Text

Understanding the Significance of RF Shielded Rooms

In the present era, the laws and regulations are becoming more and more stringent. That is why it becomes essential to test the electronic devices that receive radio frequency. The main object is to ensure that they are able to provide accurate measurements and comply with the regulatory requirements. Wondering how to test them? Well, leveraging the RF shielded rooms is the key. In this blog, you will explore everything about RF shielding. Let’s dive in!

What is an RF Shielded Room?

Radio frequency interference (RFI) prevents the electrical circuits of devices from operating normally. That is where the RF shielded rooms come into the picture. It is basically an enclosure that contains the radio signals inside or minimises their emission outside the container.

Need of RF Shielding for Effective Testing

Communication systems and electronic devices have become a necessity in the digital era. However, radio frequency interference can give rise to several problems and lead to security breaches and loss of data. It also has the ability to confuse communication systems, disrupt electronic equipment, and degrade the performance of various services. Breakdown of certain technologies is even a possibility. If the interference is not controlled properly, it can lead to more severe consequences and affect the success of projects.

RF shielding proves to be an effective measure to limit the electromagnetic field of RF signals from causing any undesired effects. It helps absorb or reflect the electromagnetic waves that are harmful to electronic devices and humans. Moreover, it allows accurate testing of the electronic devices in a controlled environment.

Applications of RF Shielded Rooms

Telecommunication

Maintaining the reliability and quality of wireless communication systems is crucial for the telecom sector. That is where the RF shielded rooms prove to be useful. It helps isolate signals effectively and prevent crosstalk between communication channels.

Automotive Sector

In the modern era, vehicles are equipped with advanced electronic systems like engine control, communication, and navigation. All these systems are susceptible to electromagnetic interference. RF shielding helps protect these electronic systems from external signals. As a result, you can be sure of reliable and smooth operations.

Defence and Aerospace

In the defence and aerospace sectors, RF shielding plays a vital role in protecting sensitive electronic systems against external electromagnetic interference. It is essential for communication equipment and radar systems on aircraft and spacecraft.

Research Laboratories

It is no surprise that research laboratories conduct a lot of sensitive measurements or experiments. In such cases, radiofrequency interference can affect the accuracy of the results. RF shielding prevents interference and allows the experts to carry out the experiments in a hassle-free manner.

Conclusion

RF shielded rooms effectively block the external radio frequency signals and facilitate efficient testing of electronic devices. From aerospace and defence to the automotive sector, the applications of these enclosures are many. Are you in search of high-quality and reliable enclosures? In that case, Simultech Australia is the perfect choice. Connect with the professionals today, discuss your specific needs, and get the best solutions at competitive prices.

Blog Source:https://simultechaustralia.wordpress.com/2023/12/16/understanding-the-significance-of-rf-shielded-rooms/

0 notes

Text

Exploring the Prominent Applications of Anechoic Chambers

Did you know? The anechoic test chambers market size is likely to reach USD 1.4 billion by 2027. (https://growthmarketreports.com/report/anechoic-test-chambers-market-global-industry-analysis) Yes, that’s true! The evolution of stringent regulations and laws in the electronics sector relating to EMI is one of the main reasons for the growing demand for anechoic chambers. In this blog, you will explore the different uses of these chambers. Let’s dive in!

What are Anechoic Chambers?

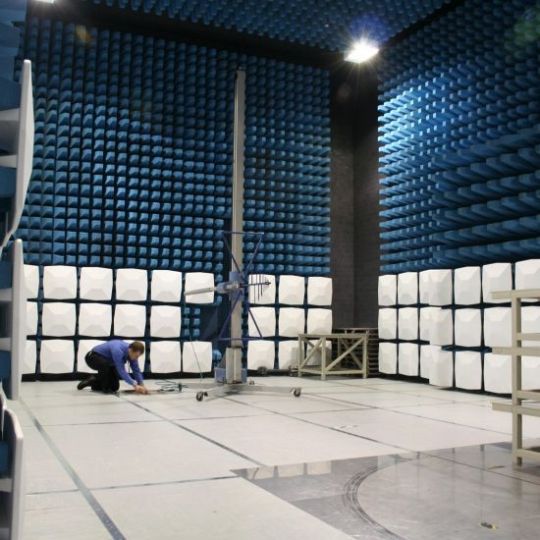

An anechoic chamber is a specialised equipment used to test the electronic devices against different regulatory standards. It is basically an enclosure that can completely absorb reflections of either electromagnetic or sound waves. The core aim of the device is to resist electromagnetic waves and suppress the emission of such waves to the external world.

Top Applications of Anechoic Test Chambers

Electromagnetic compatibility (EMC) is crucial for the development and certification of different electronic devices. It ensures that the devices can perform optimally in diverse environments. The anechoic chambers are used to test the following.

Radiated Immunity

The anechoic test chambers measure the ability of devices to function properly in the presence of radiated EMI. The devices are placed in the chamber and subjected to stimulated electromagnetic radiations at different intensities and frequencies. It helps evaluate the performance of the devices and ensures that they operate effectively under the conditions.

Conducted Emissions

The chamber measures the amount of EMI conducted from a device onto signal or power lines. It helps analyse and measure the emissions at various levels of intensities and frequencies.

Surge Immunity

The anechoic test allows electronic device manufacturers to evaluate the ability of products to withstand sudden surges in voltage. The devices are exposed to stimulate surge events and the response is noted. It aims to ensure that the devices continue to operate in a hassle-free manner under such conditions.

Magnetic Field Immunity

The testing equipment measures the ability of devices to function effectively in the presence of strong magnetic fields. The devices are subjected to different intensities of magnetic field and their performance is evaluated.

Antenna/ RF Performance Testing

Optimal RF performance is vital for the final certification of electronic devices. The anechoic chambers help measure the performance of the transmitters. As a result, the designers can determine whether the antenna meets the requirements or requires any changes.

Passive Antenna Pattern Testing

The anechoic chamber allows passive antenna pattern testing for matching, trimming, or designing antennas. It tests the performance of the antennas during the design phase and helps avoid costly reworks. Moreover, it can provide greater insights relating to the efficiency and benefits of the design.

Conclusion

In the competitive era, the optimal performance of electronic devices matters a lot to satisfy customers. Moreover, complying with the government regulations is also essential. That is why electronic devices must undergo testing. Anechoic chambers prove to be an ideal solution for testing the performance of the devices. Are you in search of reliable chambers at affordable prices? If yes, Simultech Australia can be your go-to platform. Connect with the professionals and get the best quality products for your unique needs.

Blog Source:https://simultechaustralia.wordpress.com/2023/12/16/exploring-the-prominent-applications-of-anechoic-chambers/

0 notes

Text

Use of Salt Spray Corrosion Test Chamber in Marine Industry

Did you know? Nearly 90% of ship failures are due to corrosion. (https://iopscience.iop.org/article/10.1088/1755-1315/508/1/012143/pdf#:~:text=Statistics%20show%20that%20about%2090,salt%20concentration%20in%20the%20air.) It is no surprise that ships are exposed to rainfall, humidity, temperature, and more. As a result, the chances of corrosion are higher. Therefore, manufacturers of ship parts look for solutions to increase the resistance and durability of the products. That is where the salt spray corrosion test chamber comes into the picture. In this blog, you will explore the significance of this chamber in the marine industry. Let’s dive in!

Need for Conducting Corrosion Tests in the Marine Sector

The marine atmosphere is highly corrosive owing to the rising levels of humidity and salinity. As marine ships and machinery are usually built of metals like steel, they tend to degrade rapidly. With the weakening of the components, the risk of ship accidents increases. The accident of marine vessels carrying dangerous items like oil can lead to severe consequences on the water body. To prevent such accidents and ensure marine safety, conducting corrosion tests matters a lot.

Benefits of Leveraging Salt Spray Corrosion Test Chamber

Are you still wondering why the salt spray corrosion test chamber matters for the marine sector? Take a look at the prominent benefits.

Corrosion Resistance Evaluation

The salt spray test chambers allow the manufacturers to effectively evaluate the resistance ability of the coating, material, or surface of the marine ships and machinery against corrosion. It helps ascertain their performance and durability in different challenging circumstances.

Quality Control

Salt spray corrosion tests enable the manufacturers to check the quality of the materials and coatings of the ships. They make sure that the marine vessels meet all the necessary requirements.

Cost-effective Analysis

Previously, manufacturers had to test the products in a real-world environment to analyse the performance of the materials and surfaces of the marine ships. As a result, the cost of analysis was relatively higher. However, the salt spray chambers help manufacturers to save a lot on such costs. The chambers provide a controlled and realistic environment to evaluate the performance with ease.

Material Selection

Different materials are available for the ships and other machinery used in the marine sector. Salt spray corrosion test chambers help compare the ability of different materials to withstand harsh weather conditions and salt water. As a result, you can easily choose the most suitable material for the marine projects.

Research and Development

To thrive in the competitive era, improving the products is the need of the hour. That is why manufacturers keep experimenting with new coatings and materials. It enables them to understand which compositions perform the best under corrosive conditions.

Compliance with Standards

Every industry has to comply with specific regulations and standards. The marine industry is no different. Salt spray corrosion test helps improve the reliability and quality of the ships. As a result, complying with the industry standards becomes easy.

Conclusion

Evaluation of coatings and materials of the marine ships and machinery is possible with the salt spray corrosion test chambers. Are you in search of the best chambers at competitive prices? If yes, Simultech can be the perfect choice.

Blog Source:https://simultechaustralia.wordpress.com/2023/12/16/use-of-salt-spray-corrosion-test-chamber-in-marine-industry/

0 notes

Text

Test The Altitude Effects Correctly with Altitude Chamber

Altitude, or you can say pressure testing, has become crucial for industrial, consumer, and military applications where components or products are required to work in low-pressure situations. These products need to be durable enough to handle rapid decompression easily. So, if you are manufacturing products for such industries, you must make sure that all the products meet the required standard. And for this, you can use an industry-grade pressure or altitude chamber. Read on to explore more about these chambers and how they can help you in your production line.

A Crucial Testing Chamber for Many Industries

Altitude or pressure chambers are designed to effectively simulate the temperature, vacuum as well as the altitude of various environmental conditions. The primary purpose of these chambers is to ensure that the parts and components can handle the pressure while shipping viaair. Different from a hypobaric test chamber, a modern pressure chamber can combine different factors, such as humidity, vibrations, icing, temperature,etc. By considering all these elements, you can create ideal real-world testing situations for effective analysis. These machines are widely used in automotive, aerospace, power, defence and other industries. And it is forecasted that altitude test chamber will grow at a CAGR of 5.5 percent in the coming years.

(Reference: https://dataintelo.com/report/global-altitude-test-chamber-market/).

Exploring Major Uses for These Chambers

Industrial altitude testing chambers are designed to create combined and extreme environments. As a result, it becomes easier for you to evaluate the resilience, strength as well as capabilities of products or components. However, there are certain vital considerations to remember if you want to invest in a modern altitude chamber. Let’s have a look at them:

Low And High Altitude

By using power vacuum pumps installed in the pressure chamber, you can easily create atmospheric conditions of up to 100,000 feet. On the other hand, to simulate situations like a sudden decrease in cabin pressure, you can use the rapid decompression features. Different situations can be simulated by adjusting instruments and programmed controls. It can be said that these powerful machines can greatly help with product improvement.

Temperature Testing

Equipped with advanced features,an altitude testing chamber can also offer a combined temperature and altitude simulation. However, while testing, ensure you adhere to the required test standards. These chambers meet the aeronautical environmental test norms and support different temperature profiles. Besides, some chambers come with an advanced cascade system that utilizes a refrigerant to lower the temperature. It supports a temperature range between -40-to-180-degree C.

Humidity Testing

Through humidity testing, you can test the longevity of different flight components under special circumstances. This test checks the durability of metals used, paints, coating, etc. By effectively diagnosing the humidity effects, you can extend your products’ lifespan. It can operate between a humidity range of 10-98 percent.

Vibration Testing

With an altitude chamber, it is possible to conduct vibration testing. That helps you know whether the components or parts can withstand vibrations’ effects. The machine will simulate various transportation conditions. With this test, you can determine the part’s point of failure. The data you will get from the machine can be analyzed for product improvement and other developments.

Final Words

With the best altitude chamber, you can easily examine the capabilities, resilience, and durability of components, instruments, and parts utilized in the aerospace industry. You can ensure that the products will perform at their maximum level under any condition. So, get in touch with a trusted supplier and buy this testing chamber now!

Blog Source:https://simultechaustralia.wordpress.com/2023/08/14/test-the-altitude-effects-correctly-with-altitude-chamber/

0 notes

Text

Ensure Better Product Quality withaWalk-In Environmental Chamber

Nowadays, everyone wants quality products,so it has become imperative for manufacturers to maintain the quality of their products. Here, a walk-in Environment Chamber can be of great help. These chambers are intelligently designed to evaluate the product’s characteristics to determine if it can withstand external conditions, such as dryness, heat, humidity, and cold. Such chambers have different applications and can be used in various industries such as automotive, aerospace, electronics, defence, and more. Keep reading to explore more about these chambers.

What Do You Mean by Walk-In Test Chamber?

In simple words, awalk-in environmental chamber is a well-insulated testing box that can be configured to different sizes to test products. It helps manufacturers know how the product will perform by simulating different conditions under which the product will be used. In the automotive industry, these chambers can be used to test motorcycles to full-size vehicles. They can simulate multiple conditions like altitude, humidity, temperature, vibration,etc. As people need durable and quality products, testing all the products for durability has become an important part of the product development process. And such machines are designed to simplify that task. This is a major reason why this market is projected to grow at around a CAGR of 2.18 percent (Markets and Markets). Some major reasons to use these environmental chambers are:

Effective for sample conditioning

Better sample aging considering different factors like humidity and temperature

Help with weather testing or waterproofing, electronic testing, and testing of the product lifecycle.

Your Guide to Choose the Best Testing Chamber

Choosing the best walk-in testing chamber is crucial to make sure that all the materials and products are evaluated properly. So, here are some important points you need to keep in mind to pick the best one based on your requirements.

Machines’ Capabilities

You should keep in mind that not all environmental testing chambers are developed equally. Some chambers are versatile,while others are designed for specific testing conditions. So, ensure that the chamber type you wish to buy can create the desired condition.

Don’t Forget to Check Available Safety Features

Some modern walk in environmental chambers come with multiple features, for example, alarm, auto shut-off, and more. The availability of such features ensures that you can keep the products protected during testing.

Chamber’s Interfaces

For maximum convenience, you should get a chamber with interfaces that let you easily connect the walk-inenvironmental chamber to a computer. Monitoring the chamber’s internal condition will become much easier if the machine has easy-to-understand interfaces. Besides, you can also control it remotely.

Maintenance Requirements

All electronic products require maintenance. However, ensure that the environmental chamber you are buying is simple to maintain. This way, you can prevent yourself from spending hours cleaning the chamber.

Size of The Chamber

Choose the size of the walk-in environmental chamber based on the product you want to test. It should be large enough to easily accommodate your requirements.

Conclusion

Looking at the current demand, it can be said that a walk-inenviron mental chamber is crucial for every manufacturer. It offers a well-controlled environment to carry out testing. However, prefer buying it from a reputed supplier to enjoy maximum benefits. Only a reliable supplier can provide you with a certified chamber thatworks flawlessly in every environmental condition.

Blog Source: https://simultechaustralia.wordpress.com/2023/08/14/ensure-better-product-quality-withawalk-in-environmental-chamber/

0 notes

Text

Investing in an Antenna Test Chamber: Why It Matters?

Have you ever wondered how wireless signals reach a special area? Well, the networks and connections live only because antennas exist. What if the antenna goes down? Your wireless network is likely to get into trouble. That is why using the antenna test chamber has become more vital than ever before. Read on to find out the significance of these chambers.

A Quick Overview of Antenna and Its Working

Before you dive into the details of antenna test chambers, you must have an idea of its working. Antenna basically refers to an electromagnetic signal sensing element that converts radio frequency signals into electromagnetic signals that can propagate through free space. It allows the transmission of data between two points. In other words, wireless communication is possible only because of the antennas.

Need of Antenna Testing

Antenna testing helps in providing valuable insights into the performance of the antennas. As a result, it enables the engineers to evaluate whether the antennas possess the desired characteristics or not. With the use of an antenna test chamber, making the essential changes and enhancing the overall performance becomes easy.

Tips to Invest in the Right Antenna Test Chambers

No doubt, antennas are at the core of efficient wireless connectivity and effective data transfer. To test their performance and gain accurate results, the use of appropriate antenna test chamber matters. Consider the essential tips that enable you to make the right choice.

Operating Frequency

It indicates the frequency range that the antenna measurement system is capable of measuring. The range usually varies between 4 to 110 GHz.

Measurement Capabilities

When investing in an antenna test chamber, you must evaluate what all characteristics the chamber is able to measure. Try to look for systems capable of measuring sidelobe levels, beamwidth, radiation pattern, 3D radiation pattern, and cross-polarization of the antennas.

DUT Size and Weight

DUT refers to the Device Under Test. Before selecting an antenna measurement system, you must have an idea of the maximum size and weight that it can support. An ideal system is one that can measure devices up to 0.5 m in diameter in size and up to 50-100 lbs in weight.

Number of Antennas

Also, consider the number of probes or antennas that the antenna measurement system features.

Cost

The cost of the antenna test chamber is something you cannot overlook. Try to set a budget and look for cost-effective systems with the required capabilities.

In addition to these aspects, you must also consider your other requirements to determine the right system for measuring the performance of antennas.

Conclusion

In the modern era, doing without wireless communication systems is not possible. However, to ensure a smooth and effective transfer of data, the optimum performance of the antennas matters. So, leveraging the antenna test chambers is the need of the hour. It can help reveal a lot about the limitations and capabilities of the antennas. Are you in search of a reliable antenna test chamber? Talk to the experts of Simultech Australia right away and discuss your unique needs.

Blog Source: https://simultechaustralia.wordpress.com/2023/08/14/investing-in-an-antenna-test-chamber-why-it-matters/

0 notes

Text

Salt Fog Test Chamber: An Effective Solution for Corrosion Testing

Did you know that corrosion can cause damage worth USD 2.5 trillion? (Source: https://www.appmfg.com/blog/4-galvanic-corrosion-statistics-you-should-know )It may sound surprising to you, but it’s actually true! Now you might be thinking about how to stop it then. Well, it is inevitable! The exposure of products to environmental factors like temperature, moisture, and acidity can result in corrosion. Preventing it entirely is not possible! However, you can slow down the process.

Are you into manufacturing products that are likely to corrode? If yes, it is time to leverage the salt fog test chamber. Wondering what it is? Read on to find out the details!

What is a Salt Fog Test Chamber?

A salt fog test chamber is a device that performs the salt spray test or fog test of materials in a controlled environment. The core aim of the equipment is to stimulate the corrosive conditions that several coatings and materials may encounter in real-world environments. It helps in the identification of suitable materials for different applications.

Benefits of Using a Salt Fog Test Chamber

#1 Evaluate the Corrosive Resistance of Different Materials

Investing in a salt fog test chamber can enable you to find out how corrosion-resistant a product, material, or coating is. It helps you to determine the resistance of the following.

Paint coatings

Electroplated nickel, chromium, tin, and copper

Phosphorated surfaces with primer, paint, rust-preventive materials, or lacquer

Organic coatings

Zinc plating

Apart from evaluating the corrosion resistance of different materials, it allows for making helpful comparisons. It can help manufacturers to make informed decisions relating to the selection of the right materials for various applications.

#2 Test the Quality of Products

In the competitive era, it has become vital to develop products that can effectively stand the test of time. That is why quality matters the most in recent times. So, if you want to stand out in your industry, testing your products with a salt fog test chamber is vital.

Are you wondering how it can help? It enables the manufacturers to determine the effectiveness of the products and make necessary improvements to slow down corrosion. It helps in accessing their durability and performance in corrosive conditions. In short, it can boost the productivity of materials and enhance the quality of products.

#3 Cost-Effective

Getting a salt fog test chamber may seem to be a significant investment. However, it can aidin saving more in the long run. Using the chamber during the production process can enable manufacturers to identify potential inconsistencies or issues earlier. As a result, taking corrective actions and preventing losses later becomes easy.

#4 Meet the Desired Standards

There are several industry standards that are to be met during the launch of a product. A salt fog test chamber can help manufacturers ensure that their products meet the specifications and corrosion resistance standards of the industry.

Conclusion

The salt fog test chambers are indeed helpful in accessing the corrosion resistance of materials. Are you in search of a high-quality corrosion test chamber from a reputed company? If yes, Simultech can be the best option for you. Talk to the professionals today and discuss your needs!

Blog Source:https://simultechaustralia.wordpress.com/2023/08/14/salt-fog-test-chamber-an-effective-solution-for-corrosion-testing/

0 notes

Text

Functions and Applications of Environmental Testing Chambers

The manufacturing and research ecosystem has tremendously transformed in the past few years. Thorough testing and stringent quality checkpoints facilitate seamless end products, and environmental testing chambers play a significant role in assessing the performance and reliability of different products under diverse conditions. Equipment like salt fog test chambers can simulate real-world environments to evaluate the functionality, durability and Quality of a wide array of materials and devices. Wondering how these testing chambers work? Read on to find out!

Anechoic Chambers:

These testing chambers minimise the reflections of electromagnetic or sound waves. The Anechoic chambers have space with minimal external interference as their walls are lined with materials that dampen and absorb acoustic or electromagnetic energy. Mostly, these chambers are used in the telecommunication, automotive, aerospace and electronics industries.

One of the primary applications of anechoic chambers is electromagnetic compatibility (EMC) testing. Manufacturers use these chambers to assess the electromagnetic emissions and susceptibility of their electronic devices. By placing the device inside the chamber, engineers can measure the electromagnetic radiation it emits and evaluate its compliance with regulatory standards. Anechoic chambers are also used for antenna testing and acoustic measurements, enabling engineers to analyse the performance and characteristics of antennas and audio equipment.

Cyclic Corrosion Chambers:

Cyclic corrosion chambers are used by researchers and manufacturers to simulate the harsh environmental products that end products might encounter during their lifespan. These chambers primarily work by replicating environmental factors like salt spray, humidity, temperature and corrosive gases. When the products are subjected to accelerated corrosion cycles, manufacturers can assess their corrosion resistance and scrutinise their long-term durability.

The automotive industry extensively uses cyclic corrosion chambers to test the corrosion resistance of vehicles and their components. By exposing automotive parts to corrosive conditions, manufacturers can identify potential weaknesses and develop corrosion protection measures. Cyclic corrosion chambers are also used in the construction industry to assess the durability of building materials exposed to harsh climates and corrosive environments.

Chamber Rental Services:

Not all companies have the resources or need to invest in permanent environmental testing chambers. In such cases, chamber rental services provide a convenient solution. Chamber rental services allow companies to access specialized testing equipment and facilities temporarily. This flexibility enables businesses to conduct environmental testing without incurring significant upfront costs or long-term commitments. This facilitates enterprises to choose the specific chamber that suits their testing requirements. Chamber rental services are indispensable for small and medium-sized enterprises, research institutions, and startups that may not have the budget or infrastructure for dedicated testing facilities.

Salt Fog Test Chambers:

Salt fog test chambers, also known as salt spray chambers or salt corrosion chambers, are specifically designed to assess the corrosion resistance of materials and coatings. These chambers create a controlled corrosive environment by spraying a saltwater solution into a sealed chamber, subjecting test specimens to a continuous salt fog. The corrosive action of the salt fog replicates the damaging effects of coastal or marine environments.

Salt fog test chambers are widely used in automotive, marine, aerospace, and coating industries. Manufacturers can evaluate the corrosion resistance of materials such as metals, paints, coatings, and surface treatments. By subjecting these materials to prolonged exposure to salt fog, engineers can determine their performance and durability in harsh environments. Searching for chamber rental services to simulate environmental conditions in your manufacturing or research facility? Find them at Simultech now!

0 notes

Text

Why Should You Invest in a Corrosion Test Chamber?

Have you seen a brown-coloured coating on the metal objects? Well, you must have. That’s corrosion! The exposure of metals to the surrounding environment results in an electrochemical or chemical reaction and ultimately leads to corrosion.

Corrosion can cause significant damage to the machines, buildings, and other utilities. As a result, it can cost you much to get them repaired. However, a point to note here is that the cost is much more than just financial. Therefore, opting for a corrosion test chamber is the need of the hour.

In this blog, you will explore the importance of investing in corrosion test chambers. Let’s dive in!

Effect of Corrosion

Most people have a perception that the metals like steel and iron corrode. However, non-metallic materials like plastic and concrete also suffer the effects of corrosion. Let’s see how corrosion affects different materials.

Metals

Corrosion of metals is quite common. It results in the loss of their mechanical properties and loss of efficiency. It may even lead to pollution owing to the release of particles from corrosion.

On Polymers

Corrosion of the polymers isn’t easy to discover. The material may look the same from the outside. However, it is likely to lose its mechanical strength. Gradually, they will start cracking.

On Structure

Corrosion can also affect brides, buildings, and other critical structures. When corrosion attacks concrete, it can lead to loss of strength, reduced bond strength, fatigue, and limited ductility.

The Cost of Corrosion

No doubt, repairing or replacing corroded structures involves a lot of costs. However, as discussed above, the cost of corrosion is not limited to financial loss. Accidents due to corroded structures can result in loss of life and give rise to safety concerns. To avoid such incidents, investing in corrosion test systems is a smart decision.

The Need for Corrosion Testing

Corrosion tests help check the resistance of materials or coatings to the process of corrosion that triggers naturally due to reaction with moisture, oxygen, gas, and more. It allows comparing and accessing the behaviour of the materials in a corrosive environment. It enables the manufacturers to easily understand how corrosion affects their products. As a result, choosing the right material to avoid the reaction becomes easy.

Applications of Corrosion Test Chambers

The corrosion test chambers find use in a wide range of industries. It includes the following:

Aerospace Sector – Airplanes, aerospace vessels, and space shuttles are manufactured with premium-grade coated metals. The corrosion test chambers help evaluate the corrosion resistance strength and improve the quality of aerospace products.

Automotive Sector – The purchase of automobiles is on the rise in recent times. The test chamber allows automotive companies to test the metal parts and ensure they are corrosion-proof.

Paint Manufacturing Sector – Paints and coatings are used to increase the shelf life of different products. However, it is vital to ensure whether the paint is corrosion-resistant or not. The salt spray chambers help test the corrosion resistance of the coatings and paints.

Conclusion

If you want to test the resistance of materials, corrosion testing can help. Whether you are looking for a corrosion test chamber, temperature chamber, or antenna measurement chamber, Simultech can be your one-stop destination. Moreover, the experts can also offer plant growth chambers at the best prices. Reach out to the experts today!

0 notes

Text

Understanding the Need for Antenna Measurement System

Is wireless connectivity possible without the antennas? Well, the answer is no. For effective communication, antennas are essential. The use of antenna is extensive and widespread. They play a pivotal role in meeting the need for quicker data transfer and rapid downloading. Moreover, they also offer more bandwidth with minimal interference.

But what if antennas are present but fail to work in the desired manner? That is where the need for antenna test systems comes into the picture. These systems measure the antenna performance and provide an idea of whether it possesses the necessary characteristics or not.

In this blog, you will explore the growing demand for the antenna measurement system. Let’s dive in!

Driving Factors of Antenna Measurement System

The antenna measurement market was USD 739 million in 2022. However, it is likely to reach USD 1081.3 million in 2028. (https://www.businessresearchinsights.com/market-reports/antenna-measurement-system-market-103008) Have you ever wondered what is the reason for the growing demand? Consider the key driving factors listed below.

Growth of 5G Initiatives

No doubt, technology is evolving at a rapid pace continuously. One of the latest trends in the tech world is the increase in the use of 5G technology. Today, most of the smartphones and other mobile devices are powered by technology. To ensure optimal performance, using the antenna test chamber is vital. It helps identify potential performance issues, strengthen networks, and increase their reliability. As a result, people will be able to communicate seamlessly and perform their work in a hassle-free manner.

Expansion of IoT

The Internet of Things (IoT) is another trend that is dominating the tech space. With the evolution of IoT, the need for high-speed transmissions has increased a lot. Even in harsh weather conditions, people expect uninterrupted communication and exchange of data. To evaluate the antenna’s efficiency and performance, antenna measurement systems are essential.

Customer Satisfaction

Customers usually expect the antennas to perform well all the time and ensure consistent communication. The success of wireless products depends on how effectively the antennas can meet the needs of the customers. So, ignoring antenna verification and evaluation can have a direct impact on the trust of your customers. On the other hand, the measurement system can provide you with detailed insights and make you confident about the antenna performance.

Optimise the Design of the Antenna

A simple antenna evaluation with the help of antenna measurement equipmentallows for making the necessary changes early in the product cycle. The systems can test and verify the antenna and RF link. Moreover, it can also check other design elements. It enables you to win the trust of the customers and ensure that the specifications and quality of the antennas are compliant with the relevant regulations in the industry.

Conclusion

In modern communication systems, the antennas are a crucial component. The antenna will ultimately enhance the success of the wireless products or cripple them. So, why take a chance? Are you looking for a high-quality and reliable antenna test chamber? If yes, reach out to the professionals of Simultech Australia today and discuss your specific requirements.

0 notes

Text

Top Industries that Need Environmental Chambers

Today, the regulations relating to the quality standards of products are becoming more and more stringent. To ensure the delivery of optimal quality products, industries rely on environmental test chambers. It helps in testing the functionalities of products under various environmental conditions. While the market share of these chambers was USD 880 million in 2022, it is likely to reach 1.2 billion by 2032. (https://www.futuremarketinsights.com/reports/environmental-test-chamber-market) That clearly shows the accelerating demand for different types of environmental test chambers, from altitude chamber to thermal chamber. But the question is which industries require the test chambers the most? Read on to find out the details!

Electronics Sector

Environmental factors like temperature, moisture, and humidity can affect the operations of electronic devices. That is why electronic companies leverage test chambers to check the stability of different components in various environmental conditions. The components you can test in the environmental chambers include circuit boards, touch panels, semiconductors, switches, and ICs.

Defense Sector

The military sector has to strictly follow several requirements and standards while manufacturing the equipment. The core aim is to ensure optimum performance. Therefore, it becomes vital to test military equipment in demanding, hazardous, and harsh conditions. That is where the environmental test chambers prove to be beneficial. They help determine the reliability of the products and enhance the safety of military personnel.

Pharmaceutical Sector

As the quality of pharmaceutical products can have a direct impact on the health and well-being of people, their testing becomes all the more important. The environmental test chambers allow pharmaceutical companies to stimulate different temperature conditions and evaluate the reaction of the products. Along with testing the drugs, the chamber also helps determine the endurance ability of the packaging materials. As a result, it enables companies to stay compliant with legal requirements, regulations, and standards.

Aerospace Sector

Safety, efficiency, and reliability are among the many concerns of the aviation and aerospace industries. The environmental test chambers help in testing the atmospheric conditions and determining the viability of the products.

Automotive Sector

In the automotive industry, small chambers find use to test the small parts. On the other hand, for testing larger parts like mechanisms and assemblies, the walk-in environmental chamber can be used. The test chambers help the automobile industry to improve the quality and lifespan of cars.

Solar Energy

With the rapid depletion of resources, the reliance on renewable energy sources like solar energy is on the rise. The test chambers evaluate solar panels in different environmental conditions. It determines the efficiency and effectiveness of solar panels in humidity, damp heat, and other conditions.

Conclusion

The environmental chambers greatly benefit various sectors and enable them to meet the standards, requirements, and regulations of the industry. Are you in search of an environmental chamber for sale? If yes, Simultech Australia can be the perfect destination for all your test chamber needs. With a complete range of products, they can provide you with the right test chamber suitable for your specific requirements. Reach out to the experts today!

0 notes

Text

Three Intriguing Controlled Chambers and Their Usage

Believe it or not, the industrial biosphere is full of enticing processes. You only see the tinkering part of the machines creating end products flawlessly for the commercialized retail shelves. However, industrial growth is unprecedented and more sophisticated than we might ever see. One of these technological wonders include controlled chambers. From the battery testing chambers to anechoic chambers, the science behind these controlled environments is quite exciting. Want to know more? Well, read on to find out how each controlled chamber works!

Unveiling the Secrets of Anechoic Chambers: The Silent Environments for Acoustic Testing

Anechoic chambers, with their advanced acoustic properties, are designed to eliminate external noise and echoes, creating an environment of near-perfect silence. These chambers are extensively used for acoustic testing and measurements, helping researchers understand and improve the performance of audio equipment, automotive components, and aerospace systems.

Within the anechoic chamber, specialized sound-absorbing materials cover the walls, ceiling, and floor, which absorb sound energy instead of reflecting it. This results in an extremely quiet environment with minimal reverberation, ensuring accurate measurements of sound sources and reducing external noise interference. Anechoic chambers are often equipped with an array of microphones and sophisticated testing equipment, enabling precise analysis of sound waves, frequency responses, and directional characteristics.

The Power of Cyclic Corrosion Chambers: Testing Materials under Realistic Conditions

Cyclic corrosion chambers are invaluable tools for evaluating the durability and corrosion resistance of materials, coatings, and finished products. These chambers replicate real-world environmental conditions by subjecting test specimens to alternating cycles of temperature, humidity, and corrosive agents. This testing methodology helps researchers assess the performance of materials in harsh environments, enabling them to develop more robust and corrosion-resistant products.

Cyclic corrosion chamber rental is an excellent investment because these chambers are capable of simulating a wide range of environmental conditions, including salt spray, humidity, temperature variations, and even acid rain. By subjecting samples to these conditions in a controlled manner, researchers can accelerate the corrosion process, allowing them to evaluate material performance and predict their durability over an extended period. This information is invaluable in industries such as automotive, aerospace, and construction, where exposure to corrosive elements is a significant concern.

Exploring the Benefits of Salt Fog Test Chambers in Corrosion Testing

Salt fog test chambers are specifically designed to assess the corrosion resistance of materials, coatings, and products in aggressive salt-laden environments. These chambers create a controlled atmosphere of salt fog, mimicking the harsh conditions experienced in coastal regions or industrial settings. By subjecting test specimens to prolonged exposure to the salt fog, researchers can accurately determine their resistance to corrosion and evaluate the effectiveness of protective coatings.

These test chambers are widely utilized in industries such as marine, automotive, and electronics, where corrosion prevention is critical. These chambers operate by atomizing a solution of sodium chloride (salt) and dispersing it as a fine fog within the chamber. The salt particles settle on the test specimens, initiating the corrosion process. By monitoring the extent of corrosion and evaluating its effects on the materials, researchers can make informed decisions regarding material selection, coating application, and corrosion mitigation strategies.

Intrigued by the possibilities?

Controlled chambers play a pivotal role in scientific research, engineering development, and industrial quality control. For more information, reach out to our team now!

0 notes

Text

The Science of Simulated Environments: Temperature, Antennas, Corrosion, and Plants

The physical world, as we see around us is immensely fascinating. Billions of scientific phenomena happen around us every day. From rusting of iron to nitrogen fixation in leguminous plants, nature never fails to astound us. Since time immemorial humans have been studying and leveraging natural prowess for their own advantage and the stimulated environments are one such invention that has helped mankind understand their surrounding world better. From controlled temperature chambers to corrosion test chambers, here's how the realms of temperature, antennas, corrosion, and plant growth converge.

In this blog, we will delve into the science behind these simulated environments and explore their diverse applications across various industries. From testing the durability of materials to optimizing wireless communication and advancing agricultural research, the use of controlled environments has revolutionized scientific endeavours. Let's embark on a journey to uncover the secrets behind these simulated ecosystems.

Temperature Chambers: Unlocking Extreme Conditions

Within the realm of product testing and development, temperature chambers play a vital role. These chambers allow researchers and engineers to subject materials and products to extreme temperature conditions, ranging from scorching heat to freezing cold. By simulating these environments, the chambers help assess the performance, reliability, and durability of various objects, such as electronics, automotive components, and aerospace equipment.

Temperature chambers are used across diverse industries, including electronics manufacturing, automotive, and aerospace. For instance, in the electronics industry, components and devices must withstand varying temperature conditions to ensure their functionality and longevity. Temperature chambers enable precise testing, ensuring that these products can endure the harshest environments.

Antenna Measurement Chambers: Enhancing Wireless Communication

In the era of connectivity, antennas play a crucial role in enabling wireless communication. Antenna measurement chambers provide controlled environments to evaluate the performance of antennas, ensuring optimal signal strength, range, and radiation patterns. These chambers eliminate external interferences and allow for accurate measurements of parameters like gain, efficiency, and polarization.

The applications of antenna measurement chambers are far-reaching. From developing high-speed wireless networks to designing satellite communication systems, these chambers enable engineers to fine-tune antenna designs for maximum efficiency. By meticulously testing and analyzing antennas in a controlled environment, the signal quality can be enhanced, leading to improved wireless connectivity across various industries and everyday devices.

Corrosion Test Chambers: Safeguarding Durability

Corrosion poses a significant threat to the durability and lifespan of materials. Corrosion test chambers provide controlled environments that mimic the corrosive conditions materials may encounter in real-world scenarios. By accelerating the corrosion process, researchers can assess the performance of materials and coatings, evaluate their resistance to rust, and develop effective corrosion prevention strategies.

The economic impact of corrosion is substantial. According to a study by NACE International, corrosion costs the global economy over $2.5 trillion annually. Corrosion test chambers help mitigate these costs by enabling researchers to identify the most effective materials and coatings for specific applications, thus ensuring durability and reducing maintenance expenses.

Plant Growth Chambers: Nurturing Agricultural Advancements

In the agriculture and plant research landscape, plant growth chambers are indispensable tools. These chambers create controlled environments that regulate temperature, humidity, lighting, and other parameters to simulate different climates and growing conditions. Plant scientists and researchers utilize these chambers to study plant physiology, optimize growth conditions, conduct experiments, and develop new cultivation techniques.

These chambers offer significant benefits for crop research, enabling scientists to explore plant responses to various environmental factors and stressors. Additionally, these chambers are instrumental in advancing vertical farming, urban agriculture, and sustainable food production practices. By harnessing the power of simulated environments, researchers can enhance crop yields, develop climate-resilient plant varieties, and contribute to food security.

This isn't the end. There's a lot more to discover in the simulated environment ecosystem than what meets the bare eye. Stay tuned for more insightful information!

0 notes

Text

Demystifying Antenna Measurement Systems: A Comprehensive Guide

There's no denying that the world has shrunk. How? Well, everything is connected. From the smartphone ecosystems to satellites, aerospace dynamics, and whatnot, we thrive in an era of technological advancements. Many simple yet ubiquitous inventions have propelled our tech-enabled growth, and one of them is antennas. These simple machines are useful beyond our imagination, but to ensure antennas work efficiently within their expected range, antenna measurement systemsare used by manufacturers.

Antennas play a pivotal role in modern communication systems, enabling wireless connectivity across various industries. However, designing and optimizing antennas require precise measurement techniques. Antenna test systems provide invaluable insights into antenna performance, radiation patterns, efficiency, and other essential parameters. By accurately assessing these characteristics, engineers can refine designs, troubleshoot issues, and meet stringent performance standards.

Components of Antenna Measurement Equipment

Antenna measurement equipment consists of several key components, each serving a specific purpose. These include:

Positioner: The positioner allows controlled movement of the antenna during testing, enabling measurements at different angles and orientations. It ensures accurate data collection by precisely controlling the antenna's position.

RF Source: The RF source generates the radio frequency signal that powers the antenna during measurements. It provides a stable and adjustable signal to simulate real-world conditions.

Antenna Measurement Receiver: The receiver captures and analyzes the signals received from the antenna. It measures various parameters such as gain, radiation patterns, impedance, and polarization.

Measurement Software: This software facilitates data acquisition, processing, and analysis. It provides a user-friendly interface for controlling the measurement process, visualizing results, and generating reports.

Techniques in Antenna Measurement Systems

According to Business Research Insights, the market for Antenna measurement systems is projected to reach USD 1081.3 Bn by 2028.

Source: https://www.businessresearchinsights.com/market-reports/antenna-measurement-system-market-103008

These systems employ various techniques depending on the requirements and available resources. Here are a few commonly used techniques:

Near-Field Measurement: In this technique, the antenna is measured close to the source, allowing a detailed analysis of its characteristics. Near-field measurements are particularly useful for evaluating radiation patterns and detecting performance anomalies.

Far-Field Measurement: Far-field measurements are conducted at a distance from the antenna, simulating real-world operating conditions. These measurements provide insights into the antenna's radiation characteristics and allow evaluation of its performance at different angles.

Compact Range Measurement: Compact range measurement systems or antenna test chamberscreate an environment that mimics far-field conditions in a limited space. They enable accurate measurement of antenna performance without requiring an expansive outdoor test range.

Applications of Antenna Measurement Systems

Antenna measurement systems find applications in various industries, including telecommunications, aerospace, automotive, and research institutions. Here are a few notable applications:

5G Networks: Antenna measurement systems play a crucial role in the development and deployment of 5G networks, ensuring optimal performance, coverage, and compatibility with evolving standards.

Wireless Communication: These systems enable the characterization and testing of antennas used in wireless communication devices, such as smartphones, routers, and IoT devices, ensuring reliable connectivity.

Satellite Communication: Antenna measurement systems are employed to assess the performance of satellite antennas, ensuring accurate data transmission and reception.

Need more information on Antenna Measurement systems and wondering how they can be used? Contact the team at Simultech Australia now!

0 notes

Text

Understanding the Significance of Battery Test Chambers

Technological advancements surround mankind like their kith and kin, and power sources like batteries are no exception. Ranging from smartphones to EVs, our reliance on batteries makes battery test chambers all the way more vital. Batteries undergo rigorous testing before they hit the market. Testing in batteries helps determine at what point they combust, melt, create thermal events and function.

Holistically speaking, a battery test chamber is a controlled environment that allows manufacturers to simulate the conditions that batteries will experience in real-world applications. These chambers can test batteries for different parameters, including temperature, humidity, pressure, and vibration. By subjecting batteries to these conditions, manufacturers can identify weaknesses and opportunities for improvement in their designs. Wondering how a testing chamber or thermal chamber helps the development of new batteries? Read on to find out!

Climate Tests: Battery test chambers can simulate extreme temperatures, both hot and cold, to assess the performance and longevity of batteries in different climates and ensure their suitability for various applications.

Performance and Ageing Tests: These test chambers enable manufacturers to evaluate battery performance over time by subjecting them to continuous cycles of charging and discharging, allowing for accurate assessment of ageing characteristics and performance degradation.

Environmental Simulation Tests: Battery test chambers can replicate environmental conditions such as humidity, pressure, and chemical exposure, allowing manufacturers to evaluate battery performance and reliability in real-world scenarios.

LV-124 Tests: LV-124 is an automotive industry standard for electrical components. The test chambers can ensure that batteries meet the stringent requirements for safety, performance, and reliability in automotive applications.

Vibration Tests: In addition, battery test chambers can also simulate vibrations that batteries may experience during transportation or operation. This allows manufacturers to assess the structural integrity and performance of batteries under various vibration conditions, ensuring their reliability in demanding environments.

Accelerated Testing and Faster Time-to-Market

According to Statista, the global battery testing equipment market was around 473 million USD in 2020, which is projected to reach around 653 million USD in 2027, with a steady growth rate of 4.7% CAGR.

In the past, testing batteries under a wide range of conditions could take months or even years. However, with the use of battery test chambers, manufacturers can test their products under different conditions in a matter of weeks or even days.

By accelerating the testing process, manufacturers can bring new products to market more quickly and gain a competitive advantage. This is especially important in industries, such as electric vehicles, where battery performance is critical to product success.

The bottom line

The performance of a battery is dependent on both external influences as well as internal events. Factors such as overcharging, external heating, deep discharge, external short-circuit, and excessive charging current can damage the battery externally. Whereas, internal forces such as electrode-electrolyte reactions and electrochemical reactions can hamper the battery’s internal performance. An environmental chamber for sale can be immensely helpful in analysing the performance of a battery under different conditions, which allows manufacturers to outline the strengths and weaknesses of their product for better safety and efficiency.

Are you searching for reliable battery testing chambersor altitude chambers? Contact the professionals at Simultech Australia, or visit their website now!

1 note

·

View note