#Caterpillar ET Software

Text

How to Adjust the Fuel Ratio Control of Caterpillar 3208 Diesel Engine

This article explains how to adjust the Caterpillar 3208 diesel engine fuel ratio control

Caterpillar 18 Digits Factory Password Calculator One-Time Calculate Service

NOTE: The same tools are needed for the fuel ratio control adjustment that were used for the fuel setting.

Make reference to Fuel Setting for the tools needed and instructions to install the tools.

NOTE: The fuel setting must be correct before an adjustment is made to the fuel ratio control. Make reference to Fuel Setting.

1. Remove shutoff solenoid (1) and cover (2). Install tools and "zero"dial indicator as shown in Fuel Setting Steps 2 through10.

2. To check the fuel ratio control setting, move the governor lever slowly to the high idle position. Make a record of the reading on the dial indicator.

Compare the reading with the specification given in the Fuel Setting And Related Information Fiche.

Caterpillar ET 2024A & 2023C & 2019C Electronic Technician Diagnostic Software Download and Installation

3. If an adjustment is needed, remove three bolts (3)

from the fuel ratio control. Hold the governor lever in the high idle position and turn flange (4) until the fuel ratia control setting is correct.

CAT Caterpillar ET 3 Diagnostic Adapter 317-7485/478-0235 Diagnostic Tool-high quality

4. Move governor lever to low idle and again move the lever slowly to high idle to check the fuel ratio control setting.

5. Install bolts (3). Flange (4) can be turned a small amount to give alignment for bolts (3).

6. Remove tools and install cover (2) and shutoff solenoid (1).

0 notes

Text

Caterpillar Machine Map Adjustment Guide

Caterpillar Machine Map Adjustment Guide

Purpose

ECMs use maps to control the various operating points of the equipment. The Map Adjustment feature allows these existing maps to be modified.

Note: For more information on this feature, please see REHS3004 Special Instruction Using the Map Adjustment Software.

Accessing

To access the Map Adjustment feature, select “Map Adjustment” from the Service menu. The Map Adjustment screen is displayed.

Screen Layout

CAT ET 2024A

Cat adapter 3

The Map Adjustment screen consists of the following areas:

Selected Map Properties Area

The information selected in this area determines the appearance of the remainder of the Map Adjustment screen. This area consists of drop-down menus and checkbox options:

Drop-down Menus Map Number – This drop-down provides the title of the maps available for selection. These available selections depend upon the ECM.

Map Type - There are four possible selections for Map Type Base - Refers to the factory default map shipped with the ECM

Previous - If changes have been made to the Working Map, this map type may be selected to return to the previous settings

Current - Refers to the map currently loaded on the ECM. The information listed in the Map Data Area for this map cannot be modified.

Working Map - Refers to the modifiable version of the map currently loaded on the ECM. Map modifications may be made by clicking the up or down arrows in the Map Data Area and then can be loaded to the ECM by clicking the Submit button.

Data Modify Mode – From this drop-down, the user may select whether the data will be modified for only a single value (“Single Value”), or for all the values in a column (“All Values”).

Switch Independent Variable - From this drop-down, the user may select whether or not to switch the independent variable displayed by the map from the default variable to another variable.

Checkbox Options Monitored Parameters - Click this checkbox to view the parameters, as well as their values and units of measure, that are being monitored by the ECM. This information will appear in the table to the right of the Selected Map Properties section.

Map View - Click this checkbox to view the selected map in 2D. The map will resemble a traditional 2D graph and will be displayed to the right of the Selected Map Properties section.

3D Map View - Click this checkbox to view the selected map in 3D. The 3D map is viewable from any angle and will be displayed to the right of the Selected Map Properties section.

Map Data Area

This area displays the data for the selected map in a table format. The table displays up to seven columns and always includes the Modifiable Range, Valid Range, Offset, and Resolution for the selected parameter. The information in the remaining columns depends upon the variables selected in the Selected Map Properties area.

Buttons

The buttons available in the Map Adjustment screen depend upon the ECM and may include: Factory – Click this button to reset either the selected map or all maps to Factory settings

Submit – Click this button to submit changes made in a Working Map to the ECM. Factory Passwords may be required to adjust the maps.

Note: This button is enabled only when Working Map is the selected Map Type.

Copy to Working – Click this button to transfer the selected map to the Working Map type, which will allow it to be modified.

Note: This button is disabled when Working Map is the selected Map Type.

Load from File – Click this button to load Map Adjustment information from an existing file.

Save to File – Click this button to save the current Map Adjustment information to a file.

More... – Click this button for more options in the Map Adjustment screen. Setup Configuration settings may be modified, and the Calibration Feedback can be set to “Enabled” or “Disabled”.

Calibration Feedback Enable – Click this button to enable Calibration Feedback, which is a special mode that the engine may need to be in for the Map Adjustment to run. Once the calibration feedback has been enabled, this button changes to Calibration Feedback Disable.

0 notes

Text

Best Quality A #CAT #Caterpillar ET3 Diagnostic Adapter iii Real Cat Caterpillar 317-7485 Communication Adapter 3 With Cat ET 2019C Download Software With 6pin,9pin and 15pin cable for Both new and old truck

Whatsapp / Wechat : +86 13691674080

Skype : [email protected]

0 notes

Text

How to troubleshoot the problem of caterpillar engine starter not running

caterpillar 320A engine starter not running Possible causes and troubleshooting methods are as follows.

the battery. https://www.heavydutydiag.com/product/caterpillar-et-2022a-electronic-technician-diagnostic-software/

(1) The battery output voltage is low. Check the condition of the battery. If necessary, recharge or replace

(2) Wire or switch failure. Repair wires or switches. If necessary, replace wires or switches.

(3) The starter solenoid coil is faulty. Install new starter solenoid.

(4) Starter failure. Repair or replace starter.

CAT Caterpillar ET 4 Diagnostic Adapter Truck Diagnostic Tool

1 note

·

View note

Text

Sotreq abre novas vagas de emprego para Mecânicos de manutenção, Almoxarife, Ferramenteiro e muito mais nas regiões de RJ, SP, MT, RS, BA e GO

A Sotreq, empresa que atua nos setores de construção, energia, mineração e petróleo marítimo, está com diversas vagas de emprego para profissionais de diversas áreas de atuação. As vagas na Sotreq são voltadas para candidatos que residem nos estados do Rio de Janeiro, São Paulo, Mato Grosso, Rio Grande do Sul, Bahia e Goiás. Entre as principais oportunidades estão as de mecânico, ferramenteiro, operador e muito mais.

Confira a lista de vagas de emprego abertas pela Sotreq em várias localidades

Separamos uma lista com as principais vagas na Sotreq em diversas áreas de atuação e algumas informações importantes:

Mecânico de Manutenção Externo

Necessário ensino médio completo, experiência com manutenção de equipamentos da marca CAT, inglês básico, CNH B, disponibilidade para viagens, entre outros.

Analista de Tecnologia de Mineração

Necessário ensino superior completo, conhecimento no setor de equipamentos da marca CAT, CNH B, experiência com operação de mina, sistemas de gestão de frota, KPIs de operação, inglês intermediário, disponibilidade para viagens pontuais.

Auxiliar de Almoxarifado

Necessário ensino médio completo, pacote office, desejável CNH B e experiência com Almoxarifado.

Auxiliar Administrativo de Serviços

Necessário possuir experiência com rotinas administrativas, ensino médio completo, pacote office, disponibilidade para viagens, inglês nível básico, entre outros.

Assistente de Vendas

Necessário Ensino Médio Completo, Experiência em vendas internas e técnicas, de preferência no setor comercial de empresas do mercado de petróleo e marítimo, conhecimento avançado em excel, desejável conhecimento em SAP e Power Bi, desejável conhecimento em Inglês.

Operador de Máquina Operatriz

Necessário Ensino Médio Completo, desejável CNH B, Necessária experiência com operação de equipamentos operatrizes como Torno, Fresas, Furadeiras de bancada, entre outros.

Mecânico de Manutenção Interno

Necessário ensino médio completo, conhecimentos em software de gestão SAP Conhecimento em sistemas operacionais Caterpillar (SIS;ET), experiência em atendimento ao cliente, experiência em confecção de orçamentos utilizando sistemas SAP e SIS, inglês técnico intermediário entre outros.

Envie seu currículo ou se cadastre nas vagas de emprego da Sotreq

Os interessados nas vagas da Sotreq devem acessar a página de oportunidades da empresa na plataforma VAGAS. Na página é possível encontrar ainda diversas outras oportunidades, incluindo para estágio, aprendiz e muito mais. Ao selecionar, é necessário ler atentamente às informações disponibilizadas como requisitos, atribuições, qualificações, benefícios, dados da empresa e outros.

Para a candidatura os profissionais interessados nas vagas de emprego devem preencher um formulário atualizado com dados importantes como nome completo, CPF, data de nascimento, entre outros.

A empresa, além de uma ótima remuneração, ainda disponibiliza aos seus colaboradores diversos benefícios como assistência médica, auxílio farmácia, vale-refeição, participação nos lucros ou resultados, previdência privada, cesta de natal, assistência odontológica, vale-transporte, entre outros.

CLIQUE AQUI PARA SE CANDIDATAR

Sobre a Sotreq

O Grupo começou a surgir em 1941, quando a Sociedade de Tratores e Equipamentos Ltda e a Caterpillar fecharam um acordo, que valia para a área geográfica que compreendia o Distrito Federal e os estados do Rio de Janeiro, Minas Gerais e o Espírito Santo, além da parte situada ao sul de Goiás.

No mesmo ano, a empresa foi fundada oficialmente. A princípio, além de tratores e moto-escrêiperes CAT, a empresa vendia cabos de aço, guinchos, guindastes, dragas, barcaças, locomotivas, tratores agrícolas de rodas, entre outros. Os primeiros 21 colaboradores se instalaram em um escritório, na extinta rua São Pedro, no Centro do Rio de Janeiro.

O post Sotreq abre novas vagas de emprego para Mecânicos de manutenção, Almoxarife, Ferramenteiro e muito mais nas regiões de RJ, SP, MT, RS, BA e GO apareceu primeiro em Petrosolgas.

0 notes

Text

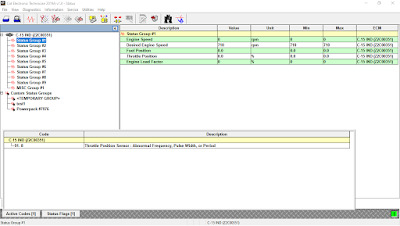

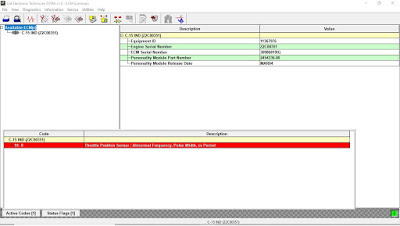

Throttle Position Signal Abnormal (Error Code SPN 91 – FMI 8)

SPN91 FMI8

CID 0091 FMI 08 Throttle Position Signal Abnormal

MID 036 CID 0091 FMI 08

Conditions Which Generate This Code:

The Electronic Control Module (ECM) detects an incorrect frequency on the throttle signal.

System Response:

The code is logged. The ECM flags the throttle position as invalid data and a default value of zero percent is used.

Possible Performance Effect:

The engine speed is limited to low idle.

Troubleshooting:

Throttle Position Sensor Circuit – Test

System Operation Description:

Use this procedure to troubleshoot any suspect problems with the throttle position sensor. Also use this procedure to troubleshoot an active 91-08 Throttle Signal Abnormal.

The throttle position sensor eliminates the mechanical throttle and governor linkages. The sensor that is installed depends on the engine’s configuration.

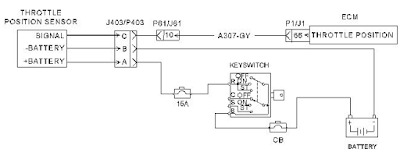

Figure 1.2 – Throttle Position Sensor (with a knob and electronic)

Refer to Figure 1.3 – The sensor creates a signal that is Pulse Width Modulated (PWM). The duty cycle varies with the throttle position. The signal has a low duty cycle when the throttle is at low idle (0-22%). The signal has a high duty cycle when the throttle is at high idle (75-100%). The Electronic Control Module (ECM) processes the signal in order to control the engine speed.

The signal from the throttle position sensor has a specific frequency. The frequency of the signal must be between 150 Hz and 1050 Hz or the ECM will activate a 091-08 diagnostic code.

Test Step 1. Inspect the Electrical Connectors and the Wiring

A. Turn the keyswitch to the OFF position.

B. Thoroughly inspect J1/P1 ECM connector and P61 Customer connector (if available). Inspect the connections on the throttle position sensor.

P1 terminal that is associated with the throttle position sensor:

(P1-66) Throttle position), J1/P1 ECM connector.

(10) Throttle position), J61 and P61 Customer connector.

C. Perform a 45 N (10 lb) pull test on each of the wires that are associated with the throttle position sensor.

D. Check the Allen head screw on each ECM connector and the customer connector for the proper torque.

Expected Result: All connectors, pins, and sockets are completely coupled and/or inserted, and the harness and wiring are free of corrosion, of abrasion, and of pinch points.

If Not OK: Repair the wiring and/or the connectors. Replace parts, if necessary. Ensure that all of the

seals are properly connected. Verify that the repair eliminates the problem.

Test Step 2. Check for Supply Voltage at the Throttle Position Sensor

A. Monitoring Cat ET, check “Active Diagnostic” code (91-8) – Throttle Position Sensor: Abnormal Frequency, Pulse Width, or period. Read More: How to Connecting Caterpillar ET Software to the ECM

B. Disconnect the P403 connector (TPS connector).

C. Turn the keyswitch to the ON position. The engine should be off.

D. Measure the voltage between terminals P403-A and P403-B (Pin A – B)

Expected Result: The supply voltage is at least 11 VDC for a 12 volt system. The supply voltage is at least 22 VDC for a 24 volt system.

If Not OK: The configuration of the wiring between the +Battery and the throttle position sensor depends on the engine’s configuration. The problem could be in the wiring or in a connector. There may be a problem with the battery.Perform the necessary repairs. Verify that the problem is resolved.

Test Step 3. Check the Signal Wire for a Short Circuit

A. Turn the keyswitch to the OFF position.

B. Disconnect the P1 ECM connector.

Note: Be sure to wiggle the harnesses during the following measurements. Be sure to wiggle each

harness near each connector.

C. Measure the resistance between terminal P1-66 and all of the other terminals in the P1 ECM connector.

Expected Result: Each resistance measurement indicates an open circuit.

If Not OK: The problem could be in the wiring or in a connector. Repair the wiring and/or the connector, when possible. Replace parts, if necessary. Verify that the problem is resolved.

Test Step 4. Check the Signal Wire for an Open Circuit

Note: Be sure to wiggle the harnesses during the following measurement. Be sure to wiggle each harness near each connector.

-Measure the resistance between terminal P1-66 and terminal P403-C (Pin C – TPS Signal).

Expected Result: The resistance measurement is less than 10 ohms.

If Not OK: The problem could be in the wiring or in a connector. Repair the wiring and/or the connector, when possible. Replace parts, if necessary. Verify that the problem is resolved.

Test Step 5. Check the Frequency or Duty Cycle of the Throttle Position Signal at the ECM

A. Connect a multimeter between terminal P1-66 on and the engine ground stud.

B. Turn the keyswitch to the ON position.

C. Measure the frequency or duty cycle of the throttle position signal. Slowly move the throttle from low idle to high idle and back to low idle while you measure the frequency of the signal.

Expexted results:

-The frequency of the signal remains between 150 Hz and 1050 Hz as you move the throttle.

-Duty cycle is between 5% and 100% (0-5 Vdc).

0 notes

Text

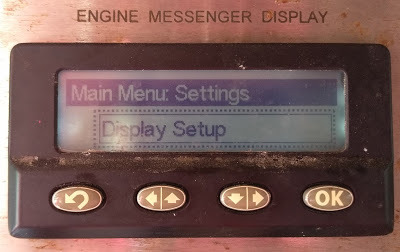

CHANGE UNITS OF MEASURE ON CAT MESSENGER DISPLAY

How to Change Units of Measure on CAT Messenger Display?

Units of Measure

From the “DISPLAY CONFIGURATION” title screen, press the Down arrow button. This screen displays the current units for the measurements.

Read More:

How to setting new CAT Messenger Display?

Change Measurement System on Caterpillar ET Software

Selecting the Display Units of Caterpillar ET Software

From the “Display Configuration” title screen, press the Down arrow button three times.

1. Main Menu – Settings

2. Settings – Display Setup

3. Display Setup – Units

4. Units – Select Units (Metric / U.S.)

0 notes

Link

We're arranging high-quality facilities for our customers in getable expenses. Competencies and hard work make our company the exceptional alternative in all machinery repairing agencies. To understand greater approximately us, you may visit at our first rate website :https://my-premium-manual-source.com/

#Obd2 Scanner#Volvo Diagnostic Tool#Heavy Duty Scanner#Diagnostics Software#Obd Diagnostic Interface#Diagnostic Software#John Deere Ag#Heavy Duty Truck Code Reader#Diesel Diagnostic Tool#Diesel Laptops#Code Reader For Diesel Trucks#Heavy Duty Truck Scanner#Cat Diagnosis#JPRO#Heavy Duty Truck Diagnostic Scanner#Truck Diagnostic Tool#Diagnostic Scan Tool#Cat Diagnostic Tool#Cat Et#Caterpillar Service Tools#Truck Diagnostic Software#Diesel Truck Scanner#Heavy Duty Truck Diagnostic Software#John Deere Diagnostic Code Reader#Jpro Software#Pf Diagnose#Truck Diagnostic Software Download#Heavy Duty Diagnostic Laptop#Heavy Duty Truck Diagnostic Laptop#Detroit Diesel Diagnostic Link

0 notes

Link

#cat adapter 3#volvo interface#vocom 88890300#volvo premium tech tool#caterpillar et#eaton service ranger#volvo ptt#john deere edl#cummins software#truck diagnostic software download#jpro software#pf diagnose#heavy duty truck diagnostic laptop#heavy duty diagnostic laptop#detroit diesel diagnostic link#paccar diagnostic software

0 notes

Text

How to Solve Caterpillar Truck Engine Cranks But Won't Start Problem

This article provides instructions for Caterpillar 3406E, C-10, C-12, C-15, C-16, and C-18 truck engines that crank but will not start.

Probable Causes:

Caterpillar 18 Digits Factory Password Calculator One-Time Calculate Service

The probable root causes are listed in order below:

Key switch

Communications between the ECM and the

Caterpillar Electronic Technician (Cat ET)

Aftermarket engine protection devices

Power to ECM

Personality Module

ECM

Electrical connections to the electronic unit

injector

Engine speed/timing signal

Engine software

Theft deterrent

Fuel supply Combustion problem Recommended Actions Perform the following diagnostic procedures in order:

1. Check the key switch.

a. Connect Cat ET to the data link connector.

b. Access the status for "Ignition Key Switch".

c. Slowly cycle the key switch ON and OFF while the status for "Ignition Key Switch"is being monitored. The status should indicate the state of the switch.

If the ECM will not communicate and the key switch is in the ON position, refer to Step 3. Note: If the Engine Shutdown Output feature isused, the status for "Ignition Key Switch"may indicate that the switch is ON even though the key switch is turned to the OFF position.

12.2021 Caterpillar ECM ECU Flash Files Full Set Download

2. Check the communications between the ECM and Cat ET.

a. Connect Cat ET to the data link connector.

b. Ensure that the key switch is in the ON position. Attempt to access one of the status screens on Cat ET.

If Cat ET indicates that the ECM will not communicate go to Step 3. If the ECM communicates go to Step 6.

Note: A new ECM has a personality module that is not programmed. A new ECM that is notprogrammed will cause this symptom. Accessing the ECM status in "WinFlash" without programmingthe personality module will cause the engine not to start or accessing the ECM status in "WinFlash"

without programming the personality module will cause the engine not to communicate. Cycling the key switch from the OFF to the ON position will correct this problem.

3. Check aftermarket engine protection devices.

These devices usually interrupt power to the ECM and the ECM will not communicate with Cat ET.

a. Check for the correct installation of the aftermarket engine protection device.

b. Check for the correct operation of the aftermarket engine protection device.

c. Verify that the ECM is receiving battery voltage.

4. Check the electrical power supply to the ECM.

a. Check the power connection of the ECM and the ground connection of the ECM.

b. Verify that the ECM is receiving battery voltage when the key switch is turned ON.

Refer to Troubleshooting, "Ignition Key Switch Circuit and Battery Supply Circuit-Test".

Caterpillar ET 2024A & 2023C & 2019C Electronic Technician Diagnostic Software Download and Installation

5. Check the personality module.

A new ECM has a Personality Module that is not programmed. The engine will not start until the personality module has been flashed. Also, the engine will not communicate until the personality module has been flashed.

6. Check the ECM.

Before replacing the ECM, try to flash program the existing ECM. Refer to Troubleshooting.

"Flash Programming".

If the ECM is suspected of being the problem, temporarily connect a test ECM. This will show whether the problem has been resolved or the problem has not been resolved.

7. Check the electrical connections to the electronic unit injectors.

a. Ensure that the J300/P300 Electronic Unit Injector connector is fully connected andensure that the J300/P300 Electronic Unit Injector Connector is free of corrosion.

b. Check for logged diagnostic codes that are related to the injectors. Refer to the injectors are present.

Troubleshooting, "Injector Solenoid Circuit -Test"if diagnostic codes that are related to

8. Check the engine speed/timing signal.

a. Observe the engine rpm on Cat ET while the engine is being cranked.

This may require Cat ET to be powered directly by the vehicle batteries or this may require Cat ET to be powered directly by a separate power source (12 VDC). Refer to Illustration 31.

9. Check for the correct engine software. ConnectCat ET to the service tool connector. Ensure that

252-11 Incorrect Engine Software is not active.

If the diagnostic code is present, refer to Troubleshooting, "ECM Memory-Test".

Connect Cat ET to the service tool connector.

Check for the following diagnostic codes:

224-11 Theft Deterrent Active

224-14 Theft Deterrent Active with Engine Cranking

10. Ensure that the theft deterrent (if equipped) is not active. Turn the key switch to the ON position.

Observe the display screen on the CAT ID.

If the display screen on the CAT ID indicates that the theft deterrent is enabled, the theft deterrent passwords must be entered before the engine will start.

CAT Caterpillar ET 3 Diagnostic Adapter 317-7485/478-0235 Diagnostic Tool-high quality

11. Check the fuel supply.

a. Monitor the exhaust for smoke while the engine is being cranked.

If no smoke is present, there may be a problem with the fuel quality or there may be a problem with the fuel supply.

b. Check the fuel quality. Refer to Testing andAdjusting, "Fuel Quality -Test". Also refer to Truck Performance and Driveability Diagnostic Guide, LEBT3477.

c. Check the fuel pressure. Refer to Testing and Adjusting, "Fuel System Pressure -Test".

d. Ensure that the fuel system has been primed.

Refer to Testing and Adjusting, "Fuel System Prime".

e. Check for fuel supply lines that are restricted.

f. Check the fuel filters.

g. If the temperature is below 0°℃ (32 °F), check for solidified fuel (wax).

12. Check for combustion problems.

Examples of combustion problems are shown in the following list: Outside temperatures are too cold.

Mechanical problem

0 notes

Text

How to Use Caterpillar ET to Viewing Logged Diagnostic Codes

The Logged Diagnostic Codes function provides a list of diagnostic codes logged by the ECM. These codes are similar to the active diagnostic codes, except that the codes displayed have been logged over time rather as they occur.

Related Contents:

Caterpillar ET 2023C 2019C 2018A Electronic Technician Software Free Download

CAT Adapter 3 ET4 478-0235 High Quality Diagnostic Adapter

Caterpillar SIS 2021 2019 2018 Full EPC+Service Manual Free Download

Caterpillar 18 digits factory password calculator

Accessing

To run the Logged Diagnostic Codes function, select “Logged Diagnostic Codes” from the Diagnostics menu; push the F4 key (If the default function keys are set); click the Logged Diagnostic Codes icon on the toolbar (if the default is set) .

Screen Layout

The Logged Diagnostic Codes screen has the following areas:

Display Area

The display area includes the following columns: Code – numbers used to identify the diagnostic codes.

Description – brief explanation of the problem identified by the code.

Occ. – lists the number of times (Occurrences) a problem has occurred

First – first service hour meter that the problem occurred

Last – last service hour meter that the problem occurred

The codes are displayed chronologically by the most recent service hour meter.

Note: For some products, the real time clock hours (RTC) and the service hour meter (SHM) are both available and are displayed as: First RTC, Last RTC, First SHM, and Last SHM.

Note: For some products, the Occ., First, or Last columns may not be displayed.

The ECM name is displayed as a category above its diagnostic code(s) list. For some products, the ECM diagnostic clock hours are displayed on the same line. These hours represent the time that the ECM has been connected and running. This time may be displayed in hours, minutes, and seconds.

Include All ECMs Checkbox

When the “Include All ECMs” checkbox is selected, active codes from all active ECMs are retrieved and displayed. These codes are grouped according to the ECM from which the code was retrieved. If an ECM supports a specific column, the screen will display a blank space in the column area of the ECM that does not support the column header information. The “Include All ECMs” checkbox is disabled when a single ECM is detected on the data link.

Buttons Clear – When clicked, this button clears the selected logged diagnostic code.

Clear All – When clicked, all logged diagnostic codes and all logged event codes are cleared simultaneously. If more than one ECM is available on the data link, all logged diagnostic and event codes may be cleared on the data link or from the current ECM only.

Troubleshoot Code – When diagnostic procedures are available for the selected code, clicking this button connects the user to the Component Based Troubleshooting Website. From there, the user can access SIS Links for more information.

Troubleshoot Symptom - When diagnostic procedures are available for the selected code, clicking this button connects the user to the Component Based Troubleshooting Website. From there, the user can access further information on symptoms based on the description provided in the Description column.

0 notes

Text

Best Quality A #CAT #Caterpillar ET3 Diagnostic Adapter iii Real Cat Caterpillar 317-7485 Communication Adapter 3 With Cat ET 2019A Download Software With 6pin,9pin and 15pin cable for Both new and old truck

Whatsapp / Wechat : +86 13691674080

Skype : [email protected]

0 notes

Text

Iveco Easy Activator V1 01 Keygen

DISCOUNT 50%

DISCOUNT 45%

AUTO-EPC.ORG

AUTO-FILE.ORG

EPC SOFTWARE

DONATION

Iveco Easy Activator V1 01 Keygen Free

Iveco easy activator v1.01 keygen. Package including: 1pc x Iveco easy activator v1.01 keygen. Xhorse Top Sales UK Ship No Tax Autel Hot Selling UK Ship No Tax. Iveco Easy Activator V1.01 Keygen. Iveco Easy Activator V1.01 Keygen. Package Including.

Key Generators

RatingComments

0 Vote(s) - 0 out of 5 in Average

0 Replies

12,564 Views

AGCO Epsilon Security Key generator - FULL UNLOCKED

0 Vote(s) - 0 out of 5 in Average

0 Replies

6,243 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

10,335 Views

ProSecCo Date & Time Changer (2018)

0 Vote(s) - 0 out of 5 in Average

0 Replies

3,543 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

4,116 Views

Hyster - YALE PC Service Tool v4.xx KEYGEN

0 Vote(s) - 0 out of 5 in Average

0 Replies

2,352 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

2,702 Views

Caterpillar ET 2017A KEYGEN

0 Vote(s) - 0 out of 5 in Average

0 Replies

2,674 Views

PACCAR ESA (Electronic Service Analyst) v4.4.9x KEYGEN

0 Vote(s) - 0 out of 5 in Average

0 Replies

3,147 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

4,032 Views

Snap-on Catalogs Keygen v2.40 (ALL Brands)

0 Vote(s) - 0 out of 5 in Average

0 Replies

4,153 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

3,161 Views

Forklift Multi ProSecCo Keygen v.1 (2016)

0 Vote(s) - 0 out of 5 in Average

0 Replies

4,127 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

3,149 Views

Daf Davie Expire Fix 300.02 + KEYGEN

1 Vote(s) - 3 out of 5 in Average

0 Replies

3,847 Views

1 Vote(s) - 5 out of 5 in Average

0 Replies

4,700 Views

JPRO Commercial Fleet Diagnostics 2016v1 KEYGEN

1 Vote(s) - 5 out of 5 in Average

0 Replies

4,013 Views

5 Vote(s) - 3.4 out of 5 in Average

0 Replies

12,073 Views

IVECO Easy v12.1 (2015) KEYGEN

0 Vote(s) - 0 out of 5 in Average

0 Replies

3,536 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

5,381 Views

Users browsing this category: 1 Guest(s)

Iveco Easy Activator V1 01 Keygen Free

0 notes

Text

Keygen Iveco Easy Software

Iveco Easy Activator V1.01 Keygen. Correction Tools VAG Diagnostic Tool Auto Diagnostic Software Airbag Reset Tools Find an Auto Key Tool Other OBD2 Tools.

Keygen Iveco Easy Software Pdf

Easy Soft Software

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube. Iveco Easy Torrent Driver For Bluetooth A crack is a program, set of instructions or patch used to remove copy protection from a piece of software or to unlock features from a demo or time-limited trial. There are also crack groups who work together in order to crack. Iveco EASY activation keygen 1.0. You are not logged in or registered. Iveco EASY keygen. Iveco EASY activation keygen 1.0. Attached File(s) Iveco keygen.txt. Iveco EASY 12.1 Full dealer level diagnostics system pre-loaded on a Panasonic CF-C1 laptop with SSD hard disk drive for ultra fast dealer level diagnostics and programming. Iveco EASY 11.1, 10.1 Activator + Manual. In Stock Product Code: 33. JPRO 2015 Key Generator, JPRO Key Generator 2014, JPRO Cleaner. Cummings Incite Date Unlock + Keygen. In Stock Product Code: 34. Cummings InCite Date Unlock. This software can solve the problem with inkal Cummings expires. Scania SOPS File.

DISCOUNT 50%

DISCOUNT 45%

AUTO-EPC.ORG

AUTO-FILE.ORG

EPC SOFTWARE

DONATION

Keygen Iveco Easy Software Pdf

Easy Soft Software

Key Generators

RatingComments

0 Vote(s) - 0 out of 5 in Average

0 Replies

12,513 Views

AGCO Epsilon Security Key generator - FULL UNLOCKED

0 Vote(s) - 0 out of 5 in Average

0 Replies

6,124 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

10,205 Views

ProSecCo Date & Time Changer (2018)

0 Vote(s) - 0 out of 5 in Average

0 Replies

3,443 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

4,014 Views

Hyster - YALE PC Service Tool v4.xx KEYGEN

0 Vote(s) - 0 out of 5 in Average

0 Replies

2,235 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

2,633 Views

Caterpillar ET 2017A KEYGEN

0 Vote(s) - 0 out of 5 in Average

0 Replies

2,627 Views

PACCAR ESA (Electronic Service Analyst) v4.4.9x KEYGEN

0 Vote(s) - 0 out of 5 in Average

0 Replies

3,057 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

3,855 Views

Snap-on Catalogs Keygen v2.40 (ALL Brands)

0 Vote(s) - 0 out of 5 in Average

0 Replies

4,021 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

3,070 Views

Forklift Multi ProSecCo Keygen v.1 (2016)

0 Vote(s) - 0 out of 5 in Average

0 Replies

4,033 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

3,066 Views

Daf Davie Expire Fix 300.02 + KEYGEN

1 Vote(s) - 3 out of 5 in Average

0 Replies

3,752 Views

1 Vote(s) - 5 out of 5 in Average

0 Replies

4,572 Views

JPRO Commercial Fleet Diagnostics 2016v1 KEYGEN

1 Vote(s) - 5 out of 5 in Average

0 Replies

3,911 Views

5 Vote(s) - 3.4 out of 5 in Average

0 Replies

11,956 Views

IVECO Easy v12.1 (2015) KEYGEN

0 Vote(s) - 0 out of 5 in Average

0 Replies

3,495 Views

0 Vote(s) - 0 out of 5 in Average

0 Replies

5,336 Views

Users browsing this category: 3 Guest(s)

0 notes