#1000w fiber laser

Link

As one of the most professional 1530 fiber laser cutting machine manufacturers and suppliers in China, we're featured by quality products and good service. Please rest assured to buy 1530 fiber laser cutting machine at competitive price from our factory. 1000w 2000w 3000w 6000w 1530 fiber laser cutting machine 5x10 ft laser cutter for cs steel stainless

0 notes

Text

Affordable Handheld Metal Laser Welding Machine for Sale

A metal laser welding machine, also known as a laser welder or laser welding system, is a specialized equipment used for precise and efficient welding of metal components. It utilizes laser technology to generate a highly concentrated and intense laser beam that melts and fuses metal materials together.

Handheld Metal Laser Welding Machine

Handheld metal laser welding machines are designed to be lightweight and portable, allowing for easy transportation and maneuverability. They typically have a compact size and ergonomic design, enabling operators to access and weld difficult-to-reach areas or perform welding tasks in different locations.

Handheld metal laser welding machines offer the advantages of mobility, accessibility, and versatility in metal welding applications. They provide a convenient solution for on-site repairs, small-scale production, or situations where traditional fixed-position laser welding machines may not be feasible.

Welding head

The laser is eventually fired from the welding head and applied to the material.It consists of nozzle,scale tube, protective glass,focusing lens, reflector,motor,collimator,wire feeding bracket, switch button, waterways,QBH protective sleeve and so on. Nozzle and protective lens are wearing parts. And when workers’ welding, auxiliary gas is often needed to avoid material producing gas that could react with air and to avoid residue and aerosol entering the welding head to damage the components.So we need to prepare extra nozzles and protective lens. How laser welding works?The laser is generated by laser source and is transported to welding head, then it is collected and reflected by reflector and is focused by focusing lens to reach the nozzle and finally fired to the material, after all this happens, the user could conduct welding conveniently and flexibly.

When considering a handheld metal laser welding machine, factors to consider include laser power, portability features, battery life (if applicable), cooling system, ease of use, and the specific welding requirements of your application.

Main body

Displayer is a window for interaction between user and machine. The screen of displayer is touch screen, its functions are machine parameter adjustment and language conversion. Control board equals to computer mainframe. And wire feeder is designed to melt the wire into the welding joint during material processing when the welding joint width over 5 mm.

Water chiller is used to cool laser source and welding head and could only be filled with distilled water and purified water in summer and with antifreeze in winter. And the volume of liquids contained is 15L, the replacement period of liquids is 2-3 months.

Metal Laser Welding Machine for Sale

Ranging from entry-level handheld laser welding guns to automatic laser welding systems with CNC controller, as well as professional 3D laser welding robot. All types of laser beam welders available in IGOLDEN with powers of 1000W, 2000W and 3000W for machinists.

Three-in-one laser welder

The advanced version of laser welder is the three-in-one laser welder, as its name suggests, it has multifunctions of of welding, cleaning and cutting. Its welding function is the same as that of a normal laser welder. And it could be easily to changed into the cutting pattern by the change of nozzle, when it is converted into the pattern of cutting, it could only cut some extra and useless pieces of the material edges with less precision and worse effect than normal fiber laser cutters. If it is applied in cleaning, cleaning head and special focusing lens for laser cleaner should be installed. It is easy and convenient in operation and alteration of patterns.

Metal Laser Welding Machine Features

Laser Source:

Metal laser welding machines use a laser source, typically a solid-state laser, to generate the laser beam. Common types of lasers used include fiber lasers, Nd:YAG lasers, and disk lasers. These lasers provide high power and excellent beam quality for precise and controlled welding.

Welding Process:

Metal laser welding involves focusing the laser beam onto the joint or area to be welded. The laser beam rapidly heats and melts the metal surfaces, creating a localized molten pool. Upon cooling, the molten metal solidifies, resulting in a strong and durable weld joint. The process can be performed in continuous wave (CW) mode or pulsed mode, depending on the application requirements.

Non-contact Welding:

Laser welding is a non-contact welding process, meaning the laser beam does not physically touch the workpiece. This eliminates the need for mechanical force or contact between the welding tool and the material, reducing the risk of contamination or damage to the welded parts.

Materials:

Metal laser welding machines can be used to weld a wide range of metals and alloys, including stainless steel, carbon steel, aluminum, titanium, copper, brass, and various other alloys. They are particularly effective for welding thin sheets or components with high precision and minimal distortion.

Speed and Efficiency:

Laser welding is a fast and efficient welding method. The concentrated energy of the laser beam results in rapid heating and cooling rates, allowing for high welding speeds. This contributes to increased productivity and reduced production time compared to traditional welding techniques.

Precision and Control:

Metal laser welding machines offer high precision and control over the welding process. The laser beam can be accurately focused and directed to the desired welding area, allowing for precise positioning and control of the heat input. This enables the welding of intricate or complex geometries with minimal damage to the surrounding material.

Versatility:

Metal laser welding machines are versatile and can be used for various welding applications. They can perform spot welding, seam welding, overlap welding, and even 3D welding of complex components. Laser welding can also be combined with other processes, such as laser cutting or laser marking, to create integrated manufacturing solutions.

Automation and Integration:

Metal laser welding machines can be integrated into automated production lines or robotic systems for increased productivity and consistency. They can be equipped with vision systems and sensors to aid in precise positioning and quality control.

Metal Laser Welding Machine Advantages

The laser welder has varieties of advantages and they will be explained in detail. Laser welder could be used in a wide range , it works well no matter in outdoor or from long distance. And the machine can be used flexibly and conveniently in various working occasions. Besides, there are many welding methods offered for users to choose, stitch welding, butt welding, vertical welding, flat fillet weld, inside corner weld and outside corner weld, and it has free switching of welding and cutting, users only need to change a welding nozzle to a cutting nozzle. The welding effect is good because of small heat affected zone, hard to deform and blacken, welding deeply, full melting, compact and firm structure, high weld strength.

There is no need to polish welding joint for it adopts continuous welding, the surface of welded part is smooth and well-done with no perlage and few subsequent polishing procedure. Little consumable material needed in welding process to save the costs of material. This machine is equipped with safety alarms. The nozzle works only when it touches metals and automatically stops outputting laser once the working parts moved from the platform, and the tact switch has the function of temperature sensing. Therefore, this machine has a high safety level. Last but not the least, laser welder is labor-saving for it could be operated by workers who only have short-term training. In a nutshell, the laser-welder is friendly to both owner and user with advantages of time saving, labor saving and cost saving.

How does laser welding work?

Welding by laser beam is basically very simple: Two precisely cut sheets are held together. The laser melts the edges of the sheet metal. The melt flows into each other – and the joint is complete.

Quality assurance in laser beam welding

Laser beam welding is a non-contact joining process. It is always carried out automatically. Modern laser beam welding systems are equipped with an integrated measuring system, which independently checks the dimensions of the manufactured component. This makes these systems particularly precise, which is the basis for guaranteeing constant quality.

Costs for a laser beam welding system

The costs are still the biggest disadvantage of these innovative processes. It depends strongly on what and which material is to be processed with the laser welding system. Even simple micro systems used, for example, for engraving wedding rings can cost several thousand euros. Brand-new high-performance plants rarely cost less than 100,000 euros, rather more. These expenses are offset by excellent manufacturing quality and high productivity. In fact, laser welding is usually carried out at a much higher speed than conventional electric or inert gas welding processes.

What speed is possible with laser welding?

In addition to precision and low heat input, the working speed is one of the outstanding properties of laser welding. Under ideal conditions, a long, straight endless seam can be welded at a speed of up to 60 m/minute. Since the intensity of the laser beam can be varied, the impact of the material used is less decisive for the working speed of a laser welding system. Even thick sheets can be precisely joined in a matter of seconds.

Types of laser welding

Laser welding is a versatile, low cost way of achieving high quality spot welds for different materials and thicknesses. It results across a wide range of materials. There are three common types, including CO2, YAG and fiber laser welders. There are high-power welders for large-format and thick sheets, and low-power welders for small-size parts. There are welders for metals and non-metallic materials such as plastics and ceramics.

Different methods can be classified as follows:

• Welds between slices. Including butt welds, end welds, center penetration fusion welds, and center perforation fusion welds.

• Wire and wire welds. Including wire-to-wire butt welds, cross welds, parallel lap welds, and T-type welds.

• Welds of metal wires and block components. It can successfully realize the connection between the metal wire and the block element, and the size of the block element can be arbitrary. Attention should be paid to the geometric dimensions of the wire-like components during welding.

• Welds of different metals. Welds different types of metals must solve the range of weldability parameters. The welding between different materials is only possible with certain material combinations.

0 notes

Text

MARCEDRIC KIRBY FOUNDER CEO.

MARCEDRIC.KIRBY INC.

Check out this product on the Alibaba app

Promotion 10% DISCOUNT IPG Sheet Metal 1000W 2000W plate and tube Laser Cutter Fiber Laser Cutting Machine for 10mm mild steel

0 notes

Text

1000w 1500w 2000w 3000w fiber laser washing cleaning machine for rust. WhatsApp/wechat:0086-13599259031.

0 notes

Text

Remcor Apollo BK series three chuck tube fiber laser cutting machine can cut all types of metal tubes, from mild steel to stainless and also non-ferrous metals. It is also valid for cutting some reflective metals like aluminum, brass and copper, etc. The thickness of the metal can be anywhere up to 30 mm. The diameters can be up to Ø 350mm tubes. Can cut different shapes on the surface of square tubes, oval tubes, U tubes or rectangular tubes or other special shape tube products. The most outstanding feature of our BK system is that can realize the real Zero-tailing cutting. And our automatic loading system freedom operator from the hard and heavy pipe loading problem.

Apollo BK Three-chuck Tube Laser Cutting Machine 1000w-6000w Features

Different shapes & Different sizes

1. All kinds of pipe processing, no need to change clamping scheme.

2. Match the three-dimension head to solve all kinds of the pipe inflection points.

3. CNC and CAM can calculate complex profile sections. Φ8-Φ440 mm range.

Max weight

600kgs load and unload maximum length up to 12M.

Raw material waste

Unique 3 chucks technology, zero tailing, high pipe utilization Average material can reduce up to 30%.

Labor cost

Real time, high precision, fast troubleshooting servo motor control automatic and semi load can be chosen.

Environment pollution

Dust collection box included full sealing chuck to prevent dust into chuck to have a longer lifetime.

Low efficiency

1. Simple to operate, new upgraded system with servo motor to realize the high automation and simplication.

2. High-precision chuck to make sure high speed, stability, high quality cutting.

3. Automatic loading and unloading to improve efficiency.

Apollo BK Three-chuck Tube Laser Cutting Machine 1000w-6000w Parameter Details

Item

6020-BK

7025-BK

9025-BK

9034-BK

Power range

1500-6000W

Chuck structure

3 chucks

Tube size

Round Type: Φ15-200mm

Round Type: Φ15-245mm

Round Type: Φ15-245mm

Round Type: Φ15-330mm

Square Type:15-140mm

Square Type:15-175mm

Square Type:15-175mm

Square Type:15-230mm

Positioning accuracy of x& y

±0.05mm/m

Max positioning speed x&y

100m/min

80m/min

Max cutting length

6000mm

7000mm

9000mm

9000mm

Tail length

≥ 0mm

Max weight single tube

135KG

260KG

260KG

500KG

Max loading length

6000mm

7000mm

9000mm

9000mm

Fully Annealed Table

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time. The table is equipped with automatic lubrication device, which ensure the moving parts operate in good condition and improve the service life of guide rails, gears and rack.

Follower Support

The follower support device will be optional. The follower support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), and the servo motor drives the up and down movement of the pallet assembly. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

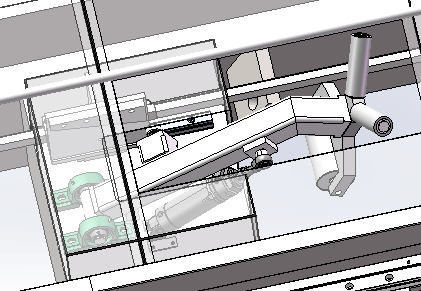

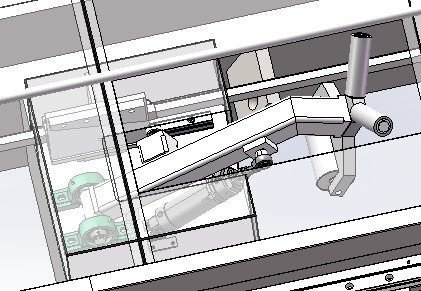

Smart Auto Focus Laser Head

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Intelligent CNC Operating System

tube laser cutting machine intelligent cnc operating system

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Pneumatic Clamp Chucks

Pneumatic clamp design on both sides. The dual-chucks help reduce tube vibration to a minimum, guaranteeing high accuracy in even complex tube configurations at high cutting speed. Suitable for cutting a range of tube diameters from Ø20 mm to Ø220 mm and various wall thicknesses.

Front chuck

tube laser cutting machine front chuck

Back chuck

tube laser cutting machine back chuck

Fractional Automatic Support Technology

Applies the intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Equipped with two sets of variable-diameter support structures, which are automatically lifted by the cylinder to avoid the rear chuck in processing. When processing profiles with different diameters, manually turn the variable-diameter wheels to achieve fit and support for different-sized profiles. The variable-diameter wheels It can be supported every two degrees of rotation to reduce the diameter of the circumscribed circular tube by 2mm

0 notes

Text

1000w - 20000w CNC Sheet Metal Fiber Laser Cutting Machine for Steel, Copper, Gold, Iron

https://www.bikudo.com/product/921537.html

#fiber #laser #cutting #machine #sheet #metal

0 notes

Text

China Co2 Laser Machine manufacturers

China Co2 Laser Machine manufacturers High steady Cnc Metal Pipe Tube Fiber Laser Cutting Machine Price fiber laser cutting machine 1000w price Product Description Fiber laser cutting machine with tube cutting JNChangtai fiber laser cutting machine model TPF -1530 - S use the world top brand parts,Raytools fiber laser head ,the laser head can automatically focus, and imported Japan FUJI servo motors and drives, high precision, high speed, large torque, performance is stable and durable, ensure the high speed operation of the whole machine.Chinese top brand fiber laser source RAYCUS, high power,high precision. Top brand control system : Cypcut control system, with automatic layout optimization. 1. Application of gantry structure and integrated cast cross-girder to achieve higher rigidity, stability, shock resistance. 2. High-performance oring possible during the laser cutting process. Technical parameters Equipment modelTPF-1530-SLaser typefiber-optic laserLaser working mediumoptical fiberLaser wavelength1060-1080 nmRECOMMEND POWER1000W, 1500W, 2000W, 3000W, 400W,5000W, 6000W, 12000W Beam quality<0.373mradX-axis distance1500mmY-axis distance3000mmZ axis distance120mmEffective cutting range3000*1500mmPositioning accuracy鈮ぢ?.02mm/mRepeat positioning accuracy鈮ぢ?.02mm/mMax. Moving speed120m/minSupport graphic formatPLT,AI,BMP,DST,DXF format (support for CORELDRAW, AI,PHOTOSHOP, AUTOCAD)Power Supply3P, AC 380V/50Hz/16A Main parts Applications Applicable and samples 1.Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc 2.Application Industries: BODOR Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters,Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, GlassesFrame, Electronic Parts, Nameplates, etc. Packaging & Shipping Packaging and shipping 1)Packaging: Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt. 2)Shipping: We cooperate with SINOTRANS company whose experience in the ocean transportation will guarantee your machine safety. We also provide train transport, especially to Russia, Ukraine and other inland countries. 3)Payment: We support T/T, VISA, Mastercard payment terms with Alibaba Trade Assurance. Company Information Factory show Contact Please contact Lisa Whatsapp/Wechat/Phone : +86 158 3005 9372 customers visit China Co2 Laser Machine manufacturers website:http://www.changtaicnclaser.com/co2-laser-machine/

1 note

·

View note

Text

Main Applications of Laser Welding

he use of laser for welding is not later than cutting. In the early days, lamp-pumped laser and YAG laser welding were mainly used, which belonged to very traditional low-power laser welding. It has been applied in many fields such as moulds, advertising characters, glasses, jewelry, etc. Sizes are very limited.

he use of laser for welding is not later than cutting. In the early days, lamp-pumped laser and YAG laser welding were mainly used, which belonged to very traditional low-power laser welding. It has been applied in many fields such as moulds, advertising characters, glasses, jewelry, etc. Sizes are very limited.

Laser welding has gradually entered high-end industries such as automobiles, rail transit, aerospace, nuclear power, new energy vehicles, and optical communications.

Power battery laser welding should be the most attention-grabbing welding application demand in recent years, followed by body and parts welding. The third is the laser welding application of consumer electronics products, in which mobile phone manufacturing and optical communication manufacturing process space is relatively large.

It is also worth mentioning that handheld laser welding has entered the heavy duty stage. The demand for handheld welding equipment based on 1000W to 3000W fiber lasers has exploded in the past two years. It can easily replace traditional arc welding and inefficient spot welding processes. Widely used in welding of hardware factories, hardware parts, stainless steel pipes, aluminum alloys, doors and windows, railings, and bathroom components. There is great potential for development in the future.

0 notes

Video

youtube

1000W fiber laser cutter cutting 1mm stainless with Au3Tech laser head a...

#youtube#1000W 2000W 3000W fiber laser cutter cutting 1mm stainless with Au3Tech laser head and system Inquiry: [email protected] Whastapp:+86 15194

0 notes

Text

Affordable Handheld Metal Laser Welding Machine for Sale

A metal laser welding machine, also known as a laser welder or laser welding system, is a specialized equipment used for precise and efficient welding of metal components. It utilizes laser technology to generate a highly concentrated and intense laser beam that melts and fuses metal materials together.

Handheld Metal Laser Welding Machine

Handheld metal laser welding machines are designed to be lightweight and portable, allowing for easy transportation and maneuverability. They typically have a compact size and ergonomic design, enabling operators to access and weld difficult-to-reach areas or perform welding tasks in different locations.

Handheld metal laser welding machines offer the advantages of mobility, accessibility, and versatility in metal welding applications. They provide a convenient solution for on-site repairs, small-scale production, or situations where traditional fixed-position laser welding machines may not be feasible.

Welding head

The laser is eventually fired from the welding head and applied to the material.It consists of nozzle,scale tube, protective glass,focusing lens, reflector,motor,collimator,wire feeding bracket, switch button, waterways,QBH protective sleeve and so on. Nozzle and protective lens are wearing parts. And when workers’ welding, auxiliary gas is often needed to avoid material producing gas that could react with air and to avoid residue and aerosol entering the welding head to damage the components.So we need to prepare extra nozzles and protective lens. How laser welding works?The laser is generated by laser source and is transported to welding head, then it is collected and reflected by reflector and is focused by focusing lens to reach the nozzle and finally fired to the material, after all this happens, the user could conduct welding conveniently and flexibly.

When considering a handheld metal laser welding machine, factors to consider include laser power, portability features, battery life (if applicable), cooling system, ease of use, and the specific welding requirements of your application.

Main body

Displayer is a window for interaction between user and machine. The screen of displayer is touch screen, its functions are machine parameter adjustment and language conversion. Control board equals to computer mainframe. And wire feeder is designed to melt the wire into the welding joint during material processing when the welding joint width over 5 mm.

Water chiller is used to cool laser source and welding head and could only be filled with distilled water and purified water in summer and with antifreeze in winter. And the volume of liquids contained is 15L, the replacement period of liquids is 2-3 months.

Metal Laser Welding Machine for Sale

Ranging from entry-level handheld laser welding guns to automatic laser welding systems with CNC controller, as well as professional 3D laser welding robot. All types of laser beam welders available in IGOLDEN with powers of 1000W, 2000W and 3000W for machinists.

Three-in-one laser welder

The advanced version of laser welder is the three-in-one laser welder, as its name suggests, it has multifunctions of of welding, cleaning and cutting. Its welding function is the same as that of a normal laser welder. And it could be easily to changed into the cutting pattern by the change of nozzle, when it is converted into the pattern of cutting, it could only cut some extra and useless pieces of the material edges with less precision and worse effect than normal fiber laser cutters. If it is applied in cleaning, cleaning head and special focusing lens for laser cleaner should be installed. It is easy and convenient in operation and alteration of patterns.

Metal Laser Welding Machine Features

Laser Source:

Metal laser welding machines use a laser source, typically a solid-state laser, to generate the laser beam. Common types of lasers used include fiber lasers, Nd:YAG lasers, and disk lasers. These lasers provide high power and excellent beam quality for precise and controlled welding.

Welding Process:

Metal laser welding involves focusing the laser beam onto the joint or area to be welded. The laser beam rapidly heats and melts the metal surfaces, creating a localized molten pool. Upon cooling, the molten metal solidifies, resulting in a strong and durable weld joint. The process can be performed in continuous wave (CW) mode or pulsed mode, depending on the application requirements.

Non-contact Welding:

Laser welding is a non-contact welding process, meaning the laser beam does not physically touch the workpiece. This eliminates the need for mechanical force or contact between the welding tool and the material, reducing the risk of contamination or damage to the welded parts.

Materials:

Metal laser welding machines can be used to weld a wide range of metals and alloys, including stainless steel, carbon steel, aluminum, titanium, copper, brass, and various other alloys. They are particularly effective for welding thin sheets or components with high precision and minimal distortion.

Speed and Efficiency:

Laser welding is a fast and efficient welding method. The concentrated energy of the laser beam results in rapid heating and cooling rates, allowing for high welding speeds. This contributes to increased productivity and reduced production time compared to traditional welding techniques.

Precision and Control:

Metal laser welding machines offer high precision and control over the welding process. The laser beam can be accurately focused and directed to the desired welding area, allowing for precise positioning and control of the heat input. This enables the welding of intricate or complex geometries with minimal damage to the surrounding material.

Versatility:

Metal laser welding machines are versatile and can be used for various welding applications. They can perform spot welding, seam welding, overlap welding, and even 3D welding of complex components. Laser welding can also be combined with other processes, such as laser cutting or laser marking, to create integrated manufacturing solutions.

Automation and Integration:

Metal laser welding machines can be integrated into automated production lines or robotic systems for increased productivity and consistency. They can be equipped with vision systems and sensors to aid in precise positioning and quality control.

Metal Laser Welding Machine Advantages

The laser welder has varieties of advantages and they will be explained in detail. Laser welder could be used in a wide range , it works well no matter in outdoor or from long distance. And the machine can be used flexibly and conveniently in various working occasions. Besides, there are many welding methods offered for users to choose, stitch welding, butt welding, vertical welding, flat fillet weld, inside corner weld and outside corner weld, and it has free switching of welding and cutting, users only need to change a welding nozzle to a cutting nozzle. The welding effect is good because of small heat affected zone, hard to deform and blacken, welding deeply, full melting, compact and firm structure, high weld strength.

There is no need to polish welding joint for it adopts continuous welding, the surface of welded part is smooth and well-done with no perlage and few subsequent polishing procedure. Little consumable material needed in welding process to save the costs of material. This machine is equipped with safety alarms. The nozzle works only when it touches metals and automatically stops outputting laser once the working parts moved from the platform, and the tact switch has the function of temperature sensing. Therefore, this machine has a high safety level. Last but not the least, laser welder is labor-saving for it could be operated by workers who only have short-term training. In a nutshell, the laser-welder is friendly to both owner and user with advantages of time saving, labor saving and cost saving.

How does laser welding work?

Welding by laser beam is basically very simple: Two precisely cut sheets are held together. The laser melts the edges of the sheet metal. The melt flows into each other – and the joint is complete.

Quality assurance in laser beam welding

Laser beam welding is a non-contact joining process. It is always carried out automatically. Modern laser beam welding systems are equipped with an integrated measuring system, which independently checks the dimensions of the manufactured component. This makes these systems particularly precise, which is the basis for guaranteeing constant quality.

Costs for a laser beam welding system

The costs are still the biggest disadvantage of these innovative processes. It depends strongly on what and which material is to be processed with the laser welding system. Even simple micro systems used, for example, for engraving wedding rings can cost several thousand euros. Brand-new high-performance plants rarely cost less than 100,000 euros, rather more. These expenses are offset by excellent manufacturing quality and high productivity. In fact, laser welding is usually carried out at a much higher speed than conventional electric or inert gas welding processes.

What speed is possible with laser welding?

In addition to precision and low heat input, the working speed is one of the outstanding properties of laser welding. Under ideal conditions, a long, straight endless seam can be welded at a speed of up to 60 m/minute. Since the intensity of the laser beam can be varied, the impact of the material used is less decisive for the working speed of a laser welding system. Even thick sheets can be precisely joined in a matter of seconds.

Types of laser welding

Laser welding is a versatile, low cost way of achieving high quality spot welds for different materials and thicknesses. It results across a wide range of materials. There are three common types, including CO2, YAG and fiber laser welders. There are high-power welders for large-format and thick sheets, and low-power welders for small-size parts. There are welders for metals and non-metallic materials such as plastics and ceramics.

Different methods can be classified as follows:

• Welds between slices. Including butt welds, end welds, center penetration fusion welds, and center perforation fusion welds.

• Wire and wire welds. Including wire-to-wire butt welds, cross welds, parallel lap welds, and T-type welds.

• Welds of metal wires and block components. It can successfully realize the connection between the metal wire and the block element, and the size of the block element can be arbitrary. Attention should be paid to the geometric dimensions of the wire-like components during welding.

• Welds of different metals. Welds different types of metals must solve the range of weldability parameters. The welding between different materials is only possible with certain material combinations.

0 notes

Video

Fiber Laser Source IPG 1000W 2000W Single Module Cutting/Welding Machine

0 notes

Text

Remcor technology is a global supplier for the turnkey fiber laser cutting lines, which have around 18 years experiences, 5000 sets installations globally. No matter what type what size and how thickness your sheet material is, we can provide you the suitable equipment. Pipe Fiber laser cutting machine mainly been applied in metal pipes and tubes fabrications, with the character of fast speed, high precision or accuracy, environmental friendly, low power consumption, low table cost, and low maintenance cost. which is widely applied in fast cutting metal pipes of steel, stainless steel, carbon steel, aluminum, copper, galvanized steel, titanium alloy, gold, silver and other material. OEM ODM services are available.

Heavy Duty bed, apply the fully plate welding bed, with higher rigidity and durable use.

Compared with two chuck clamping or traditional metal pipes cutter. Three chucks equipment can realize the real zero tailing .processing details as the following descriptio.

More flexible for pipe cutting processing especially for extra heavy duty pipes or tubes, less swing or shake.Perfect accuracy and precision.

Heavy duty type load longer tailing material avaliable.

Apollo AK Two-chuck Tube Laser Cutting Machine 1000w-6000w Parameter Details

APOLLO BK SERIES-3 Chucks

Type

6020-BK

7025-BK

9025-BK

9034-BK

Power Range

1500-6000W

Chuck Structure

3 chucks

Tube Size

Round Type: 15-200mm Square

Round Type:15- 245mm

Round Type:15- 245mm Square

Round Type:15- 330mm Square

Type:15- 140mm

Square Type:15- 175mm

Type:15- 175mm

Type:15- 230mm

Positioning accuracy of X& Y

土0.05mm/m

Max Positioning speed X&Y

100m/min

80m/min

Max cutting length

6000mm

7000mm

9000mm

9000mm

Tail length

2 0mm

Max weight single tube

135KG

260KG

260KG

500KG

Max loading length

6000mm

7000mm

9000mm

9000mm

Fully Annealed Table

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time. The table is equipped with automatic lubrication device, which ensure the moving parts operate in good condition and improve the service life of guide rails, gears and rack.

Follower Support

The follower support device will be optional. The follower support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), and the servo motor drives the up and down movement of the pallet assembly. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

Smart Auto Focus Laser Head

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Intelligent CNC Operating System

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Pneumatic Clamp Chucks

Pneumatic clamp design on both sides. The dual-chucks help reduce tube vibration to a minimum, guaranteeing high accuracy in even complex tube configurations at high cutting speed. Suitable for cutting a range of tube diameters from Ø20 mm to Ø220 mm and various wall thicknesses.

Front chuck

tube laser cutting machine front chuck

Back chuck

tube laser cutting machine back chuck

Fractional Automatic Support Technology

Applies the intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Equipped with two sets of variable-diameter support structures, which are automatically lifted by the cylinder to avoid the rear chuck in processing. When processing profiles with different diameters, manually turn the variable-diameter wheels to achieve fit and support for different-sized profiles. The variable-diameter wheels It can be supported every two degrees of rotation to reduce the diameter of the circumscribed circular tube by 2mm

0 notes

Video

youtube

starma cnc laser tech 1000w 1500w Raycus handheld laser cleaning machine...

starma cnc laser tech 1000w 1500w Raycus handheld laser cleaning machine for sale #starmacnc #lasercleaning #lasercleaningmachine #lasercleaningmachine1000w #laser Handheld Fiber Laser cleaning Machine Head rust removal laser clean Parts Au3tech HC200 The starma cnc laser tech 1000w 1500w Raycus handheld laser cleaning machine for sale on our website : https://www.starmacnclaser.com/fiber-laser-machine/laser-cleaning-machine/handheld-portable-1000w-laser-cleaner.html -Famous brand -Cheap price -CE quality -Fast delivery -Safe transport -Easy operate -Easy maintain -Long lifetime Together, we make it better.(STARMACNC) .................................................................. Mr.Andy Zhu (Overseas Sales Manager) Jinan Starma Intelligent Tech Co.,Ltd. No.277 Industrial North Road, Licheng, Jinan,Shandong, China. Mob/Whatsapp/Wechat/Viber: +86-15194126152 QQ:1714103405 (www.STARMACNCLASER.com) (www.DELLLASER.com) (www.woodcncrouters.com) (www.starmalasermachine.com) "Global High End CNC Equipment Manufactures" .....................................................................

1 note

·

View note