Text

Enhance Your Home with HPL Cladding: A Perfect Addition

When it comes to elevating the aesthetics and durability of your home, High-Pressure Laminate (HPL) cladding emerges as a versatile and stylish solution. In this guide, we'll explore why HPL cladding is the perfect addition to your home, offering a blend of functionality, elegance, and longevity that transforms ordinary spaces into extraordinary ones.

Durability That Endures

One of the standout features of HPL cladding is its exceptional durability. Crafted from multiple layers of resin-infused kraft paper and decorative sheets, HPL cladding boasts superior resistance to scratches, impact, moisture, and UV radiation. This durability ensures that your home remains pristine and beautiful for years to come, with minimal maintenance required.

Versatile Design Options

HPL cladding offers a myriad of design options to suit any architectural style or aesthetic preference. Whether you prefer the timeless charm of wood, the sleek sophistication of metal, or the vibrant hues of contemporary patterns, HPL cladding can be customized to fulfill your design vision. With a wide range of colors, textures, and finishes available, you can unleash your creativity and personalize your home to reflect your unique personality.

Enhanced Thermal and Sound Insulation

Beyond its aesthetic appeal, HPL cladding also offers practical benefits such as enhanced thermal and sound insulation. By providing an additional layer of protection against heat transfer and noise pollution, HPL cladding helps create a comfortable and tranquil living environment. Whether you're battling sweltering summers or bustling urban noise, HPL cladding ensures that your home remains a sanctuary of peace and comfort.

Easy Installation and Maintenance

Installing HPL cladding is a hassle-free process that can be completed efficiently and cost-effectively. With its lightweight nature and simple installation techniques, HPL cladding can be applied to various surfaces, including exterior walls, facades, and interior partitions, with ease. Furthermore, its smooth and non-porous surface makes cleaning and maintenance a breeze, allowing you to enjoy your newly clad home without the burden of tedious upkeep.

Eco-Friendly and Sustainable

As environmental consciousness grows, homeowners are increasingly seeking eco-friendly building materials for their homes. HPL cladding ticks all the boxes in terms of sustainability, as it is manufactured using eco-friendly production processes and can be recycled at the end of its lifespan. By choosing HPL cladding for your home, you're not only enhancing its beauty and durability but also reducing its environmental footprint and contributing to a greener future.

Conclusion: Elevate Your Home with HPL Cladding

hIn conclusion, HPL cladding offers a winning combination of durability, versatility, functionality, and sustainability that makes it the perfect addition to any home. Whether you're looking to enhance your home's curb appeal, improve its insulation properties, or simply add a touch of style and sophistication, HPL cladding delivers unparalleled performance and aesthetic value.

0 notes

Text

Demystifying Toughened Glass Prices: Understanding Value and Investment

Toughened glass, with its unparalleled strength, safety features, and aesthetic appeal, has become a popular choice for modern architectural and interior design projects. In this blog, we delve into the factors that influence toughened glass prices, helping you understand the value it offers and why it's worth the investment.

Quality and Certification

The price of toughened glass is often influenced by its quality and certification standards. High-quality toughened glass undergoes rigorous testing to ensure compliance with industry standards for safety, durability, and performance. Look for reputable manufacturers that offer certified toughened glass products, as they guarantee superior quality and reliability, albeit at a higher price point.

Thickness and Size

Toughened glass is available in various thicknesses and sizes to suit different applications and design requirements. Thicker and larger pieces of toughened glass typically command higher prices due to the increased material and manufacturing costs involved. Consider the specific needs of your project and choose the appropriate thickness and size of toughened glass to achieve the desired aesthetic and structural integrity.

Customization and Design Features

Customization options and design features can also influence the price of toughened glass. From tinted and frosted finishes to decorative patterns and etched designs, the addition of custom elements enhances the visual appeal of toughened glass but may come at an additional cost. Discuss your design preferences with your supplier to explore customization options that align with your budget and aesthetic goals.

Installation Complexity

The complexity of installation can impact the overall cost of toughened glass. Projects that require intricate cutting, shaping, and installation techniques may incur higher labor costs, especially if specialized equipment or expertise is needed. Factor in installation expenses when budgeting for toughened glass, and consider working with experienced professionals to ensure a seamless and efficient installation process.

Quantity and Bulk Discounts

Purchasing toughened glass in larger quantities may qualify you for bulk discounts or preferential pricing from suppliers. If you're undertaking a sizable project that requires multiple glass panels or installations, inquire about bulk pricing options to maximize cost savings. Additionally, consider forming long-term relationships with suppliers to access exclusive deals and discounts for future projects.

Value and Long-Term Benefits

While the upfront cost of toughened glass may seem significant, it's essential to consider the long-term value and benefits it offers. Toughened glass is highly durable, resistant to breakage, and requires minimal maintenance, making it a cost-effective investment in the long run. Furthermore, its safety features, such as shatter resistance and heat tolerance, provide peace of mind and enhance the safety and security of your home or commercial space.

Conclusion: Investing Wisely in Toughened Glass

In conclusion, toughened glass prices are influenced by various factors, including quality, thickness, customization, installation complexity, and quantity discounts. While the initial cost of toughened glass may vary, it's essential to prioritize quality and reliability to ensure optimal performance and longevity. By understanding the value it offers and investing wisely in toughened glass, you can enhance the beauty, safety, and functionality of your space for years to come.

0 notes

Text

Elevate Your Space with Decorative Laminates: A Versatile Design Solution

In the realm of interior design, decorative laminates stand out as a versatile and stylish solution for transforming ordinary spaces into extraordinary ones. In this blog, we'll explore the myriad benefits of decorative laminates and how they can elevate the aesthetic appeal and functionality of your home or commercial space.

Endless Design Possibilities

Decorative laminates offer a vast array of design options to suit every taste and style preference. From classic wood grains and natural stone textures to vibrant patterns and bold colors, the design possibilities are virtually limitless. Whether you're aiming for a timeless and elegant look or a contemporary and eclectic vibe, decorative laminates can help you achieve your desired aesthetic vision with ease.

Durable and Low-Maintenance

One of the most significant advantages of decorative laminates is their durability and low-maintenance nature. Made from high-quality materials such as resin-impregnated paper and melamine, laminates are highly resistant to scratches, stains, and fading, making them ideal for high-traffic areas and busy households. With minimal upkeep required, decorative laminates offer a hassle-free solution for maintaining a beautiful and pristine interior environment.

Cost-Effective Alternative

Compared to natural materials such as wood, stone, or metal, decorative laminates are a cost-effective alternative that delivers comparable aesthetics and performance at a fraction of the cost. This makes them an attractive option for budget-conscious homeowners and designers who want to achieve a high-end look without breaking the bank. With decorative laminates, you can create stunning interiors that exude sophistication and style without exceeding your budgetary constraints.

Versatile Application

Decorative laminates can be applied to a wide range of surfaces and substrates, making them incredibly versatile in their application. Whether you're renovating kitchen cabinets, upgrading countertops, or revamping furniture pieces, laminates can be easily installed on various substrates such as plywood, MDF, or particleboard to achieve a seamless and polished finish. Their flexibility and adaptability make them an ideal choice for both residential and commercial projects.

Environmentally Friendly Option

In an era of growing environmental consciousness, decorative laminates offer an eco-friendly option for sustainable interior design. Many laminates are manufactured using recycled materials and eco-friendly production processes, reducing their environmental impact and carbon footprint. Furthermore, laminates are highly energy-efficient to produce compared to natural materials, making them a greener choice for eco-conscious consumers.

Conclusion: Elevate Your Interior with Decorative Laminates

In conclusion, decorative laminates are a versatile, durable, and cost-effective solution for enhancing the beauty and functionality of your interior spaces. With their endless design possibilities, low-maintenance nature, and eco-friendly credentials, laminates offer a compelling choice for homeowners and designers alike. Whether you're embarking on a full-scale renovation or a simple facelift, decorative laminates can help you achieve stunning results that elevate your space to new heights of style and sophistication.

0 notes

Text

Versatility of Door Skins: Elevate Your Entryways with Style

In the world of interior design, every detail matters, and the humble door is no exception. Enter door skins – a versatile and stylish solution for transforming ordinary doors into eye-catching design elements. In this blog, we'll explore the myriad benefits of door skins and how they can breathe new life into your home's entryways.

Introduction to Door Skins

Door skins are thin, decorative panels that are applied to the surface of doors to enhance their appearance and durability. Made from a variety of materials such as wood veneer, laminate, PVC, or metal, door skins offer a cost-effective way to achieve the look of solid wood, metal, or other premium materials without the hefty price tag.

Aesthetic Appeal

One of the primary benefits of door skins is their aesthetic appeal. Available in a wide range of designs, colors, and finishes, door skins can complement any interior style, from traditional to contemporary. Whether you prefer the warmth of wood grain, the sleekness of metallic finishes, or the boldness of patterned designs, there's a door skin to suit your taste and elevate your home's aesthetic.

Durability and Protection

In addition to enhancing the appearance of doors, door skins also provide an extra layer of protection and durability. By covering the surface of the door with a resilient material, such as laminate or PVC, door skins help shield doors from scratches, dents, and other signs of wear and tear. This not only prolongs the lifespan of the door but also reduces the need for frequent maintenance and refinishing.

Easy Installation and Maintenance

Installing door skins is a straightforward process that can be completed quickly and easily, often without the need for specialized tools or expertise. Door skins are typically applied using adhesive or glue, allowing for seamless integration with the existing door surface. Once installed, door skins require minimal maintenance – simply wipe them down with a damp cloth periodically to keep them looking clean and fresh.

Cost-Effective Solution

Compared to replacing entire doors or opting for solid wood or metal doors, door skins offer a cost-effective alternative that delivers comparable aesthetic and functional benefits at a fraction of the cost. This makes them an attractive option for homeowners looking to upgrade their doors without breaking the bank. With door skins, you can achieve the look of luxury without the hefty price tag.

Conclusion: Elevate Your Doors with Door Skins

In conclusion, door skins are a versatile and stylish solution for enhancing the appearance and durability of your home's entryways. With their aesthetic appeal, durability, easy installation, and cost-effectiveness, door skins offer a myriad of benefits that make them a worthwhile investment for any homeowner. Whether you're looking to refresh your interior decor or add a touch of elegance to your home, consider upgrading your doors with door skins and transform your entryways into stunning focal points.

0 notes

Text

Exploring the Advantages of Laminated Safety Glass

In the realm of architectural and automotive glazing, safety is paramount. Enter laminated safety glass – a revolutionary material that offers unparalleled protection, durability, and aesthetic appeal. In this blog, we'll delve into the myriad benefits of laminated safety glass and why it's the ultimate choice for a wide range of applications.

What is Laminated Safety Glass?

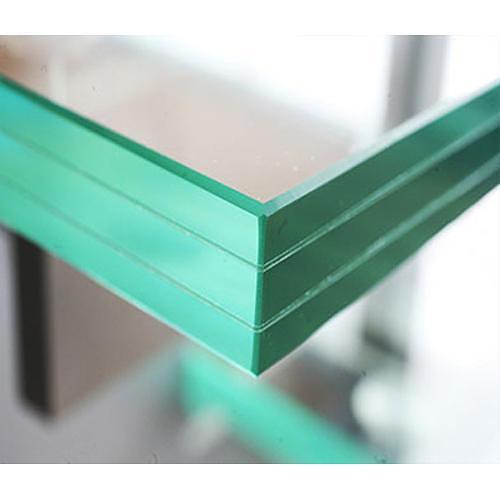

Laminated safety glass is a composite material composed of two or more layers of glass bonded together with an interlayer of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) resin. This construction results in a strong and resilient glass panel that provides enhanced safety and security compared to traditional annealed or tempered glass.

Superior Safety and Security

One of the primary advantages of laminated safety glass is its ability to withstand impact and resist shattering upon breakage. In the event of an impact, the interlayer holds the glass fragments together, preventing them from scattering and reducing the risk of injury from sharp edges or flying debris. This makes laminated safety glass an ideal choice for applications where safety is paramount, such as windows, doors, partitions, and automotive windshields.

Protection Against Forced Entry and Burglary

In addition to its safety benefits, laminated safety glass also provides enhanced security against forced entry and burglary. The tough interlayer acts as a barrier that is difficult to penetrate, making it significantly more challenging for intruders to gain unauthorized access to buildings or vehicles. This added layer of protection offers peace of mind for homeowners, business owners, and vehicle owners alike.

UV Protection and Sound Insulation

Laminated safety glass can also provide protection against harmful ultraviolet (UV) radiation from the sun. By incorporating UV-blocking additives into the interlayer or using tinted glass panels, laminated safety glass helps reduce UV exposure indoors, protecting occupants and furnishings from sun damage and fading. Additionally, the viscoelastic properties of the interlayer contribute to sound damping, making laminated safety glass an effective solution for reducing noise transmission and improving acoustic comfort in interior spaces.

Design Versatility and Aesthetic Appeal

Despite its robust safety and security features, laminated safety glass offers a high degree of design versatility and aesthetic appeal. Available in a wide range of thicknesses, sizes, and finishes, laminated safety glass can be customized to suit virtually any architectural or design requirement. Whether you prefer clear, tinted, frosted, or patterned glass, laminated safety glass can enhance the visual appeal of any space while providing peace of mind.

Conclusion: The Ultimate Choice for Safety and Style

In conclusion, laminated safety glass offers a winning combination of safety, security, durability, and aesthetic appeal that makes it the ultimate choice for a variety of applications. Whether you're looking to enhance the safety and security of your home, office, or vehicle, or simply add a touch of style to your space, laminated safety glass delivers unmatched performance and peace of mind. Consider incorporating laminated safety glass into your next project and experience the benefits firsthand.

0 notes

Text

How to Install HPL Cladding for Maximum Durability

High-Pressure Laminate (HPL) cladding is a popular choice for exterior and interior wall cladding due to its durability, aesthetic appeal, and low maintenance requirements. Proper installation is crucial to ensure the maximum durability and longevity of HPL cladding. Here's a step-by-step guide on how to install HPL cladding effectively:

Prepare the Surface:

Ensure that the surface where the HPL panels will be installed is clean, smooth, dry, and free from dust, dirt, grease, and other contaminants.

Repair any cracks, uneven surfaces, or structural issues in the substrate before proceeding with the installation.

Measure and Cut the Panels:

Measure the dimensions of the area where the HPL panels will be installed, accounting for overlaps, corners, and edges.

Use a circular saw or a jigsaw with a fine-toothed blade to cut the HPL panels to the required size and shape, following the manufacturer's guidelines for cutting HPL.

Apply Adhesive:

Apply a high-quality adhesive recommended by the HPL manufacturer evenly on the backside of the HPL panels using a trowel or roller.

Ensure that the adhesive covers the entire surface area of the panel, especially the edges and corners, to achieve a strong bond with the substrate.

Position and Install the Panels:

Carefully position the HPL panels onto the prepared surface, starting from one corner or edge and working systematically across the area.

Use spacers or temporary supports to maintain consistent gaps and alignments between panels for a uniform appearance.

Press firmly on the panels to ensure proper adhesion and remove any air bubbles or excess adhesive using a rubber mallet or roller.

Secure the Panels:

Once the panels are in place, secure them further by using mechanical fixings such as screws or rivets at regular intervals along the edges and corners.

Ensure that the fixings penetrate both the HPL panel and the substrate adequately to provide strong support and prevent panel movement or detachment.

Finish the Edges:

Use edge trims, profiles, or corner pieces specifically designed for HPL cladding to finish the exposed edges and corners neatly and protect them from moisture and damage.

Secure the edge trims or profiles using appropriate adhesives or mechanical fixings as per the manufacturer's instructions.

Seal Joints and Gaps:

Seal any joints, gaps, or seams between HPL panels using a high-quality silicone sealant recommended for exterior applications.

Apply the sealant along the edges, corners, and intersections to prevent water ingress, moisture buildup, and air leakage.

Inspect and Maintain:

After installation, inspect the HPL cladding carefully for any defects, damages, or areas that require touch-ups.

Regularly clean the HPL panels using mild detergent and water, and avoid abrasive cleaners or harsh chemicals that may damage the surface finish.

By following these steps and adhering to the manufacturer's guidelines and best practices, you can install HPL cladding effectively to achieve maximum durability, weather resistance, and aesthetic appeal for your building's exterior or interior walls.

0 notes

Text

Exploring the Impact of Toughened Glass Prices

Toughened glass, also known as tempered glass, has become a popular choice for various applications due to its strength, safety features, and aesthetic appeal. However, the prices of toughened glass can fluctuate based on several factors, and understanding these impacts is crucial for consumers and businesses. Let's explore the factors that influence toughened glass prices and their broader impact:

Raw Material Costs:

The primary material used in toughened glass production is soda-lime glass, which is derived from silica sand, soda ash, and limestone. Fluctuations in the prices of these raw materials can directly impact the cost of producing toughened glass.

Energy Costs:

The manufacturing process of toughened glass involves heating the glass to high temperatures and then rapidly cooling it to induce strength. Energy costs, including electricity and fuel for heating furnaces, contribute significantly to the overall production costs and, consequently, the prices of toughened glass.

Market Demand and Supply:

Like any commodity, the demand and supply dynamics in the toughened glass market influence prices. High demand relative to supply can lead to price increases, especially during periods of construction booms or increased demand from sectors like automotive and electronics.

Technological Advancements:

Technological advancements in toughened glass production, such as improvements in tempering processes, coating technologies, and automation, can impact prices. While innovations may lead to cost savings, initial investments in new technologies can also influence pricing.

Quality Standards and Certifications:

Meeting stringent quality standards and certifications, such as those for safety glass or energy efficiency, may require additional processes, testing, and compliance measures, which can add to the production costs and, consequently, the prices of toughened glass.

Global Economic Factors:

Economic conditions, currency fluctuations, trade policies, and geopolitical factors on a global scale can indirectly influence toughened glass prices. Changes in exchange rates, tariffs, or trade agreements can impact the cost of imported raw materials or finished products.

Environmental Regulations:

Compliance with environmental regulations, such as waste management, emissions control, and sustainable practices, may entail investments in eco-friendly technologies or processes. These initiatives can contribute to production costs and potentially affect prices.

Competition and Market Trends:

Competitive pressures within the glass industry, market trends, and pricing strategies of manufacturers and suppliers also play a role in determining toughened glass prices. Price wars, promotional offers, and supply chain efficiencies can impact pricing dynamics.

Impact on Consumers and Businesses:

Construction Sector: Fluctuations in toughened glass prices can influence construction costs for residential, commercial, and infrastructure projects. Builders, architects, and developers may need to adjust project budgets based on glass price changes.

Automotive and Electronics Industries: Manufacturers in these sectors rely on toughened glass for applications such as vehicle windows, smartphone screens, and display panels. Price variations can affect production costs and consumer pricing for these products.

Homeowners and Renovators: Consumers planning home renovations or upgrades that involve toughened glass, such as shower enclosures, windows, doors, or partitions, may need to consider price fluctuations when budgeting for these projects.

Retail and Distribution: Retailers and distributors of toughened glass products may experience margin pressures or pricing challenges due to market volatility and competitive pricing strategies within the industry.

In conclusion, toughened glass prices are influenced by a combination of factors ranging from raw material costs and energy expenses to market dynamics, technological advancements, quality standards, economic conditions, and regulatory requirements. Understanding these impacts can help consumers, businesses, and industry stakeholders make informed decisions, manage costs effectively, and navigate the dynamic landscape of the toughened glass market.

0 notes

Text

Achieving a Luxurious Look on a Budget with Decorative Laminates

Creating a luxurious and stylish interior doesn't always have to come with a hefty price tag. Decorative laminates offer an excellent solution for achieving a high-end look while staying within budget constraints. These versatile materials are available in a wide range of designs, textures, and finishes, making them ideal for elevating the aesthetic appeal of your space without breaking the bank. Let's explore how you can achieve a luxurious look on a budget with decorative laminates:

Selection of Premium Designs:

Decorative laminates come in a myriad of designs that mimic the look of natural materials such as wood, stone, marble, and metal. Opting for premium designs that emulate expensive materials can instantly elevate the luxuriousness of your space at a fraction of the cost.

Texture and Finish Variety:

Laminates offer diverse texture options, including matte, glossy, textured, embossed, and even 3D effects. Choose a texture and finish that complements your desired aesthetic, whether it's a sleek and modern gloss or a rustic textured surface.

Accent Walls and Focal Points:

Use decorative laminates to create accent walls or focal points in your space. Covering a single wall with a striking laminate design can add depth, visual interest, and a touch of luxury without the need for expensive materials or extensive renovations.

Cabinetry and Furniture Makeovers:

Transform plain cabinetry, furniture, and fixtures with decorative laminates. Applying laminates to cabinet doors, countertops, tabletops, or even furniture surfaces can give them a luxurious and customized appearance while keeping costs under control.

Flooring Solutions:

While traditional flooring materials like hardwood or marble can be expensive, laminates offer cost-effective alternatives that replicate the look of these materials. Opt for laminate flooring with realistic wood grain or stone patterns to achieve a luxurious flooring finish on a budget.

Customization and Personalization:

Decorative laminates can be customized to suit your specific design preferences. Consider incorporating custom patterns, colors, or graphics into laminates for unique and personalized elements that add a luxurious touch to your interiors.

Durability and Maintenance:

Apart from their aesthetic appeal, laminates offer durability, scratch resistance, moisture resistance, and easy maintenance. Their long-lasting properties make them a practical choice for high-traffic areas and spaces that require low upkeep.

Layering and Mixing Materials:

Experiment with layering laminates with other materials such as glass, metal, or mirrors to create dynamic and sophisticated designs. Mixing different textures and finishes can enhance visual interest and create a multi-dimensional luxurious look.

Lighting and Accessories:

Enhance the luxurious ambiance of your space with strategic lighting and stylish accessories. Proper lighting can highlight laminate surfaces, while chic accessories such as decorative mirrors, artwork, rugs, and furnishings can complement the overall luxurious theme.

Professional Installation:

For best results and a seamless finish, consider hiring professional installers experienced in working with decorative laminates. Proper installation ensures that laminates are applied correctly, minimizing the risk of bubbles, wrinkles, or uneven surfaces.

In conclusion, decorative laminates offer a cost-effective and versatile way to achieve a luxurious look in your home or commercial space. By carefully selecting premium designs, utilizing diverse textures and finishes, focusing on key areas like accent walls and cabinetry, considering flooring options, incorporating customization, leveraging durability and maintenance benefits, exploring layering and mixing materials, enhancing with lighting and accessories, and opting for professional installation, you can create a stunning and upscale interior while staying within your budget constraints.

0 notes

Text

Door Skin A Comprehensive Overview for Homeowners

As a homeowner, selecting the right door materials is crucial for enhancing the aesthetic appeal, functionality, and durability of your home's interiors. Door skin, also known as door facing or door veneer, is a popular choice due to its versatility, cost-effectiveness, and aesthetic options. In this comprehensive overview, we'll delve into the features, benefits, types, installation, maintenance, and design possibilities of door skin for homeowners.

Features of Door Skin:

Material Composition: Door skin is typically made from thin sheets of materials such as wood veneer, PVC (Polyvinyl Chloride), HDF (High-Density Fiberboard), MDF (Medium-Density Fiberboard), or metal. These materials offer varying degrees of durability, finish options, and customization possibilities.

Durability: High-quality door skins are durable, scratch-resistant, moisture-resistant, and easy to clean, making them suitable for both interior and exterior doors.

Design Options: Door skins come in a wide range of designs, colors, textures, and finishes to suit different interior styles, from classic and traditional to modern and contemporary.

Cost-Effective: Compared to solid wood or metal doors, door skins are more affordable while offering similar aesthetic appeal and functionality.

Benefits of Door Skin for Homeowners:

Aesthetic Appeal: Door skins enhance the visual appeal of doors with their decorative patterns, wood grain finishes, textured surfaces, and vibrant colors, adding a touch of elegance to your home.

Versatility: Door skins can be used for various types of doors, including interior doors, exterior doors, wardrobe doors, cabinet doors, and more, providing design consistency throughout your home.

Customization: Homeowners can customize door skins by choosing specific designs, colors, textures, and finishes that complement their interior décor and personal preferences.

Easy Installation: Installing door skins is relatively straightforward and can be done by professionals or DIY enthusiasts using adhesives, screws, or nails to secure the skin onto the door frame.

Low Maintenance: Door skins require minimal maintenance, occasional cleaning with a damp cloth or mild detergent, and routine inspection for any damages or wear and tear.

Types of Door Skin:

Wood Veneer Door Skin: Made from thin slices of natural wood, wood veneer door skins offer a classic and authentic wood grain appearance, available in various wood species such as oak, walnut, maple, cherry, and more.

PVC Door Skin: PVC door skins are durable, moisture-resistant, and come in a wide range of colors, patterns, and textures, including matte, glossy, embossed, and printed designs.

HDF/MDF Door Skin: High-Density Fiberboard (HDF) and Medium-Density Fiberboard (MDF) door skins are engineered wood products that offer versatility, durability, and a smooth surface for painting, laminating, or veneering.

Metal Door Skin: Metal door skins, such as stainless steel or aluminum, provide a sleek and modern appearance, ideal for contemporary interiors or commercial applications.

Installation Process:

Prepare the Door: Ensure that the existing door frame is clean, dry, and free from any defects or damage. Remove old paint, varnish, or adhesive residues as needed.

Cut the Door Skin: Measure the dimensions of the door frame and cut the door skin to fit using a sharp utility knife, saw, or scissors, leaving allowances for edges and corners.

Apply Adhesive: Apply a suitable adhesive (recommended by the manufacturer) evenly on the backside of the door skin, covering the entire surface area but avoiding excessive application to prevent seepage.

Attach the Door Skin: Carefully position the door skin onto the door frame, starting from one edge and smoothing out any air bubbles or wrinkles as you go along. Use a roller or flat tool to press the door skin firmly onto the surface.

Trim and Finish: Trim any excess door skin material using a sharp blade or router, and finish the edges with edge banding, trim pieces, or molding for a clean and seamless appearance.

Allow for Drying and Curing: Allow the adhesive to dry and cure as per the manufacturer's instructions before using the door. Avoid excessive moisture exposure during this period to ensure proper bonding.

Maintenance Tips for Door Skin:

Regular Cleaning: Wipe the door skin surface regularly with a soft cloth or sponge dampened with mild detergent and water to remove dust, dirt, or stains.

Avoid Harsh Chemicals: Avoid using abrasive cleaners, solvents, bleach, or harsh chemicals on the door skin as they may damage the finish or surface texture.

Protective Measures: Use door mats, rugs, or protective pads near doors to prevent scratches, dents, or impact damage from heavy objects or footwear.

Inspect for Damage: Periodically inspect the door skin for any signs of damage, peeling, or delamination, and address any issues promptly to prevent further deterioration.

Design Possibilities with Door Skin:

Wood-Look Finishes: Achieve the warmth and elegance of natural wood with wood veneer door skins, available in various wood species and finishes like oak, walnut, cherry, mahogany, and more.

Contemporary Patterns: Explore modern and contemporary designs with PVC door skins featuring geometric patterns, abstract motifs, floral prints, metallic finishes, or minimalist textures.

Textured Surfaces: Add depth and tactile appeal to your doors with textured door skins, including embossed patterns, brushed textures, leather-like surfaces, or stone-inspired finishes.

Customized Graphics: Personalize your doors with custom graphics, artwork, logos, or branding elements printed on PVC or metal door skins for a unique and distinctive look.

Color Options: Choose from a spectrum of colors and shades to match your interior color scheme, create contrasts, or make a bold statement with vibrant hues or subtle neutrals.

Conclusion:

Door skin offers homeowners a cost-effective, versatile, and stylish solution for enhancing the appearance of doors throughout their homes. With a wide range of materials, designs, textures, finishes, and customization options available, door skins allow homeowners to achieve luxurious aesthetics, durability, and functionality while staying within budget constraints. Whether you prefer the classic charm of wood veneer, the contemporary appeal of PVC patterns, the durability of metal surfaces, or customized graphics, door skin provides endless design possibilities to elevate your home's interior décor.

0 notes

Text

Enhancing Security with Laminated Safety Glass Solutions

In an era where safety and security are paramount concerns for homeowners and businesses alike, laminated safety glass has emerged as a reliable solution. Combining strength, durability, and resistance to impact, laminated safety glass offers enhanced protection against forced entry, accidents, and natural disasters. In this blog post, we'll explore how laminated safety glass solutions can effectively enhance security in various applications.

Understanding Laminated Safety Glass:

Laminated safety glass is a type of safety glass that consists of two or more layers of glass bonded together with an interlayer of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) resin. During the manufacturing process, the layers are fused together under heat and pressure, creating a strong and durable composite material.

Key Features and Benefits:

Impact Resistance: One of the primary benefits of laminated safety glass is its ability to withstand impact and blunt force. In the event of a breakage, the interlayer holds the glass fragments together, preventing shattering and reducing the risk of injury from sharp glass edges.

Burglary Deterrence: Laminated safety glass acts as a deterrent against forced entry and burglary attempts. Its tough construction makes it difficult for intruders to break through, providing an additional layer of security for homes, offices, retail stores, and other properties.

Sound Insulation: In addition to security benefits, laminated safety glass offers sound insulation properties, reducing noise transmission and creating a quieter and more comfortable indoor environment.

UV Protection: Some laminated safety glass products are designed with built-in UV protection, blocking harmful ultraviolet rays and helping to prevent fading of interior furnishings, artwork, and flooring.

Weather Resistance: Laminated safety glass is also highly resistant to weather elements such as wind, rain, and hail. It provides added protection during storms, hurricanes, and severe weather conditions, safeguarding windows, doors, and building facades.

Applications of Laminated Safety Glass for Security:

Windows and Doors: Install laminated safety glass for windows and doors to enhance security and protect against break-ins. Its impact-resistant properties make it a preferred choice for residential, commercial, and industrial applications.

Storefronts and Display Cases: Retail stores, banks, jewelry shops, and museums can benefit from laminated safety glass in storefronts, display cases, and partitions, deterring theft and vandalism while maintaining visibility and aesthetics.

Skylights and Canopies: Use laminated safety glass for skylights, canopies, and overhead glazing to ensure safety, durability, and weather resistance while allowing natural light to enter interior spaces.

Automotive Glass: Laminated safety glass is widely used in automotive applications, including windshields, side windows, and rear windows, providing protection against impact and improving passenger safety.

Public Buildings and Institutions: Government buildings, schools, hospitals, airports, and other public institutions can benefit from laminated safety glass installations for enhanced security and protection of occupants.

Installation and Maintenance Tips:

Professional Installation: Ensure that laminated safety glass is installed by experienced professionals using proper techniques and equipment to ensure a secure and watertight fit.

Regular Inspections: Conduct regular inspections of laminated safety glass installations to check for any signs of damage, delamination, or wear. Address any issues promptly to maintain optimal security and performance.

Cleaning and Maintenance: Clean laminated safety glass surfaces regularly using a mild detergent and water solution, avoiding abrasive cleaners or harsh chemicals that may damage the glass or interlayer.

Avoid Impact: While laminated safety glass is designed to withstand impact, avoid subjecting it to excessive force or impact that could compromise its integrity and effectiveness.

Conclusion:

Laminated safety glass solutions offer a robust and reliable way to enhance security in residential, commercial, automotive, and public environments. With its impact resistance, burglary deterrence, sound insulation, UV protection, and weather resistance properties, laminated safety glass provides peace of mind and protection against various threats and hazards. By choosing laminated safety glass for windows, doors, storefronts, skylights, automotive applications, and other installations, homeowners and businesses can create safer and more secure environments for occupants and assets.

0 notes

Text

Who Should Install Laminated Safety Glass?

Laminated safety glass has become a staple in various industries, ranging from automotive to construction. Its unique properties make it an essential component for ensuring safety and security in different applications. However, the question arises: who should be responsible for installing laminated safety glass? In this blog post, we'll delve into the specifics of this question and provide insights into the ideal candidates for installing laminated safety glass.

Automotive Industry Professionals:

In the automotive sector, laminated safety glass is a critical component of vehicle safety. Professionals such as auto mechanics, technicians, and glass installers are well-versed in the intricacies of installing laminated safety glass in automobiles.

These professionals have the necessary skills and knowledge to handle the delicate process of removing old glass, preparing surfaces, and securely installing laminated safety glass in vehicles.

Construction Contractors and Glaziers:

In the realm of construction, laminated safety glass is commonly used for windows, doors, and skylights in both residential and commercial buildings. Contractors and glaziers play a vital role in installing these glass components.

These professionals have the expertise to assess structural requirements, handle glass safely, and ensure proper installation according to building codes and regulations.

Architects and Designers:

Architects and designers are instrumental in specifying the use of laminated safety glass in building projects. Their knowledge of building aesthetics, functionality, and safety standards allows them to incorporate laminated safety glass seamlessly into architectural designs.

While architects and designers may not physically install the glass themselves, their input is crucial in determining where and how laminated safety glass should be utilized within a building structure.

Specialized Glass Installation Companies:

There are companies dedicated specifically to the installation of various types of glass, including laminated safety glass. These specialized firms employ skilled technicians who have undergone specific training for handling and installing laminated safety glass.

Opting for such companies ensures that the installation process is carried out with precision and adherence to industry standards.

DIY Enthusiasts (with Proper Training):

While some individuals may consider installing laminated safety glass on their own, it's crucial to emphasize that this task requires specialized skills and knowledge.

DIY enthusiasts who have undergone proper training and have experience in glasswork may be able to undertake small-scale installations under supervision. However, complex projects should be left to trained professionals to ensure safety and quality.

In conclusion, the installation of laminated safety glass requires expertise and precision to ensure its effectiveness in providing safety and security. Whether in the automotive industry, construction sector, or architectural realm, professionals with the requisite skills and knowledge are best suited for installing laminated safety glass. By entrusting the task to qualified individuals or companies, you can ensure that the installation process is carried out efficiently and effectively, meeting the highest standards of safety and quality.

0 notes

Text

How to Clean and Maintain Your Biggest Glass

Biggest glass surfaces, whether they're in the form of windows, doors, or architectural features, add elegance and light to any space. However, keeping them clean and well-maintained can sometimes be a daunting task. In this blog post, we'll explore some effective tips for cleaning and maintaining your biggest glass surfaces, ensuring they remain pristine and beautiful for years to come.

Gather Your Supplies:

Before you begin cleaning, gather all the necessary supplies. This typically includes a non-abrasive glass cleaner, lint-free cloths or microfiber towels, a squeegee, a bucket of warm water, and mild dish soap.

Choose the Right Cleaner:

Opt for a glass cleaner specifically formulated for large surfaces. Avoid cleaners containing ammonia or abrasive ingredients, as they can damage the glass over time. Alternatively, you can create your own cleaning solution using equal parts water and vinegar.

Remove Dust and Debris:

Start by gently wiping the glass surface with a dry microfiber cloth to remove any dust, dirt, or loose debris. This prevents scratching the glass during the cleaning process.

Clean with Care:

Spray the glass cleaner evenly across the surface and use a lint-free cloth or microfiber towel to wipe the glass in a circular motion. For large areas, consider using a squeegee to ensure an even application and thorough cleaning.

Pay special attention to any stubborn stains or spots. If necessary, apply a small amount of cleaner directly to the affected area and gently scrub with a soft-bristled brush or sponge.

Rinse Thoroughly:

After cleaning, rinse the glass surface thoroughly with clean water to remove any remaining residue or cleaner. Use a squeegee or clean cloth to wipe away excess water and prevent streaking.

Dry Completely:

To prevent water spots and streaks, dry the glass surface completely using a clean, dry microfiber towel or squeegee. Ensure that no moisture is left behind, especially along the edges and corners.

Regular Maintenance:

Incorporate regular maintenance into your cleaning routine to keep your large glass surfaces looking their best. This may include wiping down the glass with a damp cloth once a week to remove dust and fingerprints.

Inspect for Damage:

Periodically inspect your glass surfaces for any signs of damage, such as scratches, chips, or cracks. Addressing these issues promptly can prevent further damage and maintain the integrity of the glass.

Protective Measures:

Consider applying a protective coating or film to your glass surfaces to help repel dirt, water, and fingerprints. These protective measures can prolong the life of your glass and make cleaning easier.

By following these tips for cleaning and maintaining your biggest glass Lucknow surfaces, you can ensure that they remain sparkling clean and in top condition for years to come. With regular care and attention, your glass windows, doors, and architectural features will continue to enhance the beauty and functionality of your space.

0 notes