#Copper Earthing Rod

Text

Earthing Solutions, Earthing Electrodes, GI Earthing Electrodes, Chemical Earthing Rod, Pune, India

#Earthing Solutions#Earthing Systems#Earthing Electrodes#GI Earthing Electrodes#Chemical Earthing Rod#Copper Earthing Rod#Pure Copper Earthing Electrodes

0 notes

Text

#high conductivity module#Lightning protection and grounding#Lightning protection and grounding are divided into two concepts: first#lightning protection to prevent damage caused by lightning strike; The second is grounding#which is a kind of electricity use measure to ensure the normal operation of electrical equipment and personal safety.#Concept and classification of folding lightning protection grounding#Type of folded grounding body#The metal conductor buried in the soil or in concrete that directly contacts the earth and plays the role of dissipation becomes the ground#metal well pipes#the foundation of reinforced concrete buildings#metal pipelines and equipment#etc. used as metal conductors for grounding are called natural grounding bodies. The buried metal conductor specially used for grounding is#which includes copper-clad steel grounding rod#copper-clad steel grounding electrode#copper-clad flat steel#electrolytic ion grounding electrode#grounding module#.

3 notes

·

View notes

Text

PVC-covered aluminum circular condenser

Terowell is leading manufacturer ,supplier and exporter Pvc Coverded Aluminium Circular Conductor. Aluminum is often used in the manufacture of electrical conductors, due to it being ductile and relatively resistant to corrosion, as well as its low resistance and excellent conductivity, being part of the Furs range of conductors.

#PVC Covered Copper Tape#Tinned copper flexible Braided Connectors Manufacturer#Earth Bar with twin disconnecting link manufacturer#solid copper earth rod manufacturer#Copper Bonded Earth Rod manufacturers in mumbai

0 notes

Text

Forging Strong Connections: The Power of Bi-Metal Connectors

Welcome to Pioneer Power International, where we pioneer excellence in electrical solutions. Today, we shine a spotlight on bi-metal connectors, the unsung heroes of secure electrical connections, ensuring reliability and safety in every circuit.

Why Bi-Metal Connectors Matter:

In the intricate network of electrical systems, the reliability of connections is paramount. Bi-metal connectors, with their unique composition of two metals, offer a solution that withstands the test of time. By accommodating thermal expansion and contraction, these connectors maintain a tight grip on conductors, preventing loosening and subsequent failures.

Safety First:

At Pioneer Power International, safety is our cornerstone. Bi-metal connectors play a vital role in our commitment to ensuring safe electrical installations. Their ability to handle high currents without compromising integrity reduces the risk of overheating and potential hazards, providing peace of mind to both users and installers.

Versatility and Durability:

From residential to industrial applications, bi-metal connectors offer versatility and durability. Their corrosion-resistant properties make them suitable for outdoor use, while their ability to adapt to different conductor materials ensures compatibility across various systems. Pioneer Power International's range of bi-metal connectors is designed to meet the diverse needs of our clients, delivering reliability in every connection.

Conclusion:

In the realm of electrical engineering, the strength of connections defines the reliability of the entire system. Bi-metal connectors, with their robust construction and superior performance, exemplify the commitment to quality that defines Pioneer Power International. As we continue to innovate and advance, we remain dedicated to forging strong connections that power the world safely and efficiently.

#bi-metallic lugs#copperlugs#electricalconnections#copper cable lugs#aluminium lugs#aluminium cable lugs#copper bonded earthing rod#bi metal connectors

0 notes

Text

How does earthing protect solar panels from electrical faults?

The main function of the earth bond is that it protects the solar panel system from out of proportion electrical currents and electrical faults. When there is a threat of an electrical fault, the earth bond quietly directs the electricity through the ground to the ground, thereby preventing any damage to the solar panels and its associated equipment. In addition, Earthing also helps in keeping the voltage of the solar panel system stable, thereby ensuring the correct functioning and continuity of the system.

Understanding Electrical Faults:

Before explaining how to protect solar panels from electrical faults, it is important to understand the nature of these faults. Electrical faults involve various abnormalities in the electrical current in a system. These faults can arise due to various factors, such as insulation breakdown, equipment not working, or external influences such as lightning strikes. Undetected, electrical faults pose significant risks, including fire, equipment damage, and even death by electrocution.

The Role of Earthing:

Earthing, also known as grounding, is a fundamental safety measure employed in electrical systems, including solar panel installations. At its core, earthing involves connecting the electrical system to the earth through conductive materials like copper rods or plates buried underground. This connection establishes a low-resistance path for fault currents to dissipate harmlessly into the ground, thereby preventing the buildup of dangerous voltages.

Best Practices in Earthing for Solar Panel Installations:

To harness the full protective potential of earthing, solar panel installers must adhere to best practices in system design and installation. Some key considerations include:

Proper Selection of Earthing Electrodes: Choose high-quality copper or galvanized steel electrodes with adequate corrosion resistance and conductivity for long-term reliability.

Adequate Grounding System Design: Design the grounding system to meet the specific requirements of the solar panel installation, considering factors such as soil resistivity, fault current levels, and site conditions.

Regular Inspection and Maintenance: Conduct routine inspections of the earthing system to ensure its integrity and effectiveness. Check for signs of corrosion, physical damage, or loose connections that could compromise performance.

Compliance with Standards and Regulations: Adhere to relevant industry standards and regulations governing earthing practices in solar panel installations, such as NEC (National Electrical Code) guidelines in the United States.

Integration of Surge Protection Devices: Install surge protection devices (SPDs) at critical points within the solar panel system to suppress transient over voltages and enhance overall protection against electrical faults.

Conclusion

In the ever-evolving landscape of renewable energy, the safety and reliability of solar panel installations are non-negotiable imperatives. Earthing emerges as a cornerstone of this safety framework, providing vital protection against electrical faults and ensuring the longevity of solar panel systems. By understanding the principles of earthing and adhering to best practices in its implementation, solar panel installers can fortify their installations against potential hazards and foster a sustainable energy future.

0 notes

Text

Solid Copper Earth Rods

In the realm of electrical grounding systems, the importance of reliable components cannot be overstated. Solid Copper Earth Rods stand out as indispensable elements ensuring the safety and efficiency of electrical installations. Nexus Copper Pvt. Ltd., a pioneering name in the copper industry, offers insights into the significance of Solid Copper Earth Rods and their pivotal role in electrical grounding.

Understanding Solid Copper Earth Rods

Solid Copper Earth Rods serve as essential components in earthing systems, which are crucial for diverting fault currents safely into the ground. They are designed to provide a low-impedance path for electrical currents, thus safeguarding equipment, structures, and personnel from the hazards of electrical faults.

Unlike their counterparts made from alternative materials, such as galvanized steel or copper-bonded rods, Solid Copper Earth Rods offer unparalleled conductivity and corrosion resistance. This superiority stems from the intrinsic properties of copper, renowned for its high electrical conductivity and exceptional durability.

The Nexus Copper Advantage

Nexus Copper Pvt. Ltd., a company committed to excellence in copper solutions, takes pride in its range of Solid Copper Earth Rods. Through a combination of cutting-edge technology and uncompromising quality standards, Nexus Copper ensures that its earth rods meet the most stringent requirements of modern electrical installations.

High Conductivity: Solid Copper Earth Rods from Nexus Copper boast exceptional conductivity, minimizing resistance in the earthing system. This characteristic is critical for efficient dissipation of fault currents, thereby reducing the risk of electrical accidents.

Durability and Longevity: Copper, known for its resistance to corrosion and degradation, ensures the longevity of Nexus Copper Pvt. Ltd . By withstanding harsh environmental conditions, these rods offer reliable performance over an extended service life, thereby minimizing maintenance requirements and replacement costs.

Versatility: Nexus Copper offers a diverse range of Solid Copper Earth Rods tailored to suit various applications and installation requirements. Whether for industrial facilities, commercial buildings, or residential complexes, Nexus Copper provides solutions that cater to the specific needs of each project.

Compliance and Certification: Nexus Copper's Solid Copper Earth Rods adhere to international standards and undergo rigorous testing to ensure compliance with safety and performance requirements. This commitment to quality and certification underscores Nexus Copper's dedication to customer satisfaction and safety.

Applications and Benefits

Solid Copper Earth Rods find widespread use across diverse industries and applications:

Telecommunications: Ensuring uninterrupted communication networks by safeguarding equipment against lightning strikes and electrical surges.

Power Generation and Distribution: Protecting power plants, substations, and transmission lines from the damaging effects of fault currents and lightning-induced voltages.

Oil and Gas: Safeguarding critical infrastructure in hazardous environments against the risks of static discharge and electrical faults.

Residential and Commercial Construction: Providing a safe and reliable grounding solution for buildings, ensuring the protection of occupants and electrical equipment.

Conclusion

Solid Copper Earth Rods represent the pinnacle of excellence in electrical grounding solutions, offering unparalleled conductivity, durability, and reliability. Nexus Copper Pvt. Ltd., with its unwavering commitment to quality and innovation, continues to redefine industry standards by delivering superior Solid Copper Earth Rods that meet the evolving needs of modern electrical installations. With Nexus Copper Pvt. Ltd expertise and dedication, customers can rest assured that their grounding systems are fortified with the strength and resilience of solid copper, ensuring optimal safety and performance for years to come.

#Solid Copper Earth Rods#Copper Bonded Ground Rod Welded#Copper Grounding Rods#Solid Copper Bonded Grounding Rod#Copper Bonded Grounding Threaded Rods#manufacturer#supplier#exporter#Mumbai#India.

0 notes

Text

Type of GI Earthing Electrode.

Earthing electrodes are crucial components in grounding systems, designed to provide a low-resistance path for the dissipation of fault currents to the ground. There are several types of Grounding (GI) electrodes commonly used for earthing purposes:

GI Pipe Electrode:

A galvanized iron (GI) pipe can be used as an earthing electrode. It is typically buried vertically in the ground. The length and diameter of the GI pipe depend on the soil resistivity and the electrical system requirements.

GI Plate Electrode:

A GI plate is another common type of earthing electrode. It is usually buried horizontally in the ground. The size of the plate is determined based on soil resistivity and the specific requirements of the grounding system.

GI Strip Electrode:

Similar to the GI plate, a GI strip can be used as an earthing electrode. The strip is buried horizontally in the ground, and its dimensions are determined based on the grounding system requirements.

GI Electrode with Backfill Compound:

Some grounding electrodes are treated with special backfill compounds to enhance their conductivity and reduce soil resistivity. This helps in achieving lower resistance to earth.

Chemical Earthing Electrode:

In chemical earthing systems, a compound or mixture is used around the electrode to improve conductivity. This type of electrode is designed to maintain a low resistance value over time, even in high-resistivity soils.

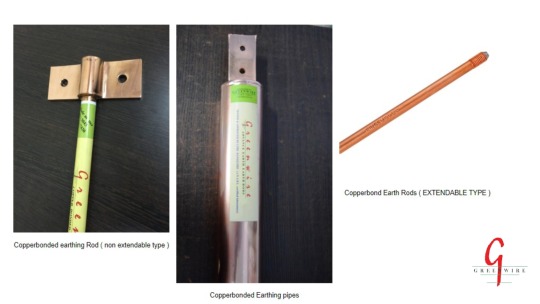

Copper-Bonded Electrode:

While not made of pure GI, copper-bonded electrodes have a thin layer of copper bonded to a steel core. This combination provides the benefits of both copper and steel, offering good corrosion resistance and electrical conductivity.

Cast Iron Electrode:

Cast iron electrodes are less common but are used in some specific applications. They are durable and have good corrosion resistance.

The choice of the earthing electrode depends on various factors such as soil resistivity, space availability, local regulations, and the specific requirements of the electrical system. It's essential to consider these factors to ensure an effective and reliable grounding system. Consulting with a qualified electrical engineer or following local electrical codes and standards is recommended when designing and installing an earthing system.

#advanced gel earthing electrode#copper bonded earthing electrode#earthing electrode#earthing strip#galvanized iron#lighting arrester#earthing rod copper

0 notes

Text

Use of Earthing Rod Copper in Making Your Dream Home

The immediate discharge of electrical energy by the use of a low-resistance wire to transfer charges straight to the earth is known as earthing. To reduce or eliminate the risk of electrocution, several forms of the earthing rod copper are utilized to connect the metallic components of electrical appliances or installations to the ground.

0 notes

Text

Copper Bonded Rods supplier

SG Power is the leading Copper Bonded rods supplier in India. Our products ensure efficient grounding and lightning protection for various applications. With our extensive range and expertise, we are committed to providing reliable solutions that meet your specific requirements. Choose SG Power for superior performance and peace of mind.

Visit: https://www.sgpower.co.in/copper-bonded-earth-rod.html

0 notes

Text

Lightning Arresters are the new lifeline of today’s world owing to the unprecedented thunderbolts and lightning taking place across the world now and then. It’s not that Lightning didn’t happen in earlier days, but nowadays, the frequency and the intensity of lightning strikes have grown exponentially to draw immediate attention and install prompt lightning protection systems to save oneself and one’s property from the menace of lightning strikes.

The climatic changes and global warming have made it mandatory for us to safeguard ourselves and our property from uncontrolled natural calamities, which we cannot control but can only safeguard ourselves in one way or another.

Conventional Lightning Arresters:

Conventional lightning arresters are solid rods or hollow pipes with a pointed top or 4–5 spikes on the top to make the lightning strike in its near vicinity fall over it rather than somewhere else. These Lightning Arresters are connected to the ground earthing with down conductors to immediately ground the lightning current into the earth without allowing it to do any damage in the surroundings. In this way, lives, structures, and other objects which come under the protective cover of the lightning arrester, stay safe from the lightning strikes.

Conventional lightning arresters are commonly available as Copper Lightning Arresters or Aluminum Lightning Arresters.

ESE Lightning Arresters are modern Lightning arresters that have a wide area of protection coverage from 35 mtrs to 107 mtrs of the radius of their installation. These ESE lightning arresters are the most commonly used lightning protection system nowadays.

True Power, , India’s №1 Chemical Earthing and Lightning Arresters company, manufactures, supplies, exports, designs, and installs Conventional and ESE Lightning Protection Systems across PAN India and selected countries.

True Power Conventional Lightning Arresters are manufactured in line with IEC 62561 part I & IEC 62305 with 99.99% Pure Copper procured from the best global suppliers, while True Power’s ESE Lightning Arresters are manufactured in line with UNE 21 186, NFC 17–102, and NFPA 780.

With more than a Lakh Lightning Protection Systems working successfully for decades, True Power has become the First Choice in Chemical Earthing & Lightning Protection Systems. True Power Products are RDSO approved, UL Listed, RoHS Certified, and have more than 50 approvals to their credit from Central and State Govt. authorities and depts.

True Power Lightning Protection Systems are installed in a wide spectrum of applications including Research & Data Centers, Hospitals, Military Installations, Residential buildings & complexes, Commercial places, Ministries, Govt. offices and residences, Oil & Gas Projects, Religious structures, Monuments and a lot of other places to discuss here all.

True Power otherwise is in 8 different electrical verticals namely: Chemical Earthing, Lightning Arresters, Solar Panels, Transformers, Module Mounting Structures, Fans, Geysers, Wires & Cables. With 3 State-of-the-art manufacturing setups, 1000+ Employees, 22 Branch offices, 40 Service Centers, and a renowned brand image across the Globe, today True Power has become a every household name.

Talk to us today and install a well-designed True Power Lighting Protection System at your place to safeguard yourself, your family, your property, and your nearby surroundings.

Contact us:

Call us: 8318455691

Email us: [email protected]

Address: D 242, Sector 63 Rd, D Block, Sector 63, Noida, Uttar Pradesh 201301

For more information visit: https://www.truepowergroup.in/lightning-arresters-A-must-for-every-home-office-industry-to-stay-safe-install-today.html

True Power Earthings Private Limited

#lightning arresters#lightning protection system#copper lightning arrester#lightning protection#lightning arrester price#lightning arrester for home#lightning arrester for building#lightning surge protector#lightning protection for buildings#surge arrester schneider#surge arrester price#lightning rod price#home lightning protection system#dc surge arrester#lightning surge arrester#lightning protection for house#lightning arrester for building price#earthing arrester#lightning protection device#ethernet lightning protection#lightning arrester for solar system#ese lightning arrester price#siemens surge arrester#lightning arrester for home price#lightning conductor installation#solar panel lightning protection#thunder protector for home#home lightning protection system cost#lightning surge protector for home#lightning protection rod

0 notes

Link

We are the leading manufacturer and supplier and Distributor of Chemical Earthing Electrode, GI Earthing Electrode in pan India in various industries. We are certified by ISO, CE, UL, ROHS certificate for the quality of our products with 100% Satisfaction.

0 notes

Text

#HDPE Earthing inspection Chamber Manufacturers#Copper Bonded Earth Rod Manufacturers#Chemical Pipe Earthing Electrode Manufacturer

0 notes

Text

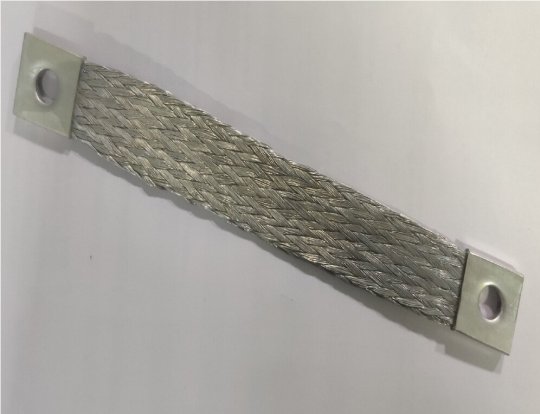

Tinned Copper Flexible Braided Connectors & Manufacturer

Terowell manufactures, exports and supplies Flexible Flat Copper Braid Bond made of numerous copper wires are likewise now and again utilized for adaptable electrical associations between large components. The various littler wires involving the twist are a great deal more impervious to breaking under repeated motion and vibration than is a cable of larger wires.

#Gunmetal Clamps manufacturer#solid copper earth rod manufacturer#Copper Bonded Earth Rod manufacturer in mumbai#u bolt clamp suppliers in mumbai#PVC Covered Copper Tape

1 note

·

View note

Text

Connecting Safety: The Role of Copper Cable Lugs

Welcome to Pioneer Power International, where safety and innovation intersect. Today, we delve into the significance of copper cable lugs in electrical connections, highlighting their crucial role in ensuring reliability and safety.

The Power of Copper:

Copper is renowned for its conductivity and durability, making it the ideal choice for electrical connections. Copper cable lugs provide a secure and efficient link between cables and electrical equipment, facilitating the smooth flow of electricity.

Reliability and Safety:

At Pioneer Power International, we prioritize reliability and safety in all our solutions. Our copper cable lugs are meticulously engineered to withstand the rigors of electrical systems, minimizing the risk of downtime and hazards.

Versatility and Performance:

Whether in industrial settings or residential applications, copper cable lugs offer versatility and high performance. Their ability to maintain strong connections under varying conditions ensures uninterrupted power supply and operational efficiency.

Conclusion:

Copper cable lugs play a vital role in ensuring the integrity and safety of electrical connections. At Pioneer Power International, we harness the power of copper to deliver solutions that meet the highest standards of reliability and performance.

#copper cable lugs#copperlugs#electricalconnections#aluminium cable lugs#aluminium lugs#bi metal lugs#copper bonded earthing rod#bi metal connector

0 notes

Link

0 notes