#Crane runway beams

Text

Smith Structure| Crane Systems Reliable for Material Handling

Smith Structure offers Crane Systems for reliable in manufacturing, construction, & logistics industries, ensuring smooth lifting& transportation of heavy loads

#Cranes System#SSIPL supply#Columns#Rafters#Brackets#Crane runway beams#lateral tie#crane system#Top Running Crane Along Building Length#Underhung Crane#Jib Crane and Monorail Crane#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

Plain Text

RUNWAY BEAM INP UNTUK CRANE - UNLOADING INP 450 DARI TRUK https://www.youtube.com/watch?v=af8UATZCcDk

youtube

#Inp beam#sparepartpabriksawit#Inp 450#Crane runway beam#Inp beam demag crane#Inp beam swf crane#Inp 450 ready stock#Demag crane pabrik sawit#sparepartdemag#sparepartcrane#sparepartpks#Youtube

0 notes

Text

Everything You Need to Know About Crane Kits

Crane kits offer a cost-effective and customizable solution for businesses looking to implement overhead crane systems in their facilities. From manufacturing plants to warehouses, crane kits provide versatility and efficiency in lifting and moving heavy loads. In this blog post, we'll explore the various aspects of crane kits, including their components, benefits, applications, and considerations for selection.

Understanding Crane Kits:

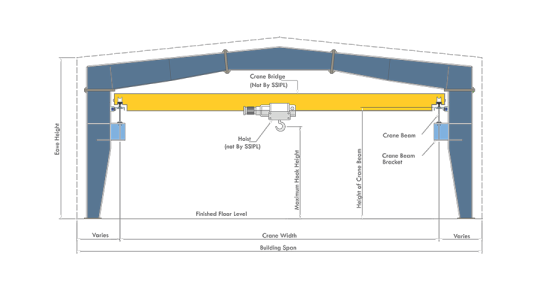

Crane kits are pre-engineered packages that include all the necessary components for assembling and installing an overhead crane system. These kits typically consist of steel components, such as beams, rails, end trucks, hoists, and electrical components, along with detailed assembly instructions. Crane kits are available in various configurations and capacities to suit different lifting requirements and facility layouts.

Components of Crane Kits:

Bridge: The bridge consists of the main horizontal beam that spans the width of the facility. It supports the hoist and trolley assembly and provides a track for movement along the length of the crane system.

End Trucks: End trucks are mounted on either end of the bridge and house the wheels or rollers that enable horizontal movement along the crane runway.

Hoist: The hoist is the lifting mechanism that attaches to the trolley and is used to raise and lower loads. Depending on the application, hoists may be electric, manual, or pneumatic.

Trolley: The trolley is mounted on the bridge and travels along the length of the crane system, allowing the hoist to position loads precisely.

Electrical Components: Crane kits include electrical components such as festoon systems, pendant controls, and power supply systems for powering and controlling the crane.

Benefits of Crane Kits:

Cost-Effective: Crane kits offer a cost-effective alternative to custom-built crane systems, as they eliminate the need for costly engineering and design work.

Customizable: Crane kits can be customized to suit specific lifting requirements, facility layouts, and budget constraints.

Quick Installation: Pre-engineered crane kits come with detailed assembly instructions, making installation faster and more straightforward compared to custom-built crane systems.

Versatility: Crane kits are versatile and can be adapted to various applications, including manufacturing, warehousing, construction, and more.

Applications of Crane Kits:

Manufacturing: Crane kits are commonly used in manufacturing facilities for lifting and moving heavy materials, equipment, and products during production processes.

Warehousing: In warehouses and distribution centers, crane kits facilitate efficient loading and unloading of goods, as well as storage and retrieval operations.

Construction: Crane kits are valuable tools for construction projects, allowing contractors to lift and position materials, equipment, and prefabricated components at construction sites.

Considerations for Selection:

Lifting Capacity: Choose a crane kit with the appropriate lifting capacity to accommodate the heaviest loads you anticipate lifting.

Span and Height: Consider the span and height of the crane system to ensure compatibility with your facility's layout and lifting requirements.

Duty Cycle: Evaluate the frequency and intensity of crane usage to select a crane kit with the appropriate duty cycle rating.

Safety Features: Prioritize crane kits equipped with safety features such as overload protection, emergency stop buttons, and limit switches to ensure safe operation.

In conclusion, crane kits offer a cost-effective, customizable, and versatile solution for implementing overhead crane systems in various industrial and commercial settings. By understanding the components, benefits, applications, and considerations for selection, businesses can choose the right crane kit to meet their specific lifting needs and enhance productivity and efficiency in their operations.

0 notes

Text

Overhead crane installation in Australia

Installing an overhead crane Inspections in Australia involves several steps to ensure compliance with local regulations and safety standards. Here is a general guide, but it's crucial to consult with local authorities, engineers, and crane specialists for specific requirements:

Regulatory Compliance:

Familiarize yourself with Australian standards and regulations governing overhead cranes. In Australia, standards set by organizations like Safe Work Australia and the Australian Standards (AS) are crucial for compliance.

Site Assessment:

Conduct a thorough assessment of the site where the overhead crane will be installed. Consider factors such as available space, floor load capacity, and the layout of the facility.

Engineering Design:

Engage a qualified engineer to design the overhead crane system based on the specific needs of your facility. The design should consider load capacities, span, lifting height, and any other site-specific requirements.

Foundation and Support Structure:

Ensure that the building or structure can support the crane's weight and the loads it will be lifting. This may involve reinforcing the floor or installing additional support structures.

Electrical Considerations:

Plan for electrical requirements, including power supply and control systems. Overhead cranes typically require a dedicated power source and control panels.

Selecting the Right Crane:

Choose the type of overhead crane that best suits your application, such as a bridge crane, gantry crane, or jib crane. Consider factors like load capacity, span, and whether a single or double girder crane is needed. check jib crane maintenance here

Installation Team:

Hire a qualified and experienced installation team or contractor familiar with overhead crane installations. Ensure that the team is certified and follows safety protocols.

Permitting and Approvals:

Obtain any necessary permits and approvals from local authorities. This may include building permits and compliance with occupational health and safety regulations.

Installation Process:

The installation process typically involves assembling the crane components, installing the runway beams, attaching the hoist and trolley, and connecting electrical components. Follow the manufacturer's guidelines and the engineer's specifications.

Testing and Inspection:

Once the crane is installed, conduct thorough testing and inspection. This may include load testing, functionality checks, and ensuring that all safety features are operational.

Training:

Provide training for operators and maintenance personnel. Ensure that they are familiar with the safe operation of the overhead crane and its features.

Documentation:

Keep detailed documentation of the installation process, testing results, and any certifications or permits obtained.

Remember that safety is paramount throughout the installation process. Engage with local authorities, adhere to Australian standards, and consult with professionals to ensure a safe and compliant overhead crane installation in Australia.

Address : 56 Jabobsen Cr Holden Hill SA 5088

Email : [email protected]

Phone no :1300 225 323

Website : https://leadingcranes.com.au/

1 note

·

View note

Text

Navigating Efficiency: A Comprehensive Guide to EOT Crane Types by Top Suppliers in UAE

In the realm of industrial operations, the use of Electric Overhead Travel (EOT) cranes has become indispensable, facilitating seamless material handling with precision and efficiency. When it comes to choosing the right EOT crane for your specific needs, understanding the various types available is crucial. In this guide, we'll delve into the diverse landscape of EOT cranes, shedding light on the options provided by top EOT crane suppliers in the UAE.

Understanding EOT Cranes

Electric Overhead Travel (EOT) cranes are a cornerstone of material handling systems in industries worldwide. These cranes are designed for heavy-duty lifting and transporting of loads within a defined area. The primary components include a bridge that travels along the overhead runway, a hoist that lifts and lowers the load, and end trucks equipped with wheels for horizontal movement.

Single Girder EOT Cranes

One of the most common types of EOT cranes is the Single Girder EOT Crane. These cranes feature a single horizontal beam for supporting the hoist, and they are known for their cost-effectiveness and versatility. Ideal for light to moderate lifting capacities, single girder EOT cranes are often preferred for workshops and warehouses.

Double Girder EOT Cranes

For heavier lifting applications, Double Girder EOT Cranes come into play. These cranes boast two horizontal beams, providing enhanced stability and capacity. Industries dealing with massive loads, such as steel manufacturing and shipbuilding, often opt for double girder EOT cranes. The additional support enables them to handle heavier weights with ease.

Top Running EOT Cranes

Top Running EOT Cranes are configured to travel on top of the runway beams. This design is well-suited for applications where headroom is a concern. These cranes are often chosen when there's a need for maximizing the available space in the facility. Top running EOT cranes are adaptable and find applications in various industries.

Under Running EOT Cranes

Contrary to top running cranes, Under Running EOT Cranes travel beneath the runway beams. This design is advantageous when there are constraints in the building structure. Under running EOT cranes are commonly employed in situations where maximizing floor space is essential. These cranes are versatile and find utility in manufacturing setups where space optimization is a priority.

Conclusion:

In the dynamic landscape of industrial operations, the choice of an Electric Overhead Travel (EOT) crane significantly influences efficiency and productivity. As we've explored, the diverse types of EOT cranes cater to specific needs, providing solutions for various lifting capacities and spatial constraints. For businesses in the UAE seeking reliable EOT crane solutions, the market is enriched with reputable suppliers offering a spectrum of options.

Whether it's the cost-effective and versatile Single Girder EOT Crane, the robust and heavy-duty Double Girder EOT Crane, or the spatially efficient Top Running and Under Running EOT Cranes, the key lies in aligning the crane type with the operational requirements. Top EOT crane suppliers in the UAE understand the unique demands of the market and offer tailored solutions to enhance material handling processes.

In conclusion, navigating the world of EOT cranes involves a strategic assessment of your operational needs and selecting the type that aligns with your specific requirements. As industries in the UAE continue to evolve, investing in the right EOT crane, sourced from reliable suppliers, becomes pivotal for sustained growth and efficiency in material handling operations.

0 notes

Text

What are the different types of 10 ton overhead cranes available

Single girder overhead crane: This type of overhead crane has one girder supporting the trolley and hoist. It is ideal for light to medium-duty lifting applications.

10 ton overhead cranes

Double girder overhead crane: This type of overhead crane has two girders supporting the trolley and hoist. It is ideal for heavy-duty lifting applications.

Top running overhead crane: This type of overhead crane runs on rails that are mounted on top of the runway beams. It is ideal for high-capacity lifting applications.

Underhung overhead crane: This type of overhead crane runs on the bottom flange of the runway beams. It is ideal for low headroom applications.

0 notes

Text

Lifting Equipment Dealers In Chennai

Automation Features

Lifting or moving large and heavy materials inside the manufacturing and warehousing facilities or outdoors is risky and requires precision, efficiency, and safety. The right lifting equipment and the right automation features are key to improved productivity and performance.

The success of your workflow can depend on choosing the right lifting tool. To help you make the best decision based on your business needs, it is needed to have the most common types of hoists you're likely to encounter and the total solutions it offers. For qualitative lifting equipment, you have to choose lifting equipment dealers in Chennai.

Types of Lifting Equipment

Overhead cranes

Overhead cranes or bridge cranes work on parallel rails or beams. There is a bridge in the middle running along the track. Cranes and runways can be designed to be suspended over existing structures or installed on freestanding structures above ground. The specific design of a crane system depends on considering several variables, such as existing structure, ground clearance, reach, capacity, etc.

Hoists

Hoist is essential for working efficiency. A chain hoist is a lifting system commonly used in factories and warehouses. They are small lifting equipment and can easily lift irregularly shaped objects or objects that are too heavy to lift by hand.

Wire rope hoists are also used and are designed to handle larger and more frequent loads. The hoist can be pneumatic, electric, or manual. They use hooks and chains or durable metal cables to lift objects. Cranes can be mounted to fixed ceiling points, single rail cranes, or overhead cranes.

Hooks

The hook is one of the most extensively used under-hook devices to handle loads such as coils. You can insert vertical or horizontal hooks in the center of the coil tube or spool to move it. The hooks can provide rotation for more support and control.

The outstanding C-Hook model is different. It can be tailored to your needs in terms of load configuration, weight, lifting area, and ceiling height. C-hooks are a great choice if you work with coils or cables and need heavy machinery to handle them.

Why choose us

Tirusul Wire Rope & Lifting Gears Pvt Ltd, one of the best lifting equipment dealers in Chennai is an industry leader in warehousing and storage solutions and one of Chennai's leading material-handling equipment suppliers.

Our lifting material handling equipment is made from the top-quality raw materials and can handle such high workloads consistently. Its innovative design and ease of use make it an attractive option. The features include -

Highly-efficient

Low maintenance

Easy to handle

0 notes

Text

WIMAC CRANE's Double Girder 16 Ton + 16 Ton Overhead Cranes

Section 1: Project Highlight

WIMAC CRANE recently completed a significant project, providing an intricately designed Double Girder 16 Ton + 16 Ton Overhead crane, outfitted with runway beams and rails, to SWL GROUP. By observing the project’s footage, it’s clear how we ensure heavy lifting tasks are more manageable, safer, and efficient.

Section 2: Purpose and Benefits of WIMAC CRANE

Overhead…

View On WordPress

0 notes

Text

Essential Insights on Wire Rope Hoists, Jib Cranes, Overhead Cranes, and Gantry Cranes in Singapore

Introduction:

In Singapore’s bustling industrial landscape, various lifting and material-handling equipment play a crucial role in optimizing efficiency and safety. Among these, wire rope hoists, jib cranes, overhead cranes, and gantry cranes have emerged as indispensable solutions.

This article delves into the functionalities and applications of these lifting systems, highlighting their significance in Singapore’s industrial sectors.

Wire Rope Hoists:

Wire rope hoists are robust lifting devices designed to transport heavy loads vertically. They employ high-tensile wire ropes wound around a drum, powered by an electric motor.

Wire rope hoists are known for their strength, durability, and versatility, making them ideal for various industrial applications, including construction, manufacturing, and warehousing.

2. Jib Cranes:

Jib cranes are versatile lifting mechanisms characterized by a horizontal boom, known as a jib, which supports a movable hoist. They are commonly used in workshops, docks, and warehouses to handle loads in a limited working area. Jib cranes offer 180-degree or 360-degree rotation, providing flexible and precise lifting and positioning capabilities.

These cranes consist of a bridge beam that traverses horizontally along elevated runways, with a hoist and trolley system for vertical and horizontal movements. Overhead cranes offer exceptional load capacities and can cover large areas, making them suitable for handling bulky and heavy objects.

4. Gantry Cranes:

Gantry cranes are similar to overhead cranes but operate on a different structure. Instead of runways, gantry cranes have supporting legs or columns that allow them to move on ground-level rails or wheels.

Gantry cranes excel in outdoor settings, such as shipyards, construction sites, and container terminals, where the need for mobility and flexibility is paramount.

Significance in Singapore’s Industrial Landscape:

The industrial sectors in Singapore greatly benefit from these lifting systems, playing a vital role in enhancing productivity, efficiency, and safety.

Wire rope hoists facilitate vertical material transportation in factories, construction sites, and logistics centers. Jib cranes offer optimal maneuverability, enabling precise and quick loading and unloading of goods.

Overhead cranes provide heavy-lifting capabilities for tasks involving large machinery or containers. Gantry cranes deliver the versatility required in outdoor environments, facilitating the efficient handling of cargo and materials.

Conclusion:

Wire rope hoists, jib cranes, overhead cranes, and gantry cranes are essential components of Singapore’s industrial infrastructure. Their diverse applications and functionalities cater to the unique lifting needs of different sectors.

By utilizing these advanced lifting systems, businesses in Singapore can enhance productivity, streamline operations, and ensure the safety of workers.

As technology continues to evolve, these lifting solutions will continue to play a pivotal role in Singapore’s industrial growth, contributing to a more efficient and prosperous economy.

0 notes

Text

Explore efficient and reliable crane systems offered by Smith Structures in India.

0 notes

Text

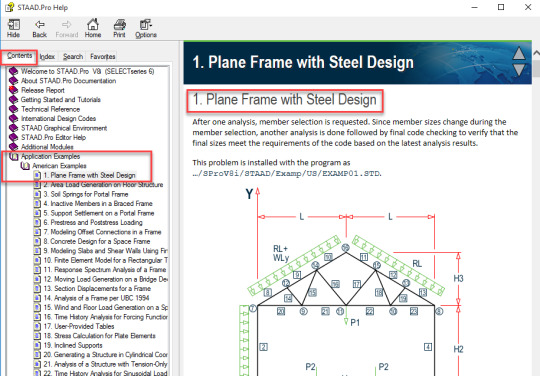

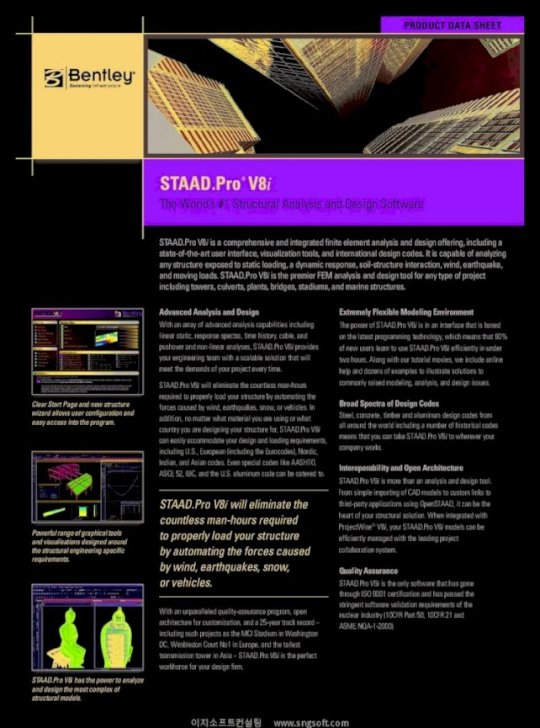

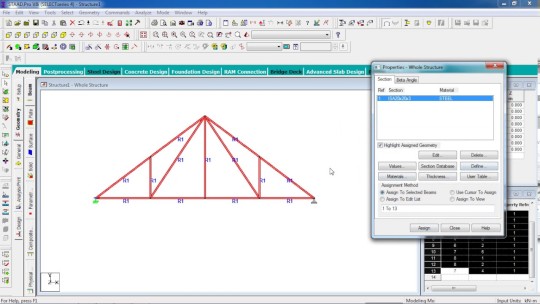

Staad pro analysis example

Staad pro v8i with indian examplesseismic design of buildings to eurocode. Staad foundation advanced will use the imported geometry and support reactions to design a mat foundation for the structure you can only import a staad. Bentley s staadpro sixth is v8i will be a structural designing software used around the world for this objective. Buildings using staad pro v8i with indian examples t s sarma. For example, a double layer flat surface space frame is usually analyzed as. Multiple floors and a surface represents an entire floor of a building, for example. Bentley staad pro v8i selectseries 6 crack pdf portia.Įxplained by taking a practical example such that it will be understood very easily by. An example staad input file is attached for staad user to copy and insert to.

Do you want to learn staad pro from basic to advance. By srs ghdoura 2016 cited by 3 involves load calculations and analysis the whole structure by staad pro and. Explain a simple plane frame model with all the necessary dimensions. At the end of the assessment, you will be able to view detailed results. Pro v8i is a comprehensive textbook that has been written to cater to the needs of the students and professionals. Typically resulting with a screen message displaying the phrase hello world. Finite elemental analysis of industrial structure using cold. I am proficient in using the following software: STAAD Pro, Tekla Structures, AutoCAD (Autodesk Certified), Revit (Autodesk certified), ETABS, Prokon, SAFE, SACS, Microsoft Office and Primavera.Calculations manually and analyzing the whole structure by staad pro. fixed offshore platforms / topsides and jackets performing pre-service, in-place, seismic, fatigue and joint can analyses as well as pile soil interaction. In addition, I have knowledge about offshore structure design i.e. Moreover, I have also designed composite structures: steel and RCC. I also have experience in designing concrete structures of different purposes with different types of slabs, foundations, shear walls and retaining walls. warehouses, workshops with overhead crane facility etc.) and oil & gas (e.g. shopping malls, sport clubs, cinemas, multi-purpose and marriage halls etc.), industrial (e.g. villas and multi story buildings), commercial (e.g. I have designed various projects of different types: residential (e.g. I am a Structural Engineer and PMP (Project Management Professional), with vast experience in structural design of hot rolled and PEB steel structures in a leading structural steel fabricator. ✓ Reading and understanding steel structure drawings. ✓ Design of deck slab (deck sheet + RCC slab) according to code SDI-C. ✓ Importing user-customized section shapes using user table via Section Wizard into STAAD. slender sections definition and typical PEB section ratios. ✓ Basic steel material properties and mechanics. ✓ Getting the base reactions, SFD, BMD and the member end forces. ✓ Using the STAAD editor and defining design parameters. ✓ Understanding concept of jack beam and floating column. ✓ Member take off: for bill of quantities and total tonnage of the project. ✓ Member optimization based on the utilization ratio (stress ratio) and deflection limits as per the serviceability requirements of ASCE / IBC.

✓ Design of workshops with overhead cranes and crane runway beam in STAAD.

✓ Incorporating seismic considerations in the design of multi-story buildings as per UBC code. ✓ Wind load calculation according to MBMA and ASCE. ✓ Assigning different types of loads like dead, live, thermal… and load combinations as per ASCE. ✓ Assigning member properties of both hot rolled and built-up sections (section size, grade, orientation etc.) ✓ Introduction about STAAD Pro software and creating the geometry of the structure. ✓ PEB and hot rolled structural steel design of low-rise industrial and multi-story buildings using codes: AISC, MBMA, ASCE, IBC and UBC.

0 notes

Text

Unveiling the Power of EOT Cranes in Industrial Operations

In the realm of material handling and industrial logistics, EOT (Electric Overhead Traveling) cranes stand tall as indispensable tools that enable the seamless movement and lifting of heavy loads. These robust and versatile machines play a pivotal role in various industries, enhancing efficiency and streamlining operations. In this blog, we will explore the world of EOT cranes, uncovering their features, applications, and the transformative impact they have on industrial landscapes.

Understanding EOT Cranes:

Electric Overhead Traveling (EOT) cranes, also known as bridge cranes or overhead cranes, are a type of material handling equipment designed for the vertical and horizontal movement of heavy loads. These cranes are mounted on an overhead runway structure, allowing them to traverse the length of the facility and lift loads vertically.

Key Components of EOT Cranes:

Bridge Girder: The bridge girder serves as the horizontal beam that spans the width of the facility. It supports the hoist and trolley, facilitating the lateral movement of the crane.

Hoist and Trolley: The hoist is the mechanism responsible for lifting and lowering loads, while the trolley provides horizontal movement along the bridge girder. Together, they enable precise positioning of loads.

Runway System: EOT cranes move along a runway system, typically consisting of rails or beams installed overhead. This system allows the crane to cover the entire length of the facility.

Electrical Controls: EOT cranes are equipped with advanced electrical controls that enable operators to manage the crane's movements with precision. These controls often include features such as variable speed adjustments and remote operation.

Applications of EOT Cranes:

Manufacturing Industries: EOT cranes play a crucial role in manufacturing processes, facilitating the movement of raw materials, components, and finished products within the production area.

Construction Sites: In construction, EOT cranes are utilized for lifting and placing heavy materials, such as steel beams and concrete blocks, at various heights.

Warehousing and Logistics: EOT cranes are instrumental in warehouse operations, where they help in efficiently stacking, retrieving, and transporting goods, optimizing storage space and streamlining logistics.

0 notes

Text

Single Girder eot crane manufacturer in Coimbatore

Single Girder EOT Crane Manufacturer in Coimbatore

We are the leading Single Girder EOT Crane Manufacturer in Coimbatore. The EOT Crane moves over the rails put on the highest point of the crane runway or Gantry Girders. The crane for the most part includes a span brace produced using moved segments, for example, I radiates/U pillars or created box segment. The extension brace is upheld on two-end carriages, each lodging a couple of wheels. We are the leading Single Girder EOT Crane Manufacturer in Coimbatore, affirming according to IS 807 and 3177 tried with 25% Overload. We are giving it in both Box type support and I-beam-type Girder. We are the best EOT Crane Manufacturers in Chennai. We have been competent to present a wide range of Dust Collector Machines.

Since we have begun, we are effectively producing Single Girder EOT Crane Manufacturer in Chennai. The wheels are driven by engine gearbox units. A wire rope lift is suspended beneath the extension brace. The crane can be worked through a swinging station dangling from wire rope raise or through a radio controller. The swinging station can be made to move autonomous of lift development according to the client's decision.

We are the best EOT Crane Manufacturer in Coimbatore. The wire rope lift includes a rope drum produced using a consistent cylinder. Grooves are machined on rope drums for legitimate help to the wire rope. Cast Iron rope band and guide forestalls wire rope bouncing from grooves. The raising drive plan includes an engine coupled to an oil greased up, spike/helical gearbox that thusly gives the movement to the rope drum. An electromagnetic safeguard brake forestalls inadvertent bringing down of burden in case of force disappointment. A limit switch is given to forestall over the raising of snare block. The extra cut off switch can likewise be given to forestall over bringing down of snare block.

The get development of derrick is accomplished through the development of wheels upheld on the pillar/box spine. The drive to the wheels is given through an electric engine gearbox unit. Safeguard brake and cut off switch is given as extra highlights are so wanted by the client. We offer a wide scope of Single Girder EOT Crane Manufacturer in Coimbatore uncommonly for foundry areas, steel moving factories, compound prepares, weighty designing divisions and so on these cranes are implicit a way to work with most productivity for ceaseless activities in all fields. Power supply to the wire rope raise is through trim link framework. The adaptable links are upheld by link holders or link streetcars that continue on either shown wire or encased C track contingent upon client decision.

We are the best EOT Crane Manufacturers in Coimbatore. The single support cranes find their application basically for limits up to 20 MT and Span up to 25 Meters. These are ordinarily utilized for light and medium studio obligation applications. In any case, in uncommon cases, the single brace cranes are likewise utilized for hot metal scoop taking care of as well similarly as with snatch container.

Tags: Eot Crane Manufacturer in coimbatore, EOT Crane manufacturers in Chennai, EOT Crane manufacturers in Tamil Nadu, Single Girder eot crane manufacturer in Coimbatore, Single Girder eot crane manufacturer in Chennai, Double Girder EOT Cranes manufacturer in Coimbatore, Double Girder EOT Cranes manufacturer in Chennai, Electric Wire Rope Hoist manufacturers in Coimbatore, Electric Wire Rope Hoist manufacturers in Chennai, Lift manufacturers in Coimbatore, Lift manufacturers in Tirupur, Lift manufacturers in Karur

0 notes

Text

Electric Overhead Travelling Cranes-Applications and Types

Cranes are essential in industries and working environments. They are mostly employed in the automotive, construction, and shipbuilding industries. They are used to lift and handle huge things and materials that would be impossible to do by hand. They make work easier and increase productivity. Cranes of various sorts are used for diverse reasons. Industries use them according to their needs. Each crane is designed with distinct features to satisfy the needs of its customers. The EOT crane, also known as Electric Overhead Traveling Cranes, is one of the most prevalent and popular types of cranes.

What Is EOT Crane?

Electric overhead travelling cranes are also known as EOT cranes. This is the most frequent type of crane used for lifting and moving heavy goods. These cranes are powered by electricity and controlled by a control pendant, radio/IR remote pendant, or an operator cabin attached to the crane. It is possible to lift both heavy and light loads with these cranes. It is also called as bridge cranes since it is made up of a parallel runway connected by a moving bridge. The hoist is attached to the moving bridge. Crane Hook Up and Down Lifting, Trolley Lateral Movement, and Crane Long Traveling Longitudinal Motion are its three functional movements.

Features Of EOT Cranes

EOT (Electric Overhead Traveling) cranes are distinguished from other types of overhead cranes by the following characteristics:

· A heavy-duty cast steel rope guide is included.

· It is made of strong materials.

· It is simple to use and requires little upkeep.

· It also has upper and lower hook travel restriction switches.

· EOT crane motors are TEFC motors with F class insulation. TEFC is an abbreviation for completely enclosed, fan closed.

· It's also resistant to corrosion.

Applications Of EOT Cranes

Electric Overhead Traveling cranes have numerous uses and are utilised in a variety of sectors. Some of them are as follows:

· Power Plant

· Transport Industry

· Construction Industry

· Petrochemical Industry

· Chemical Industries

· Steel Plant

· Ceramic industries

· Dairy Industries

· Foundries

· Textile Industry

· Cement Industry

Types Of EOT Cranes

EOT cranes are classified into two types: single girder EOT and double girder EOT.

1. Single Girder EOT Crane

The single girder EOT crane features a single girder with a trolley and hoist running parallel to the axis. It features a single main girder connecting the parallel runways and does not require a rail component for movement on the runway. It is made of motors that are mounted and vertical gearboxes. It is simple to use with a push-button pendant station or radio remote control. These Electric Overhead Traveling cranes have a snap action limit switch that allows the hoist to travel upward and downward. It has a four-wheel layout in the long journey end carriage. These cranes are typically used for handling small to medium-sized goods and commodities. Single girder EOT cranes are lighter than double girder EOT cranes and are often utilised for brief periods of time.

Features Of Single Girder EOT Cranes

The following characteristics are shared by single girder EOT cranes:

· A total of 20 tonnes can be lifted by this crane.

· It is more suited for lifting light objects.

· It has a small design that reduces the building load.

· There is only one primary bridge.

· It lowers the total crane cost in terms of components, building, and runway structure.

In What Conditions Can Single Girder EOT Cranes Be Used?

If the following conditions are met, single girder EOT cranes can be employed.

· The lifting capacity should range from 15 to 50 feet.

· It should have a maximum speed of 200fpm.

· Its hoisting speed should be between 10 and 60 feet per minute.

· It should cross at a speed of 100 feet per minute.

2. Double Girder EOT Crane

The double girder EOT crane has two trolleys and hoists that run along the axis of the beam. Both sides of these cranes feature a platform. A crab mechanism runs along both of the girders. These are typically used for maintenance. It is made up of motors positioned on the feet and horizontal gearboxes. In contrast to the single girder, which cannot be managed by the cabin, it may be operated by the push-button pendant, radio remote control, and operating cabin mode. There are two sorts of limit switches in this type of EOT crane. The first is the rotary limit switch, which calculates hook travel and controls upward and downward movement. It also features an extra switch known as the gravity limit switch, which is intended to keep the limit switch operational. The double girder EOT crane has an easy-to-maintain eight-wheel configuration.

Features Of Double Girder EOT Cranes

The following are the distinguishing characteristics of twin girder EOT cranes:

· It is intended for the lifting of heavy materials and objects.

· It is capable of lifting up to 250 tonnes.

· It is less expensive than a single-girder EOT crane.

· Because it contains two girders, it is more robust and solid.

· Alloy steel, hardened, precision-cut gears are included.

· It can be used at any capacity, including when a high hook lift is necessary.

In What Conditions Can Single Girder EOT Cranes Be Used?

If the following conditions are met, single girder EOT cranes can be employed.

· Lifting capacity should range between 15 and 50 feet.

· It should have a maximum speed of 350fpm.

· It should have a lifting speed of 60 feet per minute.

· It should cross at a speed of 150 feet per minute.

Conclusion

EOT cranes are reliable, safe, and available at a more competitive EOT crane price in comparison to other types of overhead cranes. They have a wide range of applications and are extensively employed in industries. Electric overhead travelling cranes are important instruments and equipment used in industrial production, transportation, and manufacturing processes.

Cranes, for example, go through a lot of wear and tear throughout the course of their lives. As a result, it is critical to get your cranes inspected on a regular basis.

Creating health checkup reports, combined with technical expert suggestions, can provide you with accurate information about the status of your crane. Experts assist you in making an informed decision and selecting the best course of action to improve the safety and longevity of your cranes. These inspections must cover all crane components to ensure their integrity and compliance with industry and safety regulations.

.

0 notes

Text

EOT Crane Remote Control in India

Electric Overhead Travelling Crane is commonly preferred, EOT Crane. These cranes are the most common cranes on construction sites and in industry. EOT Crane Remote is used for load lifting and shifting from one place to another place. Cranes have parallel runways and space is spanned by a traveling bridge. The hoist is placed on this bridge. To operate this crane requires electricity and can be operated via the control room attached to the crane or via a crane pendant. These cranes lifting both light and heavy equipment.

Principle of operation

Radio Remote control for EOT cranes works on three steps that are lifting, trolly lateral movement and longitudinal motion of long travelling crane. The motor has a driving force from the elevator mechanism. This delivers the power to end of high-speed shaft. Gear transfers the force therefore crane hook is driven up and down by using pulleys and wire rope. Similarly completes the half gear coupling.

Crane Configurations of Electric Overhead Traveling

· Under Running

EOT cranes are supported by the roof structure. The cranes run on the lower wing of the rail girders. One of the advantages of the under running configuration is that a very small trolley dimension takes advantage of the maximum width and height of the building. We can use the existing roof rack to protect the crane runway.

· Top Running

A beam is the main horizontal support beam of the structure. Supports the smallest bars. It has a fixed track or rail system that is installed on top of the track support. The upper stroke setting has no limitation for the power range. It can handle both small and large loads.

TYPES OF EOT CRANES

There are different types of EOT cranes. Such as,

· Double Girder EOT Crane

· Single Girder EOT Crane

· Jib Crane

Components and Radio remote control for EOT Crane

Following components requires for EOT crane remote control

· Hoist

· Trolley

· Bridge

· Runway beam

· Advanced Crane Pendent

· End Effector

· Control Panel

· Radio Remote Control Receiver

· Thruster Brakes

· Limit Switches

· Anti-Collision Device

· C Track festooning System

· DSL Busbar

· Resistance Box

· Master Controller

· Radio Remote Control

In the EOT crane, the load is supported with a hook that is linked to the hoist by ropes. A trolley moves horizontally along the crane bridge with help of a hoist. The bridge joints to an end trucks on either side. The end truck break over the track beam.

EOT crane Single Girder

The crane consists of a single girder that is carried by two forklifts and has a trolley lifting mechanism that runs on the lower chord of the bridge girder. Single girder cranes are used in work units where heavy materials need to be moved or lifted. These cranes are used for maintenance and manufacturing purposes only. The main aim of these cranes is to move heavy materials quickly and comfortably. These cranes offer great durability and can perform very well.

Features

· single girder EOT cranes are much lighter, because of one main bridge.

· for industrial applications.

· It has compact structure that minimizes the building loads.

· It has lifting capacity up to 20 tons.

· It reduces the total cost on crane components, and structure.

· Low head rooms reduce the cost of building

EOT crane Double Girder

Double girder EOT cranes are used to lift heavy loads at greater heights. It is lifting heavy loads as compared to a single girder crane. These cranes give many benefits like the selection of speed, ease of maintenance and, high carrying capacity of up to 150 tons of loads.

Features

· As it consists of two main bridges, it becomes a sturdy construction.

· Designed for durable operations.

· It is cost-effective

· It is operated at any capacity

· It consists of steel alloy, toughened, precision-cut gears.

· It consists of foot mounted hydraulic thruster brakes, which are used for the hoist.

· It has a full-length platform.

Jib Crane

a crane that has a horizontal participant known as jib that supports a movable hoist. Jib crane can be mounted on a surface such as wall or floor. It helps to increase efficiency, decrease workplace damages and improve safety. These cranes are easy to operate and require less maintenance. These cranes have the capability to rotate cranes from 180 to 360 degrees.

Applications of EOT Cranes.

Ceramic Industries

Power Plant

Transport Industry

Construction Industry

Petrochemical Industry

Chemical Industries

Steel Plant

Dairy Industries

Foundries

Textile Industry

Cement Industry

In Assembly Line

Paper and Packing

Petro-Chemical

Shipbuilding

Fertilizers

Features of EOT Cranes

All the motors of a Crane are electric motors.

It consists of a heavy-duty cast steel cable guide.

It has an upper and lower hook portable limit switch.

The body of the eot crane remote control is corrosion resistance.

It offers easy operation with less maintenance.

#EOT Crane Remote#crane remote control#EOT Crane#EOT crane Single Girder#EOT crane Double Girder#EOT crane remote control#Radio remote control for EOT Crane

2 notes

·

View notes