Text

A Quick Overview of Compact Balances and Scales

Compact weighing scales and balances are often used for general weighing in lab research, school science classrooms, home baking, and food portioning since they are frequently affordable and versatile. The use of portable scales and balances in various sectors is examined in this article.

What are Compact Balances and Scales?

Compact balances and scales are frequently used as a catch-all for various scales, including kitchen and bathroom, but they can also apply to smaller, more specialized scales. While some small balances and scales provide basic weighing and easy operation, others are highly accurate and have several built-in features. They can be battery-powered, are generally simple to clean, and are lightweight, making them convenient for transportation. Compact weighing equipment can be helpful if you need to use the same scale in many locations inside the same institution, such as different classrooms, distant work locations without electricity, and trade fairs.

Various Types of Compact Balances and Scales

A few balances are pretty inexpensive, simple to use, and reliable. They are perfect for instructing students on how to operate a digital balance. These balances are suitable for basic weighing duties in workplaces such as veterinary clinics, shipping facilities, industrial environments, and field operations. Keep in mind that these balances have a 5000 g capacity and a 0.1 g readability restriction. They are designed for quick, simple weighing when traveling.

Numerous balances are practical for measuring field samples or on confined lab tables since they can handle precise weighing duties. These balances can withstand the lab or field work demands and the curiosity of science students. They have practical elements, including shock absorption, a security hole, and a hook for weighing below the balance.

Difference Between Compact Balances and Kitchen Scales

Compact balances have better readabilities, weight capacities, and weighing attributes than conventional digital kitchen scales. They are a fantastic option if you need a reference tool for science experiments or for performing general weighing tasks that demand more capability than kitchen scales because they conveniently fall into a mid-range category between recreational and professional.

Need of a Carry Case

A carry bag is the best way to protect your equipment if you frequently travel with or transport your pricey scale or balance. A carry case is valuable if you often conduct field research, but it might be less handy if you only transfer the balance from lab to lab. The quantity of minor parts is another factor to take into account. Have you got a spare charger and batteries? And do you have other tools with the scale, such as calibration weights? If so, it might be wise to have a case to retain everything in its original location. You can lock cases as well.

How to Find the Best Compact Scale for You?

When choosing your new weighing equipment, first think about it. Many scales and balances have various weighing modes set up, giving them much flexibility. However, it is still crucial to compare the product specification to your needs. A compact balance, for instance, can be used in a kitchen or warehouse or even to weigh small animals. The easiest way to choose a tiny scale is to decide what features and levels of precision you require. You need a device that has received trade approval if you intend to use it for commercial retail. Contact us if you need assistance choosing a scale or a balance.

0 notes

Text

An Ultimate Guide to Blotting Paper

Blotting paper is a necessary material that may be found in most homes. It is an absorbent paper that can be used for various purposes since it can be used to wipe away excess liquid or oil from the skin, paper, or other surfaces. This article will examine blotting paper's characteristics, varieties, uses, and advantages.

What is Blotting Paper

It is a thin piece that absorbs excess liquid or oil from the surface. It is made of many substances, such as cotton, flax, or hemp, which are then treated to yield a smooth, absorbent sheet. It comes in a variety of sizes, thicknesses, and grades, each of which is appropriate for a particular application.

It has been around since the fifteenth century, according to the earliest sources. It was once used to dry ink on paper to stop smudging and bleeding. It is still widely used in the cosmetics industry to absorb extra sweat and oil from the skin and in labs to dry off samples or drain excess liquid from studies.

Configuration of Blotting Paper

It is manufactured using various materials and techniques to produce an absorbent, matte paper. Cotton, flax, or hemp fibers are the major components for blotting paper. These fibers are treated to remove contaminants like lignin and hemicellulose.

After being beaten, the fibers become a soft, fluffy pulp that is then treated to become a thin, dense sheet. It is treated with chemicals, such as calcium carbonate or talc, to help enhance its surface area and absorbency and give it distinct absorbent qualities. Additionally, some producers include scents or other substances to raise the scent or texture of the paper. The finished paper is soft, absorbent, and matte, making it perfect for various uses.

Different Types of Blotting Paper

Each grade and thickness of paper is appropriate for a particular application. The most typical kinds of paper are:

Laboratory Blotting Paper

To remove extra liquid from samples or tests, scientists use laboratory paper, a highly absorbent paper. It is constructed from 100 percent pure cotton fibers and is chemically treated with talc or calcium carbonate to make it more permeable. The right paper for chromatography, electrophoresis, and other scientific procedures can be found in various grades and thicknesses.

Standard Paper

Standard paper is perfect for all applications because it is produced from 100% pure cotton fibers. It is offered in various weights, from lightweight to heavyweight, and can be used for multiple tasks, including wiping away excess sweat and oil from the skin and letting the ink dry on paper.

Oil-Absorbing Paper

Blotting paper that absorbs oil is specifically made to remove extra oil and sweat from the skin. It is constructed from a mixture of cotton and wood pulp fibers, and it has been given chemical treatments, like silica or kaolin, to help it absorb oil and lessen shine. People with oily or mixed skin should use oil-absorbing paper, which comes in various thicknesses and grades.

Applications of Blotting Paper

Blotting paper has numerous applications in different industries:

Beauty Industry

Laboratory Experiments

Art & Craft

Benefits of Blotting Paper

Paper offers several benefits, which are as follows:

Non-Toxic & Environmentally Friendly

Absorbing Excess Oil & Sweat

Preventing Smudging & Bleeding

Conclusion

In conclusion, blotting paper is a valuable and essential product with several advantages. To generate an absorbent and non-shiny paper, it is made from several components and goes through several manufacturing steps. They are perfect for various uses, such as eliminating extra oil and sweat from the skin, preventing ink or paint from smearing or bleeding, and serving as an environmentally responsible substitute for other oil-absorbing materials. It is a must-have item that can make your life simpler and more convenient, whether you are an artist, a beauty enthusiast, or a scientist.

0 notes

Text

What is Distillation & its Types?

Distillation is a common technique for separating mixtures with the help of distillation apparatus based on the circumstances needed to change the phase of the mixture's components. Heat heating can separate a mixture of liquids to drive the different boiling point constituents into the gas phase. Then, the gas gets better after being re-condensed into liquid form. Double Distillation means the process of repeating it on the liquid that has been gathered to raise purity of the product. Even though the phrase is most frequently used to describe liquids, it is possible to separate gases using the opposite method by liquefying the individual parts utilizing temperature and pressure variations.

A distillery is a facility where distillation is carried out. A still is the name of the device used to undertake Distillation.

Uses of Distillation

Numerous industrial processes involve Distillation, including creating petrol, xylene, alcohol, kerosene, distilled water, paraffin, and countless other liquids. Gas can separate and liquefy. For instance, the air purifies gases such as nitrogen, oxygen, and argon.

Types of Distillation

There are four different types of Distillation which are as follows:

Simple Distillation,

Fractional Distillation,

Steam Distillation,

Vacuum Distillation

Simple Distillation

Simple Distillation may be used for two liquids' boiling points that differ noticeably or for separating liquids from solids or nonvolatile components with the help of distillation apparatus. In a straightforward distillation, the most volatile part of a combination is heated to transform it from a liquid to a vapor. As it boosts, the vapor goes inside a condenser. The condenser is typically chilled to encourage condensation of the vapor collected.

Fractional Distillation

The components used in rectification, a series of distillations, are bifurcated using a fractionating column. When a mixture's constituent boiling points are close to one another, as determined by Raoult's law, fractional Distillation is utilized. Heating a mixture causes the vapor to arise and goes inside the fractionating column during fractional Distillation. The vapor condenses on the packing material as it cools. This liquid is forced to vaporize once more by the heat of rising vapor, which advances it along the column and eventually produces a higher purity sample of the mixture's more volatile component.

Steam Distillation

Heat-sensitive components are separated via steam distillation. The mixture is given steam, which causes some of it to vaporize. This vapor is cooled and split into two fractions of liquid. The fractions are occasionally collected separately, or they might naturally separate if they have different densities. An illustration is the steam distillation of flowers to produce essential oil and distillate with a water basis.

Vacuum Distillation

Components with high boiling points are separated via vacuum distillation. When a compound's typical boiling point is higher than the temperature at which it decomposes, vacuum distillation is particularly helpful. Boiling points also decrease when the apparatus's pressure is reduced. The procedure is otherwise comparable to other distillation methods.

Distillation Apparatus

A simple scientific distillation apparatus, sometimes known as a still, comprises only a few parts. A thermometer must be part of the device. The thermometer is necessary to precisely measure and maintain the temperature corresponding to the chosen compound's boiling point. A thermometer often measures the average kinetic energy or motion inside a group of particles, such as the particles that make up a liquid or vapor in the case of Distillation.

If you are looking for the best distillation apparatus, Jade Scientific, Inc. is your one-stop solution.

0 notes

Text

A Complete Guide to Glassware Equipment: Beakers

Glassware equipment is a standard piece of equipment in lab settings. This is because glassware is reasonably affordable, quite sturdy, and provides certain levels of precision. The standard grade glass is helpful in various situations but cracks when exposed to rapid heating and cooling because of expansion and contraction.

Beakers are typically made of borosilicate glass. Borosilicate glass can withstand high-temperature changes because of its physical characteristics. This kind of glass can tolerate temperatures of up to 400° C., is chemically inert, and is simple to sterilize. Pyrex is one of the most well-known brand names for borosilicate glass. Beakers come in numerous types, such as griffin, berzelius, tricorner beakers, etc.

Metal or plastic can also be used to make beakers. Beakers made of plastic are lighter, easier to store, and never break. They are opaque and typically more expensive. Beakers have additional characteristics. Furthermore, lines are used to show the volume of beakers. These lines, however, are not intended for precise measurements; instead, they only indicate approximations of values. Beakers can also come with handles.

Uses of Glass Beakers

The glass equipment in the lab that is most frequently used is a beaker. These cylindrical objects have flat bottoms and typically contain a little beak or pouring spout. The diameter ranges from 20 to 230 millimeters. Beakers can stir, heat, mix, measure, or distribute liquids and come in various materials and sizes, from one milliliter to several liters.

Glass beakers typically feature heavier bottoms, thicker walls, and strengthened spouts and rims. They are made to endure longer and be safer.

Placement of Glass Beaker on a Hot Plate

Glass beakers are frequently handled on hot plates. A beaker is simple to place on a hot plate due to its flat bottom. On a hot plate, borosilicate glass beakers can be placed. That's because borosilicate glass can handle temperatures up to 400°C and resist extreme temperature swings.

Types of Glass Beakers

Beakers often come in two varieties. These are referred to as low-form and tall-form beakers, respectively. Griffin beakers are another name for low-form beakers. Beakers such as griffin, berzelius, tricorner beakers etc, with low forms may feature handles for simple pouring. Because of their common form, these broad flat bottom beakers are perfect for heating on a hot plate.

Berzelius beakers are another name for tall form beakers. Their height and width are opposed. These beakers have a handle, a pouring spout, and tapering edges. The best beakers for titrations are taller ones.

Where to Purchase Glass Beakers

Beakers and other robust glassware equipment are available from Jade Scientific, Inc. The beakers have beaded tops, spouts for controlled liquid flow, and thick, homogeneous walls. Each one has marking areas and is simple to write on when labeling. They give the perfect amount of heat and mechanical stress. The beakers have a tolerance of +/- 5%.

0 notes

Link

Plastic Beakers are lightweight, chemically resistant, and durable. To buy a product as per your requirement for your laboratory.

0 notes

Text

Liquids Pumps & It’s Different Types!

A mechanical device known as a pump moves various fluids from one location to another. It is a hydraulic device that raises a fluid to a higher level and transports it from one place of low pressure to another of high pressure. Liquid pumps move fluids by transforming the fluid's mechanical energy into pressure energy.

Classification of Pumps

The two primary categories of pumps are dynamic and positive displacement. Some of the pumps that fall within these two categories include the following:

Dynamic Pumps

Different dynamic pump types, including centrifugal pumps, vertical centrifugal pumps, horizontal centrifugal pumps, submersible pumps, and fire hydrant systems, will be covered in the following paragraphs.

Fire Hydrant System

Systems for fire hydrant pumps are sometimes referred to as fire pumps and fire hydrant boosters. These high-pressure pumps were created to supplement inadequate mains by increasing the force within the hydrant service, enhancing a building's ability to battle fires. This method is mainly used for irrigation and water distribution.

Centrifugal Pumps

The majority of pumps used worldwide fall into this category. The task is relatively straightforward, clearly explained, and rigorously assessed. These pumps are durable, practical, and very easy to produce. The fluid pressure will increase from the pump's inside to its outside whenever it is operating. The fluid will move throughout the system due to the pressure change.

Horizontal Centrifugal Pumps

These kinds of pumps have two impellers or more. These pumps are employed in the pumping industry. Each stage resembles a manifold pump in essence. All phases are situated in the same bunker and on the same shaft. On different horizontal shafts, at least eight more stages can be placed. Roughly equal quantities improve the cranium in each step. A single-stage or double-suction pump on the first impeller can also be a multistage pump. For this type of centrifugal pump, several pumps have been delivered and repaired.

Vertical Centrifugal Pumps

This pump model uses a throttle bushing in place of a filled container to cover the shaft. Because the bearings on these pumps are outside of the pit, the volume can fall into the pit due to their unique shaft and maintenance design.

Submersible Pumps

These liquid pumps are also called sewage, septic, and stormwater pumps. These pumps are typically used in building services and residential, commercial, industrial, agricultural, and municipal applications. Stormwater, sewage, blackwater, rainwater, trade waste, chemicals, well water, and food can all be moved with these pumps.

Various impellers, such as closed-type pumps, vortex pumps, multistage pumps, single channel pumps, convection pumps, cutting pumps, or grinder pumps, are commonly used in these plumbing applications.

Positive Displacement Pumps

Piston Pumps

A positive displacement pump, called a piston pump or a plunger pump, uses a piston to respond to a high-pressure seal. These pumps are frequently used for water irrigation, demanding a high level of dependability and delivery systems for substances like paint, chocolate, and pastries.

Peristaltic Pumps

Tube pumps and peristaltic dosing pumps are other names for peristaltic pumps. It is a volumetric pump, and its primary uses are in processing goods in the food, chemical, and water treatment industries. It can pump various liquids, including toothpaste and other chemicals, and delivers a steady flow for measuring and mixing.

Diaphragm Pumps

Pneumatic, AODD, and AOD (Air Operated Diaphragm) pumps are other names for diaphragm pumps. These pumps are primarily used in continuous mining, industrial, and general plant applications. AOD pumps are generally utilized in unstable and combustible situations and are especially useful when there is no power. Additionally, these pumps convey chemicals, industrial effluent, food production, underground coal mines, etc.

Gear Pumps

These pumps provide a constant volume of fluid with each rotation since they are rotating positive displacement pumps. These pumps use entry machinery inside and outside the network to pump the fluid in an unremarkable manner. These pumps can efficiently pump extremely concentrated fluids at high forces.

There are no loss-producing valves in gear pumps, such as friction or high impeller speeds. Because of this, the pumps can handle viscous fluids like grease and fuel. These pumps are not designed to move solids or corrosive liquids.

These are a few of the most widely used liquid pumps available in the market. And if you are exploring the best pumps, contact Jade Scientific, Inc.

0 notes

Link

Chromatography Paper is an analytical technique used to separate and analyse mixtures of soluble substances.

0 notes

Link

Desiccators are important tools for scientists who perform chemical reactions because the units help them ensure accurate chemical measurements before starting a chemical reaction. These canisters or cabinets are sometimes referred to as desiccant dryers or desiccant dehumidifiers.

0 notes

Photo

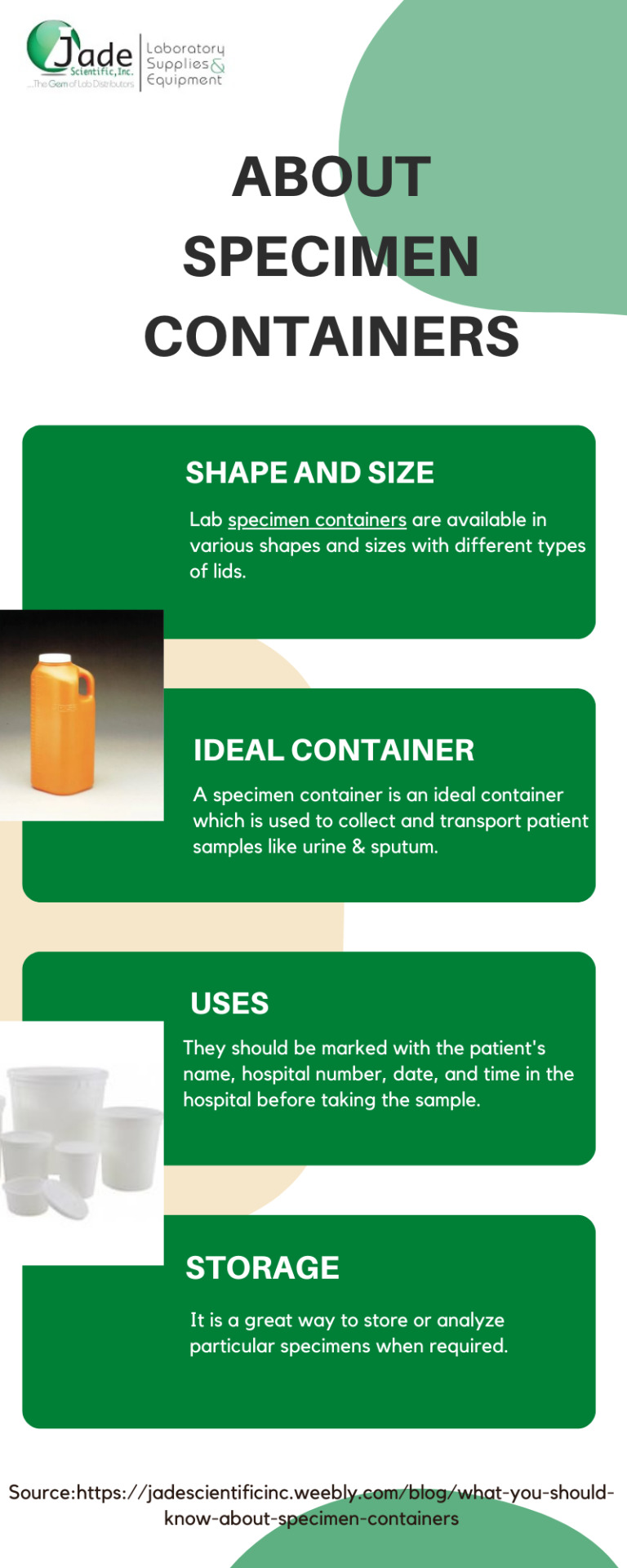

About Specimen Containers

Specimen containers consist of any number, shape, and size of containers for collecting urine, stool, mucus, or another type of bodily fluids.

0 notes

Text

Top 5 Practices When Using Analytical Balances!

If you have ever weighed a sample in a lab, you know how easily analytical balances can be thrown off. That is because, with a readability of 0.1 mg (0.0001 g) or better, even a tiny object like a bothersome fly or a few scattered hairs might cause your readings to get muddled.

Because of this, there are often stringent regulations in laboratories and other places where analytical balancing is employed to remind researchers of the necessary safety measures. If your workplace lacks such reminders, you can still maintain an analytical balance by adhering to the five recommended practices listed below.

Consistent Lab Temperature

Like people, balances perform best when they are at a comfortable temperature. The ideal ambient temperature for analytical balances is between 18 and 30 degrees Celsius. While the precise temperature you select isn't particularly crucial, you must avoid broad changes in that temperature.

Draughts and direct sunshine can cause significant misreading and other unexpected temperature changes, so keep your balance as far away from any doors, windows, and air vents as possible. Naturally, some of the best analytical balances can automatically adjust the temperature, but this feature is only present on some models, so you must be careful.

Pick a Perfectly Stable & Leveled Surface

We know that you are not taking measurements while perched on a couch cushion, but you'd be amazed at how many academic researchers fail to recognize the value of a stable surface. Always keep your balance on a heavy table or an integrated countertop, if possible.

Once you have chosen your surface, the following step is to ensure its level because even the slightest slope might cause your readings to be inaccurate. Use the adjustable foot screws and built-in bubble level to fine-tune your balance's horizontal alignment.

Make Sure to Calibrate Analytical Balances

It is similar to saving a word document. We promise that you don't want to know at the end of the day that your scale wasn't correctly calibrated the entire time.

We advise you to establish and adhere to a precise calibration routine, whether daily or weekly. It would be best if you also made it a habit to continuously, without fail, recalibrate your balance after moving it.

Clean It Before Weighing

It is crucial that you examine and clean your balance as needed before each measurement. Spilled particulates can contaminate future samples, which is terrible and messes with your findings.

Fortunately, most analytical balances can be simply disassembled, which makes cleanup relatively quick and straightforward. Dry, little spills can be cleaned up with a delicate brush, while more difficult stains can be cleaned up with mild soap or another suitable, non-aggressive cleaner.

Shut the Draft Shield Door

All analytical balances have a distinct draught shield because of their highly accurate readability. In reality, the shield prevents top loading, one of the main distinctions between analytical balances and top-loading balances.

You'll be a far more reliable and accurate data collector if you adhere to these five best practices, which are always good.

0 notes

Text

Difference Between Pipettes, Burettes, and Graduated Cylinders!

Some people don't completely understand all the applications of glassware in chemistry. Therefore, it's crucial to distinguish between measuring cylinders, burets such as acrylic burets, and measuring cylinders if you're planning to conduct any chemistry job. Understanding the many types of glassware will aid you in choosing the best option for your needs.

Graduated Cylinders

Graduated cylinders are ideal for measuring bulk volumes. They are intended to show precisely how much liquid is in the cylinder. When compared to pipettes and burettes, they have many advantages. Compared to a pipette, burettes enable the dispensing of more significant amounts. They are calibrated from bottom to top for this reason.

Burette

On the other hand, a burette is made to show how much liquid it is dispensing. It is calibrated from top to bottom for this reason. A burette is a long tube of glass with a tap at the bottom. One kind of burette has graduations running the length of it, spaced two cubic centimeters apart. To increase its level of precision and display the complete volume of a substance at each mark, it contains extra minor marks in between.

Pipettes

Compared to graduated cylinders and burettes, which can measure any amount up to their maximum capacity, pipettes can only measure a particular volume.

Difference Between Graduated Cylinders, Burette, and Pipettes

The fact that pipettes are read from top to bottom because of their calibration is a drawback. They are significantly more prone to human error because they are read from top to bottom. Because of this, it is wise to be aware of the glassware you are using and choose the type that best fulfills your needs. If you have difficulty reading the amount of liquid measured with burettes, try using a graduated cylinder instead. Additionally, the cylinder's markings are typically seen as simpler to read.

Graduated cylinders come in a broad range of sizes. The most frequently used sizes include 10 ml, 25 ml, 100 ml, 500 ml, and up to 2 liters. It is occasionally necessary to manage the necessary volume of liquid using measuring cylinders. Use a measuring cylinder if precision is your primary concern.

A graduated cylinder is therefore preferred whenever possible. Still, you can also use a pipette or burette if the circumstance doesn't require the highest degree of accuracy or if other methods could be more appropriate.

The accuracy of a burette's readings, such as acrylic burets, is calibrated to 0.2 cubic centimeters. On the other hand, a pipette is calibrated with a filling line that provides an exact volume of the substance it has at the specific spot and has a bulge in the center. Using a clean volumetric pipette, you can measure to an accuracy of 0.01 milliliters.

Conclusion

Understanding the various types of glassware is crucial for anyone planning to pursue a career in academia. Everyone from professionals to students must ensure that they are known to succeed. Because it is essential knowledge that should be committed to memory, chemistry classes test their pupils on the differences between all equipment early in their studies.

0 notes

Text

Optimize Extraction System to Improve Energy Efficiency!

Emissions from numerous businesses have an impact on the environment and air quality. Therefore, using extractor system accessories like an extraction arm that can manage dangerous fumes, dust, gas, and vapor are crucial. An improved extraction arm use can make the workplace safer and more energy-efficient. You will discover how to increase the effectiveness of your extraction system.

Hazardous Emissions Produced by Certain Operations and Industries

Workplaces that frequently produce dangerous dust, fumes, and vapors include labs, electronics manufacturing facilities, and workshops. Before they enter the breathing, zone or contaminate the environment, they aim to collect the particles or contaminants. When the contaminants spread, they might negatively affect the buildings and the air we breathe. Using machinery that filters and captures dangerous emissions is crucial for upholding a secure and sustainable working environment.

Extraction Arms Produce a Sustainable Environment and Safer Workplaces

Local exhaust ventilation (LEV) equipment comes in a variety of forms. How effectively pollutants are caught is significantly influenced by how the extraction arm is positioned. If employed properly, the extraction arm has tremendous potential for efficiency. You can make the workplace safer for you and your coworkers by adjusting the extraction arm's setting and location to the best of your ability. You also increase its energy efficiency. An adjustable extraction arm close to the pollution source is a typical example. The number of necessary extraction arms can be reduced if each one is capturing pollutants at full efficiency, reducing the production's energy consumption.

Efficient and User-Friendly Extraction Machinery

The managers and operators of factories can significantly improve worker safety and reduce energy use by implementing the recommendations mentioned above. At Jade Scientific Inc, we think it's critically that the actual capturing equipment is simple to set up and operate. Additionally, the equipment should have a stylish style that complements the workspace. To satisfy the diverse demands of the market, we continually develop multiple laboratory equipment such as extractor system accessories and many more.

How to Construct Workplace & Place Extraction Arm

A wide range of elements influence the effectiveness of the extraction mechanism. Due to factors including general ventilation, cross-draught, and operator movement, a room's air is always in motion. As a result, when dimensioning and using the extraction system, the following factors must be taken into account:

First, keep away from fast background air speeds. In particular, those that deal with vertical cross-draft from above.

Secondly, you can increase capture efficiency by mounting the extraction arms on work tables. The tables will act as a direction and a barrier for emissions.

Thirdly, the capture efficiency is decreased or unaffected by vertical partitions at vertical cross-draft.

After considering all of this into account, there are a few general rules to remember while placing your extraction arm to maximize its functionality:

It is better to position the extraction arm sideways regarding the source of the pollution when the contaminating air has a modest upward velocity.

Place the extraction arm close to the work surface so the table's surface can direct and block contaminated air from entering the arm.

Always place the extraction arm's hood as close as possible to the source of the pollution.

The workspace must be covered by the area where the extraction arm catches contaminated air.

Use a larger capture hood on the extraction arm to expand the capture zone if the extraction arm needs to be placed farther away.

We hope this article has provided you with some fresh ideas on improving your extraction systems' effectiveness with the help of extractor system accessories. For more information, contact us today!

0 notes

Photo

Uses of Buret Brushes

Burette Brush is an accessory in the laboratory that is used to clean burettes and Particularly, it has a twisted wire handle.

0 notes

Text

Difference Between Magnetic Digital Stirrers and Overhead Stirrers

It's not always easy to decide between overhead and magnetic digital stirrers. Both pieces of equipment would be a good choice for many tasks. One of its significant benefits is that magnetic stirrers are typically less expensive than overhead stirrers.

There are some factors to consider if you're choosing between buying one or the other for your lab:

Quantity of samples

Type of Vessel

Factors for Shear Stress

Viscosity of Samples

To help you in the best decision, we examine each issue in depth in this article.

Quantity of Samples

You must ensure that your equipment can handle processing high volumes. Laboratory overhead stirrers can bear maximum volumes ranging from 15 to 100 L. Overhead stirrers with a larger volume do exist. However, they are categorized as a process or industrial equipment.

Although most benchtop variants handle significantly lower maximum volumes between 250 mL and 5 L, these are still regarded as high-volume devices. Magnetic digital stirrers can handle similar amounts, which can process up to 25 L. There are even a few models which exist which are capable of handling 150 L of capacity.

Vessel Type

You should also consider the probability that the shape or size of your vessel prevents using an overhead stirrer, in which case a magnetic digital stirrer would be necessary. Although you are limited in terms of shape, there are foldable impellers that can fit into narrow-mouthed vessels. A magnetic stir bar can easily fit in containers with narrow necks because it lacks a shaft.

In closed vessels, magnetic stirrers can also provide mixing, which helps prevent contamination or carry out a process in a vacuum. An overhead stirrer can create a closed system, but this calls for particular stirrer bearings with vacuum pressure and stirrer speed restrictions.

Factors of Sheer Stress

Shear stress and whether your application requires high or low shear are other things to consider. Although your choice of stir bar can influence this somewhat, overhead mixers are generally preferable for high-shear applications. Impellers typically produce more shear stress than stir bars due to the nature of their design compared to stir bars. Additionally, there are impellers made mainly to create high shear. On the other hand, since metal impellers apply a lot of shear stress to a sample, you might want to bypass metal impellers. It will be more considerate to use a magnetic stirrer, and even dedicated cell culture stirrers may be ideal for the task.

Viscosity of Samples

When processing a high-viscosity sample with an overhead stirrer, there is a risk of straining the drive motor, which could lead to overheating and rapid wear. Some overhead stirrers have a torque sensor; if the torque rises too high, the power will be cut off, or the machine will completely shut off. Others have red warning lights that flash when they are loaded to capacity. Most contain a little internal fan that prevents the motor from overheating.

The magnetic coupling must be powerful enough to get through the viscous material's resistance with a magnetic digital stirrer. Additionally, the stir bar's vortex in viscous liquids will be relatively minor and could not be large enough to mix the sample thoroughly.

While stir bars come in various designs, unlike overhead stirring impellers, they typically do not have specialized geometries created to maximize churning in viscous materials.

Therefore, from the differences mentioned above, we hope that you are clear about which stirrer is required to fulfill your work.

0 notes

Photo

Uses of Mini Stirrers

The wrong stirring may lead to inappropriate results. That is why the lab technicians need the magnetic stirrers in order to move the stir bar around & mix the samples thoroughly. In fact, it has great use. In fact, there are some important uses of the Mini Stirrers, which you will get to know after their use.

0 notes

Text

Pick the Right Laboratory Hot Plate!

The hot plate, either analog hot plates or digital hot plates, are crucial, portable, table-top devices for specific lab processes that call for heating samples. Hot plates feature an internal heating system and a flat surface. A variety of low-boiling solvents, including diethyl ether, pentane, hexane, acetone, and low-boiling petroleum ether, can be ignited by the device at temperatures up to 350 °C. Therefore, it is never advisable to heat these chemicals on a hot plate, especially in an open vessel.

A magnetic stirrer is included with some hot plates, which makes it simpler for the heated liquid to whirl continually and create a homogeneous mixture. In student laboratories, hot plates are preferred to hot tubs since the latter can overheat, spill, or catch fire. Additionally, it requires pricey mantles, takes longer to cool, and isn't compatible with all flask sizes.

Different Types of Hot Plates

Based on the design, hot plates are divided into three types:

Stirring Hot Plate

Standard Hot Plate

Magnetic Stirrer with Hot Plates

Based on the material, hot plates are of the following types:

Polypropylene Hot Plates

Ceramic Hot Plates

Stainless Steel Hot Plates

Aluminum Hot Plates

Things to Consider When Purchasing Lab Hot Plates

Size of the Hot Plate

Hot plates come in multiple shapes and sizes. Although there are several effective mini-hotplate stirrers available for purchase, it is advised to choose a plate larger than the vessel's size you will be working with. A larger plate, however, consumes a lot of electricity and needs a three-phase power source. As a result, consider your lab's amenities while making the instrument purchase.

Capacity

When buying a hot plate, the sample subject's heating capacity is crucial. The device's marketable capacity ranges from 20 liters to 200 liters

Temperature Control

Hot plates have two different ways to regulate the temperature:

When temperature accuracy is not crucial, choose a hot plate with an analog thermostat.

With a digital temperature control system, you can regulate the temperature precisely and choose from various settings for the heating rate and timer.

Required Temperature

The range of temperatures for the various hot plates on the market is between 250 and 550 °C. But it's always advised to pick an instrument whose temperature range exceeds that needed to heat the sample.

Sample Viscosity

Buy hot plates with strong drive magnets if you're working with viscous samples. Keep in mind that a larger hot plate cannot accommodate a sample with a high viscosity. A magnetically connected device lessens the possibility of the stir bar spinning out.

Safety Features

Safety is the top priority when using tools like hot plates such as analog hot plates. The device offers numerous safety features, including:

Current limit protection

Speed ramping

High-temperature setting

Safety shield

Hot top warning indicator

Probe protection

Temperature Uniformity

Buy a digital hot plate with a stirrer if you want your temperatures to be consistent. They do a fantastic job of heat distribution. A temperature meter and a surface tracker can be used to check the temperature uniformity.

Conclusion

A crucial piece of laboratory equipment, hot plates are used to heat samples and lab materials. The market offers a variety of models, including those with and without stirring systems.

0 notes

Photo

Paper Towel Dispensers

Paper Towel Dispensers are considered one of the most common bathroom accessories used in commercial restrooms. Have a look on the types of it.

0 notes