Text

Purpose of choosing ASTM A193 grade strength

Alloy steel bolting materials meeting ASTM A193 Grade B16 criteria are the norm for strain vessels, valves, flanges, and fittings meant to face up to excessive temperatures and pressures. The maximum frequent users of these applications are the petrochemical, oil & gas, and power generation fields.

The chemical make-up of grade B16 bolts is as follows: silicon (0.15-zero.35%), chromium, manganese, phosphorus, sulfur, vanadium, and carbon. Grade B16 bolts are the maximum broadly used sort of alloy metal amongst numerous versions. These bolts' precise composition offers them with exquisite resistance to oxidation and sulfidation in addition to excessive temperature power.

To make certain that Grade B16 bolts are suitable and reliable for use in excessive-temperature and high-strain settings, the ASTM A193 widespread specifies necessities for his or her manufacturing, warmth treatment, and testing.

Could you explain the differences between B16 and B7 bolts?

While B7 and B16 bolts have similar features, what sincerely distinguishes them are their mechanical houses and material composition.

Enterprises coping with accelerated temperatures and pressures regularly make use of bolts with the B7 and B16 classifications. This is specially actual for the petrochemical, power era, and oil and gasoline sectors.

In order to achieve the required hardness and electricity, the medium carbon alloy metallic (4140) used to create B7 bolts and ASTM A193 B8 Bolts is often heated to the best temperature and then tempered. They have minimal yield and tensile strengths of 105 ksi and 125 ksi, respectively.

But the metal used to make B16 bolts is a higher alloy metal with molybdenum, chromium, and vanadium combined collectively. B16 bolts are stronger and extra proof against oxidation and sulfidation in warm conditions way to those additives. Moreover, B16 bolts have minimal yield and tensile strengths which can be corresponding to B7 bolts.

Use B7 bolts for packages desiring high energy and mild temperature resistance; use B16 bolts for packages requiring better energy and stronger resistance to oxidation and sulfidation at immoderate temperatures. B7 bolts are the endorsed desire while some diploma of heat resistance is vital.

Materials that are comparable to ASTM A193 Grade B16 consist of:

DIN EN 10269 1.4980:

European standard addresses bolts composed of a robust and heat-resistant chromium-molybdenum alloy steel.

ISO 898-1 class 10.9:

For bolts composed of alloy steels comparable to ASTM A193 Grade B16, International Standard ISO 898-1 class 10.9 provides mechanical criteria.

BS 1501-640B:

One can use British standard BS 1501-640B to fabricate fastening materials with characteristics comparable to ASTM A193 B8C bolts and ASTM A193 Grade B16. This general applies to high-power steel plates which have gone through heat remedy.

JIS SCM 4:

This Japanese business well-known specifies what to do with low-alloyed steels which have mechanical characteristics and chemical compositions equivalent to ASTM A193 Grade B16 and ASTM A193 B8M Stud Bolt.

It's vital to hold in mind that at the same time as the chemical composition and mechanical traits of numerous materials may be equal, their manufacturing methods, warmth remedy methods, and trying out requirements may additionally range. These variations may have an impact on the materials' performance for particular applications. It is advisable to study the pertinent material requirements and get advice from an experienced engineer or metallurgist when selecting bolting materials for applications involving high temperatures and pressures.

0 notes

Text

Processional usage of hastelloy fasteners

Selecting the pleasant fasteners in your tasks might be difficult due to the fact there are so many alternatives available. Due to its extremely good qualities, hastelloy fasteners have observed substantial application across numerous industries. They not best tolerate incredibly high pressures and temperatures, however they also display superb resistance to corrosion. This article will state the benefits of making use of Hastelloy fasteners and a way to pick the satisfactory type to your project.

What precisely are Hastelloy Fasteners, then?

Comprising of a few stuffs, the Hastelloy fastener exhibits splendid strength and resistance to corrosion. The nickel and chromium alloys that make up the majority of their makeup are what deliver them the functionality to face as much as oxidation and special forms of degradation over prolonged intervals of time. The several packages for hastelloy fasteners encompass rings, nuts, bolts, screws, washers, and clamps, to name just a few. Alloys are considerably greater resistant to wear and tear added on by using temperature variations or publicity to particular chemicals in difficult commercial conditions, which gives them a far longer lifespan than more traditional fastener materials like stainless-steel and iron.

A Complete Guide to Selecting the Best Hastelloy Fastener for Your Special Project

Establish the requirements that your project need.

Selecting the right Hastelloy C276 flanges calls for first figuring out the wishes of the assignment. The type of situations that the fasteners have to withstand, which includes temperature and strain, need to be cautiously studied. Due to its particular qualities, different grades of hastelloy are higher proper for different settings. In the event that your venture will come into contact with corrosive substances, for example, pick a Hastelloy grade with strong corrosion resistance. Selecting the appropriate Hastelloy fastener is critical for your challenge as it may substantially impact its toughness and achievement. You should be clean about your needs and specs so as for a fastener to keep your challenge robust and harm-unfastened. Before you proceed, you need to confirm in case you require the Hastelloy C22 or C276 alloy grade. Better corrosion resistance or greater power and performance—that is more big? That's what makes the distinction.

Don't forget to consider the range of sizes required for every component

This includes variables like body size, diameter, length, and thread length. It may be helpful to investigate specialized coatings like Lavalox® HTXTM, which provides robust protection up to 1500 degrees Fahrenheit (815 degrees Celsius) in order to guarantee the highest degree of dependability in high-temperature situations. In conclusion, a study to determine the operating pressure is necessary in order to meet the given proof loads. The loads for the conditional use case scenarios must already be in place for this analysis to be valid.

Because in their nickel-molybdenum-chromium alloy, Hastelloy C276 Fasteners are immune to a full-size form of corrosion. These corrosives encompass sulfuric acid, hydrochloric acid, and chlorine. This material has the added advantage of being surprisingly proof against pitting and cracking, and it is able to tolerate temperatures as high as 1900 stages Fahrenheit. In addition to its excessive mechanical electricity, Hastelloy C276 Fasteners are rather clean to manufacture, as in keeping with the recent cast fasteners manufacturer in India.

0 notes

Text

Understanding the Fundamentals of Stainless Steel Production

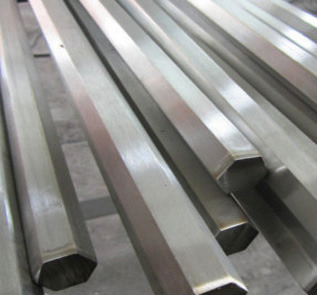

Our company relies on high-quality metal components for manufacturing. The diversity of shapes, sizes, and finishes we achieve reflects our commitment to a range of production processes, highlighting our dedication to excellence and productivity.

Modern production methods, driven by robotic and computerized technologies, have transformed the metal manufacturing landscape. These advanced techniques have become market leaders, delivering visually appealing forms and textures with consistency and precision. Hot forged fasteners manufacturer in India are excellent.

In the realm of bending metal, there are two approaches: manual and machine-driven. While the former is more prevalent, the latter offers swifter and more precise results. This process is indispensable in creating various shapes like rectangles, 'V's, 'U's, and channels, and it finds extensive use in the production of Inconel 625 fasteners, known for their exceptional quality.

The art of bending metal involves multiple steps, each demanding specific tools tailored to the desired outcome. Its popularity persists due to its versatility and cost-effectiveness, as it doesn't require an extensive array of instruments. Titanium fasteners manufacturer in India offer valuable solutions in this regard.

Cutting metal is an essential part of any metal manufacturing process, encompassing various techniques to achieve desired shapes. Among these methods, plasma cutting stands out for its accuracy, enabling clean, precise cuts through thick metals without damaging the edges. Its efficiency contributes to high output and cost-effectiveness. Stainless Steel 304 Pipe cater to global demands for their superior products.

Roll forming is a process similar to bending but excels in producing longer shapes in larger quantities. The technique's higher cost is attributed to its combination of various criteria into one set, making computer simulations a common tool. Roll forming may result in thinner yet robust walls compared to other methods, while simultaneously reducing the need for additional finishing equipment. Monel 400 flanges are the most reliable.

Stamping, a fundamental metalworking technique, is a versatile and precise process that draws inspiration from traditional stamping methods. Inconel 625 flanges are indeed outstanding. It involves creating intricate shapes on sheet metal using a specialized machine press or analogous equipment. However, what sets modern stamping apart is its profound reliance on advanced computing technology. This integration of computational power minimizes errors and ensures consistent production levels, making it an invaluable resource for various industries. Hastelloy C276 pipe fittings are used widely.

The versatility of stamping allows it to deliver a myriad of modifications to sheet metal. It can punch holes, create intricate bends, emboss patterns, and even coin unique designs, tailoring its application to a broad spectrum of industries. Stainless steel 316 pipe fittings will always help you.

Stamping's influence reaches across diverse sectors, including lighting, automotive, electronics, aviation, and medicine. In the automotive industry, it plays a pivotal role in shaping intricate parts and components, while in the field of electronics, it contributes to the precision manufacturing of intricate connectors and components. Inconel 600 fasteners have been used widely. Aerospace and aviation rely on stamping for its precision in crafting structural components that meet stringent safety and performance standards. Additionally, in the medical sector, stamping is vital for creating delicate medical instruments and equipment. Incoloy 825 flanges are outstanding.

In the digital age, many companies are actively engaged in producing round bars using online platforms, offering competitive prices and access to high-quality materials, ensuring that modern stamping technologies continue to support and drive innovation in various industries. ASTM A193 B8 Bolts has the finest quality.

0 notes

Text

Corrosion-resistant alloys: An Introduction to High-Quality Flanges, Pipe Fittings, and Fasteners

The selection of materials for pipe fittings, fasteners, and flanges becomes critical in industries where corrosive conditions provide a continuous challenge.

Flanges: Hastelloy C276 and Monel 400 -

Because of its outstanding corrosion resistance, Hastelloy C276 Flanges, and Monel 400 Flanges are well-suited for use as flanges in the chemical processing, maritime, and offshore sectors.

Hastelloy C276 Flanges: In chemical and petrochemical industries, Hastelloy C276 flanges are the preferred option for crucial applications because of their exceptional resistance to a broad spectrum of corrosive chemicals.

Monel 400 Flanges: This nickel-copper alloy is ideal for marine and offshore applications because of its exceptional resistance to steam and seawater at high temperatures.

Inconel 625 Flanges & Inconel 625 Pipe Fittings -

Because of its exceptional strength at high temperatures and corrosion resistance, Inconel 625 is highly respected and may be used for pipe fittings and flanges in harsh situations.

Inconel 625 Flanges: Known for their dependability in sectors like chemical processing and aerospace, Inconel 625 flanges perform very well in situations requiring strong acids, saltwater, and high temperatures.

Inconel 625 Pipe Fittings: Designed to endure the most extreme circumstances, Inconel 625 pipe fittings ensure the integrity of your systems by providing flawless connections in challenging settings.

Excellence in Stainless Steel: 316, 304, and 904L Pipe Fittings -

Because of its durability and resistance to corrosion, stainless steel is still a popular option. Pipe fittings made of stainless steel are essential for a variety of sectors, including pharmaceuticals and food processing.

316 stainless steel pipe fittings: Because 316 stainless steel pipe fittings are corrosion-resistant, they are perfect for sectors like food processing where hygienic conditions and long-lasting materials are crucial.

304 stainless steel pipe fittings: These fittings are corrosion-resistant and versatile, and they are widely utilized in common industrial applications.

Stainless Steel 904L Pipe Fittings: Used in petrochemical and pharmaceutical sectors, stainless steel 904L pipe fittings are highly resistant to sulfuric acid and other harsh chemicals.

Fasteners: Inconel 600 and Inconel 718 -

The remarkable performance of Inconel alloys in corrosive and high-temperature conditions is well-known.

Inconel 600 fasteners: These are utilized in applications where durability and resistance to carburization and oxidation at high temperatures are essential.

Inconel 718 fasteners: These are designed for high-stress, high-temperature applications, such as gas turbines and aerospace parts.

Incoloy 825 Flanges -

The nickel-iron-chromium alloy Incoloy 825 is well-known for its ability to withstand a wide range of hostile conditions. In sectors like chemical processing and pollution control, where resistance to sulfuric and phosphoric acids is essential, Incoloy 825 flanges are used.

Overall, in businesses where corrosion is a continual danger, selecting the proper materials for flanges, pipe fittings, and fasteners is crucial. The corrosion resistance and durability required to flourish in harsh conditions are provided by materials among others. Choosing a reliable manufacturer when obtaining these components guarantees that you will get high-quality items that satisfy industry standards, ensuring the durability and functionality of your projects and systems.

0 notes

Text

Unveiling Magnificence: Hilton Steel's Hot Forged Fasteners

Hilton Steel is a leading producer in India when it comes to obtaining premium hot forged fasteners, Inconel 625 fasteners, Hastelloy C276 fasteners, and titanium fasteners. Hilton Steel, with a reputation for exact engineering and a steadfast dedication to quality, is your reliable partner for every fastening need.

Unveiling Magnificence: Hilton Steel's Hot Forged Fasteners

0 notes

Text

ASTM A193 B8 Bolts

Do you urgently want ASTM A193 B8 bolts manufacturer in India ? who keep ready stock of SA 193 grade b8 hex bolt in class 1 & will supply at a discounted price with on time delivery, get here

ASTM A193 B8 Bolts

0 notes

Text

Stainless Steel 304 Pipe

If you are searching for stainless steel 304 pipe supplier in India, don't spend your valuable time to shortlist, trust on us and buy SS 304 seamless and welded tube at factory price now. view price.

Stainless Steel 304 Pipe

0 notes

Text

Unveiling Magnificence: Hilton Steel's Hot Forged Fasteners

Hilton Steel is a leading producer in India when it comes to obtaining premium hot forged fasteners, Inconel 625 fasteners, Hastelloy C276 fasteners, and titanium fasteners. Hilton Steel, with a reputation for exact engineering and a steadfast dedication to quality, is your reliable partner for every fastening need.

Hot Forged Fasteners Manufacturer in India: An essential component of several industries, including the construction, automotive, and aerospace sectors, are hot forged fasteners. Because of their outstanding strength and longevity, these fasteners are the best choice for demanding applications where dependability and safety are crucial. Hilton Steel's modern production facilities and skilled workforce demonstrate the company's proficiency as an Indian producer of hot forged fasteners. Their fasteners are made with great care to fulfill international standards, guaranteeing excellent performance and durability.

Inconel 625 Fasteners: High-performance alloy Inconel 625 is renowned for its exceptional stability at high temperatures and corrosion resistance. Hilton Steel's Inconel 625 fasteners are designed to perform well in challenging conditions where exposure to high temperatures and caustic materials is commonplace. Inconel 625 Fasteners are a dependable option for sectors like oil and gas, chemical processing, and aerospace since they are made to provide unparalleled performance.

Hastelloy C276 Fasteners: The corrosion-resistant alloy Hastelloy C276 is well known for its resilience in harsh chemical conditions. Hilton Steel Hastelloy C276 fasteners are designed to work well in sectors of the economy where employees are often exposed to corrosive materials. For crucial applications in chemical processing plants, pollution control, and power-generating facilities, these fasteners are the best option available. Hastelloy C276 Fasteners provide unparalleled protection against stress corrosion cracking, pitting, and crevice corrosion.

Titanium Fasteners Manufacturer in India: Titanium is a metal that is common in the aerospace, medical, and marine sectors. It is strong and lightweight. As an Indian producer of titanium fasteners, Hilton Steel makes use of the special qualities of titanium to create strong, light, and corrosion-resistant fasteners. When it's necessary to reduce weight without sacrificing strength and longevity, titanium fasteners are preferred. The Titanium Fasteners Manufacturers in India are designed to withstand the demanding specifications of these sectors, guaranteeing dependability and security.

Stainless Steel 304 Pipe: Hilton Steel provides a wide variety of stainless-steel products in addition to fasteners. A versatile component utilized in a variety of sectors, including food processing and construction, is stainless steel 304 pipe. It is renowned for its remarkable durability, ease of production, and corrosion resistance. Hilton Steel is dedicated to providing high-quality stainless-steel goods, and as such, its Stainless Steel 304 Pipe is compliant with industry requirements.

Overall, Hilton Steel is a well-known brand in the sector because of its commitment to precise engineering and unwavering quality. Industries all around the globe rely on their goods because they are dependable and effective even under the most trying circumstances. When you work with Hilton Steel for all of your stainless steel and fastener requirements, you'll get expertise that goes above and beyond.

0 notes

Text

The many features and uses of stainless steel explored.

Stainless steel serves a wide variety of purposes. Stainless steel is a low carbon steel that is easy to work with and has excellent corrosion and rust resistance. The steel is coated in a tiny coating of chromium oxide, which is invisible to the human eye yet prevents rust and corrosion.

If it is indeed chemically or mechanically damaged, it can heal itself. The versatility of ASTM A193 B6 Bolts is endless.

One of stainless steel's most prominent selling qualities is its resilience in the face of extreme heat. The fact that it functions effectively in production is an additional benefit. Using stainless steel greatly speeds up the production process. Astm a193 grade b7 bolts manufacturers in India are very popular.

The fabrication of stainless steel is widely employed in the field of architectural metalwork. The catering and food production businesses make heavy use of it. Stainless steel may be cut using a variety of tools, including water jets, lasers, plasma cutters, and more. ASTM A193 B7 Threaded Rod is manufactured by a large number of firms.

Fabricators of structural steel source raw steel and form it into the required shapes for a given construction project. Engineers, architects, and steel producers are working together more than ever before to create the best in fabrication. The ASTM A193 B7 Socket Head Cap Screws consistently have high-quality.

Before being shipped out, every final product undergoes rigorous quality control inspection. The production process would not be possible without the use of both manufacturing techniques and human labor. In terms of yearly output and consumption, it appears that China dominates the market for raw steel. They use a lot of steel since they manufacture so many cars. In fact, some of the finest achievements in the globe have come from using ASTM A193 B7 Anchor Bolts.

There are a few thousand different steel shapes, but they're all made with the same methods. Each type of steel is distinguished by its own particular set of defining chemical components, physical characteristics, and environmental conditions. A large number of people in Singapore choose metal sheets. ASTM A193 B7 Eye Bolt might be of the quality you want.

Jobs in the manufacture of structural steel have migrated to India and other developing countries because of globalization because of lower labor costs there. India is widely recognized as the greatest and most cost-effective location for steel production services. It's crucial to take into account regional norms and regulations when selecting a structural steel subcontractor. ASTM A193 B7m Bolts are available at a reasonable price.

Find an experienced steel fabrication company if you need steel fabricated into anything from stairs to a footbridge to a solid door frame or anything else you might need built out of steel. For the best service that guarantees appropriate finishing and installation without breaking the bank, seek out the best fabricators in the business. Most people across the world have benefited greatly from the use of ASTM A193 B8 Bolts.

0 notes

Text

Distinct steel alloys found across the globe.

Steel alloys are extremely important to makers of metal. These objects were particularly valuable in the fabrication and feedstock sectors since the production procedure that produced them allowed for a broad variety of forms and sizes to be produced. The production of these goods involves a wide variety of operations, some of which include machining, forging, casting, assembly, and spinning.

Round, hollow, and coil stocks can all be made from steel alloys. The specifics of these industrial products may be better grasped with an awareness of the many types of alloys. The ASTM A193 B8 Threaded Rod have been performing for quite some time.

The Austenitic Alloys

The first step in the production of austenite is the reaction that takes place when an iron solution is combined with an alloy. As it cools, it undergoes a phase transition, changing into other phases such as ferrite and cementite. It is probable that pearlite will also be produced in this process. This steel alloy is a popular option due to its resistance to corrosion as well as the improved strength it achieves during cold working. ASTM A193 B8 Class 2 Bolts are simple to track down.

There are two distinct categories of austenitic alloys. The first is the 200 series, which includes manganese, nickel, and chromium. The 300 series is the second kind, and it consists of only nickel and chromium. Quenching, annealing, and other forms of tempering have an effect on the mechanical properties of austenite. India is home to some of the world's finest ASTM A193 B8M Bolts.

Iron-Based Materials

These 400-series alloys are a subset of stainless steel. Commonly referred to simply as "iron," ferrite is the same element that gives both cast iron and steel their magnetic properties. Duplex Steel Hex Bolts manufacturers in India are always willing to lend a hand. They do not harden in response to heat or other treatments. However, they can be significantly strengthened with cold working. The resistance to corrosion, ductility, and oxidation of ferritic alloys are their finest qualities. ASTM A193 B16 Bolts has been excellent.

Alloys with a martensitic structure

It is possible for a tough structure known as martensite to emerge whenever the crystalline structure of steel passes through a displacive transition. Quenching an austenitic alloy at extremely low temperatures results in the production of this type of steel. It is ductile and possesses magnetic qualities, but the only protection it would have against corrosion is at very low temperatures. India has a number of reliable sources for ASTM A453 Grade 660 Bolts.

Varieties of steel alloys

There are two additional categories of steel alloys beyond the three already discussed. A320 L7 Bolts manufacturers in India are plentiful in many states.

It's possible that aluminum or nickel is the component of this alloy that makes up this metal. They are open to having techniques of hardening and strengthening applied to them. Because they include both austenitic and ferritic metal alloys, other types of stainless steel are classified as duplex stainless steels. India is home to several providers who produces ASTM A320 L7 Stud Bolts.

0 notes

Text

Distinct steel alloys found across the globe.

Steel alloys are extremely important to makers of metal. These objects were particularly valuable in the fabrication and feedstock sectors since the production procedure that produced them allowed for a broad variety of forms and sizes to be produced. The production of these goods involves a wide variety of operations, some of which include machining, forging, casting, assembly, and spinning.

Distinct steel alloys found across the globe.

0 notes

Text

Learn the many pluses of working with steel pipes.

Tubes made of stainless steel are used in a wide variety of applications, including commercial and residential construction, as well as the transportation industry. We would have been forced to deal with a scarcity of vital industrial processes if we hadn't had access to stainless steel, which has shown to be tremendously useful and advantageous in many applications. If we hadn't had access to this material, we would have been forced to deal with a shortage. Steel tubes, which are available in a wide variety of diameters and lengths, are finding increasing use in a number of facets of modern life. This is due to the fact that steel tubes are quite versatile.

Reasons why steel pipes are preferable

Steel tubes are a typical choice for piping both liquids and gases during the transportation process. Therefore, they are beneficial in systems where both internal pressure and external pressure must be forcefully resisted. This is because they can effectively resist both types of pressure. Additionally, they are utilized if the longitudinal strains and bending are of an especially complicated kind. The help that the people have received from Duplex Steel Stud Bolts manufacturers in India has been outstanding.

Steel pipes are extremely durable and reliable even under the worst conditions. They are easily damaged by improper treatment, misalignment, temperature shifts, and bending. The usage of stainless steel from Duplex Steel Threaded Rod manufacturers in India has become common.

Pipes and fittings may be made from steel because of the material's high resistance to heat. Pipes and pipe fittings have several applications in the domestic and commercial spheres. Duplex Steel Eye Bolts manufacturers in India are always willing to lend a hand.

Steel pipe advantages

The following are some of the most common and important points to keep in mind when talking about this.

Pipes, when employed, are easy to set up, connect, run, and maintain.

Stainless steel is used in a variety of industries due to its many advantageous properties, including its resistance to corrosion, its strength under extreme pressure, its ability to withstand the shock and vibrations caused by traffic, and its ease of recycling.

Stainless steel tubes and seamless pipes are used in the home as kitchenware and pipelines, as well as in the industrial sector to transport items like petroleum, water, oil, and other fluids or gases because of these and other qualities. You can easily find the world's finest Duplex Steel Socket Head Cap Screw manufacturers in India.

In fact, seamless tube is a common material for vehicle exhaust systems. Inconel Fasteners manufacturers in India have excelled over the time.

Monel Fasteners manufacturers in India are preferred over others due of their durability and tensile strength. Most people are curious about the differences between 304 and 321 stainless steel. Stainless steel tubes from Hastelloy Fasteners manufacturers in India, thanks to its inherent properties, have proven to be a cost-effective option in the production of industrial goods. Nickel Alloy Fasteners manufacturers in India will always be effective.

0 notes

Text

Role of bolts in manufacturing companies

Bolts are a type of fastener generally used in conjunction with nuts for assembling two non-threaded components. The ease of use has made them suitable to play an essential role in developing mass production and steel structures. They consist of a head, and a cylindrical body externally threaded along part of their length.

The head is the part of the bolts characterized by a larger diameter, and its shape is designed to correspond with the appropriate tightening tools. The bolt head can perform other functions, such as distributing the clamping load over the contact surface or locking the bolt in position, preventing rotation.

The thread is a helical structure wrapped around the cylindrical body of the bolt that converts the rotary movement into a linear one, guaranteeing the tightening of the fasteners. There are various forms of threads. However, two types are the most common. Spaced threads are used on wood screws and self-tapping screws, while hardware threads are generally used on screws and bolts and are designed to mate with preformed threads on nuts or holes.

Some types of bolts have a thread that extends from under the head to the tip. However, the bolts can also be partially threaded. This means they have an area under the head entirely free of thread. The length of this non-threaded part, also called the shank can vary depending on the bolt type.

Hex head bolts

Hex head bolts are the most commonly used type of bolt for different applications in the construction and repair industry. These have progressively replaced square head bolts over the decades due to their ease of tightening. They are mainly used for joints, along with hex nuts and washers that distribute the load on the materials, preventing the head of the bolt from entering the joint. Hex Bolt manufacturer in India offers various strength classes and materials, and high-strength fasteners are often made with hex heads.

Flanged Hex Bolts

Flanged Hex Bolts are block-joined, hexagonal head washer bolts with smooth or serrated contact surfaces. These types of fasteners are commonly used to lock, for example, truck panels and offer some advantages. The forged flange under the head distributes the load widely over the contact surface, thus eliminating the need for a washer.

Square head bolts

Square head bolts have long been the gold standard in the fastener industry. These have now been superseded by the more practical hex head bolts, commonly used for cosmetic reasons. Self Tapping Screw manufacturer in India provides all types of steel products with best quality.

Square Neck Round Head Bolts

Round head square neck bolts are a type of bolt used primarily for carpentry work, particularly for fastening metal components to wood. However, these bolts are provided with a thread that makes them also suitable for use in metals. They are made by Inconel round bar suppliers with a round head, no footprint for a screwdriver or key, and a square section below the head. Square neck bolts are also used for aesthetic reasons, as they offer a pleasing appearance in many applications due to their round head.

0 notes

Text

Importance of steel fasteners and pipe fittings

When designing a new project, manufacturers will often focus on the "high value" components that embody their innovation as a business. However, innovation is not restricted by size, as illustrated by the importance of specifying the correct fasteners in many applications. Weight, cost, ease of installation and standardization of the product are four key characteristics to consider when specifying fasteners for the application. However, manufacturers must engage an experienced fastener business to balance these factors.

Design engineers could be forgiven for overlooking the humble fitting, considering the myriad of considerations that come into play when coming up with an entirely new project. The competitive nature of the modern marketplace drives the engineering approach to innovative technologies; For example, the current focus of the auto industry is on hybrid drive trains or self-parking vehicles.

Stainless Steel Pipe Fittings manufacturers want to be able to advertise something that their competitors can't. There is little perceived public interest in how a fitting has aided in the ultimate performance or design aesthetic of the latest consumer product. Very few people will walk into an auto showroom and ask if their potential new purchase will include aluminium fasteners instead of steel. Even in the industrial world, clients are more interested in headline numbers than gritty details.

Industrial fasteners manufacturer in india has worked with customers to reduce part counts by up to 40% during the design phase. The truth is that a well-optimized fastener selection can offer many tangible benefits for the manufacturer and end user. Sticking with the example of automotive design, fastener choice is just as relevant to a supercar as it is to an off-road construction vehicle or your daily driver, but in entirely different ways. Designing something from scratch may be one of the most overused clichés, but focusing on fasteners can lead to profitability and clarity of purpose for manufacturers.

So how can a manufacturer implement these benefits into its design?

The first step is to recognize where you could benefit from expert support. From the earliest design stages, you should work with a supply chain manager who can offer engineering expertise and understand which of the four benefits are most important to your application.

By contrast, heavy trucks and commercial vehicles will require highly durable components. Weight is less of a concern compared to strength, as drivers may be using the vehicle in extreme circumstances. Inconel Plate suppliers will also be interested in standardizing fasteners in certain areas and implementing efficient installation designs to reduce manufacturing cost and remain competitive.

Achieving fastener specifications requires a customized approach based on each application. The best way to accomplish this is to involve a fastener expert from the early design phase of a project so that fastener engineers can become familiar with your specific application and demands. The sooner a partner like Stainless Steel Sheet suppliers in India gets involved, the more entrenched the performance benefits will be with your design.

As a designer or manufacturer, fasteners can benefit all development and manufacturing stages if the optimized approach is applied. As with many things, finding the right bolt hole can be a lifesaver.

0 notes

Text

Tips To Know When Installing Pipes

There are so many reasons that show why Steel Pipes should be installed for waste water and fresh water management.Steel is used for a variety of industrial uses, with pipeline manufacturing being one of the most frequent. We may have tiny Steel Pipes as well as pipe systems in our homes, but in an industrial setting, this will be a large expenditure and a more involved procedure. Steel Pipesalong with Stud Bolt manufacturers in India must be established in your project if you want to properly plan for the transportation or flow of water or the removal of wastewater. This is something you can accomplish with a variety of materials, but steel pipes are the most effective choice right now! There are numerous reasons why industry specialists prefer Steel Pipesfrom Threaded Rod manufacturers in India over other accessible options. If you wish to build a pipeline in your property for waste water and fresh water management, you must ensure that you can do so with the assistance of industry professionals. You can fix it correctly by hiring an expertSelf Tapping Screw manufacturer in India. But first, you need understand why you should construct Steel Pipes for water and water treatment in the long run.

Corrosion is at a low level.

Many metals, such as iron, are recognized to corrode easily when exposed to water & air, which pipes are continually exposed to. However, when you work with a steel mains firm and employ the best quality Steel Pipes from Inconel round bar suppliers, you will see that they have a lower corrosion rate than most other options. This means the Steel Pipes will look brand new for years to come, and no rust or corrosion will be released into the water in any form!

There is usually a visually pleasing appearance.

In whatever you do, consider how nice the Steel Pipes will look, as we don't want them to detract from the appearance of our property or project in just about any way. If you go with plastic Steel Pipes, they might look extremely cheap and ugly to the eye, but if you go with Steel Pipes, you will find it more attractive in many ways. Steel Pipesof Hastelloy c276 round bar suppliers will have a gleaming and stunning exterior appearance that will make every money you pay worthwhile!

Steel Pipes are extremely durable.

A lot of damage can be done to your exposed Steel Pipes on the ground if there is an accident or impact of environmental causes. This is especially dangerous if your Steel Pipes are formed of materials such as plastic. However, by using Steel Pipes, you will have a very powerful set of Steel Pipes which will be able to withstand the many danger factors provided by the atmosphere around us. That's why steel pipes are superior! You can find more relevant products by searching online. Online research will be really very effective.

0 notes

Text

Why People Are Installing Steel Pipes For Water Management?

There are so many reasons that show why Steel Pipes should be installed for waste water and fresh water management.Steel is used for a variety of industrial uses, with pipeline manufacturing being one of the most frequent. We may have tiny Steel Pipes as well as pipe systems in our homes, but in an industrial setting, this will be a large expenditure and a more involved procedure. Steel Pipesalong with Stud Bolt manufacturers in India must be established in your project if you want to properly plan for the transportation or flow of water or the removal of wastewater. This is something you can accomplish with a variety of materials, but steel pipes are the most effective choice right now! There are numerous reasons why industry specialists prefer Steel Pipesfrom Threaded Rod manufacturers in Indiaover other accessible options. If you wish to build a pipeline in your property for waste water and fresh water management, you must ensure that you can do so with the assistance of industry professionals. You can fix it correctly by hiring an expertSelf Tapping Screw manufacturer in India. But first, you need understand why you should construct Steel Pipes for water and water treatment in the long run.

Corrosion is at a low level.

Many metals, such as iron, are recognized to corrode easily when exposed to water & air, which pipes are continually exposed to. However, when you work with a steel mains firm and employ the best quality Steel Pipes from Inconel round bar suppliers, you will see that they have a lower corrosion rate than most other options. This means the Steel Pipes will look brand new for years to come, and no rust or corrosion will be released into the water in any form!

There is usually a visually pleasing appearance.

In whatever you do, consider how nice the Steel Pipes will look, as we don't want them to detract from the appearance of our property or project in just about any way. If you go with plastic Steel Pipes, they might look extremely cheap and ugly to the eye, but if you go with Steel Pipes, you will find it more attractive in many ways. Steel Pipesof Hastelloy c276 round bar suppliers will have a gleaming and stunning exterior appearance that will make every money you pay worthwhile!

Steel Pipes are extremely durable.

A lot of damage can be done to your exposed Steel Pipes on the ground if there is an accident or impact of environmental causes. This is especially dangerous if your Steel Pipes are formed of materials such as plastic. However, by using Steel Pipes, you will have a very powerful set of Steel Pipes which will be able to withstand the many danger factors provided by the atmosphere around us. That's why steel pipes are superior! You can find more relevant products by searching online. Online research will be really very effective.

1 note

·

View note