#Cubic Boron Nitride (CBN) Wheels Market trends

Text

Cubic Boron Nitride (CBN) Wheels Market | Analysis Report | 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Cubic Boron Nitride (CBN) Wheels Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2031.” The study provides a detailed analysis of the industry, including the global Cubic Boron Nitride (CBN) Wheels Market Share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Cubic Boron Nitride (CBN) Wheels Market?

The global cubic boron nitride (CBN) wheels market to register a CAGR of 11.3% during the forecast period.

What are Cubic Boron Nitride (CBN) Wheels?

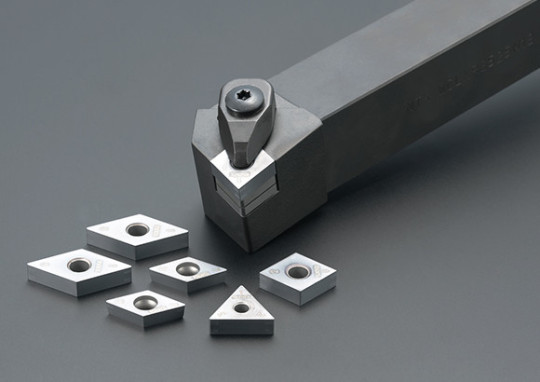

Cubic Boron Nitride (CBN) wheels are abrasive tools employed for grinding and cutting tasks, renowned for their remarkable hardness, thermal conductivity, and chemical stability. These wheels consist of synthetic crystalline CBN particles adhered to a substrate, typically aluminum or steel, offering superior performance and durability compared to conventional abrasive materials such as silicon carbide or aluminum oxide. Widely applied in precision machining, CBN wheels excel in grinding hardened steels, superalloys, and other challenging materials where high material removal rates, precision, and surface finish quality are essential. Valued for their ability to maintain sharp cutting edges, resist wear, and efficiently dissipate heat, CBN wheels enhance productivity and cost-effectiveness across various industrial applications.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1932

What are the growth prospects and trends in the Cubic Boron Nitride (CBN) Wheels industry?

The cubic boron nitride wheels market growth is driven by various factors. The Cubic Boron Nitride (CBN) wheels market includes a variety of abrasive tools highly valued for their outstanding hardness, thermal conductivity, and chemical stability. Witnessing notable expansion propelled by growing demand for precise machining solutions across sectors like automotive, aerospace, and manufacturing, this market offers a diverse array of products tailored to specific cutting and grinding needs. Major players in the CBN wheels market provide cutting-edge solutions characterized by improved durability, cutting efficiency, and surface finish quality, effectively meeting the rigorous demands of contemporary machining processes. Furthermore, ongoing advancements in manufacturing techniques and materials drive continuous innovation within the market, ensuring its ongoing growth and widespread adoption of CBN wheel technology globally. Hence, all these factors contribute to cubic boron nitride wheels market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Resin CBN Wheels

Metal CBN Wheels

Ceramic CBN Wheels

Electroplated CBN Wheels

By Application:

Automotive Parts

Metal Grinding

Industrial

Others

Market Segmentation By Region:

North America

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Saint-Gobain Abrasives Inc.

ILJIN Diamond Co., Ltd.

Noritake Co., Ltd.

Asahi Diamond Industrial Co., Ltd.

Carborundum Universal Limited

Ehwa Diamond Industrial Co., Ltd.

Diametal AG

Tokyo Diamond Tools Mfg. Co., Ltd.

Zhengzhou Hongtuo Superabrasive Products Co., Ltd.

Sandvik AB

Engis Corporation

Karnasch Professional Tools GmbH

Nanjing Sanchao Advanced Materials Co., Ltd.

SuperAbrasives, Inc.

View Full Report: https://www.reportsandinsights.com/report/Cubic Boron Nitride (CBN) Wheels-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Cubic Boron Nitride (CBN) Wheels Market share#Cubic Boron Nitride (CBN) Wheels Market size#Cubic Boron Nitride (CBN) Wheels Market trends

0 notes

Text

China Abrasives: A Comprehensive Guide to Industry Trends, Innovation, and Applications

The world of abrasives may not seem like the most exciting topic at first glance, but it plays a crucial role in a wide range of industries. From manufacturing and automotive to construction and electronics, abrasives are essential tools for shaping, finishing, and polishing materials. One of the leading players in the global abrasives market is China, known for its innovation and production capabilities. So, what sets China Abrasives industry apart, and how can you benefit from their expertise? Let’s explore these questions.

China's Dominance in Abrasive Production

China's position as a global leader in the abrasive industry is no accident. The country boasts several key advantages:

Abundant Natural Resources: China has access to vast reserves of minerals such as bauxite, alumina, and silicon carbide, which are essential for producing high-quality abrasives.

Advanced Manufacturing Technologies: China continuously invests in state-of-the-art machinery and production techniques, allowing for high precision and consistent quality.

Cost-Effective Production: Chinese manufacturers benefit from lower labor and production costs, enabling them to offer competitive pricing.

Innovative Product Development: Chinese companies are at the forefront of developing new abrasive materials and technologies, such as superabrasives and eco-friendly abrasives.

Abrasive Materials and Products from China

China's abrasive industry offers a diverse range of products tailored to various applications:

Bonded Abrasives: These are abrasive grains held together by a bonding agent, forming tools such as grinding wheels and honing stones.

Coated Abrasives: Coated abrasives feature grains bonded to a backing material (paper, cloth, or film), forming products like sandpaper and abrasive belts.

Loose Abrasives: These are free-flowing grains used in applications such as sandblasting and polishing.

Superabrasives: Superabrasives, such as diamond and cubic boron nitride (CBN), are ideal for precision grinding and cutting applications.

Applications of China Abrasives

Abrasives from China are used across numerous industries:

Manufacturing: Abrasives are essential for shaping and finishing metal, glass, and ceramics in the manufacturing sector.

Automotive: From grinding engine components to polishing bodywork, abrasives play a key role in automotive production and maintenance.

Construction: Abrasives help in cutting, grinding, and polishing construction materials like concrete, marble, and granite.

Electronics: The electronics industry relies on fine abrasives for precision polishing and surface finishing of delicate components.

Environmental Considerations and Sustainability

As the world becomes more environmentally conscious, the abrasive industry in China is making strides toward sustainability:

Eco-Friendly Abrasives: Chinese manufacturers are developing biodegradable and recyclable abrasive products to minimize environmental impact.

Energy-Efficient Production: By implementing energy-efficient practices, Chinese companies are reducing their carbon footprint and promoting sustainability.

The Future of China Abrasives

What can we expect from the Chinese abrasive industry in the coming years?

Technological Advancements: China will likely continue investing in research and development to create more advanced abrasive materials and tools.

Global Market Expansion: As China's reputation for high-quality abrasives grows, we can expect the country to expand its market share internationally.

Increased Focus on Sustainability: Environmental concerns will drive Chinese manufacturers to prioritize sustainable practices and products.

In conclusion, China's abrasive industry is a powerhouse of innovation, efficiency, and sustainability. By understanding the trends and opportunities within this industry, you can make informed decisions about the best products for your applications.

0 notes

Text

Super Abrasives Market Size, Share, Growth, Industry Analysis and Forecast 2025 | TechSci Research

According to TechSci Research report, “Global Super Abrasives Market By Product, By Application, By Region, Competition, Forecast & Opportunities, 2025”, the global super abrasives market is estimated at around $ 3.5 billion in 2020 and is projected to grow to $ 4.8 billion by 2025. Super abrasive materials are used for coating several tools, like grinding wheels to enhance their grinding output, which is driving the market growth. Rising demand for medical equipment such as surgical bone drills, pace makers, hearing aids, etc., is also boosting the growth of super abrasives market worldwide. Furthermore, manufacturing processes like machining centers and automated systems are widely using the product owing to requirement of high operating speeds for machining process. Due to the increasing implementation of these manufacturing technologies, the global super abrasives market is forecast to rev up over the next five years.

Browse 126 market data Figures spread through 118 Pages and an in-depth TOC on "Global Super Abrasives Market"

https://www.techsciresearch.com/report/super-abrasives-market/4408.html

Global super abrasives market has been segmented based on product, application and region. Considering the product, the market is fragmented into Cubic Boron Nitride, Polycrystalline, CVD diamonds and nano diamonds. Out of which, Cubic Boron Nitride (CBN) segment is the largest segment and is expected continue its dominance during the forecast period. The increasing awareness regarding the benefits of CBN over other hard materials used for various industrial processes, such as cutting, grinding, drilling, and boring, is having the most significant impact on the growth of CBN segment. Further, based on application, the automotive sector dominates the market, however, in the present scenario of Coronavirus pandemic, the automotive industry is experiencing huge fluctuations. Rapid decrease in vehicle sales coupled with shutting down of automobile and component manufacturing plants globally has negatively impacted the automotive industry. Nevertheless, super abrasives are experiencing significant demand from the medical industry. Due to the sudden onslaught of the Coronavirus pandemic, there is a sudden surge in demand for emergency medical equipment and protective gear, which is further driving the sales of super abrasives.

Download sample report @ https://www.techsciresearch.com/sample-report.aspx?cid=4408

Customers can also request for 10% free customization on this report.

Saint-Gobain Abrasives, Inc, Günter Wendt GmbH Radiac Abrasives, Inc, Noritake Co. Limited, Asahi Diamond Industrial Co., Ltd, 3M Company, Carborundum Universal Ltd, Guangdong Chanway Industrial Co. Ltd, etc., are the leading players operating in the global super abrasives market. “Asia-Pacific is expected to witness fastest growth in the global super abrasives market until 2025 on the account of increasing construction work and infrastructural activities coupled with rising per capita income levels across the developing economies such as China and India. Additionally, continuing growth of key end-user industries, like building, automotive, etc., coupled with rising emphasis on manufacturing sector, is further forecast to boost the growth of the global super abrasives market through 2025.”, said Mr. Karan Chechi, Research Director with TechSci Research, a research based global management consulting firm.

“Global Super Abrasives Market By Product, By Application, By Region, Competition, Forecast & Opportunities, 2025” has evaluated the future growth potential of global super abrasives market and provides statistics & information on market size, structure and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides, the report also identifies and analyzes the emerging trends along with essential drivers, challenges and opportunities in global super abrasives market.

About TechSci Research

TechSci Research is a leading global market research firm publishing premium market research reports. Serving 700 global clients with more than 600 premium market research studies, TechSci Research is serving clients across 11 different industrial verticals. TechSci Research specializes in research-based consulting assignments in high growth and emerging markets, leading technologies and niche applications. Our workforce of more than 100 fulltime Analysts and Consultants employing innovative research solutions and tracking global and country specific high growth markets helps TechSci clients to lead rather than follow market trends.

Contact

Mr. Ken Mathews

708 Third Avenue,

Manhattan, NY,

New York – 10017

Tel: +1-646-360-1656

Email: [email protected]

Website: https://www.techsciresearch.com/

0 notes

Text

Global Cubic Boron Nitride(CBN) Market Analysis by Key Players, End Users and CAGR Forecast to 2028

Market Overview

The most recently published Cubic Boron Nitride(CBN) Market report provides a critical assessment of key growth dynamics, emerging pathways, investment trends in key regional markets, and the competitive landscape in various regions and key players’ strategies. The study also offers insights into the proportion and size of various segments of the Cubic Boron Nitride(CBN) market. The report presents the market analysis based on several factors. Various exploration techniques such as qualitative and quantitative analysis have been used to accurately provide data. To better understand customers, he uses effective graphic presentation techniques such as charts, graphs, tables, and images.

Buy Any 3 And Pay For Only 2

Hurry Up To Grab This Exciting Discount...!

Offer Valid Till 31st March 2021.

Get Free Sample PDF @ https://ordientmarketresearch.com/sample-request/chemicals-and-materials/world-cubic-boron-nitride-cbn-market/OMR2097

The report covers a wide range of areas for a better global market experience as well as industry trends and forecasts. The report covers market models based on product types, application regions, and key vendors. In this report, variables influencing the market such as drivers, controls, and store openings have been carefully described. The review of market models, reviews, and numbers has been done on both a large scale and a micro level. It also gives a general overview of the strategies that the main competitors have received within the company. Other important variables that influence market trends regionally and globally were taken into account. These influencing factors are the socio-political situation, environmental conditions, demographics, legal organizations, and the competitive environment in the region.

Market Scope

The research report is committed to giving its readers an unbiased point of view of the global Cubic Boron Nitride(CBN) market. Thus, along with statistics, it includes opinions and recommendation of market experts. This allows the readers to acquire a holistic view of the global market and the segments therein. The research report includes the study of the market segments on the basis of type, application, and region. This helps in identifying segment-specific drivers, restraints, threats, and opportunities.

Browse Full Premium Report @ https://ordientmarketresearch.com/chemicals-and-materials/world-cubic-boron-nitride-cbn-market/OMR2097

Segmental Analysis

The report has classified the global Cubic Boron Nitride(CBN) industry into segments including product type and application. Every segment is evaluated based on growth rate and share. Besides, the analysts have studied the potential regions that may prove rewarding for the Cubic Boron Nitride(CBN) manufacturers in the coming years. The regional analysis includes reliable predictions on value and volume, thereby helping market players to gain deep insights into the overall Cubic Boron Nitride(CBN) industry.

By Type

Medium grade CBN Monocrystalline

Low grade CBN Monocrystalline

By Application

Resin bond and vitrified wheels

Resin bond grinding wheels

Vitrified wheels

Electroplated products

PcBN

Others

Regions covered in Cubic Boron Nitride(CBN) market report are:

North America

United States

Canada

Europe

Germany

France

U.K.

Italy

Russia

Nordic

Rest of Europe

Asia-Pacific

China

Japan

South Korea

Southeast Asia

India

Australia

Rest of Asia-Pacific

Latin America

Mexico

Brazil

Middle East & Africa

Turkey

Saudi Arabia

UAE

Rest of Middle East & Africa

To Enquire About Discount Visit @ https://ordientmarketresearch.com/check-discount/chemicals-and-materials/world-cubic-boron-nitride-cbn-market/OMR2097

Global Cubic Boron Nitride(CBN) Market Report provide in-depth information about the Leading Competitors involved in this report:

Element Six

Momentive

ILJIN

Saint-Gobain

Sumitomo Electric Industries

Sandvik Hyperion

Tomei Diamond

FUNIK

Zhengzhou Zhongnan Jete Superabrasives

Famous Diamond

Besco Superabrasives

Berlt Hard Material

Zhengzhou Zhong peng

Henan Huanghe Whirlwind

Yuzhou Hehui Superhard Material Company

Reasons To Buy Cubic Boron Nitride(CBN) Market Report(Key Points):

1.The report provides important statistics on the market status of the Cubic Boron Nitride(CBN) Devices manufacturers and is a valuable guidance and guidance tool for companies and individuals interested in the industry.

2.The report provides a basic overview of the industry including definition, applications, and manufacturing technology.

3.The report includes the company profile, product specifications, capacity, production value, and market share for major vendors for 2021-2028.

4.The overall market is then further subdivided by company, country, and application/type for the competitive landscape analysis.

5.The report estimates Cubic Boron Nitride(CBN) Devices industry market development trends for 2021-2028.

6.An analysis of the upstream raw materials, the downstream demand and the current market dynamics is also carried out.

Browse More Reports:

Global Methyl Methacrylate Mma Market 2021 New Business Opportunities Growth Segmented By Prominent Players

Influenza Treatment Market Size Industry Share Estimated To Experience A Hike In Growth By 2021 2028

Contact Us

Mangesh Mahajan

Head of Business Development

Phone: +91-7385620197

Email: [email protected]

Web: https://ordientmarketresearch.com/

0 notes

Text

Global Cubic Boron Nitride(CBN) Market Analysis by Key Players, End Users and CAGR Forecast to 2025

Market Overview

The Global Cubic Boron Nitride(CBN) Market is foreseen to experience a fall from USD XX billion in 2020 to USD XX billion in 2021 at a CAGR of XX%. The descent is primarily the result of economic decline across countries unsettled due to ongoing Coronavirus outbreak, including controlling it. Thereafter, the Cubic Boron Nitride(CBN) market is likely to restore and expand at a CAGR of XX% from 2021, stretching up to USD XXX billion in 2025.

BUY ANY 3 AND PAY FOR ONLY 2

Hurry Up To Grab This Exciting Offer…………!

This Discount offer is valid till 31st March 2021

Get Free Sample Report @https://ordientmarketresearch.com/sample-request/chemicals-and-materials/world-cubic-boron-nitride-cbn-market/OMR2097

The research document comprises market traits, opportunities, industry size, fragmentation, territorial breakdowns, market shares, ongoing trends, competitive landscape, and strategies for the Cubic Boron Nitride(CBN) market. The report also tracks essential information about the market and predict market expansion by the geographic landscape. It also positions the market under the extensive Cubic Boron Nitride(CBN) market framework and collates it with other alternative markets.

This report also offers the planners, policymakers, senior leadership, and traders crucial details to estimate the global Cubic Boron Nitride(CBN) market as it arises from the COVID-19 closure.

Market Scope

The Cubic Boron Nitride(CBN) Industry sets out tendencies that affect various subsidiary industries. Therefore, the Global market has ruled for being one of the leading revenue generators over the past several decades. This industry has challenged every economic disruption and withstands the test of time. Though this could benefit to motivate new market players in the Global industry, the preference for product development and novel procedures could assist new participants in obtaining a stronghold.

Browse Full Premium Report @ https://ordientmarketresearch.com/chemicals-and-materials/world-cubic-boron-nitride-cbn-market/OMR2097

Cubic Boron Nitride(CBN) Market Research Report is Segmented as Follows:

Product Types can be segregated as:

Medium grade CBN Monocrystalline

Low grade CBN Monocrystalline

Applications can be segregated as:

Resin bond and vitrified wheels

Resin bond grinding wheels

Vitrified wheels

Electroplated products

PcBN

Others

Regions covered in this report are:

North America

United States

Canada

Europe

Germany

France

U.K.

Italy

Russia

Nordic

Rest of Europe

Asia-Pacific

China

Japan

South Korea

Southeast Asia

India

Australia

Rest of Asia-Pacific

Latin America

Mexico

Brazil

Middle East & Africa

Turkey

Saudi Arabia

UAE

Rest of Middle East & Africa

Checkout Inquiry For Buying or Customization of Cubic Boron Nitride(CBN) Market: https://ordientmarketresearch.com/enquiry/chemicals-and-materials/world-cubic-boron-nitride-cbn-market/OMR2097

Global Cubic Boron Nitride(CBN) Market Report provide in-depth information about the Leading Competitors involved in this report:

Element Six

Momentive

ILJIN

Saint-Gobain

Sumitomo Electric Industries

Sandvik Hyperion

Tomei Diamond

FUNIK

Zhengzhou Zhongnan Jete Superabrasives

Famous Diamond

Besco Superabrasives

Berlt Hard Material

Zhengzhou Zhong peng

Henan Huanghe Whirlwind

Yuzhou Hehui Superhard Material Company

Innovations in the technology field have contributed to the growth of the Global industry. The arrival of energy- and cost-efficient appliances have rejuvenated procedures in the Cubic Boron Nitride(CBN) industry.

Economic expansion in developing countries as well have arisen as an advantage for the Global industry. Although strict rules that supervise global production and processing affect the growth rate of the Global industry.

Enquire about Discount for This Report @ https://ordientmarketresearch.com/check-disco

#Global Cubic Boron Nitride(CBN) Market#Cubic Boron Nitride(CBN) Market#Cubic Boron Nitride(CBN)#Cubic Boron Nitride(CBN) Market Comprehensive Analysis#Cubic Boron Nitride(CBN) Market Comprehensive Report#Cubic Boron Nitride(CBN) Market Forecast#Cubic Boron Nitride(CBN) Market Forecast to 2028#Cubic Boron Nitride(CBN) Market Growth#Cubic Boron Nitride(CBN) Market in Asia#Cubic Boron Nitride(CBN) Market in Australia#Cubic Boron Nitride(CBN) Market in Canada#Cubic Boron Nitride(CBN) Market in Europe#Cubic Boron Nitride(CBN) Market in France#Cubic Boron Nitride(CBN) Market in Germany#Cubic Boron Nitride(CBN) Market in Israel#Cubic Boron Nitride(CBN) Market in Japan#Cubic Boron Nitride(CBN) Market in Key Countries#Cubic Boron Nitride(CBN) Market in Korea#Cubic Boron Nitride(CBN) Market in United Kingdom#Cubic Boron Nitride(CBN) Market in United States#Cubic Boron Nitride(CBN) Market Report#Cubic Boron Nitride(CBN) Market Research#COVID 19 impact on Cubic Boron Nitride(CBN) Market

0 notes

Text

Cubic Boron Nitride(CBN) Market 2019 Industry Survey, Market Size, Competitive Trends, Outlook And Forecasts 2024

"Market Scenario of the Cubic Boron Nitride(CBN) Market:

The latest Cubic Boron Nitride(CBN) Market Research study involves some major activities to estimate the current market size for the global Cubic Boron Nitride(CBN) market. It presents a detailed analysis based on the thorough research of the market dynamics like market size, growth scenario, potential opportunities, and operation landscape & trend analysis.

Request your Sample PDF Report: @ https://www.alexareports.com/report-sample/37521

This research is conducted to understand the current landscape of the market, especially in 2019. Top-down and bottom-up approaches were employed to estimate the complete market size. This will help all the manufacturers and investors to have a better understanding of the direction in which the market is headed.

The report offers a comprehensive analysis of Cubic Boron Nitride(CBN) industry, standing on the readers’ perspective, delivering detailed market data and penetrating insights. It assesses the impact of the technological advancements, changes in investment habits, and in-depth overview of Product Specification. This report focuses on the Cubic Boron Nitride(CBN) industry status, presents volume and value, key market, product type, consumers, regions, and key players.

Top Key Players Covered in this report – Element Six, Momentive, ILJIN, Saint-Gobain, Sumitomo Electric Industries, Sandvik Hyperion, Tomei Diamond, FUNIK, Zhengzhou Zhongnan Jete Superabrasives, Famous Diamond, Besco Superabrasives, Berlt Hard Material, Zhengzhou Zhong peng, Henan Huanghe Whirlwind, Yuzhou Hehui Superhard Material Company,

Product type: Type 1, Type 2

Applications: Resin bond and vitrified wheels,Resin bond grinding wheels,Vitrified wheels,Electroplated products,PcBN,Others,

The report will be helpful in keeping an eye on growth factors, shortcomings, threats, and the lucrative opportunities that the market will offer over the forecast period. The report also features the revenue; industry size, share, production volume, and consumption in order to gain insights about the politics and tussle of gaining control of a huge chunk of the market share.

Click Here To Get Exclusive Discount @ https://www.alexareports.com/check-discount/37521

Cubic Boron Nitride(CBN) Market Competitive Analysis:

The Cubic Boron Nitride(CBN) Industry is most lucrative due to the presence of several established players and their constant evolving marketing strategies to expand their market share. The vendors available in the market complete centered on price, quality, brand, product differentiation, and product portfolio. The vendors are increasingly emphasizing product customization through customer interaction.

Market Segmentation: Global Cubic Boron Nitride(CBN) Market

– The market is based on type, application, and geographical segments.

– Based on type, the market is segmented into Type 1, Type 2.

– Based on application, the market is segmented into Resin bond and vitrified wheels,Resin bond grinding wheels,Vitrified wheels,Electroplated products,PcBN,Others,.

The study offers the market growth rate, size, and forecasts at the global level along with geographic economies: North America, Europe, Asia-Pacific, South America, and the Middle East and Africa

The key elements of the Cubic Boron Nitride(CBN) Market Study:

To analyze and forecast the market size of Cubic Boron Nitride(CBN), in terms of value.

To classify and forecast global Cubic Boron Nitride(CBN) Market based on organization size, end-user and regional distribution.

To identify drivers and challenges for Global Cubic Boron Nitride(CBN) Market.

To examine competitive developments such as expansions, new product launches, mergers & acquisitions, etc., in Global Cubic Boron Nitride(CBN).

To conduct the pricing analysis for Cubic Boron Nitride(CBN).

To identify and analyze the profile of leading players involved in the manufacturing of Global Cubic Boron Nitride(CBN).

To Enquire About This Comprehensive Report, Click Here@ https://www.alexareports.com/send-an-enquiry/37521

In the end Cubic Boron Nitride(CBN) Market Report delivers conclusion which includes Breakdown and Data Triangulation, Consumer Needs/Customer Preference Change, Research Findings, Market Size Estimation, Data Source. These factors will increase business overall.

Thank you for your time. You can also ask for individual chapter wise or section or region wise report version.

About Us:

Alexa Reports is a globally celebrated premium market research service provider, with a strong legacy of empowering business with years of experience. We help our clients by implementing decision support system through progressive statistical surveying, in-depth market analysis, and reliable forecast data. Alexa Reports is a globally celebrated premium market research service provider, with a strong legacy of empowering business with years of experience. We help our clients by implementing decision support system through progressive statistical surveying, in-depth market analysis, and reliable forecast data.

Contact Us:

Alexa Reports

Ph no: +1-408-844-4624 / +91- 7030626939

Email: [email protected]

Site: https://www.alexareports.com

"

0 notes

Text

Bonded Abrasives Market Latest Trends, Demand and Analysis 2025

Abrasive is a material used to mold or provide finishing to a piece of work, through a process that requires buffing, grinding, cutting, and polishing. Abrasion depends on the difference between the hardness of the material and the abrasive (with the latter being the harder of the two).Abrasives are used in a wide variety of industrial, domestic, and technological applications. Abrasives and abrasive products are extensively used for various applications such as cutting, grinding, drilling, polishing, lapping, honing, and buffing.There are various types of abrasives available such as bonded abrasives, coated abrasives, raw super-abrasives, steel abrasives, and loose abrasive grains. Bonded abrasives are either synthetic or natural abrasive grains bonded together into a solid form, usually in the shape of a wheel. Bonded abrasive products include cut-off and grinding wheels, cylinders, segments, inserts, snagging wheels, sticks, mounted wheels, discs, cones, plugs, and inserts.

Planning to lay down strategy for the next few years? Our report can help shape your plan better.

Abrasive grains (natural as well as synthetic) are bonded onto a surface material through a matrix made from resin, glass, rubber, or other binding materials. Surface materials such as ceramics, metal, or plastics are used to produce bonded abrasives. Selection of the type and shape of the bonded abrasive depends upon the metal processing operation. For instance, abrasive stones are employed for honing, either internal or external, surfaces.Different types of bonds are used to bond abrasive grains to the surface material. Sometimes, abrasives grains are electroplated to braze onto metal substrates. Other surface materials include systems with resin, glass, rubber, or shellac. The bond formed between abrasive grains and surface substrate system vary from low-strength to high-strength bonds.Super-abrasive material comprises diamond and cubic boron nitride (CBN). Ceramic abrasives include metal oxides of aluminum and iron. Other abrasives include carbides of silicon, tungsten, and boron.

To obtain all-inclusive information on forecast analysis of global market, request a PDF brochure here.

Demand for bonded abrasives is increasing globally due to its use in several applications such as grinding, forming, sharpening, and finishing. Rise in demand for bonded abrasives from aerospace, automotive, machine tool, foundry, metal fabrication, and welding industries is expected to drive the bonded abrasives market.Requirement for bonded abrasives from the upcoming automotive industry is anticipated to boost the market. Bonded abrasives are largely employed in surface finishing and designing of automobiles. Increasing demand for the advanced technology-based machineries are expected to propel the bonded abrasives market. The bonded abrasives are used to provide smooth finish to various tools and machineries. Regular maintenance of workshops is further driving the bonded abrasives market.

For more actionable insights into the competitive landscape of global market, get a customized report here.

In terms of abrasives used, the bonded abrasives market can be divided into synthetic diamond, cubic boron nitride, carbides (silicon, boron, and tungsten), ceramic metal oxides (aluminum and iron), steel abrasive, and others. Based on product form, the market can be segmented into wheels (wheels, discs, and dishes), inserts (cups, cylinders, and sticks), and others (stones and segments). In terms of end-user industry, the market can be segregated into machinery, electrical & electronic equipment, transportation, metal fabrication, and others (including construction, medical devices, power generation, and cleaning & maintenance).Major players operating in the bonded abrasives market are forward integrating into manufacturing various abrasive machining tools as well as backward integrating into production of abrasive materials. Key players operating in the market include 3M, Robert Bosch GmbH, Asahi Diamond Industrial Co. Ltd., Carborundum Universal Ltd., Entegris Inc., Grindwell Norton Ltd., ILJIN Diamond Co. Ltd., Norstel AB, Reishauer AG, Saint-Gobain, Sandvik AB, and SHOWA DENKO K.K.

0 notes

Text

Global Cubic Boron Nitride Market 2019 | Manufacturers In-Depth Analysis Report to 2024

The latest trending report Global Cubic Boron Nitride Market 2019-2024 added by DecisionDatabases.com

Cubic Boron Nitride (CBN) is a synthetic chemical compound made up of boron and nitrogen atoms in a one-to-one ratio. Unlike other types of boron nitride, it exists as a cubic crystal lattice, with its atoms arranged in a symmetrical, cube-shaped structure like the crystalline structure of diamond. Its material properties include extreme hardness, stability under heat, and superior chemical resistance.

The worldwide market for Cubic Boron Nitride is expected to grow at a CAGR of roughly xx% over the next five years, will reach xx million US$ in 2024, from xx million US$ in 2019.

This report focuses on the Cubic Boron Nitride in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Browse the complete report and table of contents @ https://www.decisiondatabases.com/ip/41673-cubic-boron-nitride-industry-analysis-report

Market Segment by Manufacturers, this report covers

· Element Six

· Momentive

· ILJIN

· Saint-Gobain

· Sumitomo Electric Industries

· Sandvik Hyperion

· Tomei Diamond

· FUNIK

· Zhengzhou Zhongnan Jete Superabrasives

· Famous Diamond

· Besco Superabrasives

· Berlt Hard Material

· Zhengzhou Zhong peng

· Henan Huanghe Whirlwind

· Yuzhou Hehui Superhard Material Company

Market Segment by Regions, regional analysis covers

· North America (United States, Canada and Mexico)

· Europe (Germany, France, UK, Russia and Italy)

· Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

· South America (Brazil, Argentina, Colombia etc.)

· Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

Market Segment by Type, covers

· CBN Monocrystalline

· CBN micro mist

Market Segment by Applications, can be divided into

· Resin Bond and Vitrified Wheels

· Resin Bond Grinding Wheels

· Vitrified Wheels

· Electroplated Products

· PcBN

· Others

Download Free Sample Report of Global Cubic Boron Nitride Market @ https://www.decisiondatabases.com/contact/download-sample-41673

The content of the study subjects, includes a total of 15 chapters:

Chapter 1, to describe Cubic Boron Nitride product scope, market overview, market opportunities, market driving force and market risks.

Chapter 2, to profile the top manufacturers of Cubic Boron Nitride, with price, sales, revenue and global market share of Cubic Boron Nitride in 2017 and 2018.

Chapter 3, the Cubic Boron Nitride competitive situation, sales, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast.

Chapter 4, the Cubic Boron Nitride breakdown data are shown at the regional level, to show the sales, revenue and growth by regions, from 2014 to 2019.

Chapter 5, 6, 7, 8 and 9, to break the sales data at the country level, with sales, revenue and market share for key countries in the world, from 2014 to 2019.

Chapter 10 and 11, to segment the sales by type and application, with sales market share and growth rate by type, application, from 2014 to 2019.

Chapter 12, Cubic Boron Nitride market forecast, by regions, type and application, with sales and revenue, from 2019 to 2024.

Chapter 13, 14 and 15, to describe Cubic Boron Nitride sales channel, distributors, customers, research findings and conclusion, appendix and data source.

Purchase the complete Global Cubic Boron Nitride Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-41673

Other Reports by DecisionDatabases.com:

Global Silicon Nitride (CAS 12033-89-5) Market by Manufacturers, Regions, Type and Application, Forecast to 2023 @ https://www.decisiondatabases.com/ip/12362-silicon-nitride-industry-market-report

Global Hexagonal Boron Nitride Market by Manufacturers, Regions, Type and Application, Forecast to 2023 @ https://www.decisiondatabases.com/ip/27647-hexagonal-boron-nitride-market-analysis-report

About-Us:

DecisionDatabases.com is a global business research reports provider, enriching decision makers and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research report, customized research reports, company profiles and industry databases across multiple domains.

Our expert research analysts have been trained to map client’s research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise and meaningful data at a lightning speed.

For more details:

DecisionDatabases.com

E-Mail: [email protected]

Phone: +91 9028057900

Web: https://www.decisiondatabases.com/

#Cubic Boron Nitride Market#Cubic Boron Nitride Market Report#Cubic Boron Nitride Industry Report#Cubic Boron Nitride Market Analysis#Cubic Boron Nitride Market Growth#Cubic Boron Nitride Market Trends#Cubic Boron Nitride Market Outlook#Global Cubic Boron Nitride Industry Report

0 notes

Text

Superabrasives Market to Garner Brimming Revenues by 2025

Superabrasives Market: Overview

An abrasive is a material which molds or provides finishing to a work piece through a process which includes buffing, grinding, cutting, as well as polishing. Abrasion typically depends on the difference in the hardness of the material and the abrasive (with the latter being the harder of the two).

Unlike regular abrasion where any two solid materials that repeatedly rub against each other tend to wear away, superabrasives possess the kind of hardness that enables them to stay usable for a longer period of time.

Get Research Report Overview @ https://www.transparencymarketresearch.com/superabrasives-market.html

On the basis of hardness, the top two superabrasives include diamond and cubic boron nitride (CBN). Industrial diamonds used as superabrasives are exceptionally hard materials. However, they display several technological limitations. For instance, when a diamond comes in contact with a ferrous alloy such as steel or a nickel superalloy, the resulting formation of carbide leads to its abrasion. Also, a diamond-containing tool can only be used at moderate temperatures and on non-metallic materials or non-ferrous alloys. Since CBN does not exhibit any difficulties in terms of being able to retain its hardness in a wide range of temperatures, it is preferred over diamond abrasives, especially while machining ferrous materials and superalloys.

Superabrasives find applications related to industrial operations such as turning, cutting, buffing, drilling, boring, grinding, finishing, honing, sharpening, and super finishing. Diamond is primarily employed for grinding cemented carbide, glass, ceramics, and hardened tool steel and cubic boron nitride for hardened steel and wear-resistant superalloys.

Superabrasives Market Trends

Orthopedic implant manufacturing creates opportunities for grinding machines. Joint reconstructive surgery includes knee, hip, and shoulder procedures, all of which involve orthopedic implants and associated instrumentation, which typically require grinding during their manufacturing processes. With the orthopedic implants industry expanding every year, the competition among manufacturers of these components is rising as well. The right machine coupled with the CAD/CAM software are the tools needed to effectively respond to the needs of this market. At the same time, manufacturers are increasingly moving toward harder materials such as cobalt chromium alloys for knees and other parts, which can be machined in one go with added ease. The joint reconstruction sector witnessed significant technological advancements in the past decade. A new trend emerging in the field of knee arthroplasty is the development of patient-specific implants. With the use of 3D scanners and the sculptural computer-aided design (CAD) technology, patient-specific implants can now be designed and manufactured with higher efficiency and at a lower cost. Use of CBN tools, especially in grinding machines in metal processing and the manufacturing of orthopedic implants in the medical industry, propels the market.

Based on product, the market for superabrasives can be segmented into the diamond and cubic boron nitride segments. End-users of superabrasives include machinery, electrical & electronics, transportation, metal fabrication, construction, medical devices, and others. Superabrasives can be employed in the following forms: loose, coated, and bonded. They are available as powder, mesh, inserts, and wheels.

Get PDF Brochure for more Professional & Technical industry insights: https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=24938

Superabrasives Market: Region-wise Outlook

The market for superabrasives is fragmented, with several companies operating in the market. It was dominated by Asia Pacific due to the presence of numerous manufacturers in the region, followed by Europe. Demand in Europe is predicted to be higher than that in North America and this trend is anticipated to continue over the forecast period. Latin America and Middle East & Africa constituted comparatively minor shares in the global superabrasives market.

Superabrasives Market: Key Players

Key players operating in the superabrasives market include 3M, Element Six, Sandvik AB, NanoDiamond Products, ILJIN DIAMOND CO. LTD., Asahi Diamond Industrial Co. Ltd., Saint-Gobain, DuPont, SuperAbrasives Inc., Show Denko K.K., and Tomei Diamond Co. Ltd.

About us:

Transparency Market Research (TMR) is a U.S.-based provider of syndicated research, customized research, and consulting services. TMR’s global and regional market intelligence coverage includes industries such as pharmaceutical, chemicals and materials, technology and media, food and beverages, and consumer goods, among others. Each TMR research report provides clients with a 360-degree view of the market with statistical forecasts, competitive landscape, detailed segmentation, key trends, and strategic recommendations.

Contact us:

Transparency Market Research

90 State Street,

Suite 700,

Albany

NY – 12207

United States

Tel: +1-518-618-1030

USA – Canada Toll Free 866-552-3453

Email: [email protected]

Website: http://www.transparencymarketresearch.com

0 notes

Text

Superabrasives Market Growth to be Driven by Technological Advancements 2025

A new research report by Transparency Market Research offers a comprehensive evaluation of the global Superabrasives Market. The study, titled “Superabrasives Market - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2017 - 2025”, is available for sale on the firm’s website.

Superabrasives Market: Overview

An abrasive is a material which molds or provides finishing to a work piece through a process which includes buffing, grinding, cutting, as well as polishing. Abrasion typically depends on the difference in the hardness of the material and the abrasive (with the latter being the harder of the two).

Unlike regular abrasion where any two solid materials that repeatedly rub against each other tend to wear away, superabrasives possess the kind of hardness that enables them to stay usable for a longer period of time.

View Report Preview:

https://www.transparencymarketresearch.com/superabrasives-market.html

On the basis of hardness, the top two superabrasives include diamond and cubic boron nitride (CBN). Industrial diamonds used as superabrasives are exceptionally hard materials. However, they display several technological limitations. For instance, when a diamond comes in contact with a ferrous alloy such as steel or a nickel superalloy, the resulting formation of carbide leads to its abrasion. Also, a diamond-containing tool can only be used at moderate temperatures and on non-metallic materials or non-ferrous alloys. Since CBN does not exhibit any difficulties in terms of being able to retain its hardness in a wide range of temperatures, it is preferred over diamond abrasives, especially while machining ferrous materials and superalloys.

Superabrasives find applications related to industrial operations such as turning, cutting, buffing, drilling, boring, grinding, finishing, honing, sharpening, and super finishing. Diamond is primarily employed for grinding cemented carbide, glass, ceramics, and hardened tool steel and cubic boron nitride for hardened steel and wear-resistant superalloys.

Superabrasives Market Trends

Orthopedic implant manufacturing creates opportunities for grinding machines. Joint reconstructive surgery includes knee, hip, and shoulder procedures, all of which involve orthopedic implants and associated instrumentation, which typically require grinding during their manufacturing processes. With the orthopedic implants industry expanding every year, the competition among manufacturers of these components is rising as well. The right machine coupled with the CAD/CAM software are the tools needed to effectively respond to the needs of this market. At the same time, manufacturers are increasingly moving toward harder materials such as cobalt chromium alloys for knees and other parts, which can be machined in one go with added ease. The joint reconstruction sector witnessed significant technological advancements in the past decade. A new trend emerging in the field of knee arthroplasty is the development of patient-specific implants. With the use of 3D scanners and the sculptural computer-aided design (CAD) technology, patient-specific implants can now be designed and manufactured with higher efficiency and at a lower cost. Use of CBN tools, especially in grinding machines in metal processing and the manufacturing of orthopedic implants in the medical industry, propels the market.

Based on product, the market for superabrasives can be segmented into the diamond and cubic boron nitride segments. End-users of superabrasives include machinery, electrical & electronics, transportation, metal fabrication, construction, medical devices, and others. Superabrasives can be employed in the following forms: loose, coated, and bonded. They are available as powder, mesh, inserts, and wheels.

Superabrasives Market: Region-wise Outlook

The market for superabrasives is fragmented, with several companies operating in the market. It was dominated by Asia Pacific due to the presence of numerous manufacturers in the region, followed by Europe. Demand in Europe is predicted to be higher than that in North America and this trend is anticipated to continue over the forecast period. Latin America and Middle East & Africa constituted comparatively minor shares in the global superabrasives market.

Request to view Sample Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=24938

Superabrasives Market: Key Players

Key players operating in the superabrasives market include 3M, Element Six, Sandvik AB, NanoDiamond Products, ILJIN DIAMOND CO. LTD., Asahi Diamond Industrial Co. Ltd., Saint-Gobain, DuPont, SuperAbrasives Inc., Show Denko K.K., and Tomei Diamond Co. Ltd.

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

0 notes

Text

Cubic Boron Nitride (CBN) Wheels Market | Analysis Report | 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Cubic Boron Nitride (CBN) Wheels Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2031.” The study provides a detailed analysis of the industry, including the global Cubic Boron Nitride (CBN) Wheels Market Share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Cubic Boron Nitride (CBN) Wheels Market?

The global cubic boron nitride (CBN) wheels market to register a CAGR of 11.3% during the forecast period.

What are Cubic Boron Nitride (CBN) Wheels?

Cubic Boron Nitride (CBN) wheels are abrasive tools employed for grinding and cutting tasks, renowned for their remarkable hardness, thermal conductivity, and chemical stability. These wheels consist of synthetic crystalline CBN particles adhered to a substrate, typically aluminum or steel, offering superior performance and durability compared to conventional abrasive materials such as silicon carbide or aluminum oxide. Widely applied in precision machining, CBN wheels excel in grinding hardened steels, superalloys, and other challenging materials where high material removal rates, precision, and surface finish quality are essential. Valued for their ability to maintain sharp cutting edges, resist wear, and efficiently dissipate heat, CBN wheels enhance productivity and cost-effectiveness across various industrial applications.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1932

What are the growth prospects and trends in the Cubic Boron Nitride (CBN) Wheels industry?

The cubic boron nitride wheels market growth is driven by various factors. The Cubic Boron Nitride (CBN) wheels market includes a variety of abrasive tools highly valued for their outstanding hardness, thermal conductivity, and chemical stability. Witnessing notable expansion propelled by growing demand for precise machining solutions across sectors like automotive, aerospace, and manufacturing, this market offers a diverse array of products tailored to specific cutting and grinding needs. Major players in the CBN wheels market provide cutting-edge solutions characterized by improved durability, cutting efficiency, and surface finish quality, effectively meeting the rigorous demands of contemporary machining processes. Furthermore, ongoing advancements in manufacturing techniques and materials drive continuous innovation within the market, ensuring its ongoing growth and widespread adoption of CBN wheel technology globally. Hence, all these factors contribute to cubic boron nitride wheels market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Resin CBN Wheels

Metal CBN Wheels

Ceramic CBN Wheels

Electroplated CBN Wheels

By Application:

Automotive Parts

Metal Grinding

Industrial

Others

Market Segmentation By Region:

North America

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Saint-Gobain Abrasives Inc.

ILJIN Diamond Co., Ltd.

Noritake Co., Ltd.

Asahi Diamond Industrial Co., Ltd.

Carborundum Universal Limited

Ehwa Diamond Industrial Co., Ltd.

Diametal AG

Tokyo Diamond Tools Mfg. Co., Ltd.

Zhengzhou Hongtuo Superabrasive Products Co., Ltd.

Sandvik AB

Engis Corporation

Karnasch Professional Tools GmbH

Nanjing Sanchao Advanced Materials Co., Ltd.

SuperAbrasives, Inc.

View Full Report: https://www.reportsandinsights.com/report/Cubic Boron Nitride (CBN) Wheels-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Cubic Boron Nitride (CBN) Wheels Market share#Cubic Boron Nitride (CBN) Wheels Market size#Cubic Boron Nitride (CBN) Wheels Market trends

0 notes

Text

Bonded Abrasives Market to Record an Exponential CAGR by 2025

Abrasive is a material used to mold or provide finishing to a piece of work, through a process that requires buffing, grinding, cutting, and polishing. Abrasion depends on the difference between the hardness of the material and the abrasive (with the latter being the harder of the two).

Read Report Overview @

https://www.transparencymarketresearch.com/bonded-abrasives-market.html

Abrasives are used in a wide variety of industrial, domestic, and technological applications. Abrasives and abrasive products are extensively used for various applications such as cutting, grinding, drilling, polishing, lapping, honing, and buffing.

There are various types of abrasives available such as bonded abrasives, coated abrasives, raw super-abrasives, steel abrasives, and loose abrasive grains. Bonded abrasives are either synthetic or natural abrasive grains bonded together into a solid form, usually in the shape of a wheel. Bonded abrasive products include cut-off and grinding wheels, cylinders, segments, inserts, snagging wheels, sticks, mounted wheels, discs, cones, plugs, and inserts.

Abrasive grains (natural as well as synthetic) are bonded onto a surface material through a matrix made from resin, glass, rubber, or other binding materials. Surface materials such as ceramics, metal, or plastics are used to produce bonded abrasives. Selection of the type and shape of the bonded abrasive depends upon the metal processing operation. For instance, abrasive stones are employed for honing, either internal or external, surfaces.

Different types of bonds are used to bond abrasive grains to the surface material. Sometimes, abrasives grains are electroplated to braze onto metal substrates. Other surface materials include systems with resin, glass, rubber, or shellac. The bond formed between abrasive grains and surface substrate system vary from low-strength to high-strength bonds.

Super-abrasive material comprises diamond and cubic boron nitride (CBN). Ceramic abrasives include metal oxides of aluminum and iron. Other abrasives include carbides of silicon, tungsten, and boron.

Demand for bonded abrasives is increasing globally due to its use in several applications such as grinding, forming, sharpening, and finishing. Rise in demand for bonded abrasives from aerospace, automotive, machine tool, foundry, metal fabrication, and welding industries is expected to drive the bonded abrasives market.

Requirement for bonded abrasives from the upcoming automotive industry is anticipated to boost the market. Bonded abrasives are largely employed in surface finishing and designing of automobiles. Increasing demand for the advanced technology-based machineries are expected to propel the bonded abrasives market. The bonded abrasives are used to provide smooth finish to various tools and machineries. Regular maintenance of workshops is further driving the bonded abrasives market.

In terms of abrasives used, the bonded abrasives market can be divided into synthetic diamond, cubic boron nitride, carbides (silicon, boron, and tungsten), ceramic metal oxides (aluminum and iron), steel abrasive, and others. Based on product form, the market can be segmented into wheels (wheels, discs, and dishes), inserts (cups, cylinders, and sticks), and others (stones and segments). In terms of end-user industry, the market can be segregated into machinery, electrical & electronic equipment, transportation, metal fabrication, and others (including construction, medical devices, power generation, and cleaning & maintenance).

Based on region, the global bonded abrasives market can be segmented into North America, Latin America, Europe, Asia Pacific, and Middle East & Africa. Asia Pacific is currently the leading the market. This trend is likely to continue over the forecast period. Europe held the second-largest share, followed by North America, in the bonded abrasives market. North America and Europe are likely expand at a sluggish pace in the near future.

Request to view Sample Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=35330

Major players operating in the bonded abrasives market are forward integrating into manufacturing various abrasive machining tools as well as backward integrating into production of abrasive materials. Key players operating in the market include 3M, Robert Bosch GmbH, Asahi Diamond Industrial Co. Ltd., Carborundum Universal Ltd., Entegris Inc., Grindwell Norton Ltd., ILJIN Diamond Co. Ltd., Norstel AB, Reishauer AG, Saint-Gobain, Sandvik AB, and SHOWA DENKO K.K.

0 notes

Text

Superabrasives (Turning, Cutting, Buffing, Drilling, Boring, Grinding) Market Research Report 2025

An abrasive is a material which molds or provides finishing to a work piece through a process which includes buffing, grinding, cutting, as well as polishing. Abrasion typically depends on the difference in the hardness of the material and the abrasive (with the latter being the harder of the two).

Unlike regular abrasion where any two solid materials that repeatedly rub against each other tend to wear away, superabrasives possess the kind of hardness that enables them to stay usable for a longer period of time.

On the basis of hardness, the top two superabrasives include diamond and cubic boron nitride (CBN). Industrial diamonds used as superabrasives are exceptionally hard materials. However, they display several technological limitations. For instance, when a diamond comes in contact with a ferrous alloy such as steel or a nickel superalloy, the resulting formation of carbide leads to its abrasion. Also, a diamond-containing tool can only be used at moderate temperatures and on non-metallic materials or non-ferrous alloys. Since CBN does not exhibit any difficulties in terms of being able to retain its hardness in a wide range of temperatures, it is preferred over diamond abrasives, especially while machining ferrous materials and superalloys.

Obtain Report Details @ http://www.transparencymarketresearch.com/superabrasives-market.html

Superabrasives find applications related to industrial operations such as turning, cutting, buffing, drilling, boring, grinding, finishing, honing, sharpening, and super finishing. Diamond is primarily employed for grinding cemented carbide, glass, ceramics, and hardened tool steel and cubic boron nitride for hardened steel and wear-resistant superalloys.

Superabrasives Market Trends

Orthopedic implant manufacturing creates opportunities for grinding machines. Joint reconstructive surgery includes knee, hip, and shoulder procedures, all of which involve orthopedic implants and associated instrumentation, which typically require grinding during their manufacturing processes. With the orthopedic implants industry expanding every year, the competition among manufacturers of these components is rising as well. The right machine coupled with the CAD/CAM software are the tools needed to effectively respond to the needs of this market.

At the same time, manufacturers are increasingly moving toward harder materials such as cobalt chromium alloys for knees and other parts, which can be machined in one go with added ease. The joint reconstruction sector witnessed significant technological advancements in the past decade. A new trend emerging in the field of knee arthroplasty is the development of patient-specific implants. With the use of 3D scanners and the sculptural computer-aided design (CAD) technology, patient-specific implants can now be designed and manufactured with higher efficiency and at a lower cost. Use of CBN tools, especially in grinding machines in metal processing and the manufacturing of orthopedic implants in the medical industry, propels the market.

Enter your information below to receive a sample copy of this report @ http://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=24938

Based on product, the market for superabrasives can be segmented into the diamond and cubic boron nitride segments. End-users of superabrasives include machinery, electrical & electronics, transportation, metal fabrication, construction, medical devices, and others. Superabrasives can be employed in the following forms: loose, coated, and bonded. They are available as powder, mesh, inserts, and wheels.

Superabrasives Market: Region-wise Outlook

The market for superabrasives is fragmented, with several companies operating in the market. It was dominated by Asia Pacific due to the presence of numerous manufacturers in the region, followed by Europe. Demand in Europe is predicted to be higher than that in North America and this trend is anticipated to continue over the forecast period. Latin America and Middle East & Africa constituted comparatively minor shares in the global superabrasives market.

Superabrasives Market: Key Players

Key players operating in the superabrasives market include 3M, Element Six, Sandvik AB, NanoDiamond Products, ILJIN DIAMOND CO. LTD., Asahi Diamond Industrial Co. Ltd., Saint-Gobain, DuPont, SuperAbrasives Inc., Show Denko K.K., and Tomei Diamond Co. Ltd.

0 notes