Photo

Slag pot is an important device in steel making. It is a load-bearing device to collect molten or solid slag generated during metallurgical or chemical processes. The steel mill equipment is a bowl-shaped container with lifting lugs at both sides. A grilling is installed inside the pot, under at least 300mm of the upper surface and divides the inner pot into some pieces. The slag pot that purchased by metallurgical enterprises generally is made by traditional cast process with long manufacturing cycle, short service life, and great scrapped quantity. Chaeng, through continuous technical innovation in production process, makes slag pots that have more advantages such as short cast period, long service life and strong resistance to deformation.

1 note

·

View note

Video

rotary kiln support roller and kiln tyre

WhatsApp:+8615638871509

email:[email protected]

0 notes

Photo

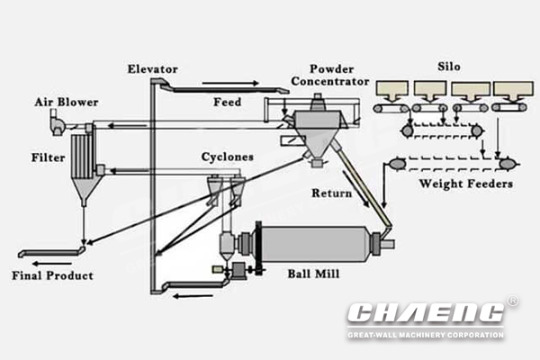

Cement clinker grinding unit adopts ball mill to grind clinker

CHAENG cement ball mill equipment can reduce energy consumption by 30% and increase the processing amount by 15-20%.

#cement #clinkergrinding #ballmill #cementmill

web:http://cementgrindingmill.com/

email:[email protected]

WhatsApp:+8615638871509

1 note

·

View note

Photo

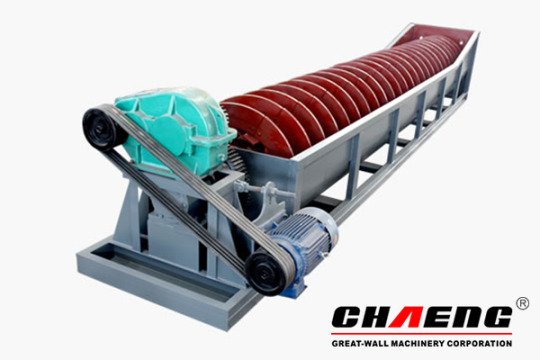

CHAENG XL Screw Sand Washer can clean and separate the dirt and debris in sand and gravel. It has features of good structure, high efficiency, durability, good cleaning and dehydration effects, and stable fine-grained products. It is widely used in industries of highways, hydropower, construction for material washing, classification, purification, and the washing of fine-grained and coarse-grained materials.

1 note

·

View note

Photo

Lime Rotary Kiln Process Description

Material will be feed into kiln tail through chute in gas chamber. As kiln shell is inclined and it rotates slightly, material will move along round shell and will also move along shaft direction from kiln tail to kiln head. Material will be processed through pre-heat, decompose, calcined and will be feed into cooler. Fuel will be given through gas or coal burner at kiln head and will be combusted in kiln. Heat will be transferred to material by fire radiate, hot air flow, kiln brick transfer. The heat will heat and calcine material enough and make it final product.

0 notes

Video

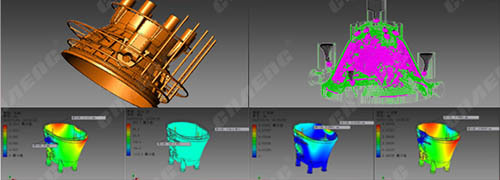

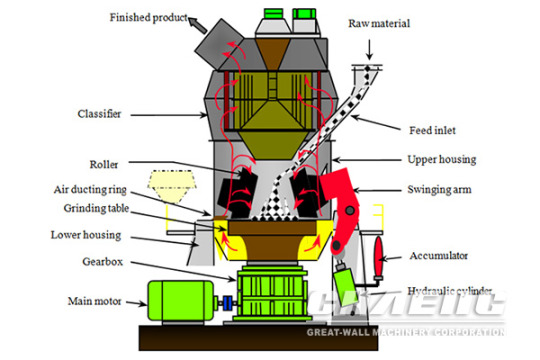

Grinding table is one of the key parts of the vertical roller mill. It is mainly composed of table body, liner plate, pressure block, retaining ring, scraper plate, wind ring, wind deflector and other components. CHAENG optimizes the casting technology and adopts the advanced water glass sand molding technology to make the base of the grinding plate evenly stressed, increase the bite angle between the grinding table and rollers, and avoid the erosion of the non-wear-resistant surface of the grinding table.

0 notes

Video

Rotary kiln tyre is also called rolling ring or riding ring, which is one of the main components on the rotary kiln. The kiln tyre must have sufficient strength, durability amd rigidity. CHAENG is able to provide customers with high-quality kiln tyre according to drawings.

Weight1-90 Tons

MaterialZG45, ZG42CrMo

ApplicationCement, metallurgy, chemical, construction industries

CustomizableYes, based on user's drawings

Whatsapp:+86156389871509

Email:[email protected]

0 notes

Photo

jaw crusher, impact crusher, cone crusher

whatsapp:+8615638871509

email:[email protected]

0 notes

Photo

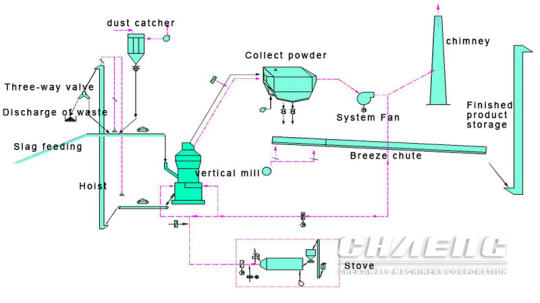

The important position of vertical mill in slag grinding plant #slag #verticalmill #slagmill

whatsapp:+8615638871509

email:[email protected]

0 notes

Photo

CHAENG GRM vertical roller mill has the integrated functions of grinding, drying, powder selecting and conveying, with innovative technologies of high grind efficiency

Fineness :3300-3800 cm²/g

Capacity :50-250 t/hMotor

Power :1000-5000kw

Application :Cement Plant, Clinker Grinding Unit, Thermal Power Plant

Order Online

Chat Now

1 note

·

View note