Text

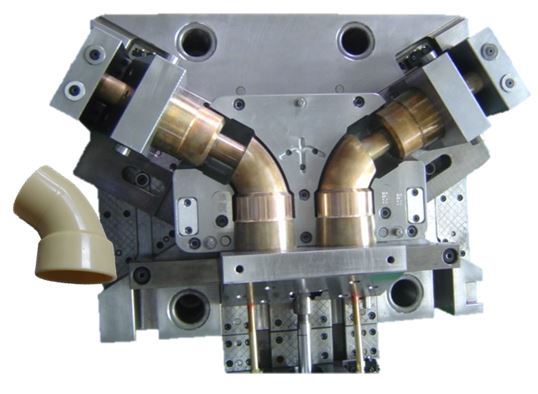

Custom Injection Molding Products For Quality Performance And High Productivity

The mold or die describes the tooling utilized to create plastic parts in molding. Generally, injection mold tooling has been expensive to manufacture as well as were only utilized in high-volume manufacturing applications where hundreds of components and parts were created.

What products are Injection Molded?

Injection molding is a widely used process that is being employed in many things like wire spools, automotive parts and components, storage containers, gears, and many plastic products.

Custom-made Injection Molding

Injection mold manufacturer utilizes custom-made injection molding that represents the making of plastic parts for details applications i.e. personalizing the elements according to the client's needs. The completed products can then be used as is, or as a part of other products. To do so requires injection molding products and tooling (ordinarily called a mold or die). The molding equipment includes a clamping unit to open and close the mold rapidly and an injection operation to warm and inject the product into the shut mold. Injection molding utilizes very high pressures and usually, the equipment is hydraulic or, increasingly, electrical. Tooling for production injection molding applications needs to have the ability to survive under high pressure and is made from steel or lightweight aluminum. The possibly high price of injection mold tooling frequently drives the business economics of injection molding products and applications. Injection molding is an efficient means to make custom parts.

Molded components can be personalized, and they confer additional practicality when it involves performance, longevity, and reliability. Personalized injection molding products can make a substantial distinction for all sorts of sectors and they also implement much better performance and outstanding ways of working in tandem with the requirements of the market. The benefits of Custom-made molded parts are seen right after their implementation and setup. Right from tiny rubber grommets to steel molding for aeronautics and various other manufacturing demands on a bigger range, the value of customized molded products can be skilled all over.

A lot of the injection mold manufacturers handling customized injection molding products provide specific customer stipulations as and whenever called for in all the areas of packer parts. The numerous markets that require these items are an automobile, medical/dental, and commercial rooms among numerous others. These are highly in demand in the labeling as well as relevant sector markets.

Most of the popular automobile companies manufacturing interior parts utilize the services of these industrial built rubber as well as plastic products producers for various applications locations like door and lock knobs. Also, housings for seat controls and seat belts in this industry include customized molded products.

All good injection mold manufacturers of industrial molded rubber and plastic items are indispensable to the tooling market. They are so created to meet the demands of top-notch function along with an appearance in all the above-mentioned industry fields. They fulfill all army application design requirements for quick turnaround capacities.

Dong Guan Gui Cheng Mold Co. Ltd. (GC PRECISION MOLD) is a full-service plastic injection mold manufacturer in China facilitating precision prototyping, mold design, mold manufacturing, and other injection mold tooling processes. For more information about our company and manufacturing process, reach us out on +86-0769 33857766.

0 notes

Photo

PLASTIC MOLD INJECTION

Injection Molds China Products, we are a plastic injection moulding company incepted two decades back at Coimbatore to produce high quality plastic injection mouldings for both complete product and component parts. Contact us for the best services

PLASTIC MOLD INJECTION

0 notes

Text

PRECISION INJECTION MOLD

If you are looking for someone who can teach you about Plastic Mould Manufacturers then you can contact us for all your concerns related to the following and we have a team of experts that can solve your issues for sure. Visit our website for more information.

PRECISION INJECTION MOLD

0 notes

Photo

INJECTION MOLDING COMPANIES

Danke Mold is a professional and high-quality plastic injection molding manufacturer, and quick-turn manufacturing company in southern China. We provide plastic injection molding, rapid tooling, rapid prototyping from concept prototype to volume production. if you are looking for injection and plastic mold services, we are happy to help you with our best services.

INJECTION MOLDING COMPANIES

0 notes

Text

Injection Molding: What Is The Significance Of Using Injection Molding?

Injection molding companies utilize an exceptionally functional approach to manufacture products such as fabrication of plastic parts, automotive parts, and so on. Injection Molding is among the preferred techniques for making parts due to the fact that it has numerous benefits over other methods of parts molding. This approach is generally a favored alternative for casting single, thin-walled plastic components.

What is made using Injection Molding?

Practically any type of plastic part or element can be done efficiently and properly with injection molding from components for kitchen area utensils, electronic devices, automobiles, clinical devices, and various other products.

Basic components are easily made. Yet, complicated components can be swiftly made too, because of the high pressures of injection molding, force material right into every nook of the tool. This can't be done successfully with other casting methods. Since injection molding remains in precision high-pressure casting, that is, including casting products under pressure, it is feasible to cast a broader range of details right into the layout of the part over various other casting techniques.

How does injection molding work?

The production procedure of injection molding itself is fairly straightforward. Small material granules or plastic pellets are fed right into a container. The pellets are after that crushed and heated into a thick plastic slag. The hot liquefied slag is fed right into a device that infuses the liquid under very high pressure into a metal die. The die is the adverse form of the finished segment. As this space is filled up, the plastic is cooled down and the completed part is ejected with the procedure repeating countless times.

What is the cost of the Injection Molds?

The price could be anywhere from $7,500 to $75,000, as well as the dimension of the injection mold, which can suit a 400 square foot garage.

Are there any disadvantages of Injection Molds?

Of course with all making advantages, there are also constraints to injection molding. The primary disadvantage of injection molding is the cost of the equipment.

Parts with large undercuts cannot be cast utilizing this approach either. The initial cost to manufacture tooling is really expensive. That is because the devices need to be precision machined out of lightweight aluminum or other non-ferrous metals to hold up to the heat as well as too long manufacturing continuities. So, though the manufacturing expense is reduced, in order to amortize the tooling cost, parts production must be high.

However, for standard function as well as for brief product operations, an economical injection molding process can be utilized, wherein a two-part or multi-part block injection mold is developed out of silicone rubber and other casting material and is injected under pressure into the mold with a large plastic hypodermic needle. The resulting casting can be extremely thin-walled, and the technique can be used by the injection molding companies as proof of concept before pricey devices are ordered.

Dong Guan Gui Cheng Mold Co. Ltd. is a leading plastic mold and injection molding company in China. We are specialized in customized precision injection molds mainly for automotive molds such as multiple cavities molds and more. For more information, get in touch with us through mail or call us on +86-0769 33857766.

0 notes

Photo

INJECTION MOLDS COMPANIES

Injection Molds China Products, we are a plastic injection moulding company incepted two decades back at Coimbatore to produce high quality plastic injection mouldings for both complete product and component parts. Contact us for the best services

INJECTION MOLDS COMPANIES

0 notes

Text

Know The Working of Plastic Injection Molding

You should understand that plastic injection molding is widely used and the very common technique for mass manufacturing of plastic items in the whole world for its ease of use and convenience. Products of plastic prepared with this technique contain plastic tables and chairs, covers for electronic items and knives and disposable spoons, some other cutlery items as well, for business consumption.

Injection Molding History

Initially, injection molding was arrived to solve an issue faced in profusion by billiard players. In the 19th century balls of billiard were initially prepared of ivory, gained from the tusks removed from elephants. On the other hand, celluloid was one of the very first plastics utilized to make billiard balls.

The Process Explained

The technical process utilized for manufacture of plastic items by application of Injection Mold Company is very much simple. You plastic is soften and taken within a big size syringe. After that, it is put within the shaping mold of suitable shape s per to the product being produced and cooled down for an adequate requisite time till it achieves the preferred shape. Though, the real practical procedure of injection Molding Company is not that much easy and can be generally separated into 3 parts- the molding section, the injection unit and at last the clamp. Pellets of plastic are slowly poured into the injection unit throughout a tunnel that gets slowly liquefied and they are in a molten phase by the time they come at the barrel’s front. When it comes at the shaping mold, it is chilled down to harden into the preferred fixed shape. Then the mold goes back again to its previous unusual condition in the machinery.

All objects of injection molded begin with plastic pellets that are some millimeters in the preferred diameter. They can be efficiently mixed with a specific limited amount of pigment, known as "colorant" or with approximately 15% of cast-off material-after the combination is fed into a machine of injection molding. Untimely molding units of plastic mould manufacturers utilized the plunger to force down from the higher side. Though, the external regions were either very hot or very cold and the melting procedure didn’t properly work. The specific solution to this was a responding screw- often observed as the crucial contribution which was nothing less of a rebellion in the plastic products manufacturing business. The screws encourage shearing stress needed to melt the plastic material- with remaining heat originating from the normal heater bands nearby the machinery. The soften plastic is inserted into the shaping mold, after that it releases air from the vents situated sideways. Plastic that has the thickness of honey, is thick sufficient to not be free from these vents that are just some microns wide.

Witness marks of carving on plastic items are even a considerable part of marketing as you want to be capable to look and search some witness marks and parting lines to validate and confirm the product genuineness. These are formed utilizing detachable inserts and can confirm to be highly helpful for tracking down problems.

0 notes

Text

Top Reasons That You Should Use Injection Molding Technique

Mainly, injection molding is a process of manufacturing. In this procedure, soften material is inserted into an exceptional mold. Generally, this system is perfect in case you wish to fabricate parts of plastic material. You can perform the molding irrespective of the possible complexity, size or application of the concluding product. This procedure is actually simple as the plastic material is injected and melted utilizing an injection into a specially shaped mold.

Some More Important Details

With the assistance of plastic injection molding service, you can add enough amounts of details to a specific product. As high amount of pressure is used, the soften material provides an excellent shape to the final product. Therefore, this system is a wonderful choice if you wish to add too much of detail to your preferred products. It is one of the major reasons this technique is popular.

Durability

In this kind of approach, fillers are placed into the mold that decreases the density of material and improves the product’s strength. For specific products, it is feasible to amend the strength. Some other methods do not provide this type of freedom.

According to the time, the systems begin functioning better. So, it is feasible to make some products in a short time period.

Process Automation

As this method makes the complete process automatic, you can without any difficulty make good quality products. CAD and computer-aided manufacturing assist a lot in creating the molds for different kinds of products.

One main advantage of automation of plastic mold companies is that it assists in making an appropriate design and permits reasonable costs. Really, the expense comes down as the entire procedure is done with the assistance of dominant robotic machines. The last product is very much smooth and clean. The charges of making the final product are not that much high. Thus, the decreased costs give enough investment return for the owners.

Speed

The complete procedure is quick and can be done in no more than some minutes as per on the complexity of mold. Evaluated to injection moulding products, other possible techniques tend to use enough time. Therefore, the quick speed saves too much of money.

Ecological

The procedure is good for the surroundings. In the process of plastic injection molding, there is negligible destruction to the environment. As the resources are professionally used, the surroundings wouldn’t be impacted negatively. Too much plastic is simple to recycle at the last of each and every job. Thus, there is not anything left to dispose.

Finishing

At the process end, the final products are refined and smooth. There is approximately no finishing needed, makers do not need to spend extra amount on the inspection. The concluding product is completely free of flaws.

Therefore, these are the advantages that spur on makers to apply the technique of injection molding. Reasonable cost, greater quality, and greater efficiency are the major reasons this procedure is chosen. In case you are starting your own business, we recommend that you utilize this method for excellent results.

0 notes

Text

Know The Benefits of Plastic Injection Molding

Identification of the product performs a very important role in discussing about the position of product and brand in the market. Nameplates plastic can convey brand, messages, description, classifications, warnings, schematics, instructions and some other kinds of product details.

Injection Molding China nameplates assist to recognize your products and assist them show up in the crowd. Earlier than we go more, let us take a quick glance at the process of plastic injection molding.

The process of Plastic Injection Molding

The process of plastic injection over mold is not a difficult one. Processes of molding of this type containing metals go back several years, and basic ideas haven’t changed, just the systems as well as materials.

Obviously, you have noticed what the completed product appears are. You have noticed them more times than you can be conscious of. You have noticed them as appliance, car emblems and business nameplates, customized nameplates of plastic, nameplates of recreational product, point-of-purchase, signs and plaques. They effectively fill the world close to you, but do you recognize how are they prepared?

The procedure starts with a plastic pellet prepared of a combination of inorganic and organic polymers, with additives to help in the melting procedure. This small size pellet is tossed into a hopper with lots of other pellets. It starts the journey from one specific pellet to finished product. Another step is getting ready the plastic.

The pellets are efficiently released onto different threads of a big size turning screw. Once the pellets move along, they are perfectly heated to melting level of temperatures, anywhere approx 400 degrees. Obviously, the greatest plastic quality is the greater temperature it takes to completely melt it. The pellets are moved along the screw as the procedure even needs force and friction. The screw offers both as the pellets move along its outside and crash with each other.

The force on the mold is kept even as the molten plastic gets cool to a solid situation. This phase can take some minutes as the mold soaks up the heat from the soften plastic, and sequentially is cooled by coolant which encircles it. Even as the part is getting cool, the screw comes back to its real position, gathering more pellets from the hopper. It is then removed from the mold and then shifts to its secondary procedures like decoration, shipment or sub assembly. The mold closes, as well as the procedure starts all over again.

Benefits of Plastic Injection Molding

There are more than a few important benefits of using the services of best Injection Mold Company:

You should understand that plastic injection molding permits intricate and complex shapes to be produced. Shapes will be too costly or difficult to manufacture with different procedures.

It permits for a high volume nameplate of plastic and customized plastic symbols to be produced at similar time with similar quality and mold.

The metallic molds have a longer life. Once you come back again for upcoming order, the mold would be all set and your upcoming order will be the same to your first. Even, their original cost is lower too.

#Over Mold#Injection Moulding Products#Injection Molding China#Plastic Injection Molding Service#injection Molding Company

1 note

·

View note