Text

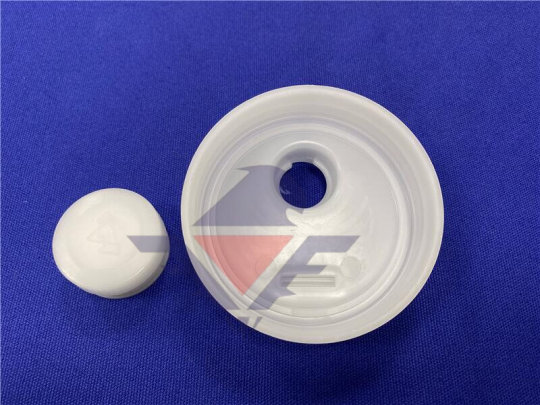

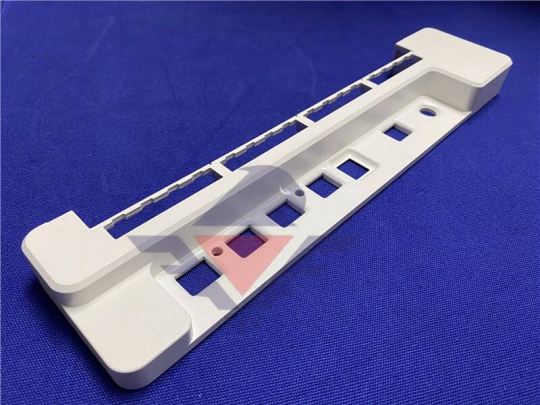

Plastic Machining

https://www.ljzcncmachining.com/plastic-machining/

In industrial design, in addition to commonly used metals, engineers also favor engineering-grade plastics. These plastic machined parts have favorite characteristics such as optical transparency, wear resistance, and corrosion resistance. LJZ has been providing professional plastic machining, surface finishes, and assembly services for a long time, our CNC plastic parts not only ensure performance but also attract customers in perfect appearance.

Surface Finishes In Machined Plastic Parts

We are not only good at surface treatment of metal products but also professional in surface finishes of CNC plastic machined parts: painting, silk screen printing, powder coating, electroplating, laser engraving, polished transparent, fumigated transparent, dyeing, etc.

Engineering Grade Plastics That We Mostly Work With

The most commonly machined engineering plastics are ABS, POM, PTFE, PEEK, Nylon, Acrylic, polycarbonate etc. These CNC plastics have long been used in electronics, instrument & equipment, precision machinery, aerospace, medical and other fields.

Here are some of these engineering plastics for your reference, but NOT limited.

Plastic

Color

Characteristics

Application

ABS

Natural

Black

Transparent

High mechanical strength

High rigidity

High surface hardness

High dimensional stability

Quick prototype

Electronics, electrical appliances,

Plastic housings and components

PMMA

(Acrylic)

Transparent

High mechanical strength

Can be polished and transparent

Good insulation

Aviation

Electronics

Optics manifold

Medical components

POM

Black

White

High mechanical strength

High compressive strength

Wear resistance

Good machinability

Precision mechanical parts

Water-resistant parts

Bearings, gears, impellers, bushing, gaskets

PTFE

White

High-temperature resistance

Wear and corrosion resistant

Good flame retardancy

Oil & gas

Instruments

Mechanical components

PEEK

Yellow

Black

Natural

High rigidity and hardness

preservative

High-temperature resistance

UV and radiation resistance

Aerospace

Medical treatment

Electronic

Mechanical

0 notes

Text

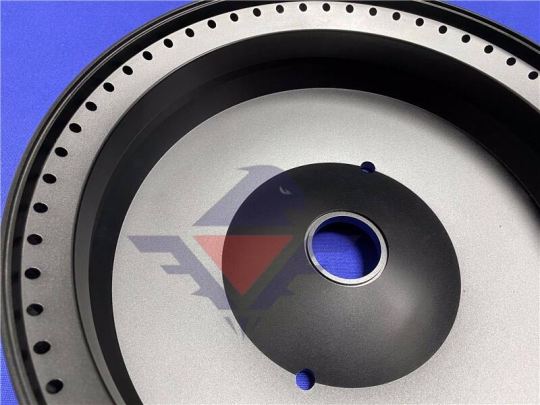

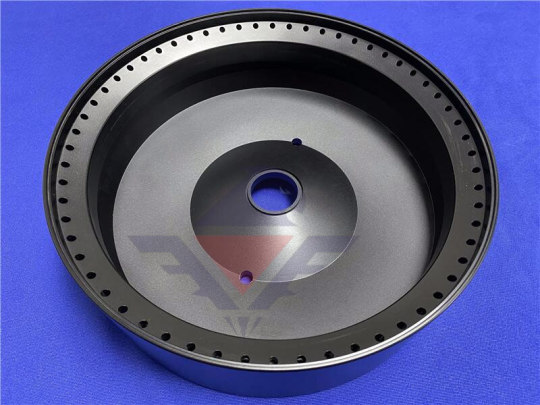

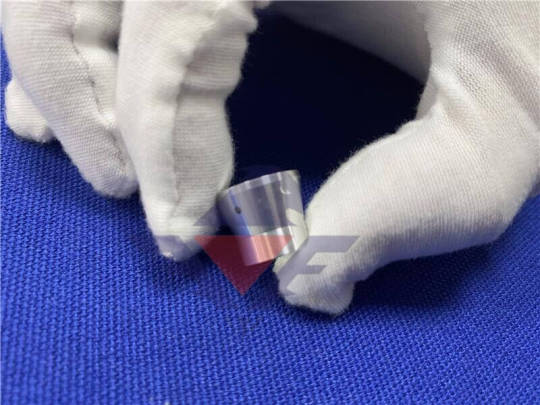

Optical Machining and Molding

https://www.ljzcncmachining.com/optical-machining-molding.html

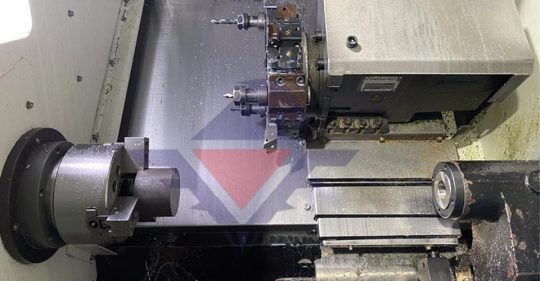

Optical equipment has very high requirements for machined parts accuracy, roughness, and assembly. Therefore, project engineers prefer manufacturers with high-precision CNC machines, testing equipment, and rich experience for optical machining. LJZ has abundant experience, imported CNC machines, high-precision testing equipments, professional production team, which make us the preferred supplier for optical companies.

Materials Used In Optical CNC Machining

LJZ has been providing fast prototyping and optical CNC machining services for large optical companies for a long time. We have machined a lot of optical components or parts and have comprehensive understanding of materials. Common used materials for optical equipment are: aluminum, stainless steel, magnesium, titanium, zinc, nickel, copper, plastics etc.

Surface Finishes On CNC Optical Components

To improve your optical parts' performance and appearance, or just the icing on the cake, LJZ also provides you the matching surface treatments such as anodizing, electroplating, sandblasting, polishing, engraving, silk screen, painting and so on.

Optical Components and Parts That We Machine

LJZ CNC machined optical parts or equipment mainly includes:

Microscopes accessories

Telescopes accessories

Cameras accessories

Optical Instrument frame, enclosure;

Mirror holder

Eyepiece tube

Rotary objective tube

Adjustment rod

Other optical instrument parts

For more details, contact us now!

0 notes

Text

Medical Machining and Molding

https://www.ljzcncmachining.com/medical-machining-molding/

Medical device or equipment requires high precision dimensions, real materials, and specified surface treatments. LJZ provides CNC machining services for medical device or machined products for a long time. With rich experience in machining and assembly for medical application, our excellent international team is helping more and more medical companies by providing rapid prototyping, small batch production and sovling delivery, quality, assembly and other problems.

Our CNC Medical Services

Our medical CNC machining capabilities

For ease of use, engineers often design sophisticated medical products with different shapes, which cannot be completed by CNC milling and turning alone. LJZ is equipped with the most complete processing technology, such as: Turning and milling, internal and external grinding, surface grinding, WEDM/EDM, Swiss turning, plastic injection molding and so on.

Surface treatment of medical device machining

Since medical device products is in close contact with the human body, the safest and environmentally friendly surface finishes are required. Common surface treatments that we work with are includeing anodizing, electroplating, passivation, sandblasting, laser carving, painting, and so on.

Commonly used materials for medical CNC machining

To produce an ideal precision parts with high quality, the suitable, and high-grade raw materials are required. Therefore, LJZ is very strict in the selection of materials for medical products, all input materials must be tested by spectrum analyzer. Our commonly used materials are including aluminum, titanium, stainless steel, PMMA, PEEK, PEI, and so on.

Medical Device Development

In addition to precision CNC machining and high-volume Swiss machining service. LJZ also provides a series of services for medical equipment R&D and manufacturing, which includes medical prototype development, small-batch rapid tooling or low volume CNC manufacturing, and high volume medical injection molding.

Our professional engineering team makes key design adjustments through design for manufacturability (DFM) feedback for each quotation, thereby saving development time and costs. Choose from hundreds of medical grade plastics, metals, and elastic materials. We are able to finish prototype parts or small batch production in one day as soon as possible to simplify your supply chain before and after the product is put on the market.

Clean Room Injection Molding

In order to meet the stringent standards of customers in the medical industry, we have obtained ISO13485, built a clean room and trained professional medical injection molding personnel, which means that we are qualified to engage in the R&D, processing and production of medical parts and equipment. Our medical molding manufacturing expert team can help you quickly transform FDA Class I and Class II devices or non-structural components from prototypes to production.

Top-Tier CNC Machined Medical Parts

The recognition of our healthcare customers comes from our professional services and trustworthy quality assurance,we are proud of this.

ISO 9001 and 13485 standards.

Rapid prototyping, precision CNC Swiss machining and medical injection molding solutions for medical clients.

Strict compliance with PPAP.

Strict production control, quality control and excellent after-sales service.

Need engineering support for medical projects? Start with a free quote today!

0 notes

Text

Materials

https://www.ljzcncmachining.com/materials/

Titanium

Titanium alloy has high strength and low density, good mechanical properties, good toughness, and corrosion resistance. So titanium parts are widely used in medical, aviation, aerospace, chemical, metallurgy, and other industries.

Aluminum

Aluminum alloy materials are favored by engineers in various industries, and it is a commonly used material in CNC machining due to its high machinability.

Stainless Steel

Stainless steel has become one of the materials often selected by engineers due to its corrosion resistance and wear resistance.

Brass

Copper or brass has excellent electrical and conductivity, ductility, corrosion resistance, wear-resistance, and other unique properties, which make brass or copper machining parts are widely used in power, electronics, energy, machinery, and other fields.

Plastic

In industrial design, in addition to commonly used metals, engineers also favor engineering-grade plastics. These plastic machined parts have favorite characteristics such as optical transparency, wear resistance, and corrosion resistance.

0 notes

Text

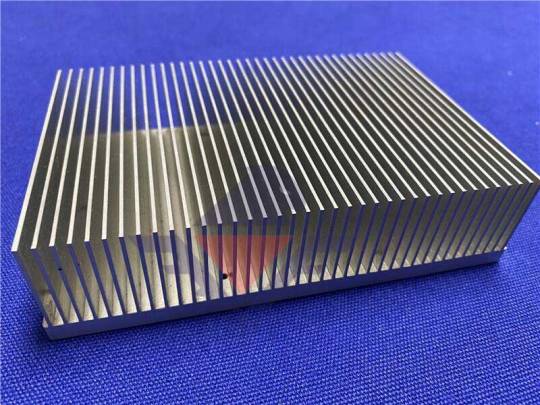

Consumer Products Machining and Molding

https://www.ljzcncmachining.com/consumer-products-machining-molding/

LJZ continues to improve our production capabilities and machining level to meet the huge demand for high-quality and cost-effective components or parts in global electronic products market. Our excellent delivery record and highly competitive prices make electronics manufacturers believe in us, our professional machining personnel recognize the tolerance and efficiency required by electronics industry.

Materials and Surface Finishes of Electronic Machining

The surfaces of electronic appliances are diverse. Some are for anti-corrosion and oxidation, and some are for aesthetics. Design engineers will choose the appropriate surface finishes to meet customized needs. LJZ is proficient in at least 21 kinds of surface treatments such as: Painting, dyeing, polishing, powder coating, silk screen printing, laser etching, anodizing, electroplating, etc.

The materials of electronic machining that we often work with are aluminum, zinc, magnesium, copper, brass, ABS, PC, PET, PMMA, POM, PEEK, etc.

Application of Our Consumer Electronic Parts

Relying on our advanced CNC technology and processes, we can meet CNC machining needs for consumer electronic products. Our parts or products are commonly used in:

Computers

Communications

Phone

Watches

Housings

Fixtures

Consoles

Heat sinks

Knobs

Handles

Buttons

And not limited

Advantages of Our Electronic Machining

Machining specialties - Our capabilities in Swiss machining, high-level multi-spindle and CNC turning maintain the tolerances within standard. Simultaneously, minimize the cost.

Quality leadership - An ISO 9001 supplier with the highest quality and standards for demanding fields like automobile, aerospace, medical technology and 3C products.

Global sourcing - LJZ CNC machining is located in Dongguan with the most complete supply chain and the most competitive cost.

Guaranteed delivery - Effective inventory management procedures, safety stock planning and timely global delivery make us the most trusted partner of electronics companies.

Contact us today for accurate and competitive price for your electronics machining projects!

0 notes

Text

Brass Machining

https://www.ljzcncmachining.com/brass-machining/

Copper or brass has excellent conductivity, ductility, corrosion resistance, wear-resistance, and other unique properties, which make brass or copper machining parts are widely used in power, electronics, energy, machinery, and other fields. We are equipped with complete and professional technologies for copper and brass CNC machining services such as CNC milling, CNC turning, grinding, wire cutting, EDM, etc.

Application of Our CNC Brass and Copper Parts

If you have high requirements for the physical properties of your product materials, copper and brass will be your good choice. Copper is one of the most machinable materials and its acceptable price and good performance make it is preferred by engineers.

CNC brass and copper parts are generally suitable for:

Fitting

Gears

Bearings

Turbine blades

Motors

Valve components

Fasteners

Pump components

Flanges

Not limited

Surface Finishes on CNC Machined Brass and Copper Parts

Copper and brass are very active metal and easy to be oxidized. Our commonly used surface treatments for CNC machined brass and copper parts are passivation and electroplating.

Passivation: Passivation has the effect of preventing oxidation and corrosion, and can effectively protect the surface of copper and brass products.

Electroplating: Electroplating can enhance the corrosion resistance of copper, and improve conductivity and heat resistance.

Benifits of Our Brass and Copper Machining

CNC brass or copper parts are durable and cost-effective. Our brass screw machine parts are made to meet your specifications and requirements! You will get the most advantages of our brass and copper CNC machining service:

Latest CNC technologies enable us to machine different brass or copper parts. Familiar with different materials' characteristics helps us to offer you valuable suggestions for your project.

Custom machining single prototype or a large batch of brass screw machine parts with in-time worldwide delivery.

Spectrometer detects raw materials to ensure its authenticity and safety.

Look for high quality copper or brass parts? Start with free quote Now!

0 notes

Text

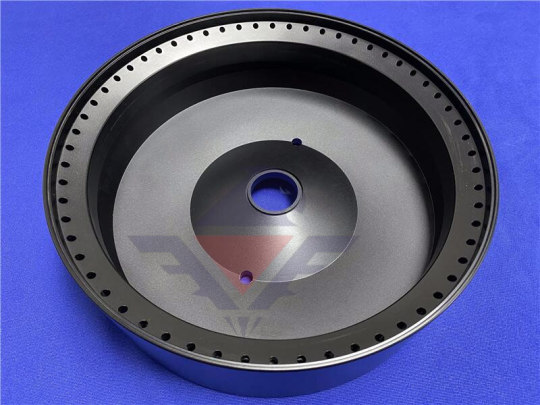

Automotive Machining and Molding

https://www.ljzcncmachining.com/automotive-machining-molding/

In recent years, automotive industry is developing fast and getting attention to more and more countries, and we are very optimistic about the prospects of automotive industry. We have been providing automotive machining from many years for SHENZHEN BYD. At the same time, more and more automotive companies are cooperating with us to accelerate the development of new products and bring them to the market faster.

Our Automotive Machining Services

Our capabilities of automotive machining

Newly designed automotive parts are diverse and complex. LJZ is good at flexible using of multiple technologies and skills for automotive products. Our precision machining technology includes: CNC Swiss machining, CNC turning and milling,Multi spindle cam automatics,CNC grinding, EDM/WEDM, and so on.

Materials used in automtotive machining

We have the experience of machining more than 475 kinds of materials which includes materials for auto parts. At LJZ automotive CNC machine shop, we equipped with spectrum analyzer to ensure the authenticity of raw materials. Common materials of auto parts that we work with are: aluminum, stainless steel, copper, brass, PVC, POM, NYLON, PEEK, etc.

Surface finishes on machined auto parts

Many automobile parts will be requested for corresponding surface treatments to enhance the corrosion resistance and wear resistance so as to increase the service life. Common surface treatments for CNC machined auto parts include: blackening, electroplating, anodizing, laser engraving, silk screen, and so on.

Why is LJZ Used for Automotive Development?

Rapid Prototyping

Customized auto prototypes and parts including performance parts and aftermarket parts. Without sacrificing development speed, prototyping to reduce design risks.

Mass Customization

Customize more diversified and customized automotive functions. Through our precise Siwss machining and automotive plastic injection molding process, we can quickly occupy the market.

Tools and Fixtures

Improve the manufacturing process and create higher automation and simplified assembly of components through custom fixtures.

Common Automotive Applications

Assembly line components

Fixtures

Enclosure and housing

Plastic dashboard components

After-sales parts

Lens and lighting components

And more

Why LJZ for Automotive Development?

ISO 16949 standard, PPAP, FMEA and FAI reporting are available for automotive customers basically demand.

Provide technical consultation, pre-review of drawings, structural analysis, risk assessment, constructive design suggestions, cost analysis and other services.

475 kinds of materials + 30 kinds of processing technology + 21 kinds of surface treatment + customized packaging

Contact us for more details, or simply start with a free quote now!

0 notes

Text

Aluminum Machining

https://www.ljzcncmachining.com/aluminum-machining/

Aluminum alloy materials are favored by engineers in various industries, and it is commonly used material in CNC machining due to its high machinability. Aluminum can be quickly and easily cut by machine tools, and deforms less which leads to higher accuracy. Aluminum is widely used to create specified precision parts in various industries today.

CNC Aluminum Parts Surface Treatments and Applications

CNC aluminum parts are widely popular in almost every industry due to its excellent machinability. Another benefit of aluminum machined parts is that there are many options for its surface treatment, such as:

Anodizing

Powder spraying

Painting

Polishing

Sandblasting

Laser engraving

CD pattern

Applications of CNC Machined Aluminum Parts

Aircraft components

Automotive components

Medical Devices

Optical Parts

Aluminum Gears

Worm Gears

Aluminum enclosure

Aluminum Housings

Aluminum Panels

Spline Shafts

And many more

You've come to us to expect high-quality,efficiency,and excellent service, and that's what you will get from us!

Aluminum Grades that We Work with

Aluminum CNC parts are used in various industries, so choosing the most suitable material is very important. As an expert in aluminum machining, we are familiar with the characteristics of each aluminum. Below are some of the aluminum commonly used in our daily machining:

AL 2000 series

2011, 2014 2017 2024

AL 3000 series

3004 3018 3104 3105 3105 3040

AL 4000 series

4032 4043

AL 5000 series

5005 5052 5082 5083

AL 6000 series

6061 6063 6040

AL 7000 series

7072 7075

Quality Assurance for CNC Aluminum Part

From the outside, different aluminum are indistinguishable by the naked eyes which greatly affects the quality of products. In order to ensure the authenticity of raw materials, LJZ is equipped with spectrometer which is able to strictly detect raw materials with testing report. Moreover, we also provide SGS material certificate according to customer's requirements.

Need Custom Aluminum Machining? Request a quote Now!

0 notes

Text

Aerospace Machining and Molding

https://www.ljzcncmachining.com/aerospace-machining-molding/

CNC machining technology has become one of the key technologies for aerospace parts manufacturing. In particular, advanced CNC machining technology has transformed the UAV design concept. Our industrial CNC services include aerospace parts machining and aerospace machined product. Also, we are capable to provide surface treatment and assembly services to save you time and costs.

Available Materials In Aerosapce CNC Machining

Due to the performance requirements of aircraft and spacecraft, there are certain requests for raw materials, which must have the characteristics of light weight, corrosion resistance, stress cracking resistance, and easy be coated. Common materials used in machined aerospace parts are: aluminum alloy, stainless steel, titanium alloy, magnesium alloy, carbon fiber and other composite materials, etc.

All this materials are checked by spectrometer at our aerospace machine shop!

Surface Finishes On CNC Aerospace Components

At LJZ, we provide customers with a series of services of drawing review-machininig-surface treatment-assembly. Therefore, we are not only expert in CNC machining, but also has rich experience in surface finishes. The surface finishes that we often do are: anodizing, powder coating, painting, polishing, electroplating, silk screen, laser marking and so on.

Why Do Aerospace Companies Like Us?

Specialize in on-demand CNC manufacturing for aerospace rapid prototyping and small batch production.

With more than one hundred high speed and high precision CNC machines, the facilities of our aerospace machine shop are designed for complex aerospace parts machining, rapid prototyping and mass production manufacturing solutions.

Comply with ISO 9001 quality system, at least 6 inspection procedures from raw material to shipment. Also, we are knowledge of DFARS materials source.

Need reliable and trust supplier? Get a free quote now!

1 note

·

View note