Text

Insulated Collapsible Cooler Bag

High performance VIP as core insulation layer.

Excellent performance.

Detachable, foldable, easy to operate.

Portable design, lightweight handling.

Medical, fresh, food, and other recycling needs.

Advantages of Insulated Collapsible Cooler Bag

Portability

01

The collapsible design makes it easy to store and transport when not in use. It can be folded down to a compact size, making it convenient to carry around.

Space-Saving

02

When not in use, the bag can be collapsed and stored away easily, saving valuable storage space in your home or vehicle.

Easy to Clean

03

The interior of the bag is usually easy to clean, which is important for maintaining hygiene and preventing the growth of bacteria.

0 notes

Text

Insulated Bag

High performance VIP as insulation layer

Excellent performance, fresh storage and transportation

Beautiful and not easily dirty

Strap design, can be lifted and carried back

Energy conservation and environmental protection

Food grade materials

Usage: City distribution for food, takeout, Medical, fresh, food, and other recycling needs, etc.

Types of Insulated Bag

Insulated Pizza Delivery Bag

Food Delivery Insulated Bag

Insulated Collapsible Cooler Bag

Fabric Insulated Box

Insulin Cooler Travel Case

Insulated Cover

Rolling Cart Insulated Cover

Applications of Insulated Bags

01

Portability

Insulated bags are designed with portability in mind, making them easy to carry for picnics, grocery shopping, or meal deliveries.

02

Eco-Friendly Materials

They are constructed using energy-saving and environmentally friendly food-grade materials, ensuring both safety and sustainability.

03

Customization

Insulated bags can be tailored to specific insulation and cold chain requirements, catering to diverse customer needs.

04

Versatile Applications

These bags find applications in various industries, including food delivery, pharmaceuticals, and retail, maintaining temperature control for a wide range of products.

Materials Used in Insulated Bags

VIP (Vacuum Insulation Panel)

VIP is a cutting-edge core insulation layer used in insulated bags. It boasts exceptional insulation properties due to its vacuum-sealed, micro-porous silica or fiberglass core. This core material ensures outstanding thermal resistance, keeping contents hot or cold for extended periods.

High-Quality Aluminum Film

VIPs are equipped with high-quality aluminum film on both sides of the insulation core. This aluminum film enhances the bag's durability and prevents heat transfer, ensuring the bag's contents remain at the desired temperature.

Aesthetic Appeal

The aluminum film not only serves a functional purpose but also adds to the bag's aesthetic appeal. Its sleek, reflective surface gives the bag a modern and premium look, making it a popular choice for various applications, including food delivery bags and medical supply transport.

0 notes

Text

Ice Pack

Based on the Supertech parent company, who owned the world-class and complete vacuum insulation technology, Supertech Cold Chain has developed a series of cold chain insulation equipment assembled with vacuum insulation panel. Its thermal insulation and energy saving effect are better than any other common insulation product in the market and fully meeting the requirement of customer in cold chain transportation and storage areas.

Our efficient coolant has great latent heat, sufficient cold storage energy, no salting out and supercooling phenomenon, good thermal stability, smooth phase transition temperature, ow coefficient of thermal expansion; no corrosive and toxic, certified by air DGM. Also can be carried on the plane and through mail delivery. Cost effective, can be used repeatedly.

Types of Ice Pack

PCM Ice Pack

Advantages of Ice Packs

01

In Real Cold Chain Transportation

Especially for long-term transportation, passive cold chain insulation boxes are commonly used, mainly in terms of usage, avoiding charging troubles. Additionally, even for long-term transportation, such as 72 hours, the configuration of the cold source inside the box can be adjusted to achieve this. This article focuses on introducing the use of phase change cold storage technology in refrigerated insulation boxes.

02

Movable Refrigerator

A refrigerated insulation box with a cold source can be used on a refrigerated truck or on a regular truck, because to some extent, it is a "movable refrigerator".

Thermal Performance of Ice Packs

Different uses of ice storage agents with different phase transition points in ice boxes and bags

Each plastic box is made by blow molding, and the different materials filled inside have different corresponding uses. It is generally used for pharmaceutical transportation, such as vaccine reception and transportation, blood transportation, 2-8 degree drug transportation, etc. The required transportation time and configuration of the box are different, and the requirements for ice box, ice board, ice bag, paper box ice, etc. are also different.

Cold storage agents are widely used in cold chain systems

With the characteristics of fast cooling, large cold storage capacity, long cold retention time, recyclability, non-toxic and pollution-free.

FAQs of Ice Pack

What is an ice pack?

An ice pack is a portable plastic bag filled with water, or refrigerant gel, which can be frozen and used to provide coolness to help reduce swelling, pain, or body temperature.

0 notes

Text

Hollow Sheet Insulated Box

Soft PU-VIP as insulation layer.

The outer box is a lightweight and high-strength foldable box.

Overall detachable, reducing empty container recycling costs.

Customizable size.

Repairable and recyclable.

Suitable for cold chain transportation, considering the demand for empty container transportation.

Specification of Hollow Sheet Insulated Box

Insulation box model

Capacity

(L)

Inside dimensions

(mm)

Outer dimensions

(mm)

Wall thickness

(mm)

Weight

(kg)

PCM phase change point

(℃)

PCM weight

(kg)

STRZ-V48a

48

368*368*360

438*438*430

35

11

0/5

11.3

STRZ-V48b

48

368*368*360

408*408*400

20

6.95

0/5

11.3

Advantages of Hollow Sheet Insulated Box

Lower Logistics Recycling Costs

01

This tray insulation box is detachable and can be disassembled into six insulation boards stacked together when recycled or not in use, reducing the total volume by half; Whether it is the logistics cost when customers purchase products or the logistics cost when customers retrieve insulated boxes, there is a clear cost reduction.

Simple Cargo Loading and Unloading Process

02

When loading goods, a forklift can be directly used to place the goods with pallets in the bottom tray of the insulation box from any direction, without the need for manual movement of the goods from the existing pallets into the insulation box, and then the insulation board can be clamped and assembled into a complete insulation box; The same applies when unloading goods. Greatly reduces the labor cost of transporting goods.

Unique Ice Box Fixing Bracket

03

By using a special ice box fixing bracket to combine multiple ice boxes into one ice box accessory, existing ice boxes can be fully utilized to meet the "big ice box" requirements of the large box, without considering the mold opening problem of the large ice box involved in the large insulation box, and greatly facilitating the transportation and loading and unloading of the ice box in the insulation box.

Excellent Insulation and Barrier Performance

04

This tray insulation box uses PU-VIP composite material as the core insulation material. After practical testing, the insulation time of 0-5 ℃ can reach 200 hours in a harsh environment with an average temperature of 35 ℃.

Diverse Practical Application Scenarios

05

This tray insulation box can be applied to various cold chain transportation fields such as aviation cold chain transportation of biological agents, drugs, vaccines, etc., factory turnover transportation of drugs, vaccines, etc., and cold chain transportation of fresh food.

0 notes

Text

High Temperture Corematerial-Based VIP For Wide Temperature Range (-196℃-800℃)

With unique structure of thermal dissipation - thermal insulation - thermal dissipation", achieved thermal insulation in vertical direction through vacuum process, High thermal conductivity materials provide good thermal dissipation along the VIP plane direction, which can be organically combined with the thermal dissipation system to achieve thermal management Customize the solution of your energy storage and insulation in the extreme temperature zone from -196'C to 800°C . As an innovative thermal insulation material, wide temperature range VIP can replace non-vacuum insulation material, such as high silica cotton, ceramic fiber felt, aerogel felt, glass fiber paper, PIR, PUR, etc.

The VIP is the fifth generation VIP upgraded product of our company, which mainly solves the heat insulation problems in the field of new energy batteries and energy storage. It is a kind of product made of aluminum foil or stainless steel foil as membrane material, basalt fiber, high silicon fiber and others as core materials. After vacuuming, it is encapsulated by welding. M-VIP has features of high and low temperature resistance, low thermal conductivity, long service life, puncture resistance, high compressive strength and Class A non-combustible. It can be used as high temperature thermal insulation materials instead of high silica oxygen cotton, silica aerogel and aerogel felt.

Advantages of High Temperture Corematerial-Based VIP For Wide Temperature Range (-196℃-800℃)

Unique Structure of ''Heat Dissipation-Thermal Insulation-Heat Dissipation''

01

The interior of the metal VIP is filled with heat-resistant core materials and vacuumed, showing excellent heat insulation effect in the direction perpendicular to the metal VIP. The external cladding material is aluminum foil or stainless steel foil with high thermal conductivity, which has good heat dissipation effect in the direction parallel to the metal VIP. The heat sink with high thermal conductivity can also be connected at the edge and connected to the heat dissipation system so as to play a better heat dissipation effect. Metal VIP can be applied to new energy battery heat insulation and other special heat insulation scenarios.

Excellent Heat Insulation at Steady

02

State high temperatures:The thermal insulation properties of 8mm VIP and 9mm aerogel felt with the same length and width were compared at 400℃ and 600℃. Compared with aerogel felt, the back temperature of VIP metal was significantly lower and the heating rate was slower.

Excellent Heat Insulation at Unsteady High Temperatures

03

In the unsteady (rapid temperature rise) tests, the metal VIP insulation performance was better than the aerogel felt.

0 notes

Text

Fumed Silica Film

SNG (gas-silicon) is a high-barrier film developed for gas-silicon vacuum insulation panels. It has excellent anti-aging, oxygen and water resistance properties. The porous structure of the gas-silicon film has a strong adsorption effect on water vapor and is resistant to external pressure With low sensitivity and longer lifespan, it is suitable for scenes requiring long lifespan, such as construction.

Specification of Fumed Silica Film

product name

unit

SNG (gas-silicon) Fumed Silica Film

test method

thickness

μm

93

GB/T6672

width

mm

200-1100

GB/T21302

Puncture strength

N

21

GB/T21302

Total solvent residue

mg/㎡

<5

BS6455:1984

Helium transmission rate

mbar·L/(S·㎡)

5*10-8

Intrinsic benchmark

water vapor transmission rate

g/㎡·24hr

<0.01

GB1037

Oxygen transmission rate

cc/㎡·d

<0.1

GB/T31354

seal strength

N/15mm

>60

QB/T2358

High and low temperature aging 80℃→-30℃reciprocating cycle for 28 days,65%RH

△k=mW/(m·k)

≤1.0

GB/T39548

High temperature and high humidity aging 70℃,90%RH aging for 30 days

△k=mW/(m·k)

≤2

GB/T39548

features

/

cost-effective,

/

The performance is fully ahead of the foreign products of the same model

Advantages of Fumed Silica Film

01

Cost-Effective

02

The Performance Is Fully Ahead Of The Foreign Products Of The Same Model.

0 notes

Text

Food Delivery Insulated Bag

High performance VIP as core insulation layer.

Food temperature difference less than 5 ℃ within 2 hours.

Beautiful and lightweight, easy to clean.

Food grade materials.

City delivery of food, takeout, etc.

Advantages of Food Delivery Insulated Bag

Versatility

01

These bags can be used for a variety of food items, from pizzas and burgers to salads and ice cream. This makes them a versatile tool for any food delivery service.

Professional Appearance

02

Using insulated bags can give a more professional appearance to your delivery service, showing customers that you care about the quality of your food and service.

Environmentally Friendly

03

Many insulated bags are reusable, making them a more environmentally friendly option than disposable packaging.

0 notes

Text

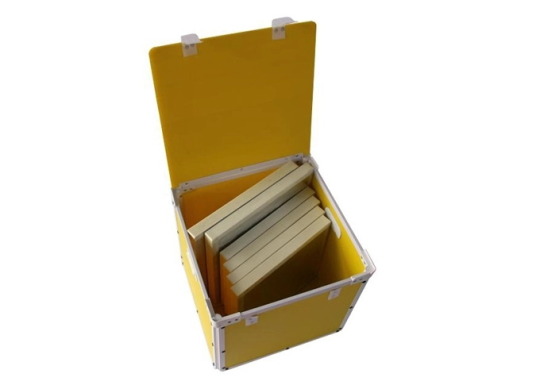

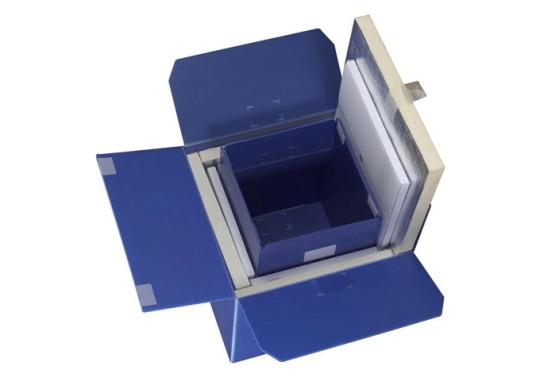

Foldable Insulated Box

Soft PU-VIP as insulation layer.

The outer box is a lightweight and high-strength foldable box.

Overall detachable, reducing empty container recycling costs.

Customizable size.

Repairable and recyclable.

Suitable for cold chain transportation, considering the demand for empty container transportation.

Specification of Foldable Insulated Box

Insulation box model

Capacity

(L)

Inside dimensions

(mm)

Outer dimensions

(mm)

Wall thickness

(mm)

Weight

(kg)

PCM phase change point

(℃)

PCM weight

(kg)

STRZ-V48a

48

368*368*360

438*438*430

35

11

0/5

11.3

STRZ-V48b

48

368*368*360

408*408*400

20

6.95

0/5

11.3

Advantages of Foldable Insulated Box

01

This tray insulation box is detachable and can be disassembled into six insulation boards stacked together when recycled or not in use, reducing the total volume by half; Whether it is the logistics cost when customers purchase products or the logistics cost when customers retrieve insulated boxes, there is a clear cost reduction.

Simple Cargo Loading and Unloading Process

02

When loading goods, a forklift can be directly used to place the goods with pallets in the bottom tray of the insulation box from any direction, without the need for manual movement of the goods from the existing pallets into the insulation box, and then the insulation board can be clamped and assembled into a complete insulation box; The same applies when unloading goods. Greatly reduces the labor cost of transporting goods.

Unique Ice Box Fixing Bracket

03

By using a special ice box fixing bracket to combine multiple ice boxes into one ice box accessory, existing ice boxes can be fully utilized to meet the "big ice box" requirements of the large box, without considering the mold opening problem of the large ice box involved in the large insulation box, and greatly facilitating the transportation and loading and unloading of the ice box in the insulation box.

Excellent Insulation and Barrier Performance

04

This tray insulation box uses PU-VIP composite material as the core insulation material. After practical testing, the insulation time of 0-5 ℃ can reach 200 hours in a harsh environment with an average temperature of 35 ℃.

Diverse Practical Application Scenarios

05

This tray insulation box can be applied to various cold chain transportation fields such as aviation cold chain transportation of biological agents, drugs, vaccines, etc., factory turnover transportation of drugs, vaccines, etc., and cold chain transportation of fresh food.

1 note

·

View note