Text

We take pride in offering customized services to suit our client’s specifications on a timely and cost effective basis. For the benefit of our clients, we have installed the latest and effective laser metal cutting equipment in our premises. For accurate and systematic cutting of metal, we have installed Bystronic Laser Cutting Systems that provide flexible and cost effective services.

#lasercuttingservice#lasercuttingmetal#laser cutting design#laser cutting company#laser cutting benefits

0 notes

Text

Stainless Steel Fabrication

We have several years of experience in stainless steel fabrication in India and we are able to offer our clients a wide range of services and products namely:

Steel Fabrication

Fabrication Services

Stainless Steel Fabrication

Piping Fabrication Services

SS fabrication

#stainless steel fabrication#stainless steel fabrication company#stainless steel fabrications#stainless steel fabrication India#stainless steel fabrication in India#stainless steel fabricators#stainless steel fabricator#custom stainless steel fabrication

0 notes

Text

LancerFab is a reliable manufacturer and supplier of railway parts in India. With rich experience in manufacturing railway products that are critical to the sustenance and development of the railways, we offer Indian railway parts and Indian railway metro parts to the railway sector in the country.

#metal fabrication#sheet metal fabrication#railway equipment manufacturers#railway parts manufacturer#metro rail & railway parts manufacturer#metro rail parts manufacturer#railway parts manufacturer of India#metro rail and railway parts supplier

0 notes

Photo

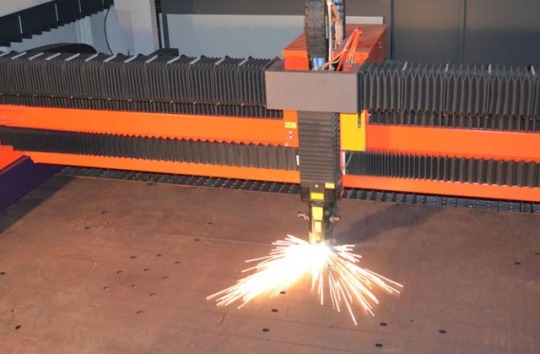

Laser Cutting

Laser cutting is best for extensive requests, tight resistances, and many-sided plans. In case you’re not certain, there are a lot of laser cutting assets accessible, and we’re cheerful to examine whether laser cutting is ideal for your task if you want to converse with a specialist specifically.

#CNC Bending#Laser Cutting#metal fabrication#sheet metal fabrication#3d laser cutting#laser cutting design#laser cutting services#sheet metal fabrication process#sheet metal laser cutting

1 note

·

View note

Photo

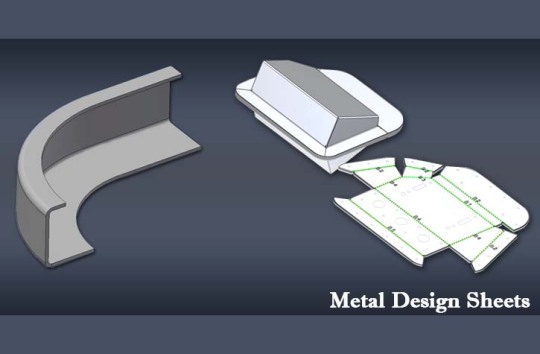

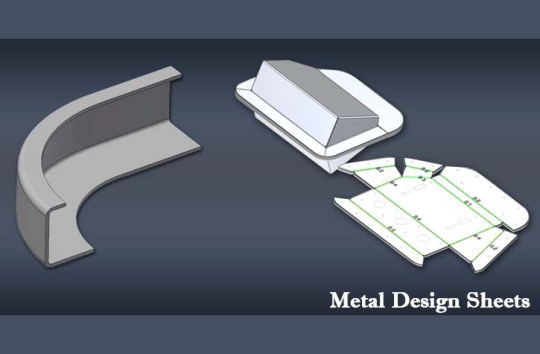

SHEET METAL CUTTING DESIGN

We are Sheet Metal Cutting Design Service Providers in Ahmedabad, using the latest technology to create most accurate and precise sheet metal design.

#sheetmetaldesign#sheetmetalcuttingdesign#sheetmetaldesignservice#sheetmetaldesignservices#metalcuttingdesign#sheetmetalcutting#sheetmetaldesignIndia#sheetmetalcutter#metallasercutting

0 notes

Photo

Metro Rail & Railway Parts Manufacturer

LancerFab is a reliable manufacturer and supplier of railway parts in India. With rich experience in manufacturing railway products that are critical to the sustenance and development of the railways, we offer Indian railway parts and Indian railway metro parts to the railway sector in the country.

http://www.lancerfab.com/metro-rail-and-railway-parts-manufacturer

#metro rail & railway parts manufacturer#metro rail parts manufacturer#railway parts manufacturer#railway parts manufacturer of India#indian railway parts manufacturer#metro train parts supplier#metro rail and railway parts supplier#metro rail parts exporter#railway parts manufacturer in india#railway equipment manufacturers

0 notes

Photo

Sheet Metal Components and Assemblies

We are counted among one of the leading manufacturers and suppliers of a wide array of Sheet Metal Assembly. Sheet metal components can be customized as per the requirements of our clients.

#sheet metal fabrication assembly#sheet metal fabrication assembly parts#sheet metal assembly parts#sheet metal parts assembly#sheet metal fabrication#custom sheet metal fabrication

1 note

·

View note

Photo

Laser cutting and CNC bending are the two most important services Lancerfab Tech Services offers. Using the latest Bystronic Laser Cutting Systems, we aim to provide flexible as well as cost-effective service to clients.

#lasercuttingservice#lasercuttingservices#cnclasercutting#metallasercutting#fabriclasercutting#lasercuttingmetal#lasercuttingservicesIndia

3 notes

·

View notes

Photo

#lasercuttingservice#lasercuttingservices#cnclasercutting#metallasercutting#fabriclasercutting#lasercuttingmetal#lasercuttingservicesIndia

1 note

·

View note

Text

Here Are 5 Proven Reasons to Pick Laser Cutting

Beginning as right on time as 1967, laser cutting turned out to be an adaptable and productive method for creating sheet metal. At present, it's still a standout amongst the most financially savvy and exact techniques for sheet metal fabrication accessible.

Here are 5 noteworthy motivations to pick laser cutting for your undertaking!

1. Generally Low Cost

The expense of laser cutting, as most other assembling procedures, is controlled by work, operation, and machine costs (devices, bites the dust, upkeep, and so on.).

Since laser cutting is a CNC profoundly computerized process, work expenses are negligible contrasted with hand-worked hardware. Working expenses and machine costs fall amidst the street contrasted with other cutting strategies.

Outsourcing laser cutting is the best choice for most ventures. If you contract a producer who as of now has laser cutting capacities, this expense is incredibly relieved.

2. Speed and Efficiency

A laser can move as fast as 20-70 inches every moment. The careful rate will shift contingent upon resilience’s and many-sided nature of the parts. Fabricating velocity will increment in the event that you have a multi-head laser or various lasers working without a moment's delay.

3. Computerization

Laser cutting is totally keep running by CNC controls. The recipes went into the PC implies every part and item is indistinguishably created – that implies less abandons per cluster.

4. High Precision

Laser cutting can make staggeringly little cuts at tight resilience’s (.005″ all things considered). That is the tradeoff: the more exactness you need, the slower the laser will move. Be that as it may, this exceptionally point by point ability is one of a kind to laser cutting. In this way, on the off chance that you require unpredictable cuts, laser cutting is the main sort of cutting that will carry out the employment well. All laser cut edges and bends are smooth, sharp, and clean. There is practically nothing, assuming any, burring in light of the fact that the laser liquefies as opposed to physically cuts the metal.

5. Enormously Versatile

Fetched, rate, robotization, and accuracy meet up to make laser cutting ideal for any size item or venture: models, modern requests, sensitive outlines, and bigger set patterns are all made basic and simple. Robotization takes into consideration creation inside a cutting run, no exchanging of bites the dust or development of sheet metal. Lasers are fit for making openings, spaces, tabs, and other cut manufactures with no intrusion of the cutting procedure.

Is Laser Cutting Right for You?

Laser cutting is best for extensive requests, tight resistances, and many-sided plans. In case you're not certain, there are a lot of laser cutting assets accessible, and we're cheerful to examine whether laser cutting is ideal for your task if you want to converse with a specialist specifically.

0 notes

Text

Performance Qualification of CNC Bending Machines

CNC bending machines, brought into generation toward the end of the 80s, has as of now caught a huge offer of the business sector. Channel bowing machines have a key line that originates from the quality of the structure, which is important to counter the resistance pretty much of the high profiled or tubular stage ebb and flow.

CNC bending machine is usually used in metal steel industry. And the service is hydraulic cutting machine, hydraulic bending machine, bending machine mould, shear blade etc.

CNC bending machines are also known as tube bending machines. They can help to take the manual labor out of the pipe bending process and can help cut the production time down tremendously for this type of work. CNC bending machines are well worth the investment and can add extra income to your business. They are the important part of any CNC cutting processes and components.

The CNC bender machines are computer controlled just like with all of the other CNC machines. Ran by computer software that needs to be downloaded into the machine, these machines can operate fully on their own and require very little human intervention. Software programmers write the program for the machines and the machine actually takes care of the rest. All an operator has to do is load and unload the machine, set up the right tools for the machine, download the software program into the machine and hit the start button. Bending is now easier than ever.

Edge rolls are portrayed by amazing working effortlessness, the likelihood of situating to level and vertical surfaces, by an extensive variety of rollers for bowing profiles of any shape and material. This arrangement of twisting machines right now gives an interesting model, the CE2 two driven rolls knurled. The structure of this machine is greatly strong and the trees are NiCr steel heat treated and fitted with roller orientation against wear. The CE2 is outfitted with pace reducer helical riggings greased up in an oil shower and the drive is by means of pedals twofold pedals to fluctuate the heading of revolution of the rollers. These metal bowing machines permit to acknowledge not just the ebb and flow of segments, bars and containers of various size and material, additionally the twist of the strip and turning iron structure.

CNC laser cutting and bending machines are the new generation of automation process which benefits the manufacturing industry in production.

Some fields of use:

Distortion field and handling iron, steel, aluminum (eg. auxiliary steel, fashions); Sector wall, railings, doors; Sector furniture segments (eg creation tables, seats, ceiling fixtures, installations… ); Sector common and mechanical plant shipbuilding: fundamental in different modern situations

0 notes

Link

Cutting at such a large number of inches every moment is awesome, however general process duration may not change much if parts get discovered in a deburring bottleneck. To guarantee a superior cut edge, administrators verifiably needed to modify cut project parameters, for example, the cut rate around sharp corners, yet they now and then found this took longer than essentially sending the whole gone through a deburring framework.

0 notes

Text

Laser Cutting Edge Quality: At a Glance

Edge quality in laser cutting has enhanced essentially throughout the decades, and a significant number of those upgrades originate from four zones: better materials, spouts, process control, and pillar quality.

Lasers have turned into the genuine workhorse of metal manufacture, and they have never been more beneficial. They cut homes at phenomenal rates, which has made material taking care of computerization significantly more imperative. All the high cutting velocity on the planet may not drastically influence general process duration if a laser sits unmoving for delayed periods, sitting tight for administrators to load sheets and empty parts.

Comparative thinking additionally applies to edge quality. Edge quality is, obviously, subjective. A mechanical engineer will take a look at a laser-cut part and find that the edge quality is bad. A welder, then again, may have a striking resemblance part and see a smooth, reliable, great edge. Notwithstanding, the application prerequisites manage what is viewed as a "quality" edge. A laser can complete a home of parts in a matter of moments, yet imagine a scenario where those parts should be sent through an optional deburring operation.

Cutting at such a large number of inches every moment is awesome, however general process duration may not change much if parts get discovered in a deburring bottleneck. To guarantee a superior cut edge, administrators verifiably needed to modify cut project parameters, for example, the cut rate around sharp corners, yet they now and then found this took longer than essentially sending the whole gone through a deburring framework.

A considerable measure has changed following the late 1990s and mid 2000s. Slicing lasers have advanced to the point where, as a rule, even thick parts rising up out of the cutting bed can skip optional deburring operations—no manual tweaking of cutting parameters required. These enhancements have come principally from progressions in four ranges: material quality, spout innovation, process control, and pillar quality.

New innovation is developing, in any case, that progressions the pillar properties of the fiber laser, permitting it to cut thick gentle steel with the same quality as CO2, yet with a large portion of the wattage. This will permit fabricators to buy a fiber laser to handle their full scope of material sorts and thicknesses, without uncommon optics.

Looking into the future, emerging technology no doubt will add another wrinkle to the laser cutting services market. Several manufacturers have developed solid-state systems known as direct-diode lasers, which offer additional efficiencies and unique processing advantages. While it is still unclear how this technology will affect the current laser options, it already has shown the ability to produce excellent edge quality.

Laser technology is forever changing. Faster, more efficient systems continue to emerge—and there is still more to come.

0 notes

Link

Also Read: Top 10 Sheet Metal Fabrication Companies in India

0 notes

Text

What things to consider While Approaching Metal Fabrication Company.

Precision Sheet Metal Fabrication services differ from organization to organization; some organize mass generation keeps running at a lower expense while others concentrate on small business with more choices for customization. Some run the array in administrations while others have practical experience in just a couple sorts of administrations. And after that, there are the connections every fashion with their customers.

Before choosing the best partner for your next for sheet metal fabrication process, you should take a look at every alternative from numerous points.

1. What are the Capabilities?

While considering abilities in metal fabrication, you could be taking a look at the space itself — is it sufficiently extensive to meet your business needs without the danger of issues during generation of your product?

What materials does the organization work with? It's a decent question, as not all makers will work with the same products. For instance, you need to make sure that your metal fabrication organization can work with the size and thickness you incline toward;

What particular generation administrations are advertised? Some key abilities incorporatelaser cutting and framing, welding, affixing, merging, establishment, metal getting done with (impacting or painting, for instance) and single or expansive generation runs.

Design is one thing to take a model through creation, however imagine a scenario where you require outline administrations. Not all metal creation organizations offer that. Ask every organization you are considering whether they can work in view of drawing (computerized or printed), whether they can make an interpretation of the drawings to shop drawings, and whether they are fit for beginning sans preparation without the assistance of an underlying configuration gave by you.

2. What Experience Does the Company Have?

Assembling is an industry where experience matters. From the workers on the ground to the business itself, you should be guaranteed that your sheet metal fabrication organization is adequately experienced to keep away from unreasonable missteps.

Have them portray how they have calibrated operations throughout the years to be as proficient and sheltered as could be expected under the circumstances. Get some information about comparative tasks they have done. Also, don't be modest about looking for references from past clients. A decent metal fabrication organization will have a bounty.

3. How Does the Company Prioritize Customer Service?

A long haul association with a metal fabrication organization generally boils down to client administration. All things considered, you would prefer not to work with an organization that neglects to perceive your interesting business needs or is unwilling to move on subtle elements critical to you.

4. How Does the Price Compare with Other Companies, and What Are You Paying For?

Get value sites from each, yet don't as a matter, of course, make a relevant comparison. There's an explanation for value inconsistencies, and now and then that works to support you. For instance, one organization may utilize a higher quality metal or more exact cutting instruments – meaning you can expect less expensive slip-ups in the long haul.

5. Is the Facility Location Convenient for You?

Business area is amazingly significant, particularly in the assembling business today. Whether you incline toward a metal manufacture organization that is close to your own office or near your clients, make sure to do the math and ensure the organization's area bodes well for you.

Also Read: Top 10 Sheet Metal Fabrication Companies in India

0 notes