnesium). These classification components are then combined to form a XXX code for classifying and predicting the soil properties under test.

The training process includes the feature selection procedure [5] and classification using the so-called “classifier”. Many classifiers have been proposed in the literature that performs classification with different degrees of accuracy. A comparative analysis was performed to select the classifier with the best results (i.e., the best match between the predicted nutrient content and the actual nutrient content determined at the KIS). The classification accuracy was validated using the leave-one-out method [6]. Only soil samples with known chemical properties were used in this validation (i.e., training set). Three subsamples represent each soil sample to allow more accurate analysis. First, a soil subsample corresponding to the measurement from the research dataset was used as a test sample, while the others were used for machine learning (i.e., training set). Then, the obtained prediction is compared with the actual soil properties (i.e., KIS code). This procedure is performed for all data from the research dataset. The results obtained for three subsamples of the same soil are averaged and used to calculate the overall classification accuracy. In other words, the percentage of predicted characteristics that match the certified laboratory characteristics is used to characterize classification accuracy. Taking three or more measurements of the same soil sample is typical in agricultural informatics to obtain a more accurate and representative result. The procedure for calculating the classification accuracy is shown in Figure 7, where the process is illustrated graphically. During the feature extraction procedure, the signal frequencies with the most relevant information for classification are selected separately for impedance magnitudes and impedance phases. Several feature selection methods are described in the literature. The Principle of Component Analysis (PCA) is selected here as one of the most common and useful [7]. An example of the classification accuracy obtained when the feature selection procedure was used and when the feature selection was not used can be seen in Table IV. It shows a significant performance improvement of the classifiers with feature selection even in the problematic soil sample without using the pre-selection feature introduced in the proposed novel classifier. Figure 8 shows the estimated weights for impedance variables according to the research dataset. The threshold value Th=0.2 is used to reduce features with a small impact on classification accuracy. Thus, 13 features were extracted. Table V shows the frequencies and their indexes obtained during feature selection. The obtained frequencies are then used for both machine learning and test signal properties prediction. Tree Bagger [8] was selected as the most promising classifier. Tree Bagger chooses a random subset of predictors for each decision partition as in the random forest algorithm. The outputs of the classifier are model parameters that are unique to each research dataset. These parameters are estimated once and then used to predict the chemical properties of the soil under study. Table VI shows the classifiers selected for comparative analysis in this research.

Results