Text

Heritage Infraspaces: Excellence in Transforming Landscapes

Transforming landscapes with precision and expertise. unveiling the artistry beneath every foundation. Heritage Infraspaces: Where excellence meet the ground

0 notes

Text

Mr. Pranil Chakraborty, GM - Heritage Infraspace

A diaphragm wall is a powerful construction technique. It's like a super-strong concrete wall, perfect for supporting structures in deep excavations.

0 notes

Text

Heritage Infraspace is a renowned construction company known for its expertise in building diaphragm walls. Their innovative approach and commitment to quality have made them a leader in the industry. With Heritage Infraspace, you can trust your construction projects to be in capable hands.

0 notes

Text

Heritage Infraspace's work of excellence continues with The Carter project!

We built a 500 mm diaphragm wall on 158 running meters and 19 metres depth for a 3-level underground basement at The Carter in Ahmedabad. Visit www.heritageconstruction.in to know more about our projects and services.

#HeritageInfraspace#HeritageConstruction#GaganGoswami#concrete#construction#basement#ahmedabadproject#carterproject#diaphragmwall#diaphragmwallconstruction

0 notes

Text

HIPL at GIFT City in Gandhinagar, Gujarat

GIFT City in Gandhinagar, Gujarat is one of the most ambitious planned business district for business and administration, and the Nakshatra group is working on their upcoming project in the zone. HIPL is working with this new age realty group from Ahmedabad by constructing the diaphragm walls for this project. Know more about how diaphragm walls play a crucial role in deep basement construction for super structures by visiting our website www.heritageconstruction.in

#diaphragm wall construction#diaphragm walls#HeritageInfraspace#diaphragmwallconstruction#diaphragmwall#GaganGoswami#Nakshtragiftcity

0 notes

Text

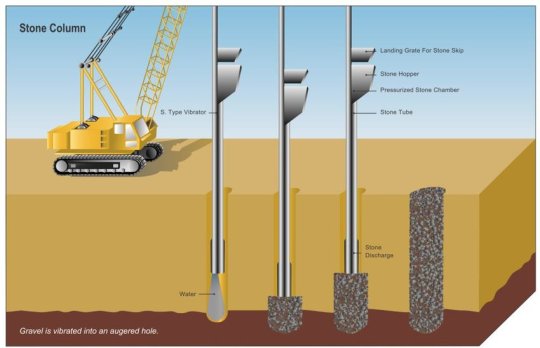

Stone Columns: A Guide to Their Construction and Benefits

When it comes to enhancing the stability and load-bearing capacity of the soil, stone columns have emerged as a popular geotechnical solution. These vertical structures, also known as vibro stone columns or aggregate piers, are created by compacting stone materials into the ground. In this article, we will explore the construction process of stone columns, their numerous benefits, and their applications in various industries.

Understanding Stone Columns

What Are Stone Columns?

Stone columns are vertical geotechnical elements constructed in the ground to improve soil properties and provide enhanced load-bearing capacity. These columns consist of compacted stone materials such as crushed rock, gravel, or sand, and are installed at regular intervals across the site.

How Are Stone Columns Constructed?

The construction of stone columns involves a process known as vibrocompaction. Vibratory probes are inserted into the ground, which vibrate and compact the surrounding soil. As the probe is gradually withdrawn, crushed stone is fed into the hole, ensuring it displaces the weak soil. This creates a column of compacted stone that reinforces the ground and provides structural support.

The Construction Process

Site Investigation and Design

Before commencing the construction of stone columns, a thorough site investigation is necessary. This investigation helps determine the soil conditions, load requirements, and the optimal layout of stone columns. Engineering calculations are performed to ensure the correct dimensions and spacing of the columns to achieve the desired outcome.

Installation of Stone Columns

Once the design phase is complete, the installation of stone columns can begin. Vibratory probes are driven into the ground at pre-determined locations. These probes impart vertical vibrations to the soil, allowing the stone material to penetrate and displace the weak soil. The process is repeated at regular intervals until the desired depth is reached.

Quality Control Measures

Throughout the construction process, quality control measures are implemented to ensure the effectiveness of the stone columns. Testing procedures such as cone penetration tests and density checks are conducted to verify the compaction level and the load-bearing capacity achieved. This helps in maintaining the desired performance and integrity of the installed stone columns.

Benefits of Stone Columns

Improved Load-Bearing Capacity

One of the primary advantages of stone columns is their ability to increase the load-bearing capacity of the ground. By reinforcing the weak soil layers, stone columns distribute the applied loads more efficiently, reducing the risk of settlement and structural failure.

Settlement Reduction

Stone columns are highly effective in minimizing settlement of structures. The increased stiffness and load-bearing capacity of the improved ground help to limit the settlement of the foundation, ensuring the long-term stability and durability of the structure.

Increased Stability

The installation of stone columns significantly enhances the stability of the soil. By compacting the stone material into the ground, the lateral resistance to soil movement is improved. This is particularly beneficial in areas with loose or unstable soils.

Cost-Effectiveness

Compared to alternative ground improvement techniques, stone columns offer a cost-effective solution. They eliminate the need for extensive excavation or deep foundation systems, saving both time and money during the construction process.

Applications of Stone Columns

Civil Engineering Projects

Stone columns find extensive applications in civil engineering projects such as highways, railways, embankments, and retaining walls. They provide stability to the soil, ensuring the safe and efficient operation of these structures.

Infrastructure Development

In the field of infrastructure development, stone columns play a crucial role in improving the load-bearing capacity of weak soil conditions. This enables the construction of critical infrastructure like airports, ports, and industrial facilities.

Foundation Stabilization

Stone columns are often employed in foundation stabilization projects. They effectively reinforce the ground beneath foundations, reducing the risk of settlement and preventing structural damage.

Conclusion

Stone columns have emerged as a reliable and efficient geotechnical solution for enhancing soil stability and load-bearing capacity. Their construction process, combined with the numerous benefits they offer, makes them a popular choice in various industries. From civil engineering projects to foundation stabilization, stone columns have proven their effectiveness and cost-efficiency. By incorporating this technique, construction professionals can ensure the durability and safety of their structures.

0 notes

Video

vimeo

HIPL built a 136.9 running metres long diaphragm wall for a 2-level deep basement at Times 40, an upcoming luxurious apartment complex in Bodakdev, Ahmedabad. It was constructed with a width of 500 mm and depth of 17 metres. Leading construction groups trust Heritage Infraspace when it comes to building of diaphragm walls for their projects.

0 notes

Video

Heritage Infraspace Diaphragm Wall Project for Tokyo Town, Ahmedabad

Another glimpse of success, this time with the Sant Group in Science City, Ahmedabad. We constructed 385.7 meters running Diaphragm Wall with a depth of 12 meters and a width of 600 mm, for 2 levels of basement of this project. Soil Anchoring works will commence post excavation.

#metro diaphragm wall#diaphragm wall#Diaphragm Wall Construction#metro diaphragm wall construction#diaphragm wall contractors#diaphragm wall construction in india#deep basements#deep basement constructions

0 notes

Video

youtube

Heritage Infraspace will be building diaphragm walls and conduct soil anchoring for Shree Realty's upcoming project, Tokyo Town in Ahmedabad. This Heritage Infraspace diaphragm wall project involves a two-level basement with a depth of 13.4 m and a width of 500mm and 20 panels, each 6m long, along with 71 anchors.

0 notes

Link

Dig a bit deeper, but you will not find any anchor!

This is because the top diaphragm wall construction companies are using retractable anchors in place of traditional ones for deep basement constructions.

Stay with the trend and find details about retractable anchors in our latest blog.

Click the link in bio!

0 notes

Link

Diaphragm walls construction are structural concrete walls built in a deep trench excavation, utilising precast concrete components or cast in Situ. We are the pioneers in the diaphragm wall construction in India.

0 notes

Text

Shaligram Group X HIPL - A Modern Residential Structure in Ahmedabad

Here's a deep dive into the diaphragm wall construction project by Heritage Infraspace Pvt Limited for an upcoming residential space in Ahmedabad being built by the prominent Shaligram Group

0 notes

Text

Are Diaphragm Walls And Retaining Walls Different?

Diaphragm walls and retaining walls are different or the same thing?

We answer this commonly asked question with some interesting insights into its construction and uses.

Read it all here: https://www.heritageconstruction.in/are-diaphragm-walls-and-retaining-walls-different/

0 notes

Text

HIPL X Shilp Group: Engineering Modern Superstructures

Shilp group X HIPL.

Underneath every mega architecture is a sturdy and dependable base, meant to uphold the legacy of contemporary engineering solutions. Explore with our latest blog how Shilp group and HIPL have together built functional, sustainable and sturdy marvels of architecture in India.

0 notes

Text

Crucial Soil Anchoring In Diaphragm Wall Construction

youtube

Soil anchoring is one of the most important aspects of diaphragm wall construction. Ground anchor bolts are used in order to link the structural and non-structural elements of the diaphragm wall to the concrete. The process of casting these anchors into the diaphragm wall is known as Soil Anchoring.

1 note

·

View note

Text

Building Engineering Marvels with One of the Best in the Industry, One Foundation at a Time!

Building engineering marvels with one of the best in the industry, one foundation at a time!

As pioneers of smart geotechnical solutions like diaphragm wall construction, Heritage Infraspace Private Limited (HIPL) holds a legacy of providing a strong and dependable foundation for modern superstructures of India along with the top construction companies in India, and Shilp Group is a leading name among them.

With over 40+ residential and commercial projects, the Shilp group has trusted HIPL with the deep basement projects at signature locations in Ahmedabad.

Learn all about the projects, the challenges faced by HIPL and the solutions developed to positively counter them.

The Client: Shilp Group, builders of excellence.

A name synonymous with quality and integrity, Shilp group has been the master of modern infrastructure. Being among the top construction companies in Ahmedabad, it is known for innovating the real estate industry with its residential and commercial properties that run over 75 lakhs sq. ft.

With a heritage of 18 years, the Shilp group has been the obvious choice in real estate when it comes to creating comfortable, stylish and better living spaces on the foundation of trust, safety, innovation and premium quality.

These core values resonate with HIPL deeply and led to the successful completion of the multi-basement diaphragm wall construction for a few signature Shilp projects.

The Projects: Symbols of trust

From diaphragm walls in dams to the ones for deep basement construction, HIPL has successfully completed multiple projects that hold superstructures of the contemporary world. And with the Shilp group, HIPL has worked on the following projects:

Residential project

1. Shilp Serene

Located in the heart of S.P. ring road, Shilp Serene is a two-basement urban infrastructure with a unique locational advantage. HIPL started the project in the year 2022 and laid down a diaphragm wall (also called D-wall) with anchoring that runs around 13m deep and 220 m in width. As the top diaphragm wall construction company in India, it completed the project within a tenure of 2 months.

Commercial projects

1. Shilp Epitome

This superstructure stands as the epitome of excellence that every construction company in India aims for. With a 14m deep and 200m wide diaphragm wall and anchoring, this commercial property supports a 3-level basement built in around 2.5 months. This project was taken up by HIPL in the year 2018-19.

2. Shivalik Shilp 2

This megastructure has a 3-level basement constructed in the year 2017. HIPL laid down a diaphragm wall along with anchoring within 2.5 months. The diaphragm wall runs 18m deep and 250m wide supporting this 13-floored business hub.

3. Shilp Business Gateway

The Shilp Business Gateway project was taken over by HIPL, the top D-wall construction company in India. It built a 3-level basement with a 20m deep and 229m wide diaphragm wall in 2021 within 1.5 months.

Continue reading Building Engineering Marvels with One of the Best in the Industry, One Foundation at a Time!

#diaphragm wall construction#construction companies#india#Shilp Group#ahmedabad#diaphragm walls in dams#construction company

0 notes

Text

Why Are D-Walls Becoming Extremely Popular with Construction Companies in India?

Diaphragm walls for top-down construction and deep basements have now become commonplace in the industry, and among construction companies in India. But how did D-Wall construction (another name for diaphragm walls) become a popular choice with civil engineers who are now confident to build towering superstructures with basements as deep as 5 levels?

Let us begin by understanding what a diaphragm wall is, how it is different from other traditional methods of ground engineering like Piling, and what makes it a desirable choice for deep basement construction.

What is a diaphragm wall?

Reinforced concrete walls built in the ground to provide support to the structure to be built above, and act as walls for the deep basement space to be built later, are known as diaphragm walls. They act as the cut-off walls for the excavated area of the site, provide a strong foundation to the surface and enclose the structure.

Piling – The traditional method of deep foundation construction

Piling is one of the oldest methods of building foundational bases for under-construction structures to transfer and manage the structural load on a deeper level. They are long, cylindrical structures that are made of either concrete, wood or steel.

There are two types of pile foundations used in building strong bases

1. End-bearing piles, that can transmit weight load directly to the deeper, stronger soil or the rock base of the site.

2. Friction piles, which transfers the load of the building to the soil across the full height of the pile, by friction.

Piling, a traditional method, is used when the structure above has heavy, concentrated loads and the spread footing won’t be able to bear the weight. So the building structure needs to bypass this layer and transfer the weight to the stronger base at depth.

While a diaphragm wall is constructed by excavating a narrow trench with a thickness ranging between 300 mm to 1200 mm, as deep as 45 metres underneath. It actually does the exact same job, and moreover, offers to act as a retaining wall for the basement, making the foundation stronger.

Yet, what makes construction companies in India choose diaphragm walls for basements?

Lower steel consumption

The cage walls made for diaphragm wall construction require lesser steel bars compared to constructing and inserting piles into the ground below. And in scenarios of unstable soil on the site, an additional casing is required on the piles, which may add an extra cost to the materials consumed.

Continue reading Why Are D-Walls Becoming Extremely Popular with Construction Companies in India?

0 notes