#AAAC Conductor

Text

A Detailed Know-how of ACSR Conductor Size Chart.

ACSR (Aluminium Conductor Steel Reinforced) is a widely used type of overhead electrical conductor for power transmission and distribution. It’s known for its strength, durability, and efficiency in carrying electricity over long distances. To facilitate the selection of the appropriate ACSR conductor for specific applications, engineers and technicians often refer to ACSR conductor size charts. In this blog, we will delve into the details of an ACSR conductor size chart, its components, and how to effectively use it for various projects.

0 notes

Text

Octopus Energy and Sterlite Power team up to decarbonise India | Sterlite Power Transmission Limited

Octopus Energy Group and Sterlite Power, a well-known Indian power transmission company, have announced a partnership to help decarbonize Indian industry and provide low-cost green power to consumers all over the world. The Memorandum of Understanding (MoU), signed at COP26, will see the two companies explore several joint retail ventures. Following the announcement of Green Grids by Boris Johnson and Narendra Modi at COP26 in November 2021, this is the first UK-India energy partnership.

0 notes

Text

Maintenance Of EHV Live Lines India | EHV Hot Line Maintenance - BNC Power

Maintenance of EHV live lines is crucial in today’s rapid development in all the sectors, like petroleum, mining, agriculture, tourism and industrial. Our maintenance of EHV hot lines helps in reduction of the outages along with breakdowns

#EHV Hot Line Maintenance#Testing of EHV substations#transmission line stringing#Switch yard#AAAC conductor#ACCC conductor

1 note

·

View note

Text

High-Quality Aluminium Conductors, AAAC Conductors, and ACSR Conductors Manufactured in India

Introduction: When it comes to the efficient transmission of electricity, the choice of conductors plays a crucial role. In India, several reputable manufacturers specialize in producing high-quality conductors, including Aluminium Conductors, All Aluminum Alloy Conductors (AAAC), and Aluminum Conductor Steel Reinforced (ACSR) conductors. These conductors are widely used in the power sector to ensure reliable and efficient energy transmission. In this article, we will explore the significance of these conductors and highlight some of the leading manufacturers in India.

Aluminium Conductors: Aluminium Conductors are widely employed in overhead power transmission lines due to their excellent electrical conductivity and lightweight nature. These conductors are made from high-purity aluminum, providing them with exceptional resistance to corrosion and offering superior mechanical strength. Aluminium Conductors are not only cost-effective but also environmentally friendly, making them a preferred choice for various electrical applications.

AAAC Conductors: AAAC Conductors are known for their excellent strength-to-weight ratio and enhanced electrical conductivity. These conductors are made from a special alloy composed of aluminum, with small quantities of magnesium and silicon. The unique combination of elements gives AAAC Conductors increased resistance to corrosion and higher temperature tolerance. AAAC Conductors are extensively used in areas with a higher risk of corrosion or where high mechanical strength is required.

ACSR Conductors: ACSR Conductors consist of a central steel core surrounded by one or more layers of aluminum strands. The combination of steel and aluminum in ACSR conductors provides them with enhanced strength, allowing for longer spans between transmission towers. These conductors are highly durable and can withstand severe weather conditions, making them suitable for both overhead transmission and distribution lines. ACSR Conductors offer excellent electrical conductivity and mechanical stability, ensuring efficient power transmission.

Leading Manufacturers in India: India boasts several renowned manufacturers specializing in the production of Aluminium Conductors, AAAC Conductors, and ACSR Conductors. These manufacturers adhere to strict quality standards and employ advanced manufacturing processes to ensure the reliability and performance of their products.

One such manufacturer is XYZ Conductors, known for their cutting-edge manufacturing facilities and a wide range of high-quality conductors. They prioritize customer satisfaction and offer customized solutions to meet specific project requirements. ABC Conductors is another leading manufacturer with a strong reputation for delivering reliable conductors with exceptional electrical and mechanical properties.

Conclusion: The demand for efficient energy transmission has led to the development of various conductors that cater to specific requirements. Aluminium Conductors, AAAC Conductors, and ACSR Conductors are among the most commonly used conductors in the power sector. With their superior electrical conductivity, mechanical strength, and resistance to corrosion, these conductors ensure reliable and efficient electricity transmission.

India houses several reputable manufacturers who excel in the production of these conductors. Their commitment to quality and technological advancements contributes to the growth and development of the power industry in the country. Whether it's Aluminium Conductors, AAAC Conductors, or ACSR Conductors, choosing a reliable manufacturer ensures the successful implementation of power transmission projects in India.

#Aluminium Conductors#AAAC Conductors#ACSR Conductors#power transmission#power transmission companies in india

1 note

·

View note

Text

Tano Cable

Henan Tano Cable Co., Ltd.( TANO CABLE for short), is a leading and professional manufacturer of cable and wire with nearly 30 years manufacturing experience, which is located in Zhengzhou city, Henan province, China.

Bare conductor(AAC, ACSR, AAAC, ACAR), overhead insulated cable, low voltage power cable, medium voltage power cable, high voltage power cable,concentric cable, building wire and so on for power transmission and distribution lines.

Bare conductor

Overhead insulated cable,

PVC insulated power cable

Medium voltage power cable

Rubber cable

Building wire

1 note

·

View note

Text

Main Stainless-steel & Aluminium Suppliers

COPALUM connectors use a particular crimping system that creates a chilly weld between the copper and aluminum wire, and is considered a permanent, maintenance-free repair. However, there is probably not sufficient size of wires in enclosures to allow a particular crimping device for use, and the resulting connections are generally too giant to put in in existing enclosures as a result of limited space (or "box fill"). Installing an enclosure extender for unfinished surfaces, changing the enclosure with a bigger one or installing a further adjoining enclosure could be done to increase the out there house. Another big advantage is that aluminium compression connectors with contact grease can withstand higher present loads than if no contact grease is added. We therefore advocate the use of cable lugs and connectors with contact grease – play it safe with a excessive cable conductor utilisation.

Most metals (with a couple of exceptions, corresponding to gold) oxidize freely when exposed to air. Aluminium oxide isn't an electrical conductor, however quite an electrical insulator. Consequently, the flow of electrons via the oxide layer may be greatly impeded. However, for the rationale that oxide layer is only some nanometers thick, the added resistance just isn't noticeable underneath most circumstances. When aluminum wire is terminated correctly, the mechanical connection breaks the skinny, brittle layer of oxide to kind a superb electrical connection.

Generally a steel core is used with the aluminium to give the conductor mechanical strength. This arrangement is termed Aluminium Conductor Steel Reinforced or ACSR. Conductors comprised completely of aluminium are often identified as All Aluminium Conductors or MC. These conductors are extensively used for busbars in out of doors substations where spans are brief. All Aluminium Alloy Conductors (AAAC) consist of an alloying of aluminium to provide a tensile strength in excess of that of MC, allowing longer spans. These conductors are really helpful for coastal areas the place extreme corrosion is a problem.

The various kinds of right-angle tube clamps are additionally obtainable with detachable heads, which make them ideal for retro-fitting in current techniques. Different materials can be found relying on the later utility space. Stone-Stamcor compression connectors have been designed to ensure dependable and controllable electrical connections which can be inspected on set up.

The free plate connector utilized stainless steel materials that provides excessive corrosion resistance. This connector permits for an easily adjustable place for aluminum profile connections. The copper compression connectors are manufactured from high-conductive electrolytic copper which are tin plated. The connector design has been matched to the cable measurement to offer the necessary electrical performance in addition to mechanical power. Aluminium lugs are easy to put in and remove, and may be hooked up to conductors using a variety of instruments, similar to crimping tools or bolt cutters. They are also durable and reliable, and may withstand the forces applied to them throughout installation and use.

Since then, Tractel has continued to enhance its operation with the registration of numerous patents, maintaining a high level of high quality and endurance, permitting this winch for use in many industrial functions. Tractel Dynafor range is the best solution for load measurement and management. Monitoring lifting methods, checking masses in factories, monitoring rigidity in energy and catenary strains as well as plenty other functions. Tractel® Blocfor fall arrest gadgets mix security and durability in an ergonomic and light-weight design which allows for extra flexibility of movement at height. Our full vary can be utilized in all configurations, vertical and horizontal, and helps a consumer and instruments up to 150 kg.

Note that internal floor of bimetallic is of copper whereas outer floor is of aluminium. Above bimetallic is used for connecting the Current Transformer Primary (connectors manufactured from copper) to the aluminium made bus. While making connection, copper facet of bimetallic is mate with copper side of bimetallic and aluminium aspect with outer face of bimetallic.

Aluminum constructing wiring for modern building is manufactured with AA-8000 series aluminum alloy (sometimes referred to as "new know-how" aluminum wiring) as specified by the industry standards such as the National Electrical Code (NEC). The use of larger gauge stranded aluminum wire (larger than #8 AWG) is pretty widespread in a lot of North America for contemporary residential building. Aluminum wire is utilized in residential applications for lower voltage service feeders from the utility to the building. This is installed with supplies and methods as specified by the local electrical utility firms. Commercially-available connectors for aluminium conductors are equipped with a particular contact grease. During the crimping process, this destroys the non-conductive oxide layer of the aluminium, which forms on the surface after just a brief time.

For smaller branch circuits with strong wires (15-/20-A circuits) typical connections of an electrical wire to an electrical system are often made by wrapping the wire round a screw on the system, additionally referred to as a terminal, and then tightening the screw. At around the similar time using steel screws became more common than brass screws for electrical devices. Overall, aluminium lugs are an integral part of many electrical installations, and are used to supply a strong and reliable connection between conductors and other electrical components. They are versatile, straightforward to install, and sturdy, making them a preferred alternative for lots of applications.

aluminium extrusion connectors

They are also straightforward to put in and can be found in all kinds of designs so that each shopper can choose the one that most intently fits their needs. Flowstore presents a spread of high-quality anti-corrosion FlowTube aluminium connectors which are exceptionally sturdy, sturdy, and straightforward to assemble. These connectors, including the FlowTube Fastlock Connectors and FlowTube Angle Connectors, ensure quick and strong construction assembly while offering excellent bodily and visual alignment between FlowTube’s aluminium profiles and extrusions. These connection failures generated warmth underneath electrical load and brought on overheated connections.

#aluminium connectors#aluminium connector#aluminium profile connectors#aluminium extrusion connectors#aluminium extrusion connector

1 note

·

View note

Text

ACSR, AAC, AAAC Aluminium Conductors Manufacturers in India

Aluminium Conductors Steel Reinforced (ACSR), also known as Bare aluminum conductors used for high-strength stranded conductors used in overhead power lines.

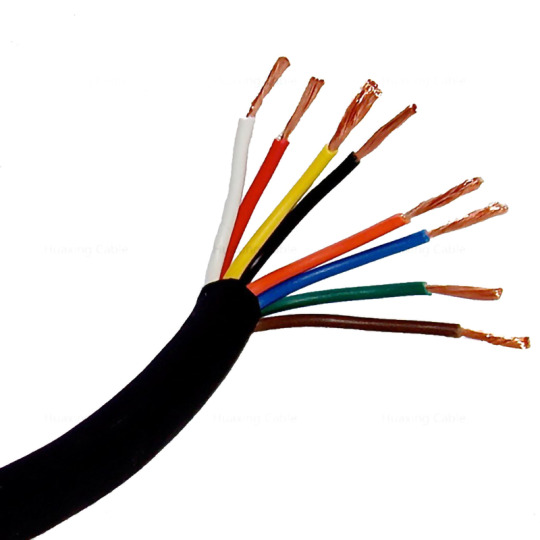

Aluminum Conductors Steel Reinforced (ACSR), also known as Bare aluminum conductors, are one of the most widely used conductors for transmission. The conductor consists of one or more layers of aluminum wires stranded over a high strength steel core that can be single or multiple strands depending on the requirement. There can be various stranding combinations of Al and steel wires lending flexibility to obtain suitable current carrying capacity and mechanical strength for the application

0 notes

Text

The main products of Huaxing Cable are AAC/AAAC/ACSR/ACAR Conductor, overhead bunched cable (ABC cable),Control cable, concentric cable, low voltage and medium voltage power cable, plastic wire, solar power cable, protection cable, etc.

We have also passed ISO9001 quality system, ISO14001 environment system, OHSAS18001 occupational health system, CCC national product certification. And so on; We can also produce wire and cable products according to IEC, ASTM, BS, DIN, AS, CSA, JIS, KS and other standards to meet the specific needs of customers.tection cable, etc.

0 notes

Text

Overhead Conductors Market Research Report With COVID-19 Update, Analysis, Types, Applications, Forecast till 2027

The market report on the Overhead Conductors Market shows lucrative growth opportunities in the Overhead Conductors industry during the next five-year period and ensures more information regarding the market trends. The following detail is the summary of extensive market research conducted by researchers at Stratview Research, a market research firm.

Click here to request a Free Sample report:

The present report will give an overview of the challenges, dynamics, growth factors, and key market players in the Overhead Conductors Market.

Overhead Conductors Market Forecast:

The Overhead Conductors Market is forecasted to grow at a rate of 4.7% CAGR during the period of 2022-2027. The Market will be experiencing an escalation in demand attributed to the growing usage of Overhead Conductors in the market.

The Overhead Conductors Market growth depends upon several factors which have direct or indirect influence on the demand. The report published by Stratview Research has the summary of such factors derived using several market analysis methods including but not limited to supply chain analysis. These methods help in analysing the strength of the companies and identify gaps as well as opportunities to lay out a successful roadmap which leads to higher profitability.

Key Players in the Overhead Conductors Market

Here are the top linchpins in the market

Lamifil, ZTT,

Sumitomo Electric Industries, Ltd.,

APAR Industries Ltd.,

Nexans,

CTC Global Inc.,

Prysmian Group,

LUMPI-BERNDORF Draht- und Seilwerk GmbH,

Special Cables Pvt. Ltd.,

Neccon Power & Infra Limited,

3M,

Taihan Electric Wire Co., Ltd.,

Midal Cables Ltd.,

KEI Industries Limited,

Diamond Power Infrastructure Ltd.,

SWCC Showa Holdings Co., Ltd.,

Southwire Company LLC,

CABCON India Limited,

Oman Cables Industry,

Galaxy Transmissions Pvt., Ltd.,

Bekaert,

Kelani Cables PLC.

Growth drivers and Market Value:

This report, from Stratview Research, studies the Overhead Conductors Market value and growth drivers over the trend period of 2022-27. According to the report -

Overhead Conductors market is likely to witness a CAGR of 10.5% during the forecast period. The prime factors that are driving the overhead conductors’ market are the initiatives towards upgradation of conventional grid transmission sub-structures and ongoing establishment of cross border electrical networks.

Based on Product Type:

Based on the product type, the market is segmented as conventional conductors, high temperature conductors, and others. Conventional conductors dominated the market in 2021 and are expected to maintain their position during the forecast period. Conventional conductor is further segmented into ACSR, AAAC, ACAR, AACSR, and AAC. in 2021, ACSR held more than 50% share of the market and is likely to witness a healthy growth during 2020-2025.

Based on Region:

In terms of regions, Asia-Pacific is estimated to be the largest market for overhead conductors during the forecast period. China, Japan, India, and Australia are among the largest consumers of overhead conductors in the region. Significant investments towards modernization of existing grid network and expansion towards remote areas are the major factors contributing towards the dominance of the region in the global market. North America and Europe are also expected to witness a healthy growth during the forecast period.

Know more about the report, click here

Overhead Conductors Market Segmentation:

The report segments based upon demographics, geographics, benefits and volume etc, have different driving factors and classifies the most-attractive segments and sub-segments. The segmentation has been done in such a way that it will not only help the users to be more efficient in terms of time, money and other resources but also allows companies to learn about their target audience so that they can tailor campaigns and increase market share and revenue.

COVID-19 IMPACT Analysis on the Overhead Conductors Market

The Covid-19 pandemic has influenced every one of the organizations, little or large, dealing in any sector. Our market analysts monitoring the situation across the globe explain that the market will generate productive possibilities for manufacturers post COVID-19 crisis. The report aims to provide a further illustration of the present scenario, economic slowdown, and COVID-19 impact on the overall industry.

Custom Research: Stratview research offers custom research services across sectors. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry at [email protected] or call us at +1-313-307-4176.

0 notes

Text

Top 5 Barbed Wire Manufacturers in Kolkata

Barbed wire is the most commonly used product for fencing and safety purposes. Their uses range from residential buildings to industrial areas and also military zones. But you have not decided which company is the best to manufacture barbed wire. Don’t worry we have a small list, that can help you to find the best-barbed wire manufacturers in India.

1: Nirmal Group:

Nirmal group was founded in 1971 by Mr. Ram Autar Saraf, with a humble start of Rs. 1 million. Since then it has grown to a $70 million enterprise with state-of-the-art manufacturing for GI Wires, aluminum conductors, steel pies manufactures, hot rolled products, barbed wire, and construction steel.

Contact Details:

Address: “Rudramani” 1720, Laskarhat EM Bypass Kolkata – 700 039

Phone: +91-33-6622-4848

Email: [email protected]

Website: www.groupnirmal.com

2: OM Wire & Wire

Om Wire & Wire Products Industries has been scaling new heights of success. Under the able headship of our mentor, Mr. Hitesh Lunia, we have been successfully bridging the gap between the need and supply. With his enterprising skills and industrious efforts, we have achieved specialization in the manufacturing of Galvanized Wire Netting, Concrete Mixture machines, Barbed Wire, Razor Barbed Wire, Scaffolding, and Shuttering Products, Construction Equipment and Machinery, etc. Today, we have carved a niche as one of the fastest emerging manufacturers, exporters, and suppliers of wire products in India.

Contact Details:

Address: 26/1/1b Strand Road, 4th Floor, Room No.6. Kolkata, West Bengal – 700001, India

Phone: +91-9830777188 / +91-9007817770

Email: [email protected] / [email protected]

Website: www.omwireproducts.com

3: Anish Industrial Corporation

Anish Industrial Corporation [Kolkata] is a company entrenched in the engineering industry for exporting and manufacturing Electrical Conductors -AAC/ACSR/AAAC/ACAR/AACSR, Galvanised Steel Stranded Stay Wires, Earth Wires, Barbed Wire, Aluminum Binding Wire & Tapes, Hardware Fittings for overhead transmission lines. With optimum quality imbibed in our range, we are thriving to become one of the leaders in our ambit of operations.

Contact Details:

Address: 135, Biplabi Rash Behari Basu Road, Kolkata – 700001, West Bengal, India

Phone: 08048970248

Website: www.anishindustrial.com

4: S.k. Weldedmesh Private Limited

Established in 1999, S.K. Weldedmesh Private Limited, are counted among the recognized Manufacturer of an optimum quality range of Barbed Wire, Tree Guards, Chain Link Fencing, etc. The offered range of products is manufactured using the finest quality basic materials. Moreover, these products are delivered by us after testing them against varied parameters of quality.

Contact Details:

Address: 147, Netaji Subhas Road, 3rd Floor, Room No. 54 & 55, Kolkata – 700001, West Bengal, India

Phone: 08046075665

Website: www.skweldedmesh.in

5: JK Wire Netting Industries

We ‘J K Wire Netting Industries’, established in the year 2003, are one of the unsurpassed manufacturers, suppliers, and exporters of Wire netting Products such as Woven Wire Mesh, Welded Wire Mesh, and Perforated Sheets. Further, we are also affianced in dealing few other related products as well.

Contact Details:

Address: 91, Netaji Subhas Road, BBD Bagh, Kolkata – 700001, West Bengal, India

Phone: 08048972285

Website: www.jkwirenettingindustries.com`

This article has listed some of the sources for barbed wire manufacturers. Thus, if you are seeking manufacturers that lead in the supply of gi wires, prestressed concrete wire, shutter spring wire, or stay wire, these industries will prove to be the best bet for you.

0 notes

Photo

Sterlite Power is a leading global developer of electric power transmission infrastructure and electric utilities solutions provider company. Click to explore more about Power Transmission Companies in India. https://www.sterlitepower.com/

#AAAC Conductor#Electrical Power Cable#3 Core Power Cable#Power Transmission Companies in India#Power Cable Suppliers

0 notes

Text

0 notes

Link

Engaging humankind by tending to the hardest difficulties of energy conveyance

Sterlite Power is a main coordinated power transmission designer and arrangements supplier universally, centered around tending to complex difficulties in the area by handling the vital requirements of time, space and capital.

We accept that power access changes social orders and conveys durable social effect. Sterlite Power is exceptionally situated to tackle the hardest difficulties of energy conveyance. READ MORE

#Aluminium Conductor#AAAC Conductor#Electrical Power Cable#3 Core Power Cable#Power Transmission Companies in India

0 notes

Text

Is the moon more round abroad? Would you say that after watching the aluminum alloy cables in Europe?

Cable is a typical heavy material and light industry. The cost of raw materials accounts for more than 70% of the total cost of cable production. Among the raw materials, conductor metals have the greatest impact. The price of wires will be affected by metal price fluctuations.

At present, two types of conductor metals are commonly used in the industry: copper metal and aluminum metal. Because copper metal has better electrical and thermal conductivity than aluminum metal, 97% of cables on the market are copper core cables.

However, China's copper resources are very scarce. Every year, a large amount of copper metal needs to be imported from abroad. The import ratio accounts for 60% of the domestic copper consumption, which can be said to be quite dependent on imports.

On the other hand, my country’s annual production capacity of electrolytic aluminum exceeds 25 million tons, which is already a serious surplus. The demand for copper in the cable industry is huge. At present, the domestic cable industry has developed into the second largest manufacturing industry after automobiles. How to replace copper with aluminum and use surplus aluminum in the cable industry with huge metal demand has become a problem that China urgently needs to solve.

It is in such an environment that the development of aluminum alloy cables has become the research direction. In fact, the research on aluminum alloy conductors began as early as the 1960s abroad, but aluminum alloy cables have not yet become mainstream conductor materials.

In North America, aluminum-magnesium-copper-iron alloys are only used in the field of low-voltage power distribution, while in Europe, aluminum alloy cables are not used at all. European countries basically use copper-core cables and pure aluminum-core cables. Why is it not adopted in Europe, which has a very advanced technology What about aluminum alloy cables?

The main reason why aluminum alloy conductors are not used in Europe is that the electrical properties of the two are quite different. Aluminum alloy wires are similar to pure aluminum in terms of conductivity and resistivity, so only those with an enlarged cross-section to 1.6 times that of copper cables Method to achieve the electrical performance of copper cables.

This means that aluminum alloy cables have no substantial improvement over pure aluminum in terms of the basic properties of electrical conductivity and resistivity. This is the first reason why European countries did not choose aluminum alloy cables.

Secondly, there are experimental data showing that the energy consumption of metal aluminum in the production and use process is about three times that of copper. This is obviously unacceptable for Europe, which focuses on efficiency and output, and in the entire production and use process, aluminum alloy The carbon emissions of cables are significantly higher than that of copper cables. The carbon dioxide emissions of metal aluminum are basically equivalent to twice that of copper metal. This is obviously an unacceptable problem for Europe that vigorously promotes low-carbon environmental protection.

In addition, there are price issues, service life and other issues. In short, Europe believes that the overall performance of the current aluminum alloy cable is not significantly improved, and there is no significant improvement or improvement from the traditional copper core cable, and it is also accompanied by higher Incidental issues such as carbon emissions, so comprehensive consideration, Europe decided not to use aluminum alloy cables.

However, this shortcoming is being changed by the Chinese research team. The rare earth aluminum alloy cables currently studied in China have not only improved significantly in performance compared with traditional cables, but also have been well controlled in terms of their cost and price. With cross-age significance, the future development direction of the cable industry must be aluminum alloy cables, and China is currently at the forefront of the world.

0 notes

Text

Troubleshooting methods for electrostatic induction cables

A very sensitive sensor device for electrostatic induction perimeter detectors. In order to ensure the correct use of this system and give full play to its functions, please read the product instructions carefully before construction, and carefully check the ACSR conductor price, ground wire, power cord, and whether it is installed correctly according to the product instructions before determining the fault, and then power on for 5 minutes After starting the test, the following situations will generally occur:

1. Not working or no switch signal output

Solution:

1) Observe the housing of the detector and check the power indicator (green light). If the green light is off, it means that the power is not connected or is not powered on.

2) Check the tamper switch when the power light is on, and depress the tamper switch when opening the cover.

3) The red light flashes when alarming, but there is no switch output (disconnect the signal connection line between the detector and the host, and use a multimeter for on-off test). At this time, check whether the motherboard plug-in and the eight-core plug have fallen off.

4) No-load detection cable is not connected. This detector must be connected to a detection cable of at least 3m, and the detection cable should be erected in the air, with a distance of at least 20cm from the ground or wall.

5) If the yellow light on the detector flashes, remove the detection cables one by one. When the yellow light is off after removal, it means that the AAAC conductor is short-circuited with the housing or the ground wire. Check the feeder head and the feeder and the detection cable. Note that the shielding layer of the feeder cannot be connected to the detection cable. When the detection cable exceeds the nominal value of the detector, the yellow light also flashes.

2. Continuous alarmSolution:

1) The detection line is grounded.

2) The ground wire is not properly connected, and the ground resistance cannot meet the requirements.

3) Two or more detectors share the same ground wire, separate the ground wire of each detector and the distance between the ground stakes is more than 2 meters.

4) Continuous alarm in direct sunlight or strong wind and rain, it is recommended to put the detector in a waterproof box.

5) If there is a wire fence around the detection cable, ground it and separate it from the ground wire of the detector. Never share it. The distance between the barbed wire and the electronic fence should be kept above 30cm.

3. Occasionally call the policeSolution:

1) The sensitivity is too high, you can turn the switch to reduce the sensitivity. (Gears 1 to 4 increase in order), the detector can be switched to working mode.

2) There are branches or movable objects in the detection range, and the movable objects within 1 meter from the detection cable should be removed.

4.the sensitivity is too lowSolution:

1) The detection cable is too close to the wall or the iron fence.

2) The detection cable is too long (super thick) or used in the over-range detection will cause the sensitivity to be too low and even work unstable, please use the recommended detection line.If you want to know about AAAC conductors size, you can consider Huaxing Cable, we will give you professional explanations and services

0 notes

Photo

Sterlite Power (Power Cable) while set up transmission infrastructure in any part of the world not only focus on quality and reliability but also gives importance to safety. https://www.sterlitepower.com/br/

0 notes