Text

ASME BPE Tubes: Revolutionizing Hygienic Tubing Solutions

ASME BPE Tubes, compliant with the American Society of Mechanical Engineers' Bioprocessing Equipment (ASME BPE) standards, are designed to meet the rigorous requirements of industries where hygiene is paramount. These tubes boast exceptional quality and performance, making them indispensable in critical processes.

Importance of ASME BPE Tubes in Industries

Hygienic Standards

In industries like pharmaceuticals and biotechnology, maintaining hygienic standards is non-negotiable. ASME BPE Tubes adhere to stringent cleanliness criteria, minimizing the risk of contamination and ensuring product purity.

Quality Assurance

ASME BPE Tubes undergo rigorous testing to guarantee consistent quality. Manufacturers adhere to strict guidelines to deliver tubes that meet the highest standards of performance and reliability.

Key Features of ASME BPE Tubes

Surface Finish

ASME BPE Tubes feature ultra-smooth surface finishes, reducing the risk of microbial growth and facilitating thorough cleaning processes.

Material Composition

Crafted from high-grade stainless steel and other corrosion-resistant materials, ASME BPE Tubes offer exceptional durability and longevity, even in harsh operating environments.

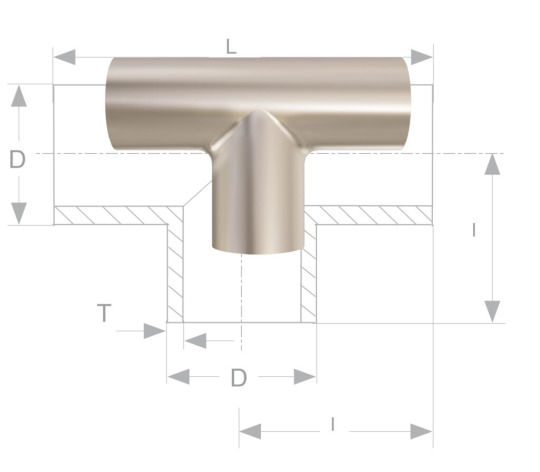

Dimensions and Tolerances

Precise dimensions and tight tolerances ensure seamless integration into existing systems, minimizing installation complexities and optimizing operational efficiency.

Applications of ASME BPE Tubes

ASME BPE Tubes find widespread use across various industries, including:

Pharmaceutical Industry: Critical for drug manufacturing processes where purity is paramount.

Biotechnology: Ideal for sterile fluid transfer and processing applications.

Food and Beverage: Ensures sanitary handling and transportation of consumable products.

Comparison with Traditional Tubing Solutions

Compared to conventional tubing materials like PVC or rubber, ASME BPE Tubes offer superior cleanliness, durability, and corrosion resistance, making them the preferred choice for industries with strict hygiene requirements.

Compliance with ASME BPE Standards

Certification Process

ASME BPE Tubes undergo rigorous certification processes to ensure compliance with industry standards and regulations, providing end-users with confidence in their performance and reliability.

Regulatory Compliance

Manufacturers adhere to ASME BPE guidelines and regulations, ensuring that their products meet the stringent requirements of regulatory bodies, thus enhancing consumer safety and product integrity.

Advantages of ASME BPE Tubes Over Conventional Tubing

Cleanability

The smooth surface finish of ASME BPE Tubes enables effortless cleaning and sterilization, minimizing the risk of bacterial contamination and ensuring product purity.

Durability

Constructed from robust materials, ASME BPE Tubes exhibit exceptional durability, withstanding harsh operating conditions and prolonged use without compromising performance.

Corrosion Resistance

ASME BPE Tubes are inherently resistant to corrosion, making them ideal for applications where exposure to corrosive substances is common, ensuring longevity and reliability.

Considerations for Selecting ASME BPE Tubes

When choosing ASME BPE Tubes, it's essential to consider factors such as budgetary constraints, compatibility with existing systems, and specific application requirements to ensure optimal performance and cost-effectiveness.

Installation and Maintenance Tips

Proper handling procedures and routine inspections are essential for the successful installation and maintenance of ASME BPE Tubes. Following manufacturer guidelines and best practices can prolong tube lifespan and prevent costly downtimes.

Future Trends in ASME BPE Tube Technology

Advancements in manufacturing processes and the emergence of novel materials promise to enhance the performance and versatility of ASME BPE Tubes, opening doors to new applications and opportunities.

Case Studies Highlighting Successful Implementation

Real-world examples demonstrate the efficacy of ASME BPE Tubes in improving operational efficiency, ensuring product quality, and meeting regulatory requirements across diverse industries.

Challenges and Limitations

Despite their numerous benefits, challenges such as cost implications and retrofitting complexities may hinder widespread adoption of ASME BPE Tubes, requiring innovative solutions and collaborative efforts from stakeholders.

Sustainability and Environmental Impact

Addressing concerns related to sustainability and environmental impact, manufacturers are exploring eco-friendly materials and production methods to minimize the carbon footprint of ASME BPE Tubes and promote a greener future.

Conclusion

In conclusion, ASME BPE Tubes represent a paradigm shift in hygienic tubing solutions, offering unmatched cleanliness, durability, and performance across diverse industries. As technology continues to evolve,

1 note

·

View note