#Copper Scrap Market Size

Text

Copper Scrap Market Size To Reach $105.90 Billion By 2030

Copper Scrap Market Growth & Trends

The global copper scrap market size is anticipated to reach USD 105.90 billion by 2030 and is projected to grow at a CAGR of 8.6% from 2024 to 2030, according to a new report by Grand View Research, Inc. Increasing use of renewable energy sources for electricity generation has resulted in technological developments in the wind generation sector. This factor, coupled with rising awareness and emphasis on clean energy and sustainability, is expected to drive the demand for copper in wind energy production. This is set to become the biggest driver for the market over the forecast period.

Further, rising investments in EV manufacturing facilities across the world are expected to positively influence copper usage, consequently benefiting the market growth over the forecast period. For instance, in March 2022, Suzuki Motor Corporation decided to invest USD 1,320.2 million in its manufacturing plant in Gujarat, India. It is also planned to produce 125,000 EVs by 2025. In addition, over past two years, companies such as Daimler, Stellantis, and General Motors invested USD 47.0, 35.0, and 23.0 billion for their EV production facilities, respectively.

Stringent environmental regulations were introduced to mitigate environmental adversities. As a result, scrap dealers are required to obtain a certificate of conformity that indicates scrap yards and businesses comply with waste regulations. Further, Standard Rules SR2015No3 describes metal recycling and waste electrical and electronic equipment authorized treatment facility (ATF) excluding ozone-depleting substances. A license is required for all metal trading and is issued by the local authority. These regulations influence demand for copper scrap and impact market growth.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/copper-scrap-market-report

The European Union has set an ambitious target to become climate-neutral by 2050. Owing to this, the region is witnessing a significant boost in the production of EVs. For instance, in July 2022, Volvo announced an investment of EUR 1.20 billion (USD 1.22 billion) to set up a new manufacturing plant in Slovakia, and the plant is expected to begin production by 2026. Similarly, the rising focus of European countries on sustainable and clean energy generation is propelling the demand for renewable energy like wind and hydro, which is positively impacting copper.

Copper Scrap Market Report Highlights

Based on feed material, the old scrap segment led the market with the largest revenue share of 51.6% in 2023. These enter the scrap value chain largely through an unorganized route.Old scrap remains the most predominant supply source of scrap, and this is expected to remain same during the forecast period

Based on grade, the #2 copper segment held the market with the largest revenue share of 31.6% in 2023, and it is also expected to grow at a significant CAGR over the forecast period, due to its wide availability

Based on application, the brass mills segment is expected to grow at the lucrative CAGR over the forecast period, owing to high demand from applications such as hardware & plumbing, valves, casings, and decorative items

Copper is of vital importance in wire & cable applications, and these are key enablers for global market.

Asia Pacific dominated the market with the revenue share in 2023, owing to factors such as focus on reducing carbon emissions by a shift in attention toward renewable energy, amendments in trade policy, and investments across Asia Pacific region are expected to positively increase copper scrap demand

In December 2022, AIM Recycling, a Canadian-based scrap recycler entered into a 50:50 JV agreement with Kalischatarra (Kalisch Recycling), a Mexican scrap recycler. This will expand the former’s customer reach in Mexico

Copper Scrap Market Segmentation

Grand View Research has segmented the copper scrap market report based on feed material, grade, application, end-use, and region:

Copper Scrap Feed Material Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Old Scrap

New Scrap

Copper Scrap Grade Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Bare Bright

#1 Copper Scrap

#2 Copper Scrap

Other Grades

Copper Scrap Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Wire Rod Mills

Brass Mills

Ingot Makers

Other Applications

Copper Scrap End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Building & Construction

Electrical & Electronics

Industrial Machinery & Equipment

Transportation Equipment

Consumer and General Products

Copper Scrap Region Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

UK

Italy

Belgium

Spain

Asia Pacific

Japan

China

India

Central & South America

Brazil

Middle East & Africa

South Africa

List of Key Players in the Copper Scrap Market

Ames Copper Group

Aurubis AG

CMC

Glencore

Global Metals & Iron Inc.

JAIN RESOURCE RECYCLING PVT LTD.

KGHM METRACO S.A.

OmniSource, LLC.

Pascha GmbH.

Perniagaan Logam Panchavarnam Sdn Bhd

S.I.C. Recycling, Inc.

Browse full Report: https://www.grandviewresearch.com/industry-analysis/copper-scrap-market-report

#Copper Scrap Market#Copper Scrap Market Size#Copper Scrap Market Share#Copper Scrap Market Trends#Copper Scrap Market Growth

0 notes

Text

U.S. Copper Scrap Market 2022 | Brass Mills Segment Is Projected To Remain The Fastest-Growing Segment

The U.S. copper scrap market size is expected to reach USD 900.6 million by 2030, according to a new report by Grand View Research, Inc. It is expected to expand at a CAGR of 4.2% from 2022 to 2030. Demand for recycled copper in foundries and ingot-making applications is projected to boost the market growth.

Copper scrap finds applications in foundries such as casting plants, bronze products, and gunmetal products. Copper casting parts made from copper alloys and bronze are used in construction, electrical, mining, oil & gas, general, and industrial applications. This segment is projected to grow on account of favorable properties of copper such as corrosion resistance, weathering resistance, low maintenance, recyclability, superior strength, magnetic permeability, electrical conductivity, and ease of fabrication.

Gain deeper insights on the market and receive your free copy with TOC now @: U.S. Copper Scrap Market Report

With electrification increasing at a rapid pace in the automobile industry, the demand for metals necessary for the transition from ICE vehicles to electric vehicles is projected to rise over the coming years. The share of EVs sales as a proportion of total vehicles has been growing. For instance, EVs sales reached 3.6% of total EV sales, in Q2 2021, as reported by Alternative Fuels Data Center.

The irregular supply of copper scrap is one of the major challenges in the industry and thus restrains the growth of the market. Loss of copper scrap occurs as most of the scrap ends up in landfill sites. The availability of scrap is also adversely impacted by the long-life cycle of copper products. It is tied up for 10 to 20 years in the transportation sector, more than 30 years in construction and infrastructure, and between 10 to 30 years in the industrial machinery & equipment sector, before it becomes available for recycling.

Technology upgrades and investments are required to improve the recycling rate around the world. This involves more machinery & equipment for scrap processing and separation, trucks and vehicles to transport scrap, technological upgrades to handle diverse, complex, and rapidly changing material compositions, and product miniaturization. Thus, these considerable hurdles restrain the growth of the copper market, as copper scrap is not available regularly for optimized production.

Private investments in the scrap sector are growing. For instance, in the U.S. Aurubis AG has targeted investment for three actions: expanding its recycling capacity including e-waste or electronic scrap, upgrading technology to convert complex materials into high-grade scrap, and developing closed loops for customers, which can end the cycle of metal waste. Similar investments have been witnessed to be on the rise in other regions such as Europe and China.

#U.S. Copper Scrap Market Size & Share#U.S. Copper Scrap Market Latest Trends#U.S. Copper Scrap Market Growth Forecast#U.S. Copper Scrap Industry Insights#COVID-19 Impacts On U.S. Copper Scrap Market#U.S. Copper Scrap Market Revenue Value

0 notes

Link

According to recent research study, the U.S. Copper Scrap market size & share is expected to grow at a CAGR of 4.56% between 2022 and 2030. The U.S. Copper Scrap industry revenue of USD 620.9 Million in 2021 is expected to grow up to USD 1.2 Billion by 2030.

0 notes

Text

Sparking Change: Sustainable Practices in Cord Generation

Cable industries perform an essential however frequently overlooked role in running our modern world. From electrical transmission to telecommunications, from structure to automotive manufacturing, cables are the silent conductors of power, information, and connectivity. In this information, we delve into the intricacies of cable industries, exploring their development, scientific developments, key participants, and the near future outlook. مفتول

A Short History:

The history of cord industries is deeply connected with human civilization's progress. Early civilizations used normal resources like vines and dog fibers to create simple cables for numerous purposes. Nevertheless, it was not before Industrial Innovation that cord production witnessed significant advancements. The invention of cord drawing products in the 19th century revolutionized the production method, permitting mass generation and standardization of line products.

Diverse Purposes:

Nowadays, wire industries appeal to a wide array of programs across multiple sectors. In the electric industry, cables are crucial for sending energy around extended distances, driving homes, industries, and infrastructure. The telecommunications market depends on cables for information indication, allowing world wide connectivity through web wires and fiber optics. In construction, cables are useful for architectural support and electrical wiring, ensuring the protection and efficiency of buildings. More over, line products and services find programs in automotive production, aerospace, healthcare, and gadgets, among others.

Scientific Inventions:

Breakthroughs in resources science, design, and automation have propelled the line industry forward. Traditional components like copper and metal continue to dominate the marketplace due to their exemplary conductivity properties. However, there keeps growing fascination with option components such as for instance carbon nanotubes and graphene, promising remarkable efficiency and efficiency. Additionally, automation and robotics have optimized the line manufacturing process, raising output, accuracy, and cost-effectiveness.

Sustainability Initiatives:

With sustainability being a paramount matter, cord industries are adopting eco-friendly methods to reduce their environmental footprint. Recycling initiatives have received footing, with companies investing in effective recycling systems to reclaim and repurpose material scrap. Moreover, initiatives are underway to produce greener solutions to mainstream cable films and padding resources, lowering dependence on fossil fuels and harmful chemicals.

Critical Players and Market Character:

The cord business is extremely aggressive, with numerous players running on equally local and international scales. Key corporations such as for instance Prysmian Class, Nexans, and Southwire Organization take control industry, leveraging their considerable manufacturing abilities and technical expertise. But, the also comprises a variety of little and medium-sized enterprises focusing on market markets and custom cord solutions. Market character are influenced by facets such as technological creativity, regulatory frameworks, infrastructure growth, and macroeconomic trends.

Future View:

Looking ahead, the ongoing future of line industries appears promising however challenging. Rapid urbanization, digitalization, and electrification trends are expected to drive need for wires across different sectors. Emerging technologies like 5G communities, electrical vehicles, alternative energy programs, and wise infrastructure can create new opportunities and market marketers for cord manufacturers. But, the industry must also understand challenges such as varying fresh product prices, geopolitical uncertainties, and regulatory pressures.

Conclusion:

To conclude, cord industries offer because the quiet backbone of our interconnected world, facilitating power transfer, conversation, and technological innovation. As society continues to evolve and grasp new technologies, the need for high-performance wires is only going to grow. By enjoying innovation, sustainability, and effort, cable producers can flourish in an ever-changing landscape, illuminating the road towards a better and more related future.

0 notes

Text

Copper Scrap Market Size To Reach $105.90 Billion By 2030

April 2024 | Report Format: Electronic (PDF)

Copper Scrap Market Growth & Trends

The global copper scrap market size is anticipated to reach USD 105.90 billion by 2030 and is projected to grow at a CAGR of 8.6% from 2024 to 2030, according to a new report by Grand View Research, Inc. Increasing use of renewable energy sources for electricity generation has resulted in technological developments…

View On WordPress

0 notes

Text

Non-Ferrous Scrap Recycling Market Scope By Sector, Metal, Region And Forecast To 2027: Grand View Research Inc.

San Francisco, 16 April 2024: The Report Non-ferrous Scrap Recycling Market Size, Share & Trends Analysis Report By Sector (Construction, Automotive, Consumer Goods, Industrial Goods), By Metal (Aluminum, Copper, Lead), By Region, And Segment Forecasts, 2020 – 2027

The global non-ferrous scrap recycling market size is anticipated to reach USD 308.5 million by 2027, expanding at a CAGR of 2.8%…

View On WordPress

0 notes

Text

Copper Scrap Market Size To Reach $105.90 Billion By 2030

The global copper scrap market size is anticipated to reach USD 105.90 billion by 2030 and is projected to grow at a CAGR of 8.6% from 2024 to 2030, according to a new report by Grand View Research, Inc. Increasing use of renewable energy sources for electricity generation has resulted in technological developments in the wind generation sector. This factor, coupled with rising awareness and…

View On WordPress

0 notes

Text

How Laser Cutting Revolutionises the Fabrication of Metal Signs

Metal signs have long been a staple in advertising, branding, and signage due to their durability, visibility, and aesthetic appeal. However, traditional fabrication methods often entail complex processes and limited design options.

Enter laser cutting technology – a revolutionary solution that is transforming the fabrication of metal signs. Here's how:

1. Precision and Detailing: Laser cutting offers unmatched precision and detailing capabilities, allowing for the creation of intricate designs and fine lines with ease. Whether it's intricate typography, ornate motifs, or elaborate logos, laser technology delivers crisp, clean cuts that enhance the visual impact of metal signs.

2. Versatility in Materials: Laser cutting is compatible with a wide range of metals, including steel, aluminium, stainless steel, copper, and brass, offering versatility in material selection for metal signs. This enables designers to experiment with different textures, finishes, and colours, opening up endless possibilities for creative expression.

3. Customisation Options: Laser cutting enables customisation at a level that was previously unimaginable with traditional fabrication methods. From personalised messages and graphics to unique shapes and sizes, laser technology allows for unparalleled flexibility in designing metal signs to suit specific branding and marketing requirements.

4. Efficiency and Speed: Laser cutting streamlines the fabrication process, significantly reducing production time and labour costs associated with traditional methods. Its high-speed cutting capabilities enable quick turnaround times, making it ideal for time-sensitive projects such as event signage, promotions, and advertising campaigns.

5. Durability and Longevity: Metal signs fabricated using laser cutting technology are highly durable and weather-resistant, ensuring longevity even in harsh outdoor environments. The precision cuts and corrosion-resistant properties of metals further enhance the durability of the signs, making them a cost-effective investment for businesses.

6. Sustainable Practices: Laser cutting promotes sustainable practices by minimising material waste and energy consumption compared to traditional fabrication methods. Its precision cutting capabilities reduce scrap, while the use of advanced technology optimises energy efficiency, contributing to environmental conservation efforts.

Conclusion: Laser cutting technology has revolutionised the fabrication of metal signs, offering unparalleled precision, versatility, and efficiency. From intricate detailing and customisation options to durability and sustainability, laser-cut metal signs are redefining the way businesses communicate their brand identity and messaging.

0 notes

Text

Unlocking the Value of Metal Scrap: The Economics of Recycling

Metal recycling is a pivotal practice with profound economic and environmental influences. Atlas Iron & Metal Co. Leads this area, supplying sustainable solutions that benefit corporations and communities.

Economic Impact of Metal Recycling

Metal recycling substantially contributes to the worldwide economy, generating over $one hundred billion annually in the United States on my own. This enterprise also sustains thousands and thousands of jobs worldwide, spanning collection, processing, manufacturing, and distribution sectors. Recycled metals reduce uncooked cloth expenses for manufacturers, improving competitiveness and passing savings to purchasers. Additionally, recycling saves up to 92% of the power required to produce new metals, similarly boosting financial performance and environmental sustainability.

Types of Metal Scrap and Value

Metal scrap is extensively labeled into ferrous and non-ferrous metals. Ferrous metals, along with metal and iron, are magnetic and typically utilized in construction and manufacturing. Non-ferrous metals, like aluminum, copper, and brass, are valued for their conductivity and resistance to corrosion. The price of metallic scrap varies based on type, quality, and marketplace situations. For instance, copper scrap holds better value due to its call for and constrained supply.

Recycling Process

Metal recycling commences with the collection and sorting of scrap metallic from various sources like households, groups, and industries. Once sorted, the metal undergoes cleaning to remove contaminants like dust and oil. Subsequently, the cleaned scrap is processed to put it together for melting. The melted metal is then poured into molds to create ingots or other shapes, which can be bought to producers to be used in production. Although energy-extensive, recycling saves good sized energy as compared to producing metallic from raw substances.

Market Demand for Recycled Metals

Industries which include car, production, and electronics drive the call for recycled metals. They depend upon recycled metals to reduce fees and meet sustainability goals. For instance, the automotive industry makes use of recycled aluminum to decrease its carbon footprint. The market for recycled metals is projected to grow due to growing environmental recognition and authorities rules selling recycling, presenting possibilities for businesses like Atlas Iron & Metal Co. To make bigger and make contributions to a sustainable future.

Challenges and Opportunities

Metal recycling faces demanding situations like excessive recycling device charges and confined consciousness approximately recycling benefits. However, those challenges also foster innovation within the industry. Advanced sorting technology, such as optical sorting, enhances efficiency and satisfaction of recycled metals, making recycling greater attractive to producers.

Government Regulations and Incentives

Governments worldwide enforce policies and incentives to sell steel recycling. For example, the EU pursuits to recycle 50% of household waste by using 2020, together with metals. Incentive packages like tax credits and subsidies encourage corporations to undertake sustainable practices.

Future Outlook

Emerging developments like blockchain technology for monitoring recycled metal origin and the use of recycled metals in three-D printing suggest a promising destiny for metallic recycling. These tendencies reduce waste and electricity intake, contributing to an extra sustainable production enterprise.

In conclusion, metallic recycling is an economically and environmentally sound exercise. By recycling steel, groups can lessen expenses, preserve sources, and make a contribution to a sustainable destiny. To examine more about how steel recycling can benefit your enterprise, touch Atlas Iron & Metal Co. At 800-540-5184. Let's work collectively to free up the cost of metal scrap and build a greener, extra rich international.

0 notes

Text

How to remove copper from waste air conditioner radiators?

The waste air conditioner radiators can be separated a large amount of metals out for recycling. As for an ordinary air conditioner radiator, the copper content is about 55%, and the aluminum content is about 40%. For the high-end air conditioner radiators, the copper content can reach to 80%. Well, how to remove copper from waste air conditioner radiators? Today let's discuss the way together.

1. Manual peeling

Use a razor blade or a power saw, cut as close to the copper pipe as you can, to cut the scrap radiator into strips, then shave off the aluminum foil and you will have a clean copper pipe. This method is easy to operate, but its efficiency is low, and it can't process large quantity waste air conditioner radiators. Besides, it's difficult to process multi-layer radiators.

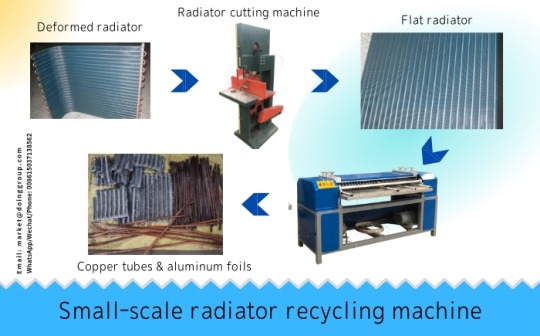

2. Separating copper tubing from aluminum fins

The second way to remove copper from waste air conditioner radiators is using radiator stripping machine. First, you need to cut the waste air conditioner radiators into suitable size single or double-layer radiators by using radiator cutting machine, then put the single or double-layer radiator into radiator stripping machine, it will separate copper tubing from aluminum fins.

Radiator stripping machine is easy to operate and occupies small land, but its efficiency is not pretty high, only 300-500kg/h. Besides, it has some limits, for example, the radiators must be flatted and undeformed, and it can't process car water tanks and industrial condenser.

3. Separating copper pieces from aluminum pieces

At first, the waste air conditioner radiators will be shred or crush into small pieces mixture of copper, aluminum and iron. Then use magnetic separator to remove iron first, after that air separator will separate copper from aluminum according to their different gravity. Finally, the copper will be removed from waste air conditioner radiators.

Air conditioner radiator recycling machine has large processing capacity, varying from 500kg/h to 2000kg/h. In addition, whether it is deformed or flat, single-layer or multi-layer air conditioner radiators, car water tanks, and condensers, it can remove copper from waste radiators easily.

Henan Doing Company is a professional e waste recycling machinery manufacturer, mainly produces e waste recycling machine, like cable/wire recycling machine, circuit board recycling machine, radiator stripping machine, air conditioner radiator recycling machine, etc. with own professional engineers team and factory manufacturing team. And the most important point is that DOING provides one-stop service and has a perfect after-sales service team. So if you want to remove copper from waste air conditioner radiators or other requirement, welcome to contact DOING, we can provide you with the best service!

Contact address:

Email: [email protected]

WhatsApp/Wechat/Phone: +86 150 3713 8562

Website: http://www.copperwirerecyclingmachinery.com/radiator/index.html

0 notes

Text

Metal Recycling Market Size, Share & Trends Report, 2030

Metal Recycling Market Growth & Trends

The global metal recycling market size projected to reach USD 1.4 trillion by 2027 registering a CAGR of 4.9%, according to a new report by Grand View Research, Inc. Increasing emphasis on circular economy and growing environmental awareness are the major factors that are likely to propel the market growth over the coming years.

International efforts to enhance global recycling capabilities and the increasing availability of obsolete scrap is likely to promote industry growth in the long term. In terms of volume, steel is the most recycled metal than other materials. This is owing to the abundant availability of steel scrap. However, the outbreak of the COVID-19 pandemic is likely to cause a severe decline in the demand for 2020.

Furthermore, the growing consumption of metal in end-use industries is also likely to play a major role in driving market growth. For instance, steel is largely consumed in the automotive, construction, industrial manufacturing, and consumer goods industries. Aluminum recycling is also gaining significant momentum as recycling aluminum saves over 90% energy compared to its primary production.

Metal manufacturers are increasingly promoting recycling as an effective way to address the problem of resource scarcity and mitigate environmental impact associated with the production process. The industry is garnering significant pace as economically viable recovery of metals from the sorted recyclates is now feasible.

Asia Pacific is predicted to be the largest as well as the fastest-growing regional market from 2020 to 2027. Proper waste management and rapid urbanization are the major factors that are likely to trigger industry growth in APAC. The growing manufacturing sector in India, China, Vietnam, Thailand, Myanmar, and Indonesia is leading to increased production activities, thereby boosting the demand for metal recycling.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/blockchain-technology-market

Metal Recycling Market Report Highlights

Asia Pacific captured the largest revenue share of 67% in 2019, in terms of volume, as the region is the largest producer of metals in the world

Steel is expected to register the fastest CAGR of 6.4%, in terms of revenue, from 2020 to 2027 owing to abundant availability of steel scrap from automobiles

The construction application segment led the market with a volume share of approximately 47% in 2019, owing to high spending in the construction sector in emerging economies of Asia Pacific

Consumer goods is expected to register the fastest CAGR from 2020 to 2027 on account of rising demand for metal products in this sector

Aluminum was the second-largest recycled product in 2019 owing to the high demand for aluminum for the production of lightweight vehicles

Metal Recycling Market Segmentation

Grand View Research has segmented the global metal recycling market report on the basis of product, application, and region:

Metal Recycling Product Outlook (Volume, Million Tons; Revenue, USD Billion, 2016 - 2027)

Steel

Aluminum

Copper

Others

Metal Recycling Application Outlook (Volume, Million Tons; Revenue, USD Billion, 2016 - 2027)

Construction

Automotive

Consumer Goods

Industrial Goods

Metal Recycling Regional Outlook (Volume, Million Tons; Revenue, USD Billion, 2016 - 2027)

North America

The U.S.

Europe

Germany

Russia

Turkey

Asia Pacific

China

India

Japan

Central & South America

Brazil

Middle East & Africa

List of Key Players of Metal Recycling Market

European Metal recycling

CMC

Utah Metal Works

GFG Alliance

Norsk Hydro ASA

Kimmel Scrap Iron & Metal Co., Inc.

Schnitzer Steel Industries, Inc.

Novelis

Tata Steel

Sims Metal Management Limited

Browse full Report: https://www.grandviewresearch.com/industry-analysis/blockchain-technology-market

#Metal Recycling Market#Metal Recycling Market Size#Metal Recycling Market Share#Metal Recycling Market Trends

0 notes

Text

Copper Scrap: Examining Strategies, Innovations, and Market Opportunities in the Global Recycling Revolution Market

The global copper scrap market size is anticipated to reach USD 105.90 billion by 2030 and is projected to grow at a CAGR of 8.6% from 2024 to 2030, according to a new report by Grand View Research, Inc. Increasing use of renewable energy sources for electricity generation has resulted in technological developments in the wind generation sector. This factor, coupled with rising awareness and emphasis on clean energy and sustainability, is expected to drive the demand for copper in wind energy production. This is set to become the biggest driver for the market over the forecast period.

Copper Scrap Market Report Highlights

Based on feed material, the old scrap segment led the market with the largest revenue share of 51.6% in 2023. These enter the scrap value chain largely through an unorganized route.Old scrap remains the most predominant supply source of scrap, and this is expected to remain same during the forecast period

Based on grade, the #2 copper segment held the market with the largest revenue share of 31.6% in 2023, and it is also expected to grow at a significant CAGR over the forecast period, due to its wide availability

Based on application, the brass mills segment is expected to grow at the lucrative CAGR over the forecast period, owing to high demand from applications such as hardware & plumbing, valves, casings, and decorative items

Copper is of vital importance in wire & cable applications, and these are key enablers for global market.

Asia Pacific dominated the market with the revenue share in 2023, owing to factors such as focus on reducing carbon emissions by a shift in attention toward renewable energy, amendments in trade policy, and investments across Asia Pacific region are expected to positively increase copper scrap demand

In December 2022, AIM Recycling, a Canadian-based scrap recycler entered into a 50:50 JV agreement with Kalischatarra (Kalisch Recycling), a Mexican scrap recycler. This will expand the former’s customer reach in Mexico

For More Details or Sample Copy please visit link @: Copper Scrap Market Report

Further, rising investments in EV manufacturing facilities across the world are expected to positively influence copper usage, consequently benefiting the market growth over the forecast period. For instance, in March 2022, Suzuki Motor Corporation decided to invest USD 1,320.2 million in its manufacturing plant in Gujarat, India. It is also planned to produce 125,000 EVs by 2025. In addition, over past two years, companies such as Daimler, Stellantis, and General Motors invested USD 47.0, 35.0, and 23.0 billion for their EV production facilities, respectively.

Stringent environmental regulations were introduced to mitigate environmental adversities. As a result, scrap dealers are required to obtain a certificate of conformity that indicates scrap yards and businesses comply with waste regulations. Further, Standard Rules SR2015No3 describes metal recycling and waste electrical and electronic equipment authorized treatment facility (ATF) excluding ozone-depleting substances. A license is required for all metal trading and is issued by the local authority. These regulations influence demand for copper scrap and impact market growth.

The European Union has set an ambitious target to become climate-neutral by 2050. Owing to this, the region is witnessing a significant boost in the production of EVs. For instance, in July 2022, Volvo announced an investment of EUR 1.20 billion (USD 1.22 billion) to set up a new manufacturing plant in Slovakia, and the plant is expected to begin production by 2026. Similarly, the rising focus of European countries on sustainable and clean energy generation is propelling the demand for renewable energy like wind and hydro, which is positively impacting copper.

#CopperScrap#CopperScrapMarket#ScrapMetal#Recycling#CircularEconomy#Sustainability#WasteReduction#GreenTechnology#IndustrialRecycling#EconomicDevelopment#EnvironmentalImpact#RawMaterials#GreenBusiness#MetalIndustry#ResourceEfficiency

0 notes

Text

The Role of Scrap Buyers Dealers in Hyderabad

In the vibrant city of Hyderabad, the scrap metal industry thrives with the presence of numerous scrap buyers and dealers. These businesses play a pivotal role in the local economy by facilitating the recycling and repurposing of various metal materials, ranging from iron and steel to aluminium and copper. With their expertise and resources, scrap buyers and dealers in Hyderabad provide valuable services to individuals and businesses alike.

Scrap buyers dealers Hyderabad act as intermediaries between scrap sellers and end-users, bridging the gap in the metal recycling supply chain. They offer competitive prices for a wide range of scrap materials, including old appliances, automotive parts, machinery components, and construction waste. By purchasing these scrap materials, they help divert valuable resources from landfills and reintroduce them into the production cycle, contributing to sustainability and environmental conservation efforts.

One of the key benefits of working with scrap buyers Hyderabad is their ability to offer convenient and efficient scrap metal disposal solutions. Whether it's a small-scale residential cleanout or a large industrial decommissioning project, these professionals can handle scrap metal collection, transportation, and processing with ease. Their fleet of vehicles and equipment enables them to efficiently manage scrap materials of various sizes and quantities, ensuring a seamless and hassle-free experience for their clients.

Moreover, scrap buyers and dealers in Hyderabad maintain strong networks and relationships within the industry, allowing them to stay informed about market trends and pricing dynamics. This knowledge enables them to offer competitive rates for scrap materials, maximizing the value for sellers while ensuring fair and transparent transactions. Whether you're looking to offload a few pounds of scrap metal or liquidate a large inventory, scrap buyers and dealers in Hyderabad can provide timely and reliable services tailored to your needs.

In addition to their role in facilitating scrap metal transactions, scrap buyers and dealers in Hyderabad also contribute to job creation and economic development in the region. Many of these businesses are locally owned and operated, employing skilled workers and supporting ancillary services such as transportation, logistics, and metal processing. By patronizing these businesses, residents of Hyderabad can support their community while responsibly managing their scrap metal disposal needs.

In conclusion, scrap buyers and dealers in Hyderabad play a crucial role in the city's scrap metal ecosystem, providing essential services that benefit both the environment and the economy. With their expertise, resources, and commitment to sustainability, these professionals offer convenient, efficient, and environmentally responsible solutions for scrap metal disposal. Whether you're a homeowner, a business owner, or an industrial operator, partnering with scrap buyers and dealers in Hyderabad ensures that your scrap metal is handled with care and integrity.

0 notes

Text

Copper Scrap Market Size To Reach $105.90 Billion By 2030

April 2024 | Report Format: Electronic (PDF)

Copper Scrap Market Growth & Trends

The global copper scrap market size is anticipated to reach USD 105.90 billion by 2030 and is projected to grow at a CAGR of 8.6% from 2024 to 2030, according to a new report by Grand View Research, Inc. Increasing use of renewable energy sources for electricity generation has resulted in technological developments…

View On WordPress

0 notes

Text

Copper Scrap Market Outlook By Feed Material, Grade, Application, End-Use, Region And Forecast Till 2030 : Grand View Research Inc.

San Francisco, 15 April 2024: The Report Copper Scrap Market Size, Share & Trends Analysis Report By Feed Material (Old Scrap, New Scrap), By Grade (Bare Bright, #1 Copper, #2 Copper Scrap), By Application, By End-use, By Region, And Segment Forecasts, 2024 – 2030

The global copper scrap market size is anticipated to reach USD 105.90 billion by 2030 and is projected to grow at a CAGR of 8.6%…

View On WordPress

0 notes