Text

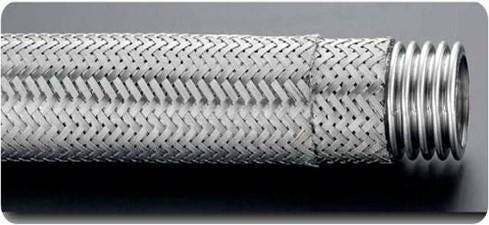

SS (stainless steel) corrugated hoses for industrial applications. SS corrugated hoses are highly valued in various industries for their durability, flexibility, and resistance to corrosion. They are commonly used for the transportation of fluids and chemicals.

0 notes

Text

The Advantages of Metal Flexible Hoses You Should Know About

Metal flexible hoses, also known as metal hoses or stainless steel hoses, are versatile components used in various industries for conveying fluids and gases. They offer several advantages due to their unique design and material properties. Here are some of the key advantages of metal flexible hoses:

High Temperature Resistance: Metal flexible hoses can withstand extreme temperatures, making them suitable for conveying hot or cold fluids in various industrial processes.

Corrosion Resistance: They are typically made of materials such as stainless steel, which is highly resistant to corrosion. This makes them suitable for conveying corrosive or aggressive fluids without degradation.

Pressure Resistance: Metal hoses can handle high-pressure applications, providing a reliable conduit for hydraulic, pneumatic, or other high-pressure systems.

Flexibility: The corrugated design of metal hoses allows for flexibility and easy installation, even in tight spaces or areas with limited movement. This flexibility reduces the need for complex piping systems and minimizes stress on connected equipment.

Vibration Absorption: Metal hoses are excellent at dampening vibrations and reducing noise in piping systems. This makes them ideal for applications where vibration control is important, such as in industrial machinery and HVAC systems.

Resistance to Physical Damage: They are robust and resistant to physical damage, including abrasion, external impact, and bending. This durability extends the service life of the hoses.

Leak Prevention: Metal hoses offer a high level of leak resistance due to their welded or mechanically sealed construction. This minimizes the risk of fluid or gas leaks, which is crucial in industries where leaks can lead to safety hazards or product loss.

Easy Maintenance: Metal hoses are relatively easy to maintain. When required, they can be cleaned, inspected, and replaced with minimal effort, which reduces downtime and maintenance costs.

Customization: They are available in various sizes, lengths, and end fittings, and can be custom designed to meet specific application requirements. This flexibility ensures that the hose can be tailored to the exact needs of the system.

Compliance with Standards: Many metal hoses are designed and manufactured to meet industry-specific standards and regulations, ensuring safety and reliability in critical applications.

Wide Range of Applications: Metal hoses find applications in various industries, including chemical processing, petrochemical, pharmaceuticals, food and beverage, HVAC, aerospace, and more, demonstrating their versatility.

Reduced Emission of VOCs: In applications where volatile organic compounds (VOCs) are a concern, metal hoses can be used to transport fluids with minimal emissions due to their sealing properties.

0 notes

Text

Metallic Flexible Hose

Here are some key characteristics and uses of metallic flexible hoses:

Material: Metallic flexible hoses are typically constructed from various metals or metal alloys, such as stainless steel, bronze, or other corrosion-resistant materials. The choice of material depends on the specific application and the fluid or gas being transported.

Corrosion Resistance: Many metallic hoses are resistant to corrosion and can handle a wide range of chemicals and aggressive media, making them suitable for use in chemical processing, petrochemical, and offshore industries.

Temperature and Pressure Range: Metallic flexible hoses are designed to operate at a wide range of temperatures and pressures. They can handle extreme temperatures, from cryogenic temperatures to high-temperature applications. The pressure rating depends on the hose’s construction and material.

Flexibility: These hoses are highly flexible, allowing them to bend and flex without compromising their structural integrity. This flexibility makes them suitable for applications where movement or vibration is present, such as in industrial machinery, exhaust systems, or pipelines.

Absorption of Vibrations: Metallic flexible hoses can absorb and dampen vibrations and shocks, which can help protect equipment and extend the lifespan of components in various industrial settings.

Compensation for Thermal Expansion/Contraction: In piping systems subjected to temperature changes, metallic hoses can accommodate thermal expansion and contraction, reducing the stress on the system and preventing damage.

Connectors and Fittings: Metallic flexible hoses are typically equipped with specialized connectors and fittings at each end to facilitate easy installation and connection to other components in a system.

Applications: Metallic flexible hoses find use in a wide range of industries and applications, including:

HVAC (Heating, Ventilation, and Air Conditioning) systems

Automotive and aerospace industries

Steam and hot water distribution

Chemical processing

Oil and gas refining

Cryogenic applications

Food processing and pharmaceuticals

Power generation (e.g., exhaust systems)

Shipbuilding and offshore drilling

These hoses are available in various lengths and diameters to suit specific requirements. When selecting a metallic flexible hose, it is crucial to consider factors like temperature, pressure, compatibility with the conveyed media, and environmental conditions to ensure safe and efficient operation. Proper maintenance and inspection are also essential to ensure the integrity and reliability of these hoses over time.

0 notes

Text

A stainless steel flanged hose is a type of flexible hose with flange connections made from stainless steel. Flanges are flat, typically circular discs with holes that allow for the connection of the hose to other components, such as pipes, valves, or equipment. These flanges provide a secure and leak-proof connection, making stainless steel flanged hoses suitable for a wide range of industrial applications.

0 notes